By understanding the differences in chemical composition, mechanical properties, heat treatment, applications, and costs, operators can choose the most appropriate casing pipe grade to ensure well integrity and operational efficiency.

Blog

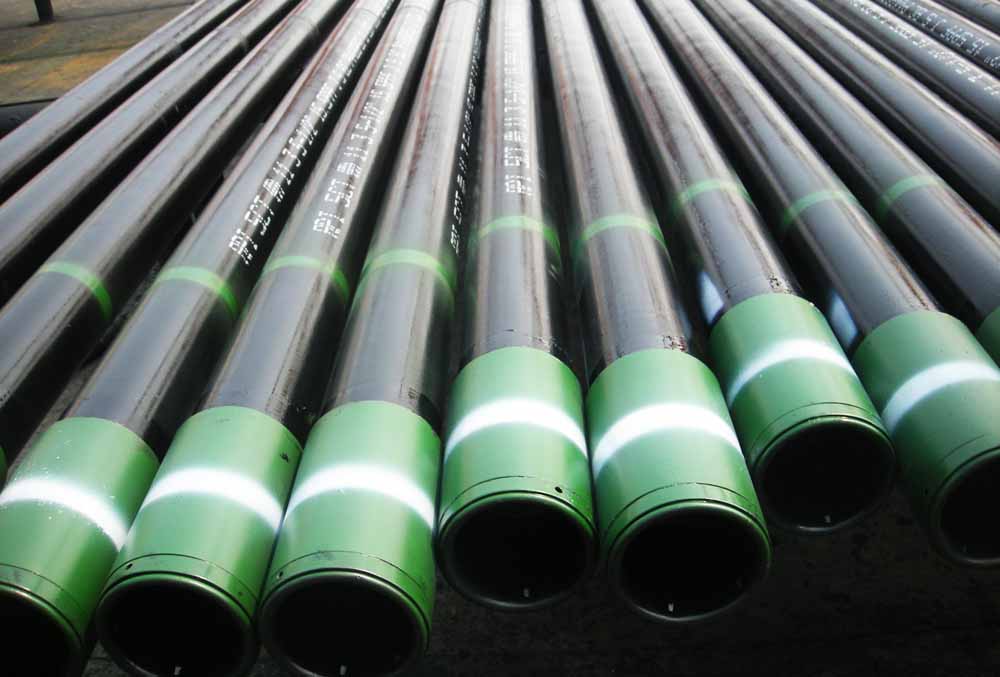

N80-1 and N80Q casing pipes are crucial components in the drilling and production of oil and gas wells. They are manufactured to meet API 5CT standards, ensuring quality, performance, and reliability. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, N80-1 and N80Q casing pipes deliver dependable performance in various drilling and production environments. Their high-strength properties and specific chemical compositions make them suitable for challenging operational conditions, providing robustness and reliability for wellbore integrity.

L80 casing tubing is a crucial component in the drilling and production of oil and gas wells. It is manufactured to meet API 5CT standards, ensuring quality, performance, and reliability. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, L80 casing tubing delivers dependable performance in various drilling and production environments. Each type (L80-1, L80 13Cr, L80 9Cr) offers specific properties tailored to different operational needs, providing versatility and robustness in challenging conditions.

M65 casing pipe is a crucial component in the drilling and production of oil and gas wells. It is manufactured to meet API 5CT standards, ensuring quality, performance, and reliability. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, M65 casing pipe delivers dependable performance in various drilling and production environments.

