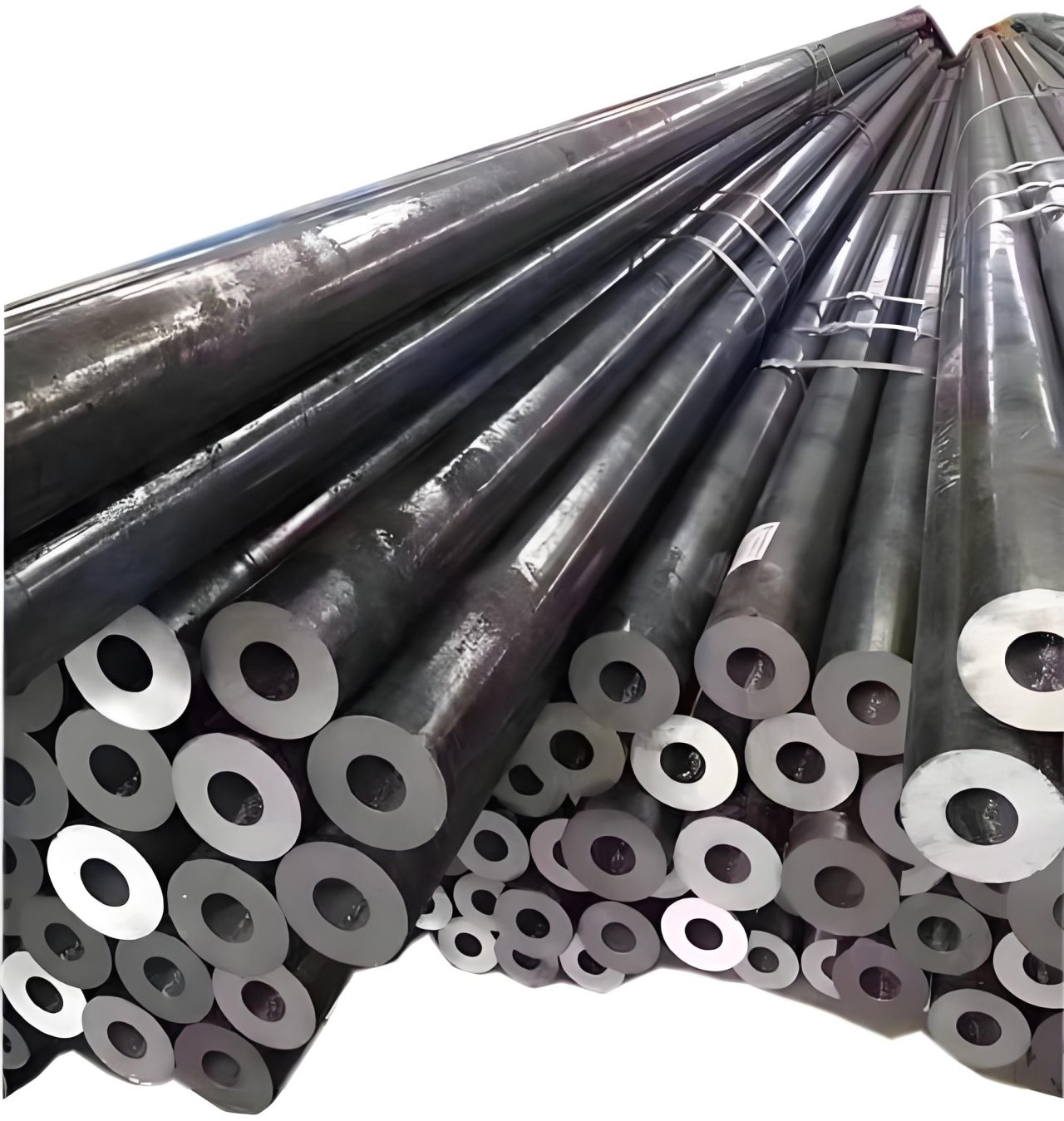

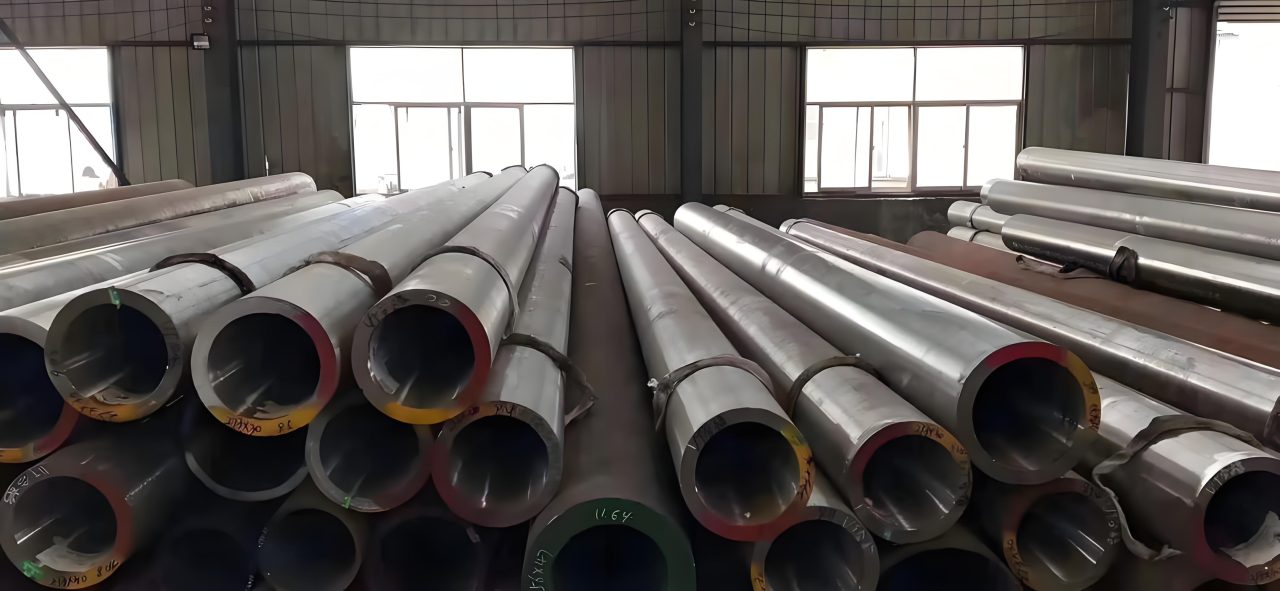

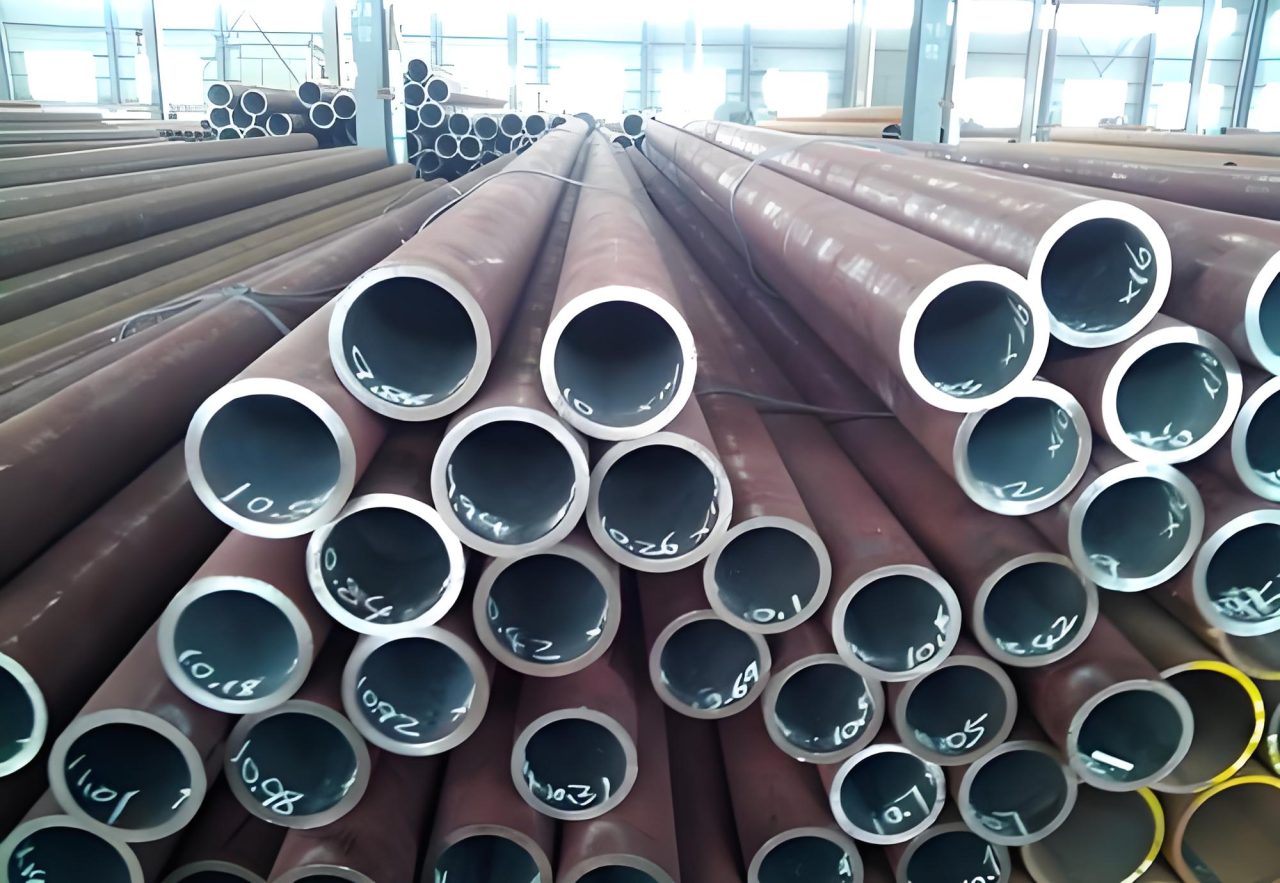

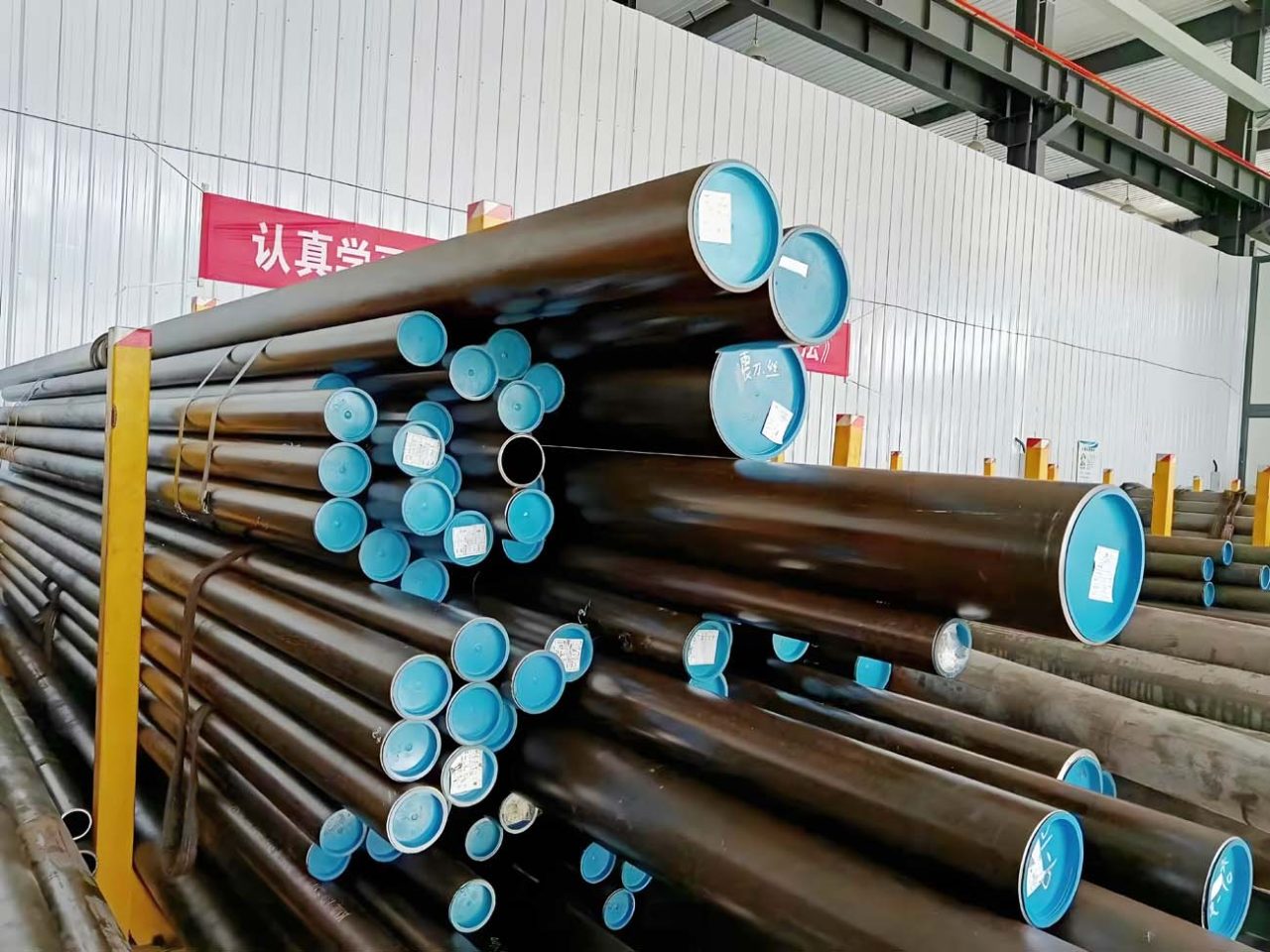

