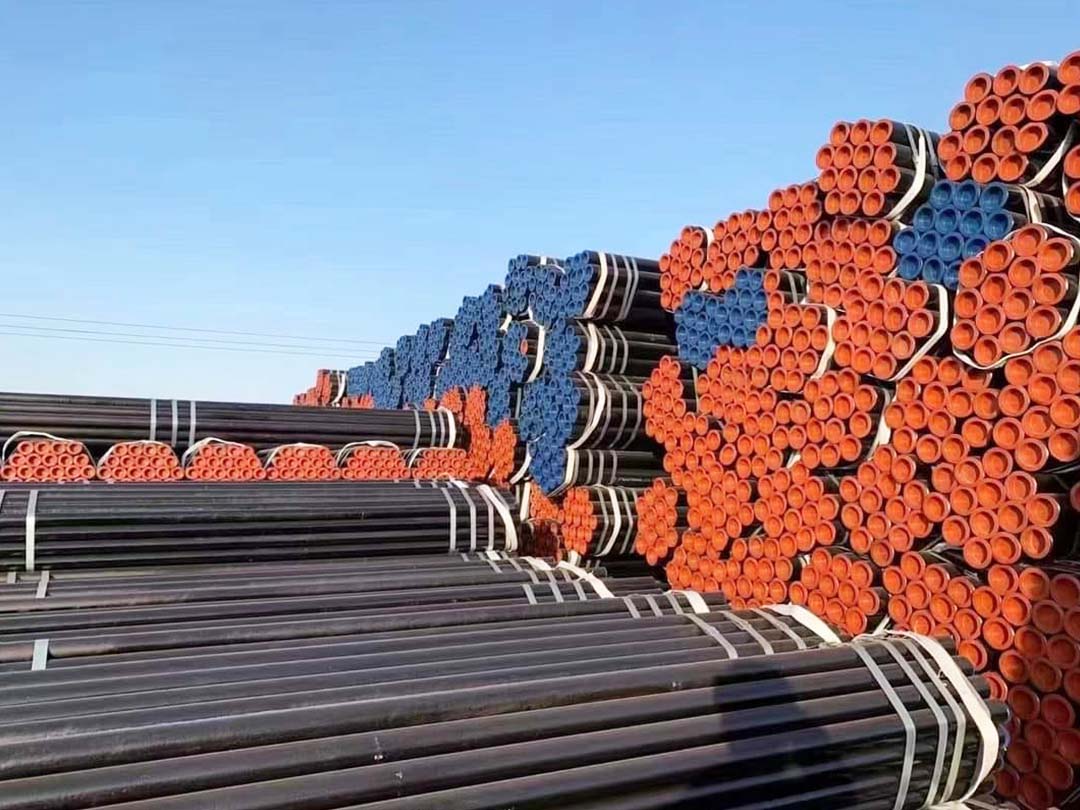

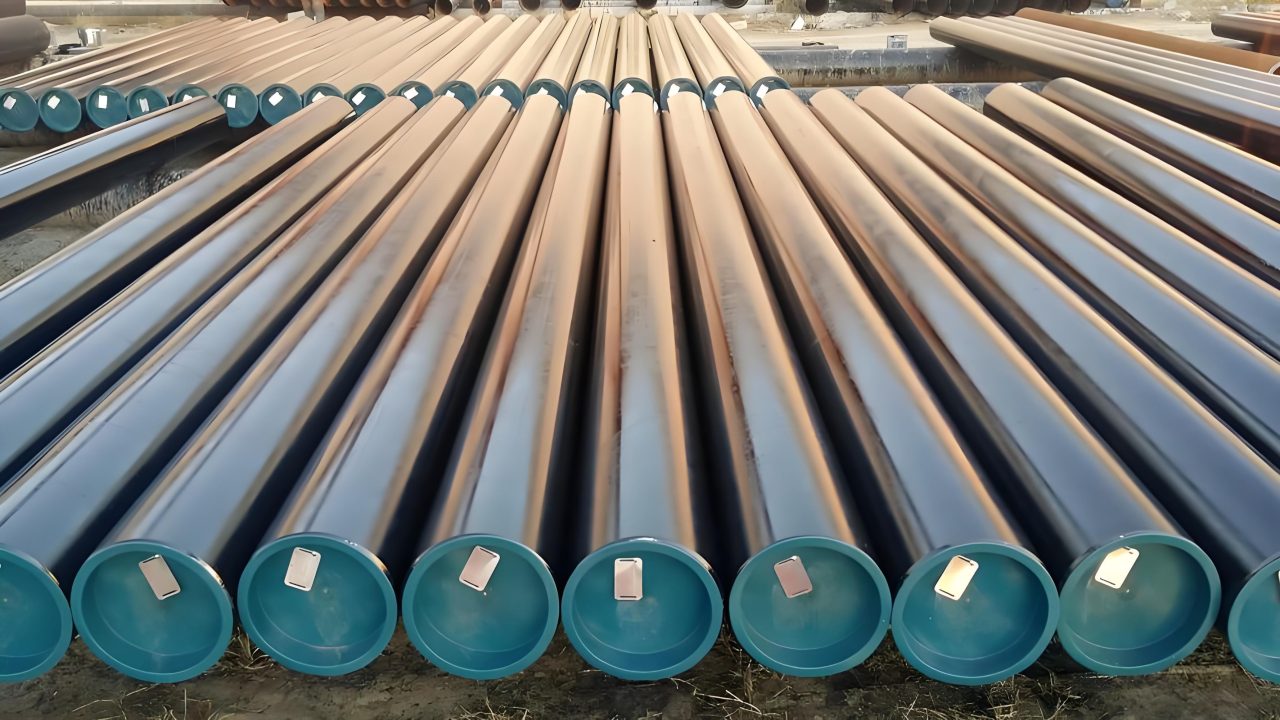

ERW welded steel pipes

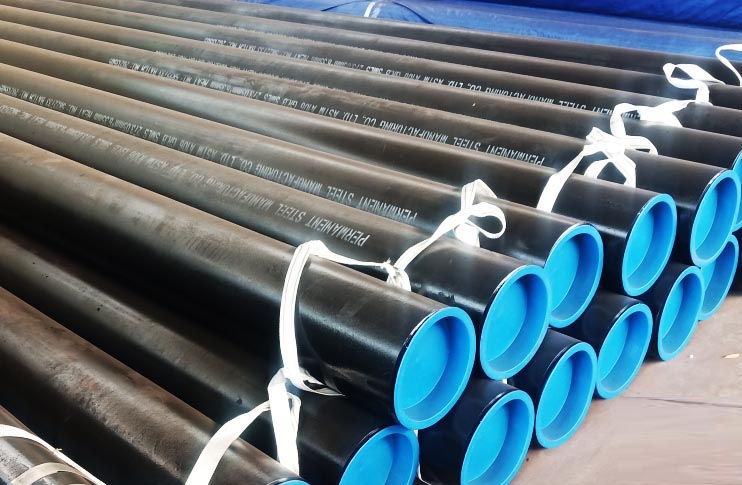

