ASTM B861 Titanium Alloy Seamless Boiler Pipe

ASTM B861 Titanium Alloy Seamless Boiler Pipe

Overview of ASTM B861 Titanium Alloy Seamless Boiler Pipe

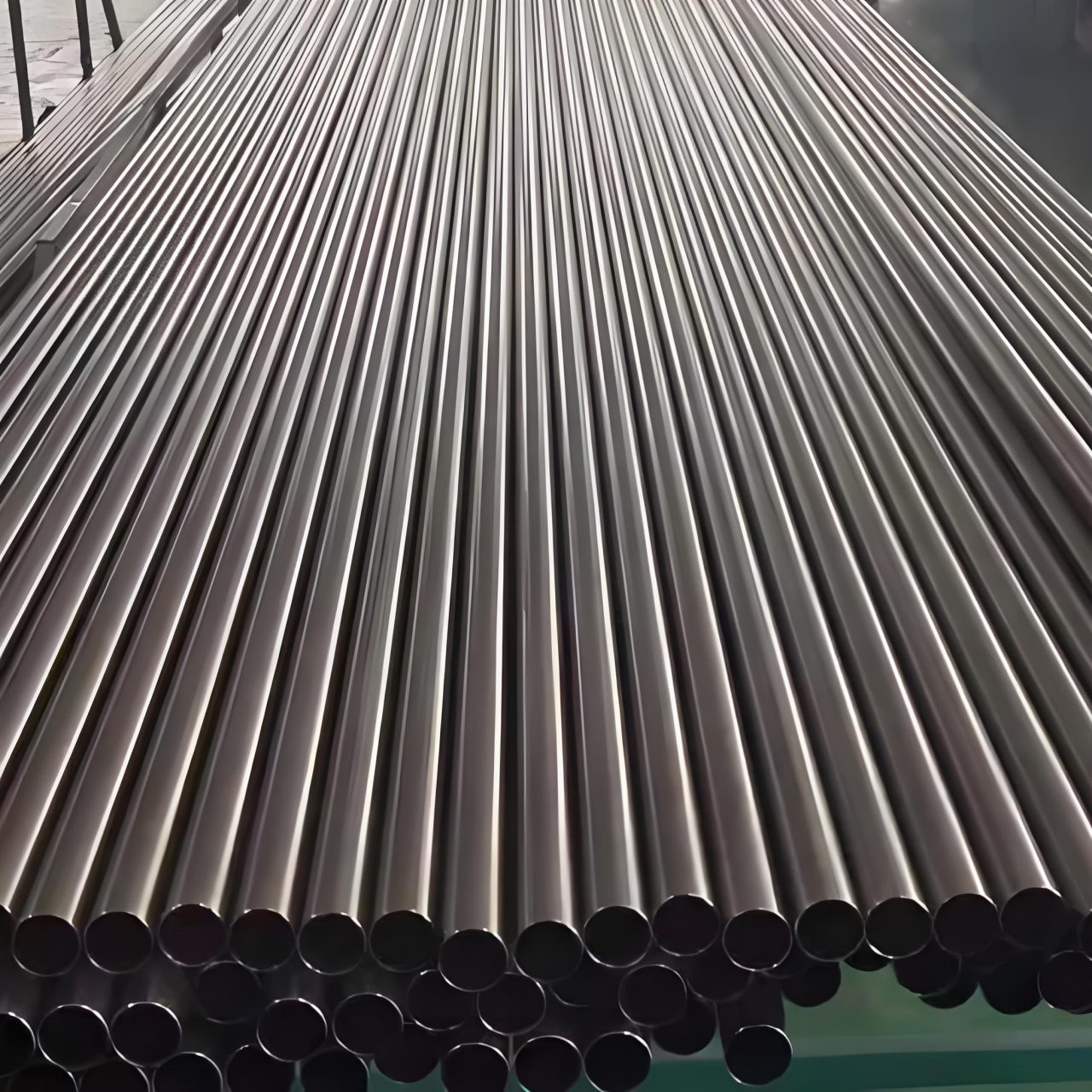

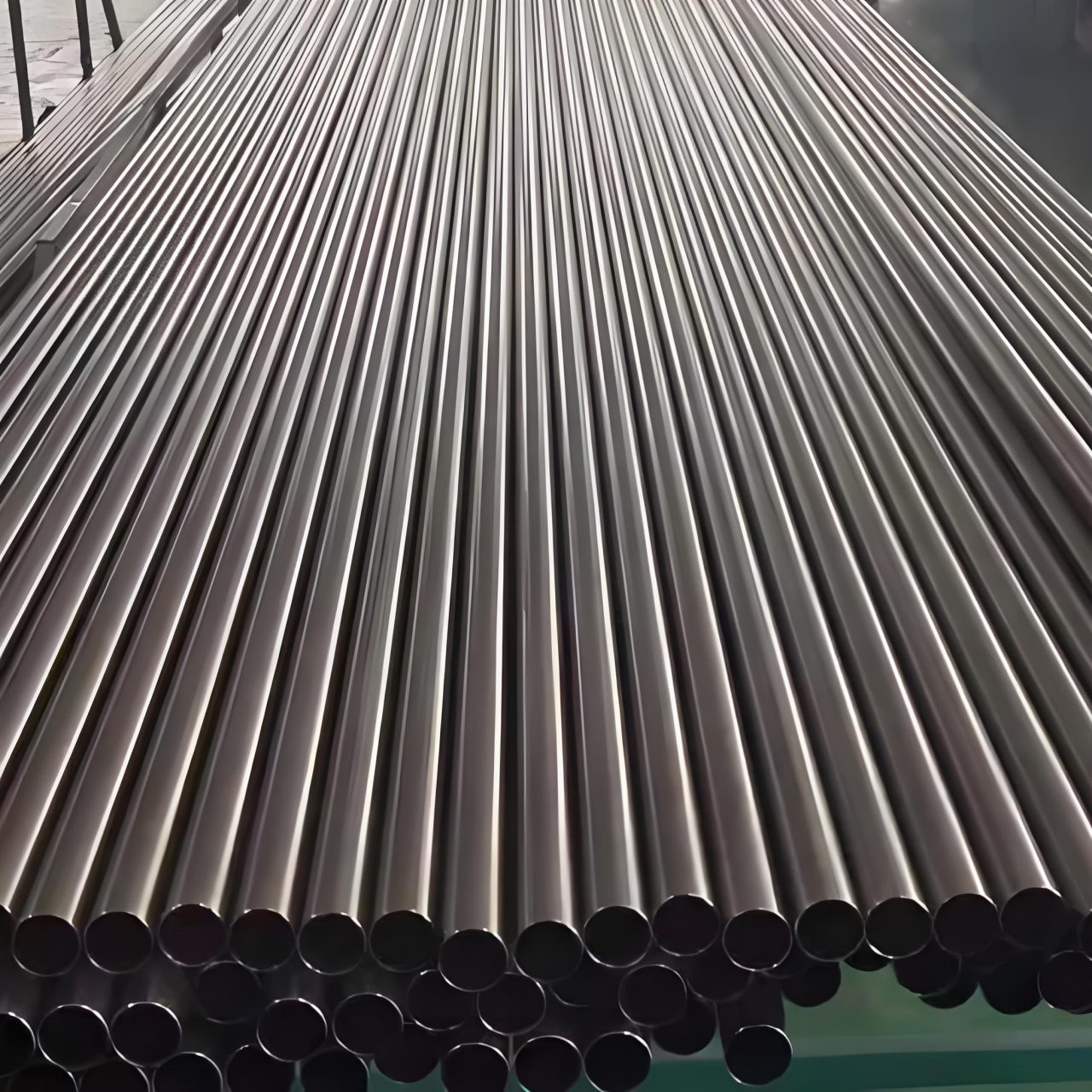

ASTM B861 is the standard specification for titanium and titanium alloy seamless pipes, designed for general corrosion-resistant and elevated-temperature service, including boiler, heat exchanger, and condenser applications. Titanium alloys, unlike steel, offer a unique combination of high strength-to-weight ratio, excellent corrosion resistance, and thermal stability, making them ideal for boiler systems exposed to high temperatures and corrosive environments. These pipes are specified for 34 grades of titanium and its alloys, with grades like 2, 7, and 12 commonly used in boiler applications due to their balance of strength, ductility, and corrosion resistance.

