Pipe Reducer – Concentric and Eccentric

Abter company carries a wide range of concentric and eccentric reducers.

Dimensional tolerances conform to ASME B16.9. Fitting wall thicknesses conform with standard schedule SCH10,SCH20,SCH30,STD,SCH40,SCH60,SCH80,SCH100,SCH120,SCH160 and ASME B36.19M wall pipe.

Butt welding fittings are permanently marked by electro-chemical etching in accordance with ASME B16.9. Estimated fitting weights are based on a density of .163 lbs/cubic inch.

A steel pipe reducer is the component in a pipeline that decreases the pipe size to a smaller bore. There are two main types of reducer: concentric and eccentric reducer. Some pipe reducers are manufactured by means of punch forming and others by bending, extruding, pushing, molding or machining.

The steel pipe reducer is used when liquid flow increases or decreases in small quantities. In order to prevent cavitation, it is also used to connect to the inlet hole of pump. Besides, it is also useful to connect joints in instrument like flow meter and control valve. The steel reducer also finds applications in sugar mills and distilleries, pumps, petrochemical, cement and construction industries and steel plants. It can be stored in fumigation-free boxes or wooden holders.

Raw Materials

* A234 – WPB WP5, WP9, WP11, WP22

* A420 – WPL3/ WPL6

* A403 – WP304/L; WP316/L

* A860-WPHY 42-46/52-60/65-70

Special Materials such as Monel, Inconel, Cu-Ni, Duplex SS etc are available on request

Specifications of the Steel Pipe Reducer

| Type | |||

| Seamless Reducer | Weld Reducer | Butt Welding Reducer | |

| Out Diameter | 1/2″ ~ 24″ | 4″ ~ 24″ | 12″ ~ 78″ |

| Wall Thickness | 3 mm ~ 150 mm | ||

| Product Type | Concentric reducer, eccentric reducer | ||

Standard Available

Our company provides steel pipe reducers of different standards to meet requirements of customers.

GB/T12459-2005 GB/T13401-2005 GB/T10752-2005

SH/T3408-1996 SH/T3409-1996

SY/T0518-2002 SY/T0510-1998

DL/T695-1999 GD2000 GD87-1101

HG/T21635-1987 HG/T21631-1990

ASME B16.9-2007 ASME B16.25-2007

MSS SP 75-2008

CSA Z245.11-05-2005

EN10253-1-1999 EN10253-2-2007 EN10253-3-2008 EN10253-4-2008

DIN2605-1-1992 DIN2605-2-1995

BS1640-1-1962 BS1640-2-1962 BS1640-3-1968 BS1640-4-1968 BS1965-1-1963

AFNOR NF A 49-289-1990 AFNOR NF A 49-170-1-1999 AFNOR NF A 49-170-2-2009 AFNOR NF A 49-170-3-2009 AFNOR NF A 49-170-4-2009