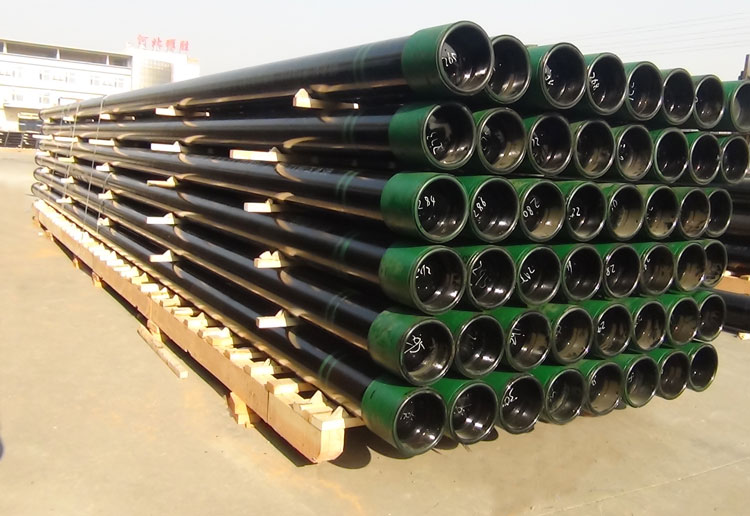

API 5CT K55 is a pipe grade specified by the American Petroleum Institute. API 5CT K55 is a type of well casing that is typically used in well drilling operations. The casing and tubing are OCTG (oil country tubular goods) that are used to form the walls of the well. The steel pipe is placed in the well and held in place by cement. The cement helps to protect the well from collapse and keeps the well fluids from escaping. API 5CT K55 is a popular choice for well drilling because it is durable and can withstand high temperatures and pressures.

The American Petroleum Institute specification API 5CT J55 Pipe is designed for use in the oil and gas industry. API 5CT J55 is a commonly used petroleum casing pipe material. It is produced according to the API 5CT standard and used in a variety of well types, both oil and natural gas. The main purposes of using casing or tubing are to protect the wellbore from collapse and to provide a conduit for well fluids. The casing is placed in the well first, followed by tubing, which is often smaller in diameter and thus can be nested inside the casing. Both casing and tubing must be made from strong materials that can withstand the high pressures and temperatures encountered deep underground. API 5CT J55 meets these requirements and is, therefore, an excellent choice for OCTG (oil country tubular goods) applications. It is typically produced as seamless steel pipe, but can also be procured in welded form. API 5CT J55 has a relatively high yield strength and good fatigue resistance, making it an ideal choice for high-pressure, high-load applications such as petroleum products.

H40 casing steel pipes are essential components in the drilling and production of oil and gas wells. These pipes are manufactured to meet API Spec 5CT standards, ensuring quality, performance, and reliability. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, H40 casing pipes deliver dependable performance in various drilling and production environments.

ASTM A358 stainless steel pipes offer a reliable solution for high-temperature and general corrosive service applications. These pipes are produced to meet specific chemical composition and mechanical property requirements, ensuring performance and durability. The specification provides flexibility in manufacturing and testing, allowing for a balance between cost and performance. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, ASTM A358 pipes deliver dependable performance in a variety of industrial applications.

ASTM A632 stainless steel pipes offer a reliable solution for low to moderate temperature and general corrosive service applications, particularly where a superior surface finish is required. These pipes are produced to meet specific chemical composition and mechanical property requirements, ensuring performance and durability. The specification provides flexibility in manufacturing and testing, allowing for a balance between cost and performance. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing, ASTM A632 pipes deliver dependable performance in a variety of industrial applications.

410S SMLS Pipes ASTM A268 TP410S Stainless Steel Seamless Tubes AISI Type 410S is a non-hardenable, low carbon modification of Type 410, providing moderate strength with moderate corrosion resistance. The low carbon content and a small titanium addition minimizes austenite formation at high temperatures, thereby restricting the alloy's ability to harden. The result is a soft, ductile condition when the material is rapidly cooled from above the critical temperature. The result is a soft, ductile condition when the material is rapidly cooled from above the critical temperature. The 410S stainless alloy is completely ferritic.

Our Steel is a recognized supplier and distributor of ASTM A778 Austenitic Stainless Steel Tubes, which has a number of great attributes to provide like durability, high strength, rust proof, and so on. Superior grade of steel and higher technology is integrated in the manufacturing of these tubes. We offer these products to exceptional surface finish for an outstanding look and outstanding resistance to corrosion. Presented ASTM A778 Welded Tubes is manufactured by our reliable experts by using best grade of stainless steel.

