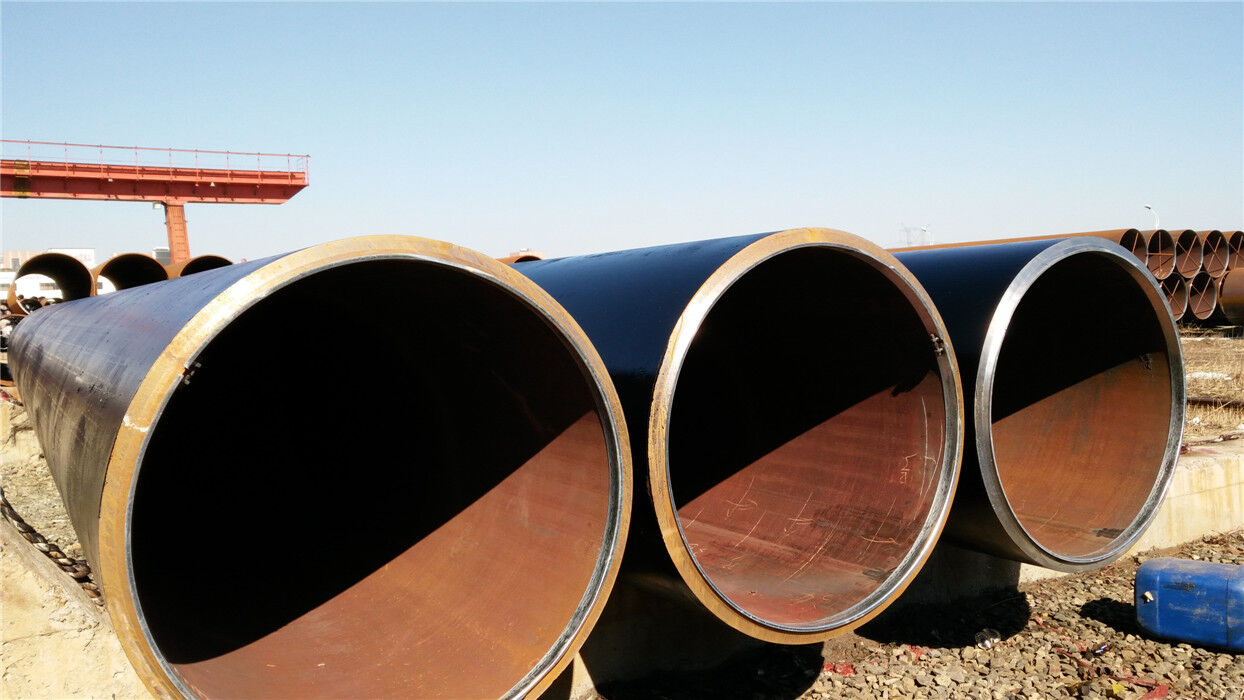

LSAW Steel Pipe (Longitudinally Submerged Arc Welding Pipe)

LSAW Steel Pipe (Longitudinally Submerged Arc Welding Pipe)

UOE SAWL PIPES

Outside Diameter:Φ508mm- 1118mm (20″- 44″)

Wall Thickness: 6.0-25.4mm 1/4″-1″

Quality Standards: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Length: 9-12.3m (30′- 40′)

Grades: API 5L A-X90,GB/T9711 L190-L625

JCOE SAWL PIPES

Outside Diameter:Φ406mm- 1626mm (16″ – 64″ )

Wall Thickness:6.0- 75mm (1/4″ – 3″ )

Quality Standards:API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Length:3-12.5m ( 10′- 41′ )

Grades:API 5L A-X100, GB/T9711 L190-L690

LSAW PIPE APPLICATIONS

CIVIL CONSTRUCTION:

Structural pipes for stadiums, bridges and buildings.

SPECIAL ITEMS:

Mother pipes for bends, pipes for slug catcher facilities (including HIC & SSC). Prefabricated tubular elements ready to be assembled at the construction yard.

ONSHORE PLANTS:

Pipes processed for the petrochemical industry, oil and gas treatments plants, power plants and reactors, oil and gas refineries, and LNG terminals.

OFFSHORE STRUCTURES:

Pipes, piles, cans and cones for offshore platform jackets. Topsides and foundation jackets for wind farms.

Longitudinally welded steel pipes are used in onshore and offshore oil and gas pipelines requiring critical service, high performance and tight tolerances. LSAW pipe are also used in conveyance of flammable & nonflammable liquids, and as structural members in construction projects.

Tolerance of Outside Diameter and Wall Thickness

| Types | Standard | |||||

| SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

| Tube end OD deviation | ±0.5%D | ±0.5%D | -0.79mm~+2.38mm | <±0.1%T | <±0.1%T | ±1.6mm |

| Wall thickness | ±10.0%T | D<508mm, ±12.5%T | -8%T~+19.5%T | <-12.5%T | -8%T~+19.5%T | 5.0mm<t<15.0mm, ±0.11<=”” p=””></t<15.0mm,> |

| D>508mm, ±10.0%T | T≥15.0mm, ±1.5mm | |||||

Chemical Composition and Mechanical Properties of LSAW Steel Pipe

| Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

| C | Mn | Si | S | P | Yield Strength

(Mpa) |

Tensile Strength

(Mpa) |

||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | – | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | – | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | – | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | – | – | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | – | – | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | – | – | – | 0.050 | 0.050 | 235 | 400 |

| SS490 | – | – | – | 0.050 | 0.050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | – | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | – | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | – | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | – | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | – | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | – | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | – | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | – | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | – | 0.03 | 0.03 | 585 | 570 | |