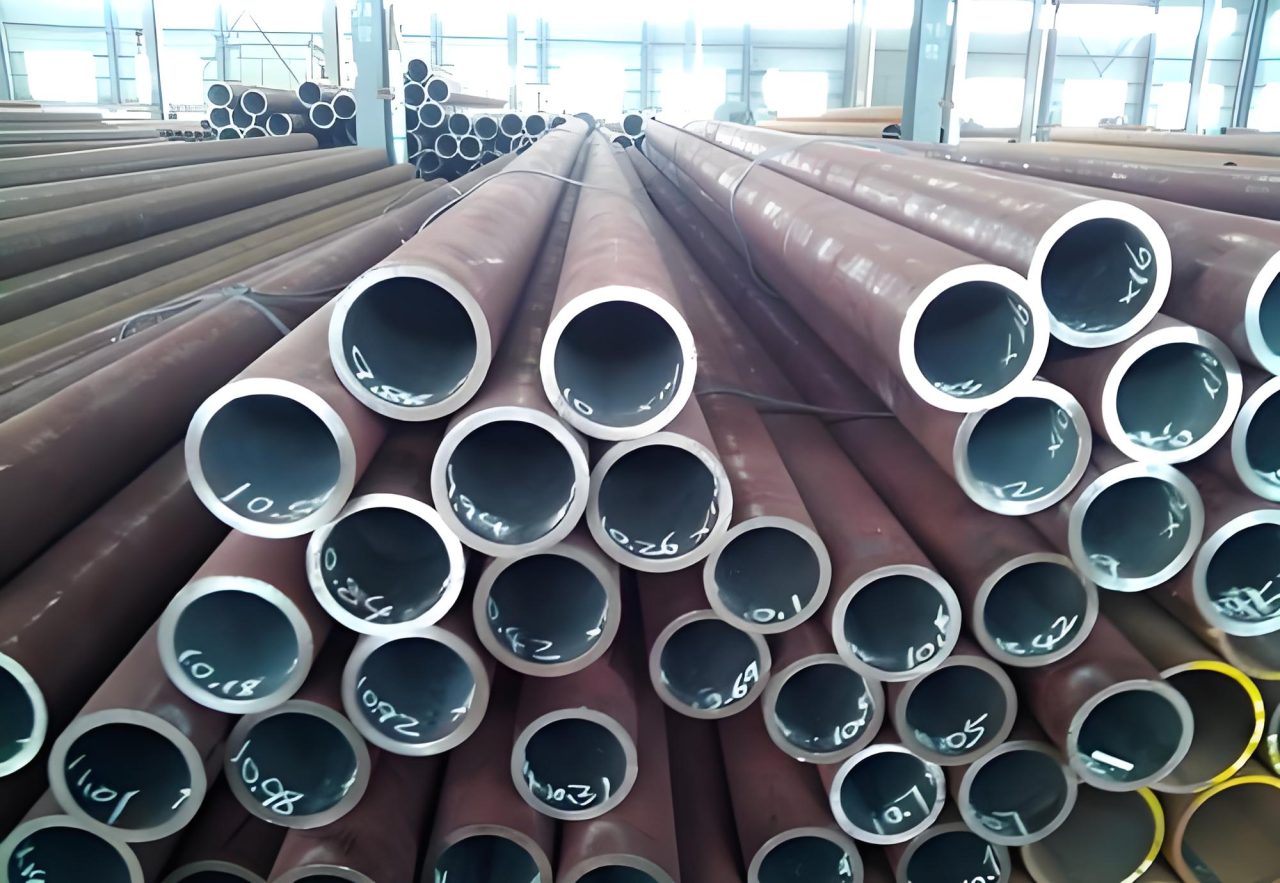

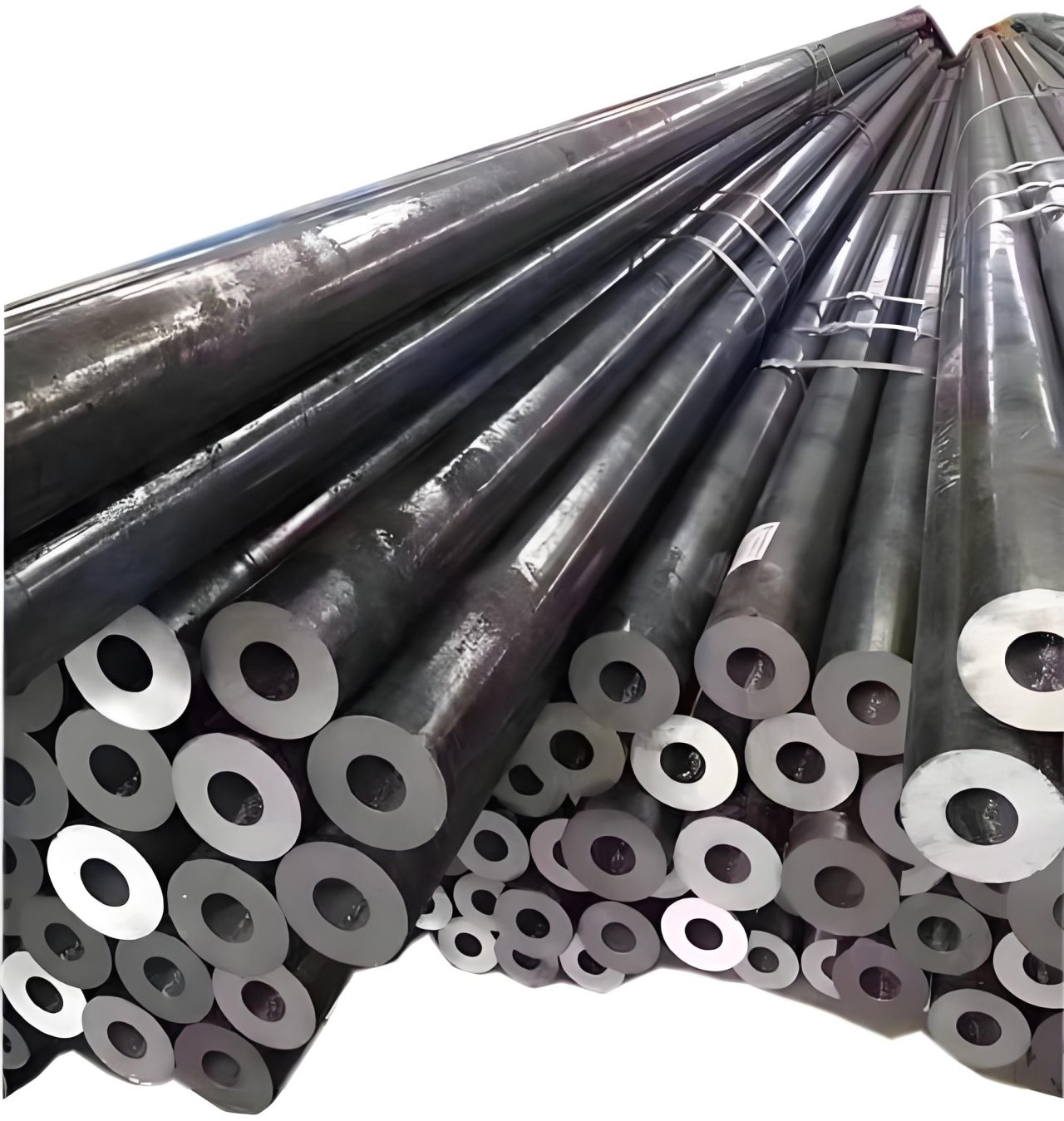

Large-diameter thick-walled seamless steel pipes, produced through advanced processes