ASTM A312 Stainless Steel Pipe Specification Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes ASTM A312 pipe is common use stainless pipe for industries. It covers diameters from 1/8” to 30” and thickness from SCH 10S to SCH 80S. General use material grades are TP304/304L, TP316/316L.

ASTM A209 alloy steel boiler superheater pipes are essential components in high-temperature and high-pressure applications, particularly in power plants and industrial boilers. Their superior mechanical properties, resistance to oxidation and corrosion, and ability to withstand extreme conditions make them indispensable for efficient and safe operation. Adherence to ASTM A209 specifications ensures these pipes meet stringent quality and performance standards, providing reliability and longevity in demanding environments. Through rigorous manufacturing processes, precise dimensions and tolerances, and comprehensive testing and heat treatment, ASTM A209 tubes deliver exceptional performance in the most challenging conditions.

By examining the chemical composition, mechanical properties, manufacturing processes, and applications, this analysis provides a comprehensive overview of ASTM A556 steel tubes, highlighting their significance in high-performance industrial applications.

By examining the chemical composition, mechanical properties, manufacturing processes, and applications, this analysis provides a comprehensive overview of ASTM A250 steel pipes, highlighting their significance in high-performance industrial applications.

By examining the chemical composition, mechanical properties, manufacturing processes, and applications, this analysis provides a comprehensive overview of ASTM A369 steel pipes, highlighting their significance in high-performance industrial applications.

ASTM A213 T11 tubing (ASME SA213 T11 tubing) is composed of Chrome Moly Alloy material and is widely used in high-temperature applications, especially in boilers and superheaters. Given its critical applications, this type of pipe is typically priced significantly higher than standard carbon pipes. Common grades in ASTM A213 Standard Common grades include T9, T11, T12, T21, T22, T91, as well as stainless grades such as TP304/L or TP316/L. ASTM A213 Standard Scope According to ASTM specifications, this particular specification pertains to seamless ferritic and austenitic steel tubes for use in boilers, superheaters, and heat exchangers. The specific grades covered by this specification include T5, TP304, and others listed in Tables 1 and 2. The tubing size ranges from an internal diameter of 1/8 inch up to an outer diameter of 5 inches, with thicknesses ranging from 0.015 to 0.500 inches (0.4 mm to 12.7 mm). If other sizes are required, they can be specified as part of the order, along with minimum and average thicknesses.

ASTM A519 specification encompasses several grades of carbon and alloy steel mechanical tubing, available in either hot-finished or cold-finished conditions. The steel utilized in this tubing can be either cast in ingots or strand cast. When different grades of steel are sequentially strand cast, the transition material must be identified.

ASTM A335 alloy steel pipes are critical for high-temperature and high-pressure applications across various industries. Their superior mechanical properties, combined with rigorous manufacturing and testing processes, ensure they meet the demanding requirements of these applications. Understanding the specifications, grades, and applications of ASTM A335 pipes helps engineers and designers select the right materials for their projects, ensuring safety and efficiency in challenging environments.

ASTM A333 Gr 10 alloy steel pipe for industrial use in both seamless and welded.Feature Outer Dimensions: 19.05mm – 114.3mm Wall Thickness: 2.0mm – 14 mm Surface treatment: Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting. Application: Seamless and Welded Steel Pipe for Low-Temperature Service.

Tubing and casing pup joints are crucial components in the oil and gas industry for adjusting the length of tubular strings to precise measurements required for specific downhole operations. They are manufactured to meet stringent API 5CT standards, ensuring reliability and performance in various operational conditions. The seamless construction, rigorous testing, and quality finishing processes ensure these pup joints meet high industry standards for safety and efficiency.