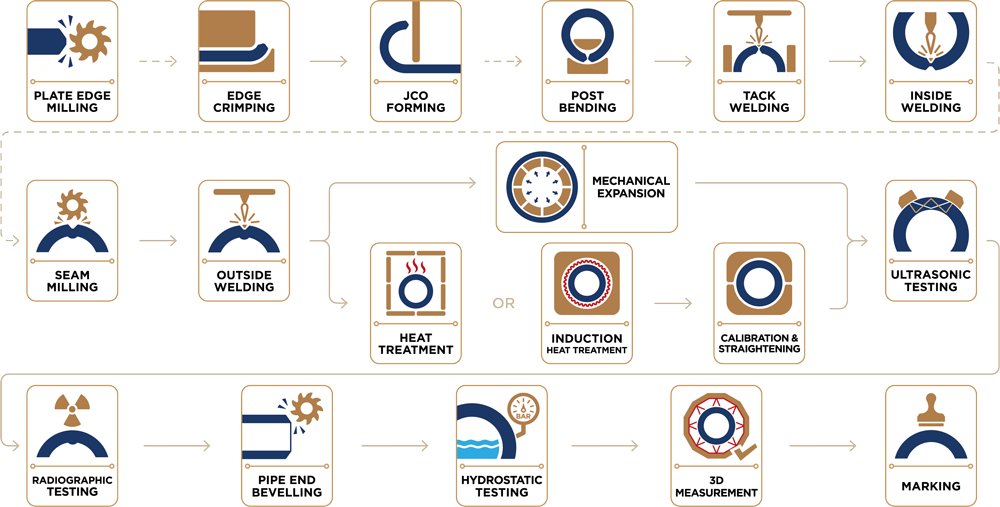

lSAW ( Welded Pipes )Manufacturing Process

UOE is a method used for production of longitudinally welded large diameter pipes. Longitudinal edges of steel plates are first beveled using carbide milling equipment. Beveled plates are then formed into a U shape using a U-press and subsequently into an O shape using an O-press.

Longitudinal edges of the plates are then tack welded followed by internal and external welds.

Pipes manufactured by this process are subjected to expanding operation in order to relieve internal stresses and obtain a perfect dimensional tolerance.

After the pipes are conveyed to cold expansion, hydrostatic testing and NDT inspection, the pipes will be subject to final inspection for the compliance to customer requirements.

Starting from incoming control up to the final inspection stage; entire process is monitored and supported by computerized system. Traceability is achieved by input controls and barcodes through entire production lines.

Production Flow

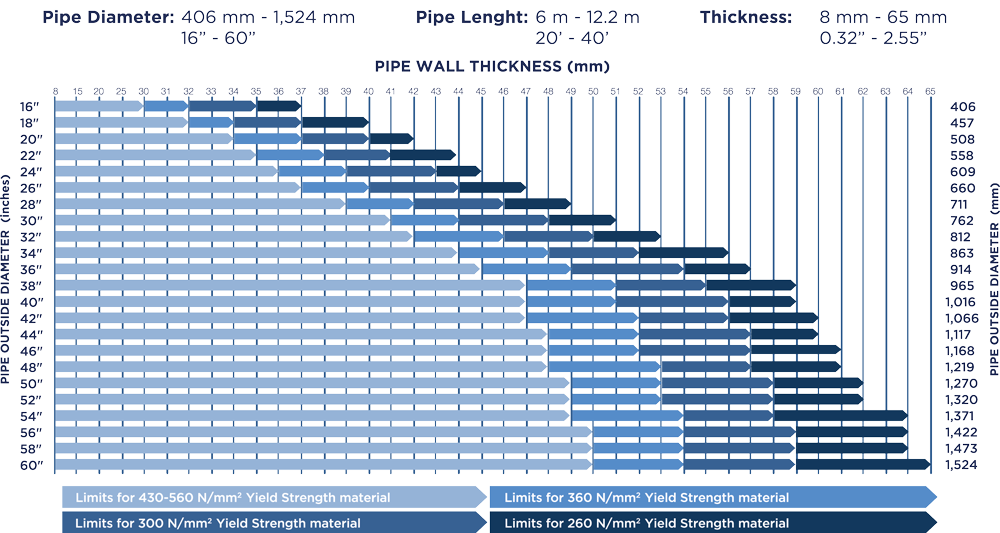

Production Range

- Pipe Diameter : 406 mm – 1,524 mm (16” – 60”)

- Pipe Length : 6 m – 12.2 m (20” – 40”)

- Thickness : 8 mm – 65 mm (0.32″ – 2.55″)

COMPANY EQUIPMENT VIEW

Oxy – Plasma cutting machines

Pre bending machine

Press bending machine

Roll bending machine

Tack welding machine

Internal LSAW machines

Milling machine

External LSAW machines

Welding portals

Grinding machine

Sizing press

Post welding heat treatment

End bevelling machines

Pipe cutting machines

AutomaticUT

Bunker RX

Hydrotest machine

Automatic dimensional inspection