DIN 30678 Three-Layer Polyethylene Coated Steel Pipes (3PE)

Abstract: This in-depth report provides a exhaustive examination of the Three-Layer Polyethylene (3PE) coating system for steel pipes, as standardized under the German Institute for Standardization’s DIN 30678. It delves into the historical context, the detailed specification requirements for each layer (Fusion-Bonded Epoxy, Adhesive, Polyethylene), the stringent manufacturing process, quality control protocols, and performance characteristics. The study underscores the role of DIN 30678 as a foundational and highly influential standard that has shaped global practices for external pipeline corrosion protection in demanding environments, particularly for buried and submerged applications. Extensive data tables are included to elucidate material properties, test methods, and comparative analyses, establishing 3PE as a premier corrosion mitigation technology.

Keywords: DIN 30678, 3PE Coating, External Corrosion Protection, Fusion-Bonded Epoxy (FBE), Copolymer Adhesive, Extruded Polyethylene, Cathodic Disbondment, Impact Resistance, Pipeline Integrity, Buried Pipeline.

1. Introduction

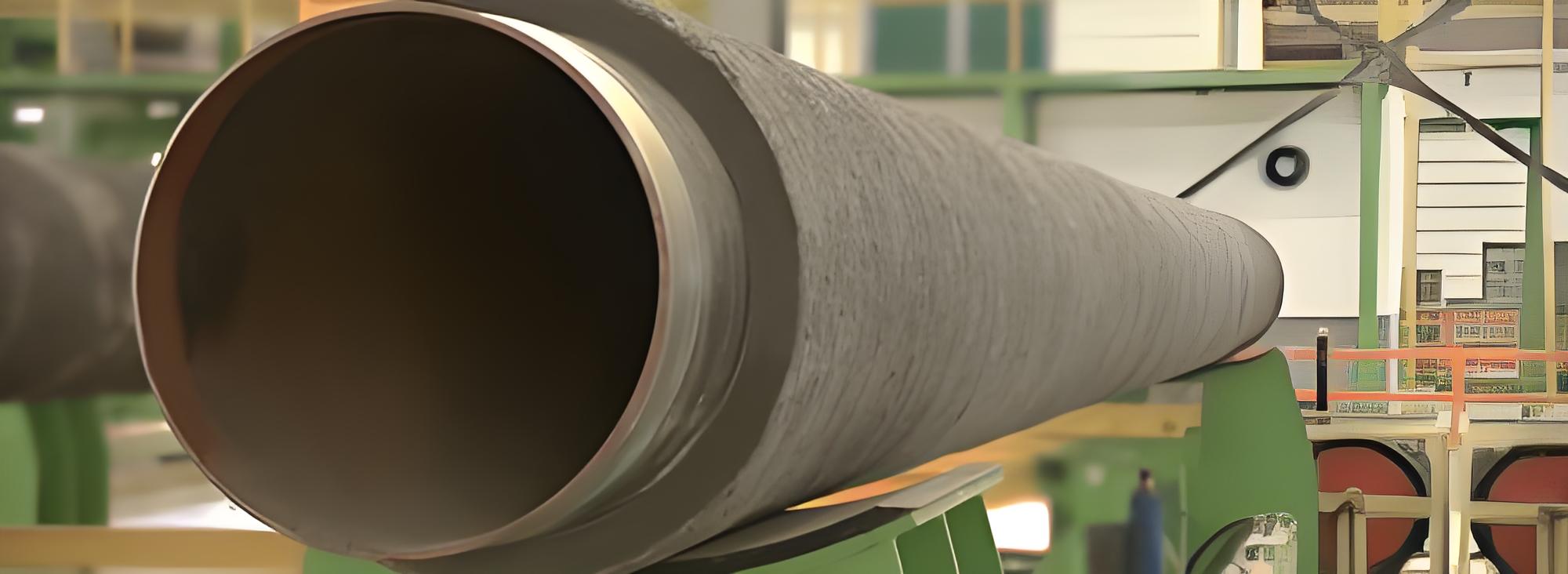

The perpetual battle against corrosion represents one of the most significant challenges in the operation and maintenance of steel pipeline infrastructure. The economic and environmental consequences of pipeline failures are immense, driving the continuous development of high-performance protective coating systems. Among these, the Three-Layer Polyethylene (3PE) coating has emerged as a globally recognized and extensively deployed solution for providing robust, long-lasting external protection to pipelines against soil corrosion, moisture, chemicals, and mechanical damage.