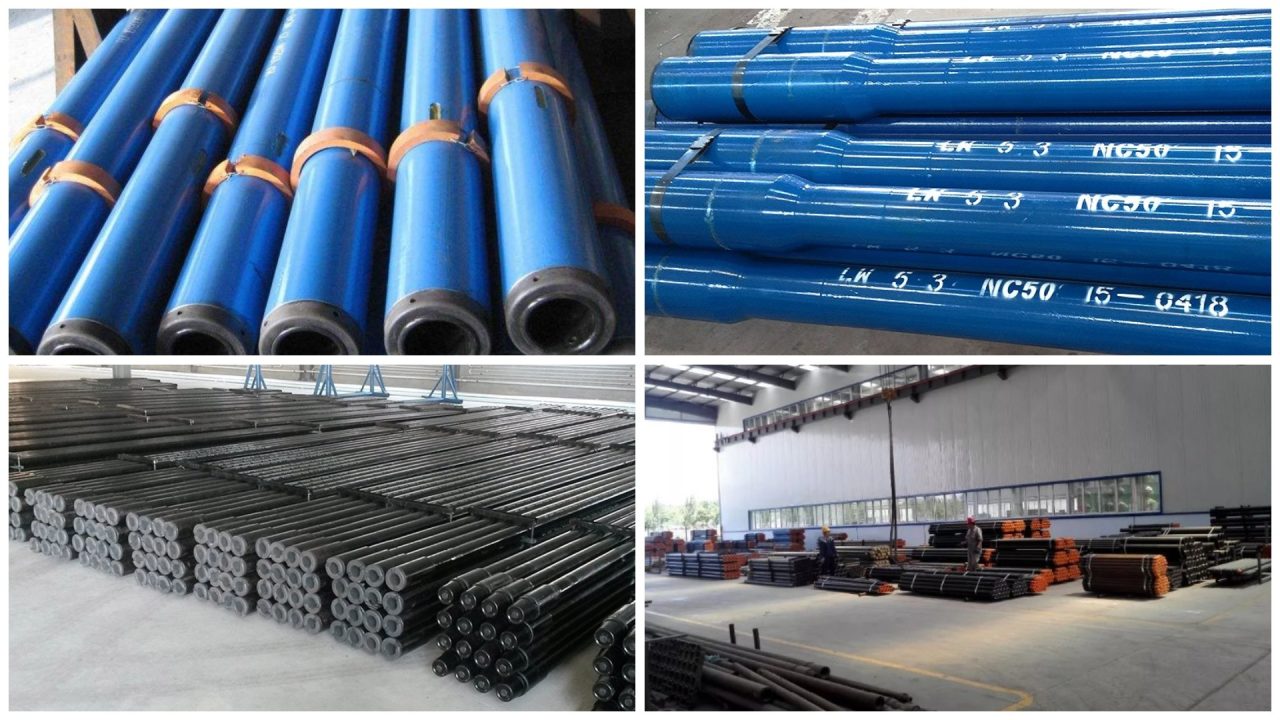

Our range of drill pipes and accessories are designed to meet the rigorous demands of oil and gas well drilling, as well as other drilling applications such as mining, geothermal, and water wells. We offer a variety of sizes, grades, and configurations to suit different needs and conditions. Our products comply with the highest industry standards, ensuring reliability, durability, and performance. For more information on our products or to discuss your specific requirements, please contact us. We are dedicated to providing high-quality drilling solutions tailored to your needs.

Drill collars are a fundamental component of the drill string, providing the necessary weight, stability, and direction control for effective drilling operations. Their various types and customizable dimensions allow for versatile applications in different drilling environments. By enhancing drilling efficiency, improving wellbore quality, and reducing equipment wear, drill collars contribute significantly to the success of drilling projects.