ISO3419-1981 ISO5251-1981

JIS B2311-2009 JIS B2312-2009 JIS B2313-2009

buttweld-Reducer

| Nominal Diameter | Outside Diameter | End to End | ||

| D1*D2 | ||||

| DN | NPS | Series A | Serices B | H |

| 20×15 | 3/4×1/2 | 26.9×21.3 | 25×18 | 38 |

| 20×10 | 3/4×3/8 | 26.9×17.3 | 25×14 | 38 |

| 25×20 | 1×3/4 | 33.7×26.9 | 32×25 | 51 |

| 25×15 | 1×1/2 | 33.7×21.3 | 32×18 | 51 |

| 32×25 | 1.1/4×1 | 42.4×33.7 | 38×32 | 51 |

| 32×20 | 1.1/4×3/4 | 42.4×26.9 | 38×25 | 51 |

| 32×15 | 1.1/4×1/2 | 42.4×21.3 | 38×18 | 51 |

| 40×32 | 1.1/2×1.1/4 | 48.3×42.4 | 45×38 | 64 |

| 40×25 | 1.1/2×1 | 48.3×33.7 | 45×32 | 64 |

| 40×20 | 1.1/2×3/4 | 48.3×26.9 | 45×25 | 64 |

| 40×15 | 1.1/2×1/2 | 48.3×21.3 | 45×18 | 64 |

| 50×40 | 2×1.1/2 | 60.3×48.3 | 57×45 | 76 |

| 50×32 | 2×1.1/4 | 60.3×42.4 | 57×38 | 76 |

| 50×25 | 2×1 | 60.3×33.7 | 57×32 | 76 |

| 50×20 | 2×3/4 | 60.3×26.9 | 57×25 | 76 |

| 65×50 | 2.1/2×2 | 73.0×60.3 | 76×57 | 89 |

| 65×40 | 2.1/2×1.1/2 | 73.0×48.3 | 76×45 | 89 |

| 65×32 | 2.1/2×1.1/4 | 73.0×42.4 | 76×38 | 89 |

| 65×25 | 2.1/2×1 | 73.0×33.7 | 76×32 | 89 |

| 80×65 | 3×2.1/2 | 88.9×73.0 | 89×76 | 89 |

| 80×50 | 3×2 | 88.9×60.3 | 89×57 | 89 |

| 80×40 | 3×1.1/2 | 88.9×48.3 | 89×45 | 89 |

| 80×32 | 3×1.1/4 | 88.9×42.4 | 89×38 | 89 |

| 90×80 | 3.1/2×3 | 101.6×88.9 | – | 102 |

| 90×65 | 3.1/2×2.1/2 | 101.6×73.0 | – | 102 |

| 90×50 | 3.1/2×2 | 101.6×60.3 | – | 102 |

| 90×40 | 3.1/2×1.1/2 | 101.6×48.3 | – | 102 |

| 90×32 | 3.1/2×1.1/4 | 101.6×42.4 | – | 102 |

| 100×90 | 4×3.1/2 | 114.3×101.6 | – | 102 |

| 100×80 | 4×3 | 114.3×88.9 | 108×89 | 102 |

| 100×65 | 4×2.1/2 | 114.3×73.0 | 108×76 | 102 |

| 100×50 | 4×2 | 114.3×60.3 | 108×57 | 102 |

| 100×40 | 4×1.1/2 | 114.3×48.3 | 108×45 | 102 |

| 125×100 | 5×4 | 141.3×114.3 | 133×108 | 127 |

| 125×90 | 5×3.1/2 | 141.3×101.6 | – | 127 |

| 125×80 | 5×3 | 141.3×88.9 | 133×89 | 127 |

| 125×65 | 5×2.1/2 | 141.3×73.0 | 133×76 | 127 |

| 125×50 | 5×2 | 141.3×60.3 | 133×57 | 127 |

| 150×125 | 6×5 | 168.3×141.3 | 159×133 | 140 |

| 150×100 | 6×5 | 168.3×114.3 | 159×108 | 140 |

| 150×90 | 6×3.1/2 | 168.3×101.6 | – | 140 |

| 150×80 | 6×3 | 168.3×88.9 | 159×89 | 140 |

| 150×65 | 6×2.1/2 | 168.3×73.0 | 159×76 | 140 |

| 200×150 | 8×6 | 219.1×168.3 | 219×159 | 152 |

| 200×125 | 8×5 | 219.1×141.3 | 219×133 | 152 |

| 200×100 | 8×4 | 219.1×114.3 | 219×108 | 152 |

| 200×90 | 8×3.1/2 | 219.1×101.6 | – | 152 |

| 250×200 | 10×8 | 273.0×219.1 | 273×219 | 178 |

| 250×150 | 10×6 | 273.0×168.3 | 273×159 | 178 |

