ASME SB338 Grade 7 titanium heat exchanger tubes, alloyed with palladium, offer unmatched corrosion resistance, thermal efficiency, and lightweight properties for demanding applications. Compliant with ASME SB338 and ASTM B338, these tubes excel in chemical processing, power generation, desalination, and marine heat exchangers. Their durability, enhanced by palladium, justifies their use despite higher costs. For technical data or quotes, contact suppliers like abtersteel.com

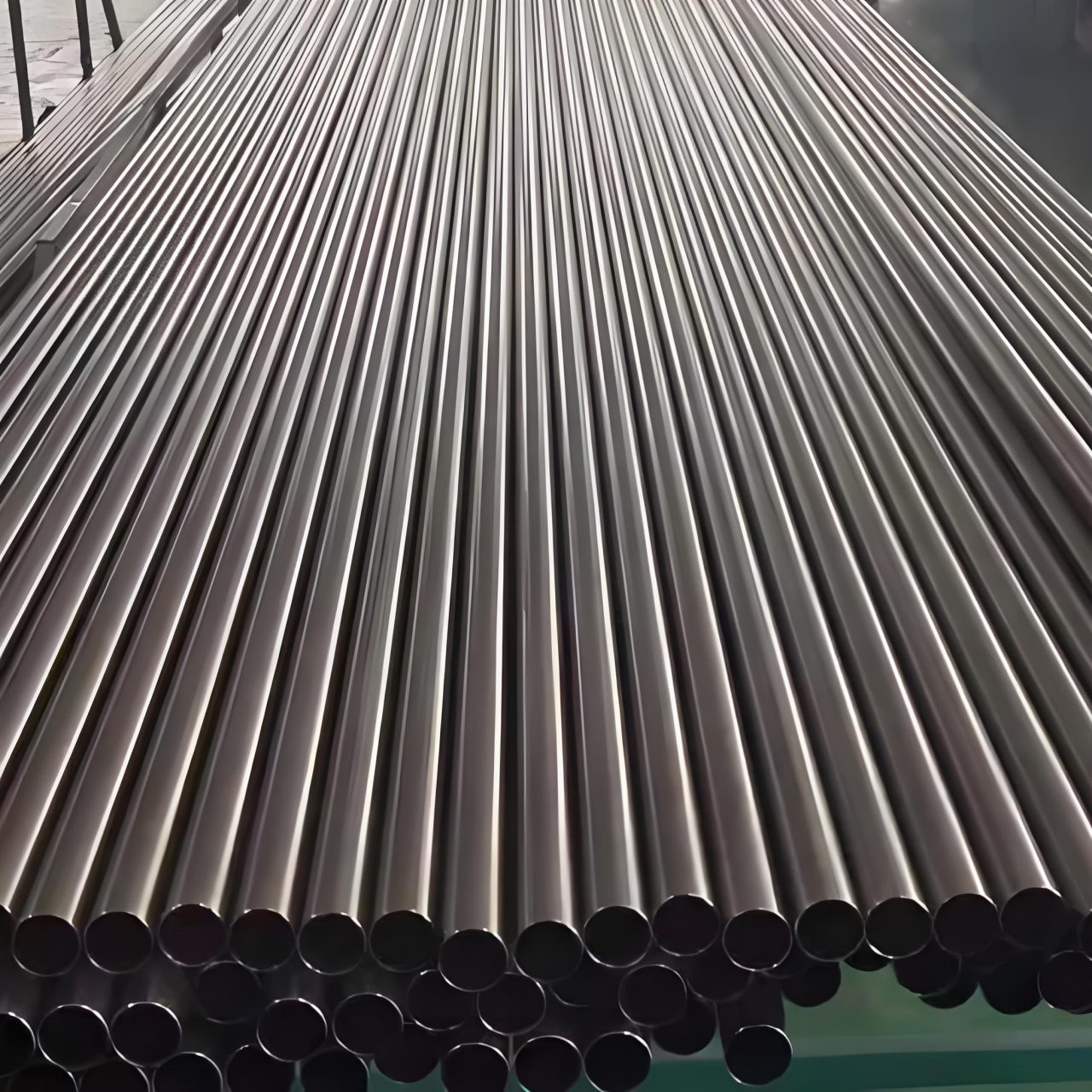

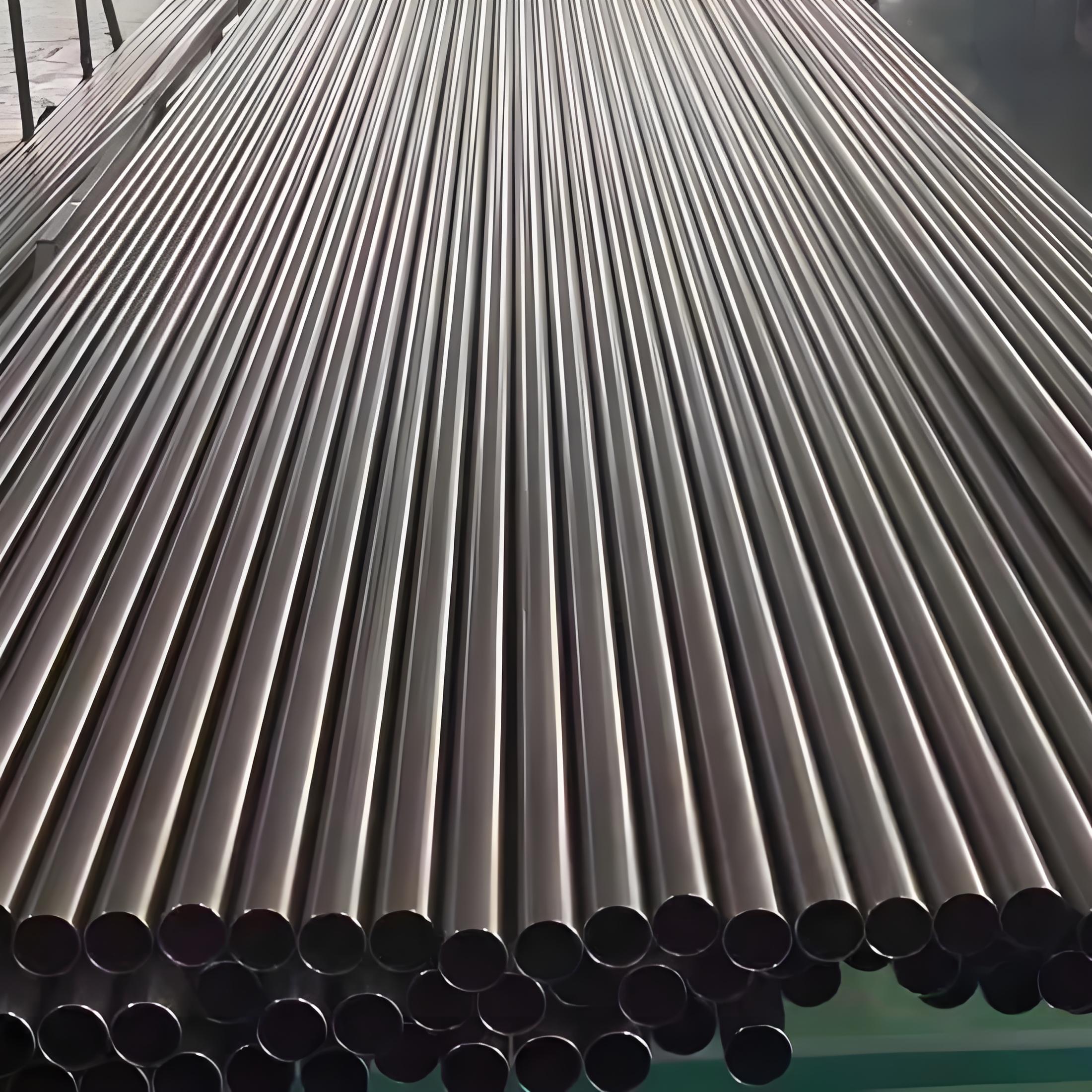

Boiler Steel Pipe

ASTM B861 titanium alloy seamless pipes are a premium choice for boiler applications, offering unmatched corrosion resistance, high-temperature strength, and lightweight properties. Compliant with ASTM B861 and ASME SB861, these pipes in grades like 2, 7, and 12 meet the demands of power generation, chemical processing, and marine boiler systems. Despite higher costs, their durability and performance justify their use in critical applications. For technical data or quotes, contact suppliers like abtersteel.com

ASTM A210 Grade A1 Seamless Tube shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. The offered ASTM A210 GR A1 CS Seamless Tubes is availed in diverse sizes and other related specifications, to meet requirements of our prominent clients.ASME SA 210 Gr.A1 Boiler Pipes that is designed according to set industry standards. As per the needs and requirements of our clients, we are involved in providing ASME SA 210 Gr. A1 Boiler Tubes. Buy ASTM A210 Grade A1 Boiler Tubes at reasonable cost from us.

Boiler Steel Pipes are critical components in many industrial applications, providing reliable performance under extreme conditions. By adhering to strict quality standards and understanding the key properties and classifications of these tubes, industries can ensure the safe and efficient operation of their thermal systems.

Boiler Pipe Application: 1 General boiler pipes are mainly used to manufacture water-cooled wall pipes, boiling water pipes, superheated steam pipes, superheated steam pipes for locomotive boilers, large and small smoke pipes and arch brick pipes. 2 high pressure boiler tubes are mainly used to manufacture superheater tubes, reheater tubes, air ducts, main steam tubes, etc. for high pressure and ultra high pressure boilers.