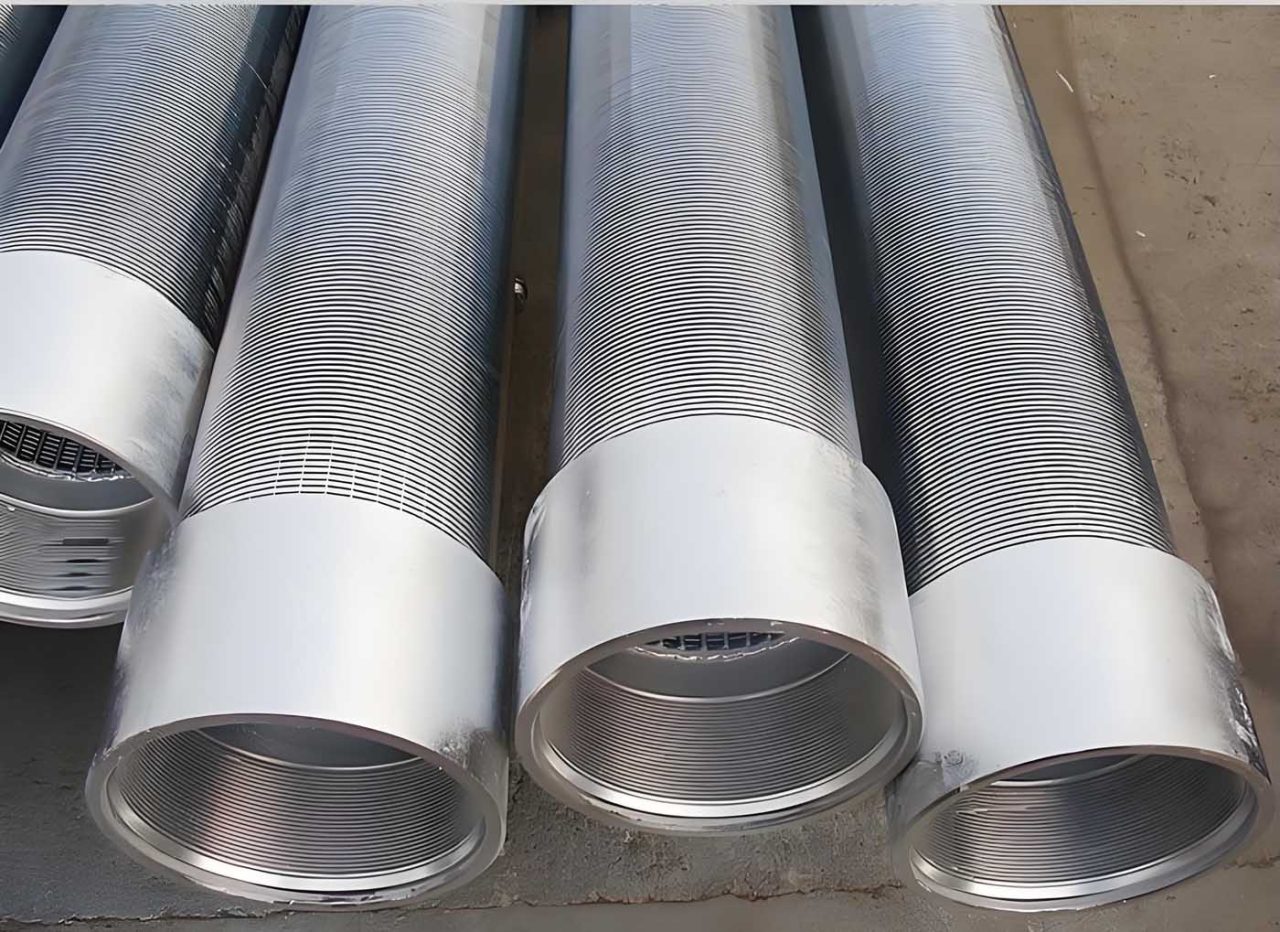

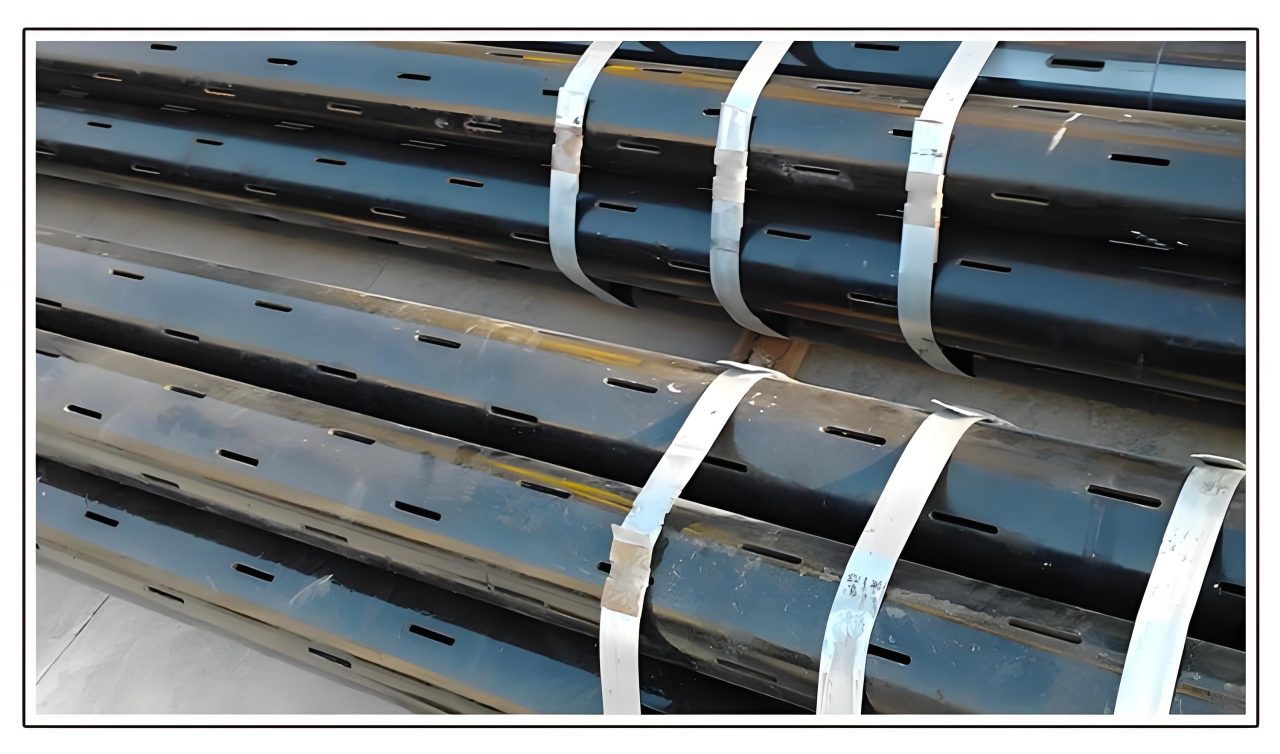

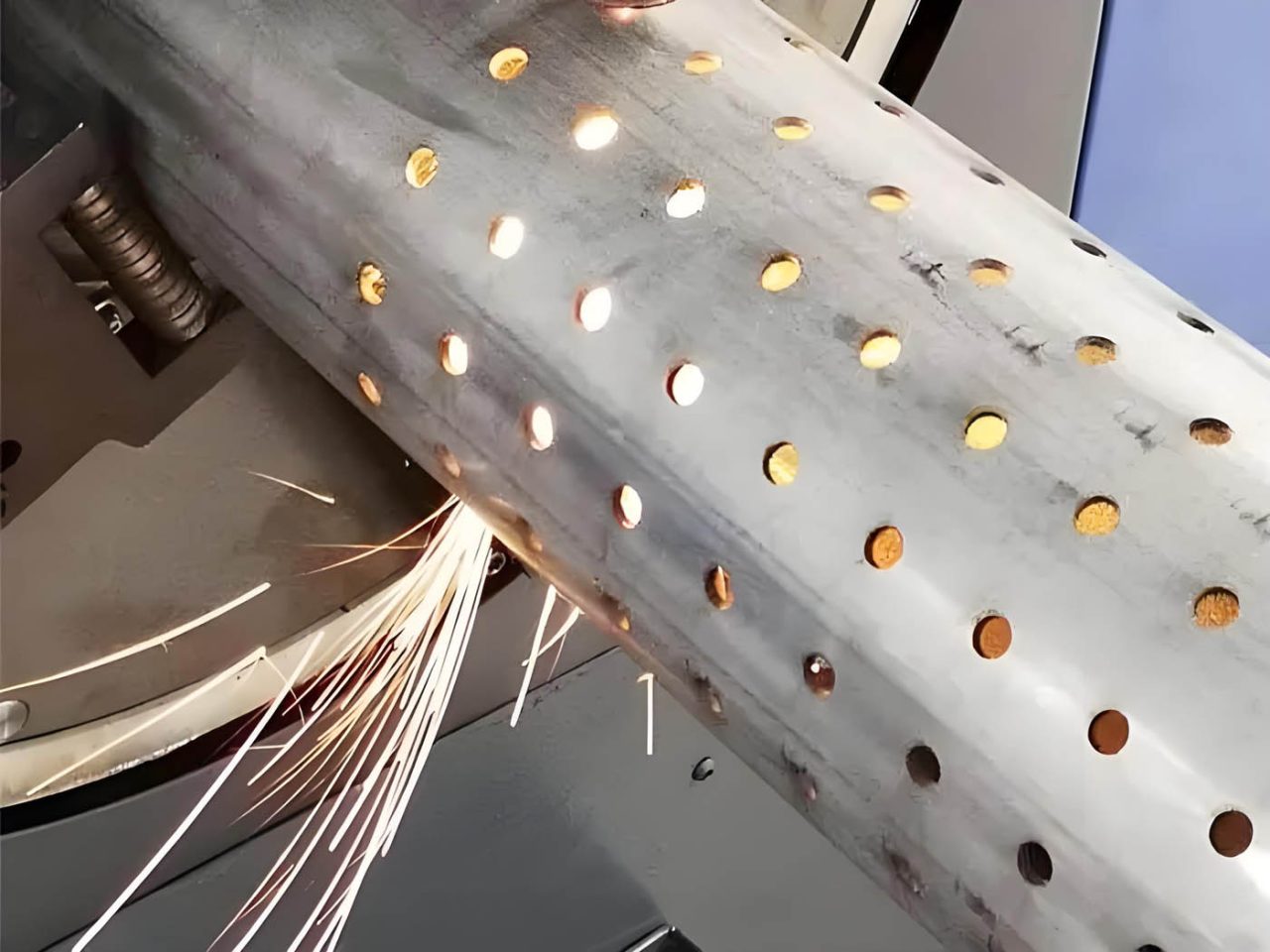

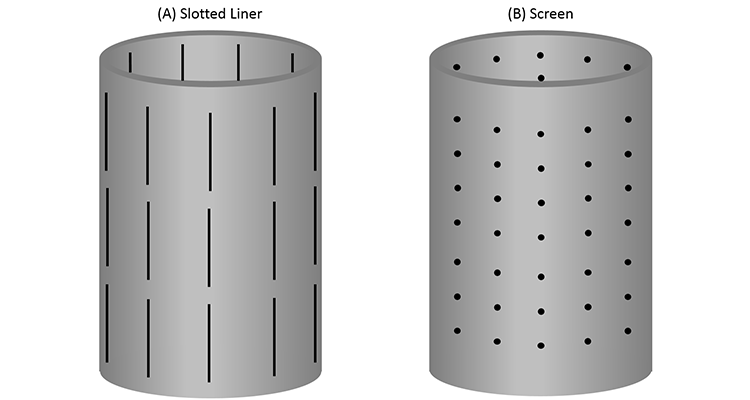

Slotted liner casing pipes are a vital component in wellbore applications, providing effective sand control and structural support. By selecting the appropriate slot size, pattern, type, and density, and ensuring the liner dimensions align with industry standards, operators can optimize well performance and longevity.