The German Institute for Standardization (Deutsches Institut für Normung – DIN) played a pivotal role in systematizing the application and quality requirements for this technology through the publication of DIN 30678, titled “Kunststoff-Mantelung von Stahlrohren und Formteilen für den Erddruckbetrieb und für Wässer” (Plastic Sheathing of Steel Pipes and Fittings for Burial and Water Applications). This standard, while specifically German, has achieved de facto international status, providing a rigorous technical benchmark for pipe coating manufacturers and pipeline operators worldwide. This report will dissect the 3PE system through the meticulous framework of DIN 30678, exploring its components, processes, and unparalleled performance attributes.

2. Historical Context and the Evolution to 3PE

The development of pipeline coatings evolved from simple single-layer systems like coal tar enamel and thin-film wraps to more sophisticated solutions. Two-layer Polyethylene (2PE) systems, which combined an adhesive with extruded PE, offered improved mechanical protection but were sometimes susceptible to disbondment due to insufficient adhesion and cathodic protection shielding.

The 3PE system was a transformative innovation that combined the best attributes of two established technologies:

- The superior, tenacious adhesion and cathodic disbondment resistance of Fusion-Bonded Epoxy (FBE), which had been used successfully as a standalone coating.

- The outstanding mechanical strength, moisture resistance, and chemical inertness of extruded Polyethylene (PE).

The introduction of a specialized copolymer adhesive layer as the crucial intermediary between the FBE and the PE created a synergistic system. The FBE provides primary corrosion protection and excellent adhesion to the steel substrate. The adhesive layer bonds molecularly to the cured FBE and is simultaneously fused into the molten PE during extrusion. The thick PE topcoat then acts as a formidable mechanical and environmental barrier. DIN 30678 effectively codified this advanced triple-layer structure, ensuring consistency and reliability.

3. The DIN 30678 Standard: A Framework of Excellence

DIN 30678 is not a mere guideline but a comprehensive specification that dictates requirements for materials, application processes, testing, and inspection. It covers both Polyethylene (PE) and Polypropylene (PP) sheathings, though 3PE is the more common variant. The standard’s authority stems from its precise and demanding nature, leaving little room for interpretation or substandard quality.

4. Deconstruction of the 3PE Coating System

The performance of the 3PE system is entirely dependent on the properties and perfect integration of its three distinct layers.

4.1 Layer 1: Fusion-Bonded Epoxy (FBE)

The FBE layer is the foundation of the entire system. Its purpose is twofold: to provide a primary, passive barrier against corrosion and to create a chemically active surface that facilitates powerful bonding with the subsequent layers.

- Composition: A thermosetting powder composed of epoxy resin, cross-linking agents, pigments (typically giving it a distinct green, tan, or red colour), and flow modifiers.

- Function:

- Corrosion Protection: It forms a continuous, high-resistance film that is impervious to moisture and ions.

- Adhesion: It chemically bonds to the steel surface at a molecular level.

- Cathodic Disbondment Resistance: This is a critical property. FBE is highly compatible with Cathodic Protection (CP) systems. If the outer PE layer is damaged and moisture reaches the FBE, the CP current can still protect the steel surface, and the FBE strongly resists disbonding (lifting away) from the steel under the influence of the CP voltage.

- Application: Applied electrostatically to a heated, cleaned steel pipe. The heat melts the powder, causing it to flow and cure into a continuous film.

Table 1: DIN 30678 Requirements for the FBE Layer

| Property | Test Standard | Unit | Requirement (Typical) | Importance |

|---|---|---|---|---|

| Thickness | DIN 30678 / ASTM D7091 | µm | Minimum 80 – 150 (varies by spec) | Must be sufficient to provide a continuous, defect-free barrier. |

| Cathodic Disbondment | DIN 30678 / ASTM G8 / G42 | mm (radius) | ≤ 10 (e.g., at 23°C, 28 days, -1.5V vs. CSE) | Crucial. Measures resistance to disbondment from CP, ensuring CP effectiveness. |

| Adhesion (Pull-Off) | ISO 4624 / ASTM D4541 | MPa | > 10 (Failure must be cohesive) | Ensures tenacious bonding to the steel substrate. |

| Flexibility | ASTM D6905 | ° | No cracking at 2.5° | Ensures the coating can withstand pipe bending during installation. |

| Impact Resistance | DIN 30678 | J/mm | No cracking at specified energy | Protects against mechanical damage during handling. |

4.2 Layer 2: Copolymer Adhesive

This layer is the “glue” of the system. It is specifically formulated to create a permanent chemical and physical bridge between the thermosetting FBE and the thermoplastic PE.

- Composition: Typically a maleic anhydride grafted polyolefin (e.g., polyethylene or polypropylene-based copolymer). The maleic anhydride groups react with the epoxy groups in the cured FBE layer, forming covalent bonds. The polyolefin backbone is then compatible with and dissolves into the molten PE of the top layer during extrusion.