| 250×125 | 10×5 | 273.0×141.3 | 273×133 | 178 |

| 250×100 | 10×4 | 273.0×114.3 | 273×108 | 178 |

| 300×250 | 12×10 | 323.9×273.1 | 325×273 | 203 |

| 300×200 | 12×8 | 323.9×219.1 | 325×219 | 203 |

| 300×150 | 12×6 | 323.9×168.3 | 325×159 | 203 |

| 300×125 | 12×5 | 323.9×141.3 | 325×133 | 203 |

| 350×300 | 14×12 | 355.6×323.9 | 377×325 | 330 |

| 350×250 | 14×10 | 355.6×273.0 | 377×273 | 330 |

| 350×200 | 14×8 | 355.6×219.1 | 377×219 | 330 |

| 350×150 | 14×6 | 355.6×168.3 | 377×159 | 330 |

| 400×350 | 16×14 | 406.4×355.6 | 426×377 | 356 |

| 400×300 | 16×12 | 406.4×323.9 | 426×325 | 356 |

| 400×250 | 16×10 | 406.4×273.0 | 426×273 | 356 |

| 400×200 | 16×8 | 406.4×219.1 | 426×219 | 356 |

| 450×400 | 18×16 | 457×406.4 | 478×426 | 381 |

| 450×350 | 18×14 | 457×355.6 | 478×377 | 381 |

| 450×300 | 18×12 | 457×323.9 | 478×325 | 381 |

| 450×250 | 18×10 | 457×273.0 | 478×273 | 381 |

| 500×450 | 20×18 | 508×457 | 529×478 | 508 |

| 500×400 | 20×16 | 508×406.4 | 529×426 | 508 |

| 500×350 | 20×14 | 508×355.6 | 529×377 | 508 |

| 500×300 | 20×12 | 508×323.9 | 529×325 | 508 |

| 550×500 | 22×20 | 559×508 | – | 508 |

| 550×450 | 22×18 | 559×457 | – | 508 |

| 550×400 | 22×16 | 559×406.4 | – | 508 |

| 550×350 | 22×14 | 559×355.6 | – | 508 |

| 600×550 | 24×22 | 610×559 | – | 508 |

| 600×500 | 24×20 | 610×508 | 630×529 | 508 |

| 600×450 | 24×18 | 610×457 | 630×478 | 508 |

| 600×400 | 24×22 | 610×406.4 | 630×426 | 508 |

| 650×600 | 26×24 | 660×610 | – | 610 |

| 650×550 | 26×22 | 660×559 | – | 610 |

| 650×500 | 26×20 | 660×508 | – | 610 |

| 650×450 | 26×18 | 660×457 | – | 610 |

| 700×650 | 28×26 | 711×660 | – | 610 |

| 700×600 | 28×24 | 711×610 | 720×630 | 610 |

| 700×550 | 28×22 | 711×559 | – | 610 |

| 700×500 | 28×20 | 711×508 | 720×530 | 610 |

| 750×700 | 30×28 | 762×711 | – | 610 |

| 750×650 | 30×26 | 762×660 | – | 610 |

| 750×600 | 30×24 | 762×610 | – | 610 |

| 750×550 | 30×22 | 762×559 | – | 610 |

| 800×750 | 32×30 | 813×762 | – | 610 |

| 800×700 | 32×28 | 813×711 | 820×720 | 610 |

| 800×650 | 32×26 | 813×660 | – | 610 |

| 800×600 | 32×24 | 813×610 | 820×630 | 610 |

| 850×800 | 34×32 | 864×813 | – | 610 |

| 850×750 | 34×30 | 864×762 | – | 610 |

| 850×700 | 34×28 | 864×711 | – | 610 |

| 850×650 | 34×26 | 864×660 | – | 610 |

| 900×850 | 36×34 | 914×864 | – | 610 |

| 900×800 | 36×32 | 914×813 | 920×820 | 610 |

| 900×750 | 36×30 | 914×762 | – | 610 |

| 900×700 | 36×28 | 914×711 | 920×720 | 610 |

| 950×900 | 38×36 | 965×914 | – | 610 |

| 950×850 | 38×34 | 965×864 | – | 610 |