Key features include:

- Corrosion Resistance: Resists pitting, crevice corrosion, and chloride-induced stress corrosion cracking in boiler water and steam environments.

- High-Temperature Performance: Maintains mechanical properties up to 600°F (316°C), suitable for superheater and boiler tubes.

- Lightweight: Approximately 40% lighter than steel, reducing structural load in boiler systems.

- Standards Compliance: Meets ASTM B861 and ASME SB861 for seamless pipe quality and performance.

Titanium seamless pipes are critical in power generation, chemical processing, and marine boiler systems, where durability and resistance to harsh conditions are paramount.

[](https://titanium.com/astm-b861-specification/)

Specifications of ASTM B861 Titanium Alloy Seamless Boiler Pipe

ASTM B861 titanium seamless pipes are manufactured to precise standards, ensuring reliability in boiler applications. The following table outlines key specifications.

| Parameter | Details |

|---|---|

| Standard | ASTM B861, ASME SB861 |

| Alloy Grades | 34 grades, including Grade 1 (UNS R50250), Grade 2 (UNS R50400), Grade 7 (UNS R52400), Grade 12 (UNS R53400) |

| Pipe Type | Seamless, Cold-Drawn |

| Size Range | Outer Diameter (OD): 3 mm to 219 mm Wall Thickness: 0.2 mm to 12.7 mm Length: Up to 12 meters (custom lengths available) |

| Surface Finish | Polished, Varnished (to prevent rust), Annealed |

| Conditions | Annealed, Aged, Cold-Worked and Stress-Relieved, Transformed-Beta, Solution-Treated |

| Testing | Hydrostatic, Eddy Current, Tensile, Flattening, Flaring, Bend |

| Certifications | EN 10204 3.1/3.2, ISO 9001, NACE MR0175 (if requested) |

| Heat Treatment | Minimum 1000°F (538°C) for cold-worked pipes, per ASTM B861 |

Standards Explanation:

- ASTM B861/ASME SB861: Specifies seamless titanium and titanium alloy pipes for corrosion-resistant and high-temperature service, covering chemical composition, mechanical properties, and testing requirements.

- Testing Requirements: Includes hydrostatic testing (50% of minimum yield strength), flattening, flaring, and tensile tests to ensure pipe integrity.

These specifications ensure that titanium seamless pipes meet the rigorous demands of boiler systems, with Grade 2 and Grade 12 being particularly suited for their weldability and corrosion resistance.

[](https://www.btboilertube.com/Boiler_Tube/ASTM_B861_Titanium_Seamless_Pipe/ASTM_B861_Grade_12_Titanium_Pipe.html)

Applications of ASTM B861 Titanium Alloy Seamless Boiler Pipe

Titanium seamless pipes are widely used in boiler systems across various industries due to their corrosion resistance and high-temperature performance. The following table highlights key applications.

| Industry | Applications |

|---|---|

| Power Generation | Boiler tubes, superheater tubes, steam piping |

| Chemical Processing | Heat exchanger tubing, condenser tubes |

| Marine | Seawater-cooled boiler systems, desalination piping |

| Aerospace | High-temperature hydraulic and exhaust systems |

| Oil and Gas | Offshore boiler piping, sour gas environments |

Detailed Applications:

- Power Generation: Grade 2 and Grade 12 titanium pipes are used in boiler tubes and superheater tubes, resisting corrosion from high-pressure steam and flue gases. Their lightweight nature reduces structural load.

- Chemical Processing: Heat exchanger tubing and condenser tubes benefit from titanium’s resistance to acids, chlorides, and high temperatures, ensuring long service life.

- Marine: Seawater-cooled boiler systems use Grade 7 pipes for their enhanced corrosion resistance due to palladium content, ideal for desalination plants.