- Function: To ensure 100% adhesion between the FBE and PE layers, preventing water ingress and delamination. Without this specific adhesive, the FBE and PE would not bond effectively.

Table 2: DIN 30678 Requirements for the Adhesive Layer

| Property | Test Standard | Unit | Requirement (Typical) | Importance |

|---|---|---|---|---|

| Application | Visual | – | Continuous, uniform veil | Must fully cover the FBE layer without gaps. |

| Thickness | DIN 30678 | µm | 150 – 400 | Must be sufficient to ensure complete bonding. |

| Functionality | Indirectly tested via Peel Test | – | – | Its performance is validated by testing the bond strength of the entire system. |

4.3 Layer 3: Extruded Polyethylene (PE) Topcoat

The PE layer is the workhorse, providing the bulk of the mechanical and environmental protection. DIN 30678 specifies requirements for both low-density (LDPE) and high-density (HDPE) polyethylene, with HDPE being preferred for its superior mechanical properties.

- Composition: Polyethylene resin compounded with carbon black (2.5 ± 0.5% for UV protection), antioxidants, and stabilizers. The carbon black must be of a fine, thermal grade to ensure uniform dispersion and optimal protection.

- Function:

- Mechanical Protection: Resists abrasion, impact, and stone penetration during handling, installation, and service.

- Environmental Barrier: Impermeable to water, soil chemicals, and microorganisms.

- Electrical Insulator: Shields the pipeline electrically, reducing the current demand for the CP system.

Table 3: DIN 30678 Requirements for the Polyethylene Topcoat

| Property | Test Standard | Unit | Requirement for HDPE | Importance |

|---|---|---|---|---|

| Density | ISO 1183 | g/cm³ | ≥ 0.940 | Higher density correlates with better mechanical strength and chemical resistance. |

| Melt Flow Rate (MFR) | ISO 1133 (190°C/5kg) | g/10 min | 0.2 – 1.2 (typically ~0.4) | Indicates molecular weight. Low MFR ensures high stress crack resistance. |

| Carbon Black Content | ISO 6964 | % | 2.5 ± 0.5 | Provides UV protection and ensures dispersion. |

| Carbon Black Dispersion | ASTM D5596 | Rating | ≤ Category 3 | Poor dispersion creates weak points susceptible to cracking. |

| Tensile Strength (Yield) | ISO 527-2 | MPa | ≥ 20 | Resistance to mechanical stresses. |

| Elongation at Break | ISO 527-2 | % | ≥ 600 | High ductility allows the coating to deform without cracking. |

| Environmental Stress Crack Resistance (ESCR) | ASTM D1693 (Condition B) | hrs | F₀ ≥ 1000 | Critical. Measures resistance to brittle failure under sustained stress and chemical exposure. |

| Impact Resistance (at -20°C) | DIN 30678 | J/mm | No fracture | Ensures toughness even at low temperatures. |

| Thickness | DIN 30678 | mm | Specified per pipe diameter (e.g., 2.0mm to 3.7mm+) | Thicker coatings provide greater mechanical protection. |

5. The Manufacturing Process: A Precision Operation

The application of a 3PE coating is a continuous, factory-controlled process that demands extreme precision. DIN 30678 outlines the critical steps:

- Surface Preparation (Abrasive Blasting): The pipe surface is cleaned to a near-white metal finish (Sa 2.5, ISO 8501-1) with a typical anchor profile of 50-100 µm. This is the single most important step, as coating adhesion is fundamentally mechanical.

- Pre-Heating: The pipe is heated in an induction furnace to a precise temperature (typically 200-240°C) to prepare it for FBE application and to drive off any moisture.

- FBE Application: The heated pipe enters a station where FBE powder is electrostatically sprayed onto it. The heat melts and cures the powder into a continuous, uniform film.

- Cooling and Inspection: The FBE-coated pipe is water-quenched and inspected for defects using a holiday detector.

- Adhesive and PE Extrusion: The pipe enters the extrusion station. The adhesive is first applied as a powder onto the warm FBE or, more commonly, the pipe passes through a cross-head die where the molten adhesive and PE are co-extruded simultaneously onto the rotating pipe. The heat from the pipe melts the adhesive powder, ensuring bonding.

- Cooling and Solidification: The coated pipe is water-cooled to solidify the PE layer.

- End-Facing: The coated ends are trimmed to expose bare steel for welding.

- Final Inspection: 100% holiday detection is performed at high voltage (typically using a spark tester with a voltage based on coating thickness). Samples are taken for destructive testing (e.g., peel test).

6. Quality Control and Testing: Ensuring Compliance

DIN 30678 mandates a rigorous regime of in-process and final testing.