like hot piercing and heat treatment, offer exceptional strength and reliability. International grades from EN (e.g., 34CrMo4) and ASTM (e.g., A519 4140) alongside GB standards meet diverse needs, from hydraulic cylinders to energy infrastructure, ensuring performance under high pressure and stress.

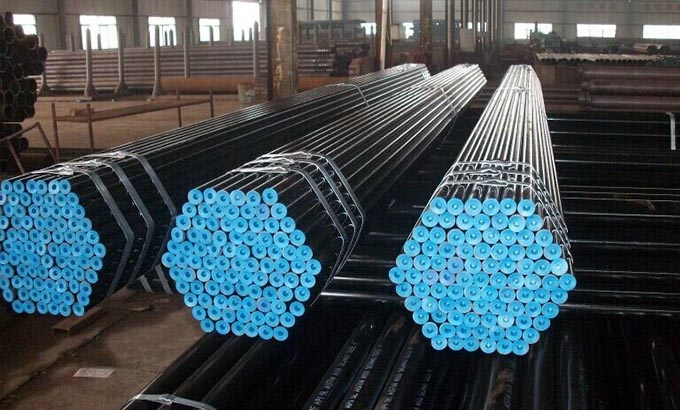

Seamless Steel Pipe

ASTM A519 is the standard specification for seamless carbon and alloy steel mechanical tubing. These tubes are used for mechanical and pressure applications as well as for transporting steam, water, and gas. ASTM A519 pipes are suitable for bending, flanging, and similar forming operations, and for fusion welding.