- Aerospace: High-temperature hydraulic systems and exhaust piping leverage titanium’s strength-to-weight ratio and thermal stability.

- Oil and Gas: Offshore boiler piping in sour gas environments relies on titanium’s resistance to H2S and chloride stress corrosion.

The excellent corrosion resistance and strength-to-weight ratio of titanium pipes make them a preferred choice over stainless steel in many boiler applications.

[](https://www.steelseamlesspipe.com/sale-26559118-astm-a861-gr-2-titanium-alloy-seamless-pipe-for-boiler-condenser-electric-appliance.html)

Chemical Composition of ASTM B861 Titanium Alloy

The chemical composition of titanium alloys under ASTM B861 is tailored for corrosion resistance and strength. The following table details the composition for key grades used in boiler pipes.

| Element | Grade 1 (%) | Grade 2 (%) | Grade 7 (%) | Grade 12 (%) |

|---|---|---|---|---|

| Titanium (Ti) | Balance | Balance | Balance | Balance |

| Nitrogen (N) | 0.03 max | 0.03 max | 0.03 max | 0.03 max |

| Carbon (C) | 0.08 max | 0.08 max | 0.08 max | 0.08 max |

| Hydrogen (H) | 0.015 max | 0.015 max | 0.015 max | 0.015 max |

| Iron (Fe) | 0.20 max | 0.30 max | 0.30 max | 0.30 max |

| Oxygen (O) | 0.18 max | 0.25 max | 0.25 max | 0.25 max |

| Palladium (Pd) | – | – | 0.12–0.25 | – |

| Molybdenum (Mo) | – | – | – | 0.2–0.4 |

| Nickel (Ni) | – | – | – | 0.6–0.9 |

Role of Key Elements:

- Titanium: Provides corrosion resistance and lightweight strength.

- Palladium (Grade 7): Enhances corrosion resistance in reducing environments.

- Molybdenum and Nickel (Grade 12): Improve pitting and crevice corrosion resistance.

- Low Interstitials: Minimize embrittlement and ensure ductility.

The controlled composition ensures optimal performance in boiler environments.

[](https://www.astm.org/b0861-24.html)

TITANIUM MATERIALS SUPPLY SCOPE |

||||||||||

| TITANIUM GRADE | UNS NO. | WIRE | BAR | SHEET | PLATE | TUBE | PIPE | FITTING | FORGING | FASTENER |

| Ti Grade 1 | R50250 | √ | √ | √ | √ | √ | √ | X | √ | √ |

| Ti Grade 2 | R50400 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Ti Grade 3 | R50550 | √ | √ | √ | √ | X | X | X | √ | √ |

| Ti Grade 4 | R50700 | √ | √ | √ | √ | X | X | X | √ | √ |

| Ti Grade 5 (6Al 4V) | R56400 | √ | √ | √ | √ | X | X | X | √ | √ |

| Ti Grade 7 (0.2Pd) | R52400 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Ti Grade 9 (3Al 2.5V) | R56320 | √ | √ | √ | √ | √ | X | X | √ | √ |

| Ti Grade 11 | R52250 | √ | √ | √ | √ | √ | √ | X | √ | √ |

| Ti Grade 12 (0.3Mo 0.8Ni) | R53400 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Ti Grade 17 | R52252 | X | √ | √ | √ | √ | √ | X | √ | √ |

| Ti Grade 23 (6Al 4V Eli) | R56401 | √ | √ | √ | √ | X | X | X | √ | √ |

| Notes 1) √-Available, X-Unavailable | ||||||||||

| Notes 2) For other grades like Ti6Al2Sn4Zr2Mo, Ti6Al6V2Sn, Ti8Al1Mo1V, Ti6Al2Sn4Zr6Mo, Ti15V3Cr3Sn3Al, please contact us for details. | ||||||||||

| Notes 3) It may differs a little for materials in different sizes, please also contact us.

|

||||||||||

Physical Properties of ASTM B861 Titanium Alloy

The physical properties of titanium alloys support their use in boiler pipes. The following table summarizes key properties for Grade 2, a common boiler pipe material.