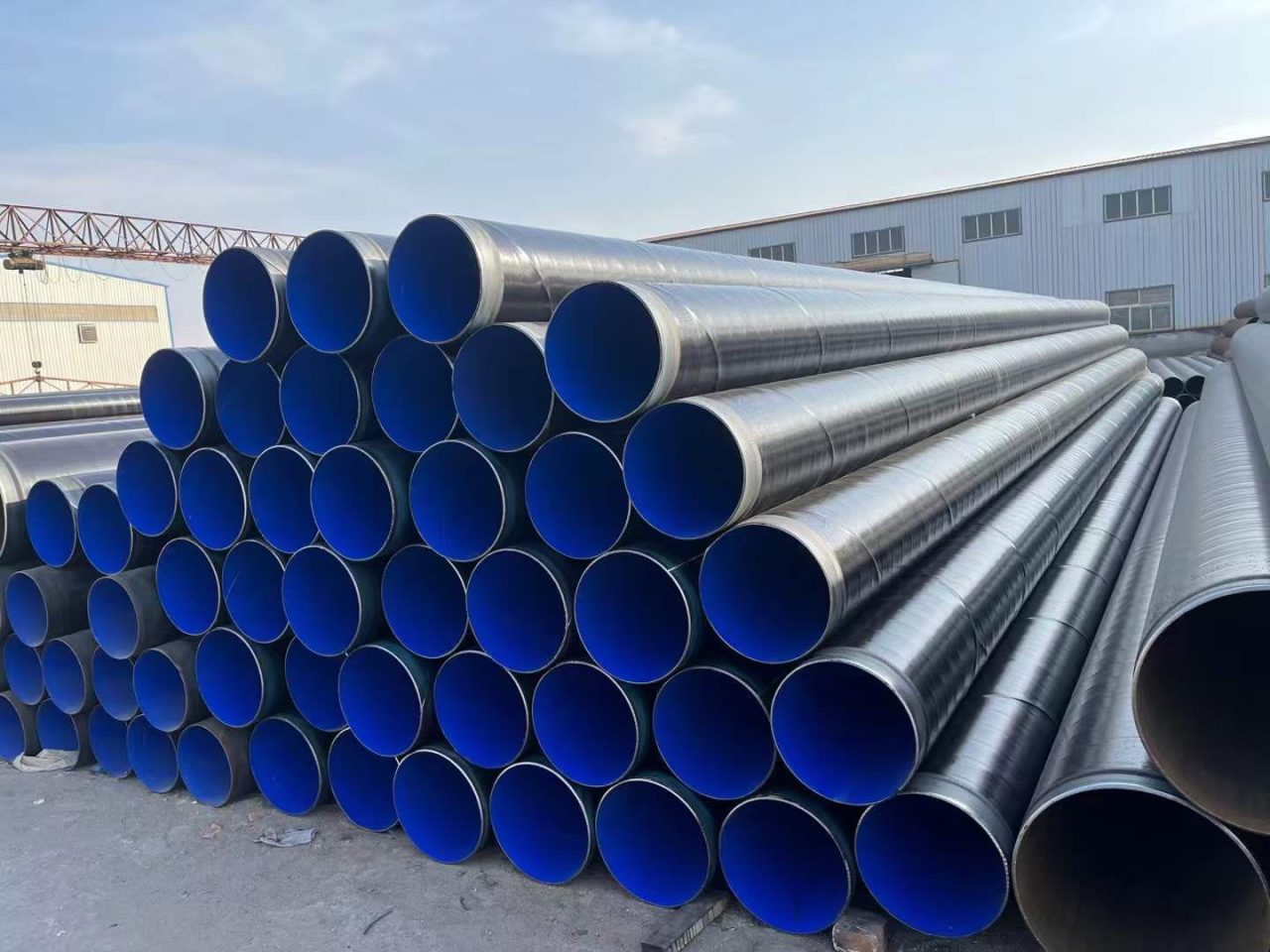

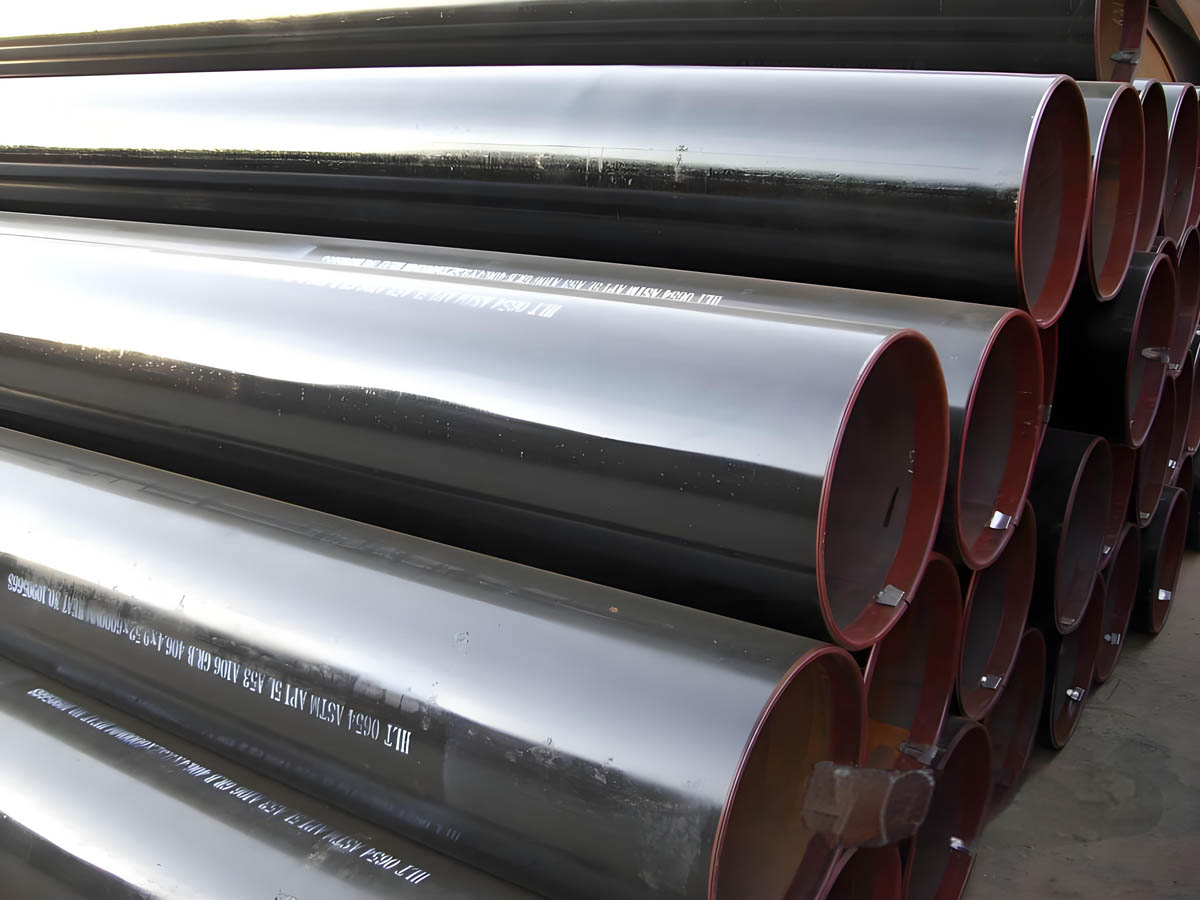

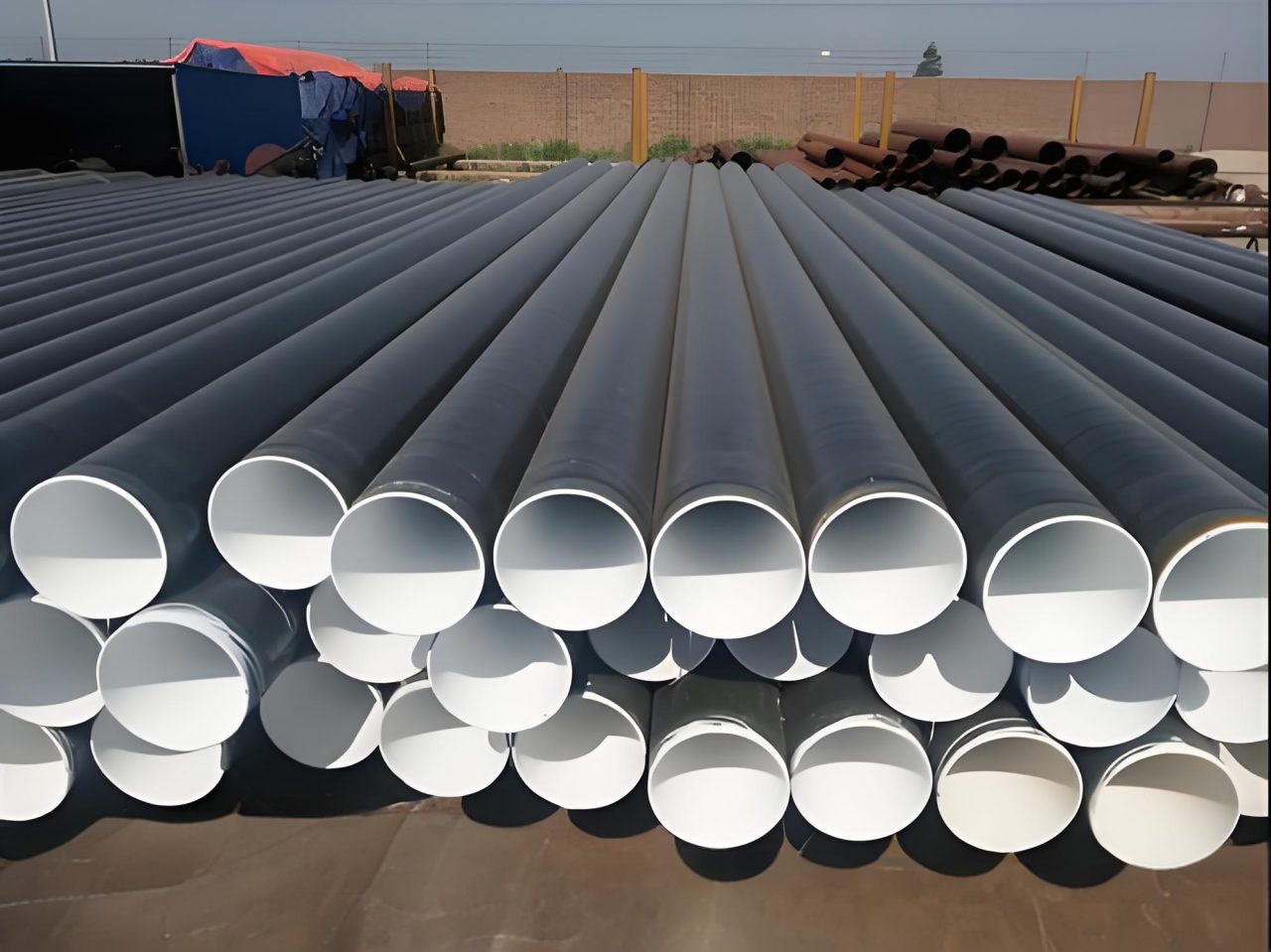