Table 4: Key Quality Control Tests as per DIN 30678

| Test | Standard | Frequency | Purpose & Acceptance Criteria |

|---|---|---|---|

| Surface Cleanliness/Profile | ISO 8501-1, ISO 8503 | Continuous | Verify Sa 2.5 and profile depth. |

| Pre-Heat Temperature | Pyrometer | Continuous | Ensure correct temp for FBE cure. |

| FBE Thickness | Magnetic Gauge | Continuous | Verify thickness is within spec. |

| Holiday Detection | DIN 30678 / NACE RP0274 | 100% of pipe | Detect any flaws (pinholes) in FBE and final PE coating. |

| Peel Test | DIN 30678 | Start/End of shift, etc. | The definitive adhesion test. A strip of PE is peeled back. Failure must occur within the PE layer itself (cohesive failure), not at the interface with the FBE. Minimum peel strength is specified. |

| Thickness of PE Layer | Ultrasonic Gauge | Continuous | Ensure mechanical protection meets design. |

| Bend Test | DIN 30678 | Sample | Coating must not crack or disbond after bending a sample pipe to a specified radius. |

7. Performance Advantages and Limitations

Advantages:

- Exceptional Mechanical Strength: Highly resistant to handling damage, soil stress, and stone impingement.

- Excellent Corrosion Protection: The synergistic effect of the three layers provides a near-impenetrable barrier.

- Superb Adhesion: The system is highly resistant to disbondment, both from soil stress and cathodic protection.

- Excellent Chemical Resistance: Resistant to soils, acids, alkalis, and solvents.

- Long Service Life: Proven performance exceeding 50 years when properly selected and installed.

- CP Compatibility: The FBE layer ensures the CP system remains effective even if the PE is damaged.

Limitations:

- Temperature Limitation: Standard HDPE softens at temperatures above 80°C. For higher temperatures (up to 110-140°C), Polypropylene (3PP) systems are used, which are also covered under DIN 30678.

- UV Degradation: While carbon black protects it, prolonged exposure to sunlight before burial can make the PE brittle. It must be stored under cover.

- Complex Repair: Damage to the coating must be repaired using specialized heat-shrink sleeves or liquid epoxy materials by trained personnel.

- Cost: The multi-layer system and complex application process make it more expensive than simpler coatings like FBE alone.

8. Comparative Analysis with Other Coating Systems

Table 5: Comparison of 3PE with Alternative Pipeline Coatings

| Coating System | Advantages | Disadvantages | Typical Application |

|---|---|---|---|

| 3PE (DIN 30678) | Best overall mechanical & corrosion protection, excellent adhesion, CP compatible. | Higher cost, temp limit (~80°C for PE), complex repair. | Cross-country pipelines, rocky areas, river crossings, demanding environments. |

| FBE Only | Excellent adhesion & CP compatibility, good temp resistance (~100°C), easy to repair. | Thin film, poor mechanical protection, requires careful handling. | Moderate soil conditions, above-ground pipe, projectiles, where CP is highly effective. |

| Coal Tar Enamel | Historical use, good moisture resistance, low cost. | Brittle, poor adhesion, environmental & health hazards, difficult repair. | Largely obsolete, replaced by modern systems. |

| 3 Layer Polypropylene (3PP) | All benefits of 3PE but with higher temperature resistance (up to 140°C). | Even higher cost, requires higher application temperatures. | High-temperature pipelines (e.g., hot oil, steam lines). |

9. Installation and Field Jointing

The performance of the factory-applied coating can be negated by poor field practices. DIN 30678-coated pipes require careful handling with nylon slings. The trench must be free of sharp rocks, often using a sand bed. The most critical activity is the coating of field welds. This involves:

- Cleaning the weld area.

- Applying a compatible liquid epoxy or FBE sleeve to the bare steel.

- Installing a radiation-crosslinked heat-shrink sleeve over the joint, which provides mechanical protection and adhesion equivalent to the mainline coating.

- Each field joint is holiday tested.

DIN 30678 is more than a standard; it is a testament to abtersteel company rigor and a blueprint for achieving exceptional longevity in pipeline infrastructure. The 3PE coating system it specifies represents the pinnacle of external corrosion protection technology, offering an unparalleled combination of mechanical resilience, environmental resistance, and electrochemical compatibility. Its layered design philosophy—where each component performs a dedicated and synergistic function—has set a global benchmark. For pipeline engineers tasked with ensuring the integrity of assets buried in aggressive environments for decades, specifying a coating that conforms to the exacting requirements of DIN 30678 remains one of the most reliable decisions they can make. The standard’s continued relevance is assured through its comprehensive, performance-based approach to material selection, process control, and quality assurance.