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ (0.163 lb/in³) |

| Melting Range | 3000–3040°F (1650–1660°C) |

| Thermal Conductivity | 16.4 W/m·K at 20°C (9.5 BTU/ft·h·°F) |

| Specific Heat Capacity | 520 J/kg·K at 20°C (0.124 BTU/lb·°F) |

| Electrical Resistivity | 0.56 µΩ·m at 20°C |

| Coefficient of Thermal Expansion | 8.6 µm/m·°C at 20–100°C (4.8 µin/in·°F) |

| Modulus of Elasticity | 105 GPa (15.2 × 10⁶ psi) at 20°C |

The low density and thermal expansion reduce stress in boiler systems, while the high melting range ensures stability at elevated temperatures.

Mechanical Properties of ASTM B861 Titanium Alloy

The mechanical properties of titanium alloys ensure reliability in boiler pipes. The following table summarizes properties for key grades in the annealed condition.

| Property | Grade 1 | Grade 2 | Grade 7 | Grade 12 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 240 min | 345 min | 345 min | 483 min |

| Yield Strength (MPa) | 170–310 | 275–410 | 275–410 | 345 min |

| Elongation (%) | 24 min | 20 min | 20 min | 18 min |

| Hardness (HB) | ~120 | ~160 | ~160 | ~200 |

Temperature-Dependent Properties (Grade 2, Approximate):

| Temperature | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 20°C (68°F) | 345 | 275 | 20 |

| 300°C (572°F) | 250 | 200 | 25 |

These properties ensure boiler pipes withstand high-pressure steam and thermal cycling.

[](https://titanium.com/astm-b861-specification/)

Fabrication of ASTM B861 Titanium Alloy Seamless Boiler Pipe

Titanium seamless pipes are manufactured via cold-drawn processes, ensuring a continuous periphery and precise dimensions. Pipes are typically annealed at a minimum of 1000°F (538°C) to relieve stresses and enhance ductility, as specified by ASTM B861. Welding for joining or repairs is feasible, particularly for Grade 2 and Grade 12, using techniques like:

- Gas Tungsten Arc Welding (GTAW/TIG): Preferred for high-quality welds in boiler systems.

- Plasma Arc Welding: Suitable for thin-walled pipes.

Use titanium filler metals and inert gas shielding to prevent contamination. Post-weld heat treatment may be required to restore properties.

[](https://www.btboilertube.com/Boiler_Tube/ASTM_B861_Titanium_Seamless_Pipe/ASTM_B861_Grade_12_Titanium_Pipe.html)

Heat Treatment

ASTM B861 titanium seamless pipes are supplied in conditions such as annealed, cold-worked and stress-relieved, or solution-treated. Annealing at 1000°F (538°C) or higher ensures optimal corrosion resistance and ductility. Cold-worked pipes require heat treatment to meet mechanical property requirements. Overheating should be avoided to prevent phase transformations that could reduce toughness.

ASTM B861 Titanium Alloy Seamless Boiler Pipe FAQs

1. Why use titanium alloy seamless pipes in boilers?

Titanium’s corrosion resistance and high strength-to-weight ratio make it ideal for boiler tubes exposed to steam, chlorides, and high temperatures, outperforming stainless steel in corrosive environments.

2. What grades are best for boiler applications?

Grade 2 offers excellent weldability and corrosion resistance, while Grade 12 provides enhanced strength and pitting resistance due to molybdenum and nickel.

3. How does ASTM B861 differ from ASTM B862?

ASTM B861 covers seamless titanium pipes, while ASTM B862 pertains to welded pipes, with different manufacturing and testing requirements.

[](https://www.shew-esteelpipe.com/titanium-tubes-pipes/astm-b862-titanium-alloy-welded-pipe.html)

4. What testing is required for ASTM B861 pipes?

Hydrostatic, eddy current, tensile, flattening, flaring, and bend tests ensure compliance with ASTM B861 standards.

5. How do titanium pipes compare to steel in boilers?

Titanium pipes are lighter, more corrosion-resistant, and suitable for high-temperature service, but they are more expensive than steel due to raw material and production costs.