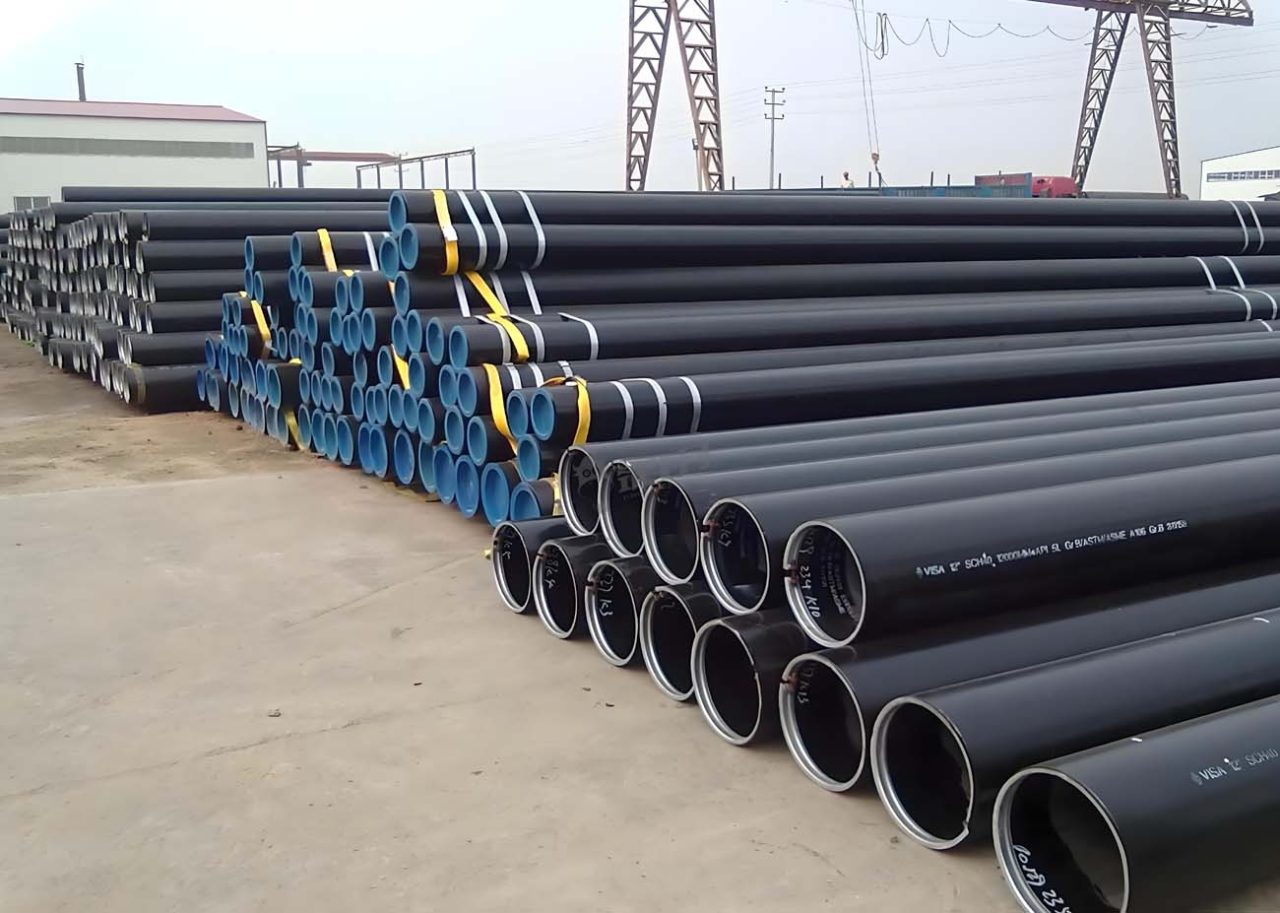

ERW Steel Pipe(Electric Resistance Welded Pipe), A53 ERW Pipe, ERW Carbon Steel Pipe Product Details of ERW steel pipe Pipe End: square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled, Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE) Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps. Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Hardness Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, NDT TEST ( ET TEST, RT TEST, UT TEST) For ERW Line Pipe For ERW Casing For ERW Structure Tube For High pressure and high temperature