| 950×800 | 38×32 | 965×813 | – | 610 |

| 950×750 | 38×30 | 965×762 | – | 610 |

| 1000×950 | 40×38 | 1016×965 | – | 610 |

| 1000×900 | 40×36 | 1016×914 | 1020×920 | 610 |

| 1000×850 | 40×34 | 1016×864 | – | 610 |

| 1000×800 | 40×32 | 1016×813 | 1020×820 | 610 |

| 1050×1000 | 42×40 | 1067×1016 | – | 610 |

| 1050×950 | 42×38 | 1067×965 | – | 610 |

| 1050×900 | 42×36 | 1067×914 | – | 610 |

| 1050×850 | 42×34 | 1067×864 | – | 610 |

| 1100×1050 | 44×42 | 1118×1067 | – | 610 |

| 1100×1000 | 44×40 | 1118×1016 | 1120×1020 | 610 |

| 1100×950 | 44×38 | 1118×965 | – | 610 |

| 1100×900 | 44×36 | 1118×914 | 1220×920 | 610 |

| 1150×1100 | 46×44 | 1168×1118 | – | 711 |

| 1150×1050 | 46×42 | 1168×1067 | – | 711 |

| 1150×1000 | 46×40 | 1168×1016 | – | 711 |

| 1150×950 | 46×38 | 1168×965 | – | 711 |

| 1200×1150 | 48×46 | 1220×1168 | – | 711 |

| 1200×1100 | 48×44 | 1220×1118 | 1220×1120 | 711 |

| 1200×1050 | 48×42 | 1220×1067 | – | 711 |

| 1200×1000 | 48×40 | 1220×1016 | 1220×1020 | 711 |

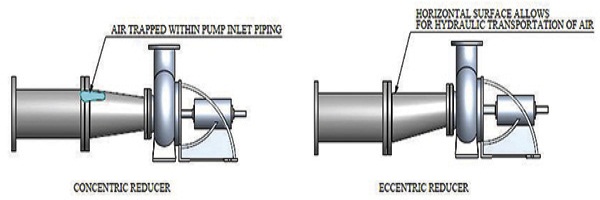

What’s the difference between CONCENTRIC REDUCER and ECCENTRIC REDUCER ?

CONCENTRIC REDUCER

The open ends of a concentric reducer are aligned and centered one to the other. Generally, this type of pipe reducer is used to modify the bore size of the pipeline by two (maximum three) measures, to avoid an excessive pressure drop in the pipeline.

If a larger reduction is needed, then a sequence of reducers shall be used to have a smooth and gradual adjustment of the pipeline bore size (vs. a drastic change).

For small bore size reductions, reducing flanges may be an alternative to buttweld reducers.

ECCENTRIC REDUCERThe open ends of an eccentric reducer are in an “offset” position one to the other.

Eccentric reducers are used, generally, for pipelines installed in a horizontal position (whereas concentric reducers are used for pipelines installed vertically or for the inlets of suction pumps, as top flat eccentric reducers).

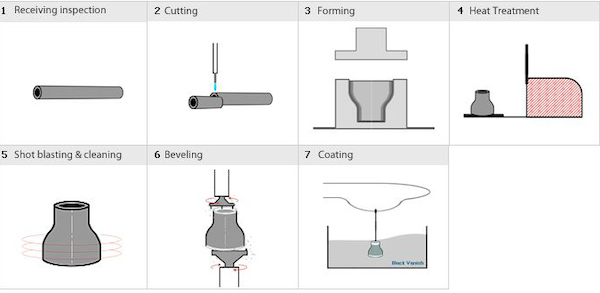

PIPE REDUCERS MANUFACTURING PROCESS

CONCENTRIC VS ECCENTRIC REDUCER

The key difference between concentric vs eccentric reducer is the centricity of the inlet vs. the outlet of the fitting, which is perfect for a concentric reducer and offset of an eccentric reducer.

BW REDUCER MANUFACTURING PROCESS

Cold forming is the most common manufacturing process for seamless eccentric/concentric reducers (welded reducers are produced with the single or double seam weld process):