PTFE lined pipe and fittings are resistant to corrosion, full vacuum and high pressure during corrosive liquid handling. Lined pipes and fittings are commonly used for highly corrosive fluid handling at high temperatures.

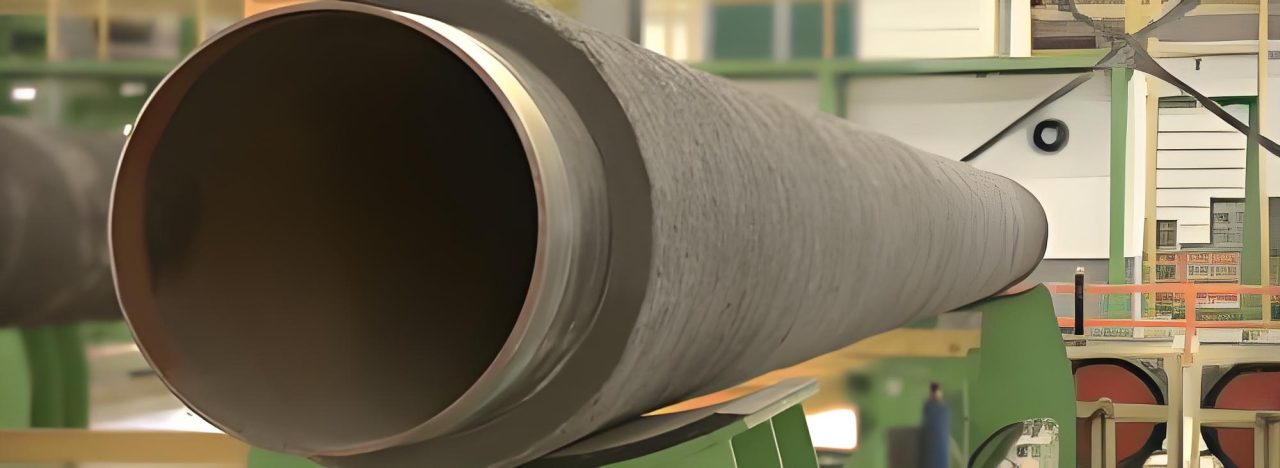

Internal coating pipes Using epoxy powder coating is for 30 years of history in a foreign country due to the wide range of sources of raw materials. Internal pipe coating is a critical process for protecting pipelines from corrosion, improving flow efficiency, and extending the lifespan of the piping system. By choosing the appropriate coating type and adhering to industry standards, operators can ensure the reliable and efficient operation of their pipelines in various industrial applications.

When choosing between hot-dip galvanizing and pre-galvanizing, consider the environmental conditions and the specific requirements of your application. Hot-dip galvanizing offers superior protection for harsh environments due to its thicker coating, while pre-galvanizing is a cost-effective solution for less demanding conditions. Both methods, when adhering to standards like ASTM A525, provide reliable corrosion protection for steel components.

The other main reason hot-dip galvanizing provides better corrosion protection is that the coating is applied during the fabrication process before the steel is installed. This means that any areas that are cut or damaged during installation will still have a protective coating. Other methods of galvanizing, like pre-galvanizing, coat the steel before it is cut and fabricated. This leaves any areas that are cut or damaged during installation vulnerable to rust and corrosion.

Concrete weight coated pipes provide essential benefits for subsea and offshore pipeline applications, including negative buoyancy, mechanical protection, and durability. By adhering to strict standards and quality control during manufacturing, these pipes ensure reliable performance and long-term

2LPP coated pipes offer a superior solution for protecting steel pipelines from corrosion and mechanical damage, especially in high-temperature and chemically aggressive environments. By leveraging the properties of fusion bonded epoxy and polypropylene, these pipes ensure long-term durability, reduced maintenance costs, and enhanced performance in critical applications. The development of polypropylene materials has significantly contributed to advancing pipeline coating technologies, providing reliable and efficient solutions for modern infrastructure needs.