ERW Steel Pipe

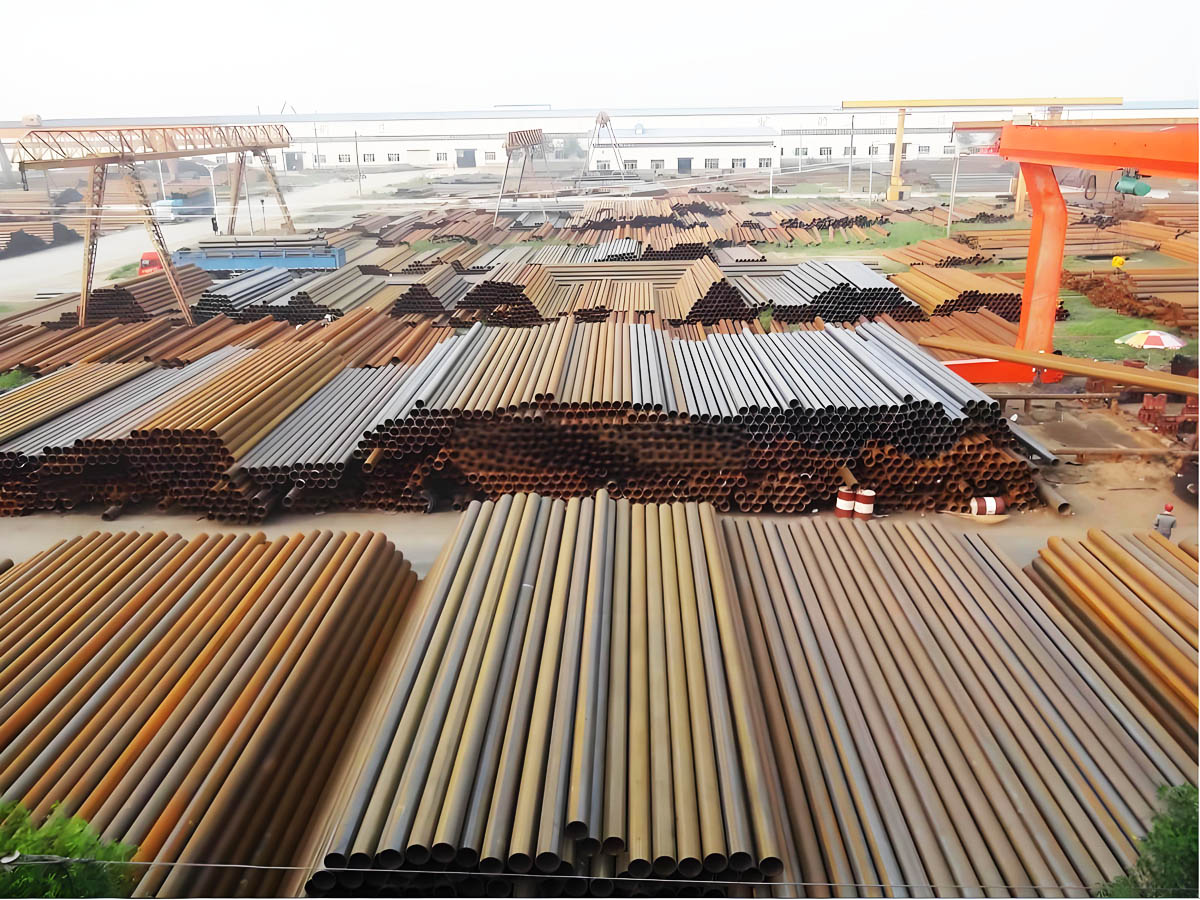

Abter is a China based ERW steel pipe manufacturer and supplier. Our main products include boiler steel tube, 3PE anticorrosion steel pipes, fiberglass insulated pipeline, to name a few. All of our high quality products are offered at competitive prices. The full chain of manufacturing foam insulated pipeline, SSAW steel pipe, etc. can be completed in China, even in one city. Lower manufacturing cost saves your purchasing cost. The detailed information of each product is shown in the corresponding product page.

ERW Welded Pipe and Manufacturing Process

ERW Steel Pipe(Electric Resistance Welded Pipe), A53 ERW Pipe, ERW Carbon Steel Pipe Product Details of ERW steel pipe Pipe End: square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled, Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE) Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Boiler Steel Pipes

Boiler Steel Pipes are critical components in many industrial applications, providing reliable performance under extreme conditions. By adhering to strict quality standards and understanding the key properties and classifications of these tubes, industries can ensure the safe and efficient operation of their thermal systems.

Seamless Steel Fluid Pipe

Seamless steel fluid pipes are vital components in many industrial systems, offering unmatched strength, durability, and reliability. By understanding their characteristics, manufacturing processes, materials, standards, and applications, industries can select the appropriate seamless pipes to ensure efficient and safe fluid transport.

Mechanical Steel Tubes

Mechanical steel tubes are essential for a variety of industrial applications requiring high strength, precision, and durability. The choice of material—whether carbon steel, alloy steel, or stainless steel—depends on the specific requirements of the application, such as mechanical properties, corrosion resistance, and ease of machining.