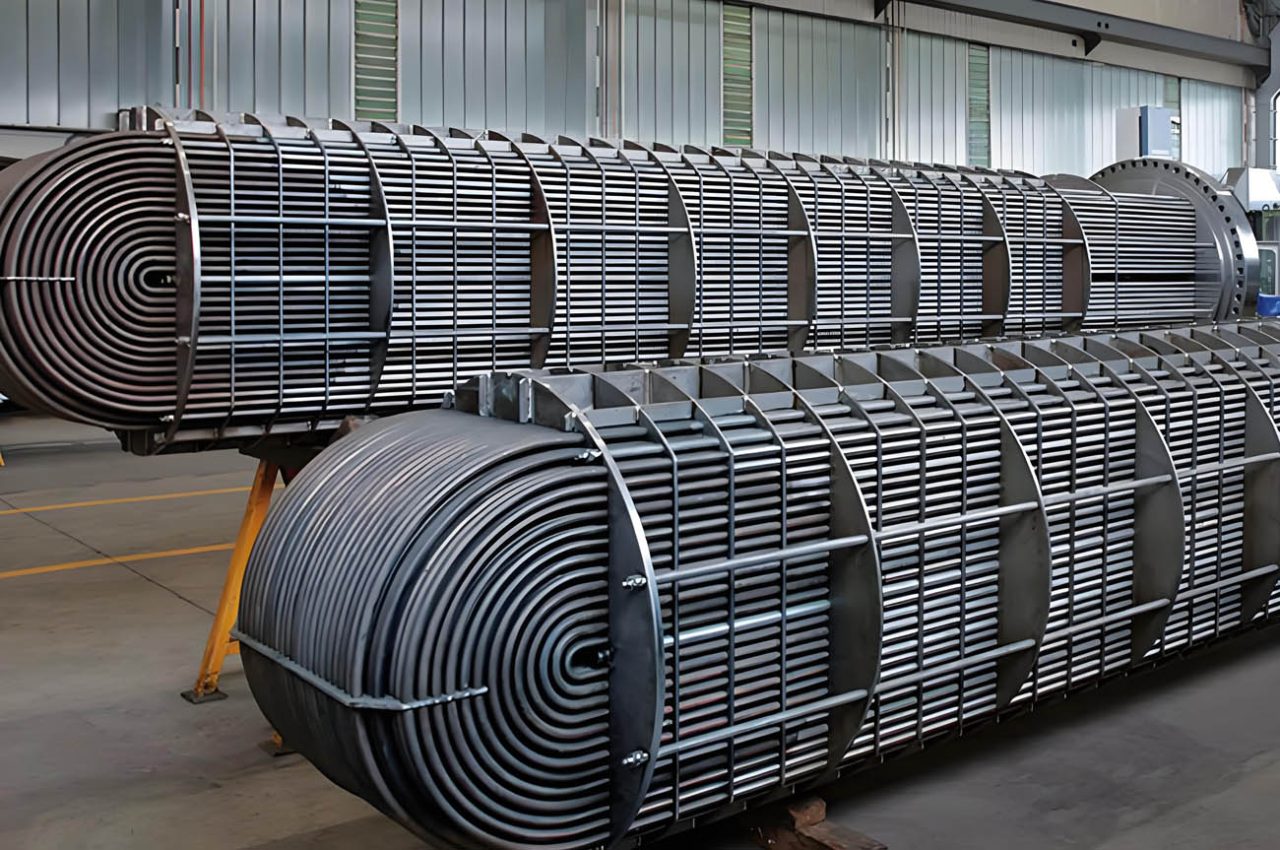

Using ASTM A192 seamless boiler pipes in power plants offers numerous advantages, including high-pressure and high-temperature resistance, seamless construction, excellent mechanical properties, and compliance with strict quality standards. These benefits contribute to the efficiency, safety, and reliability of power plant operations, making ASTM A192 pipes a preferred choice for critical boiler applications.

ASTM A335, also known as ASME SA335, is the standard specification for seamless ferritic alloy-steel pipe intended for high-temperature service. Below are the detailed chemical compositions, mechanical properties, and specifications for the most commonly used grades of ASTM A335 pipes.

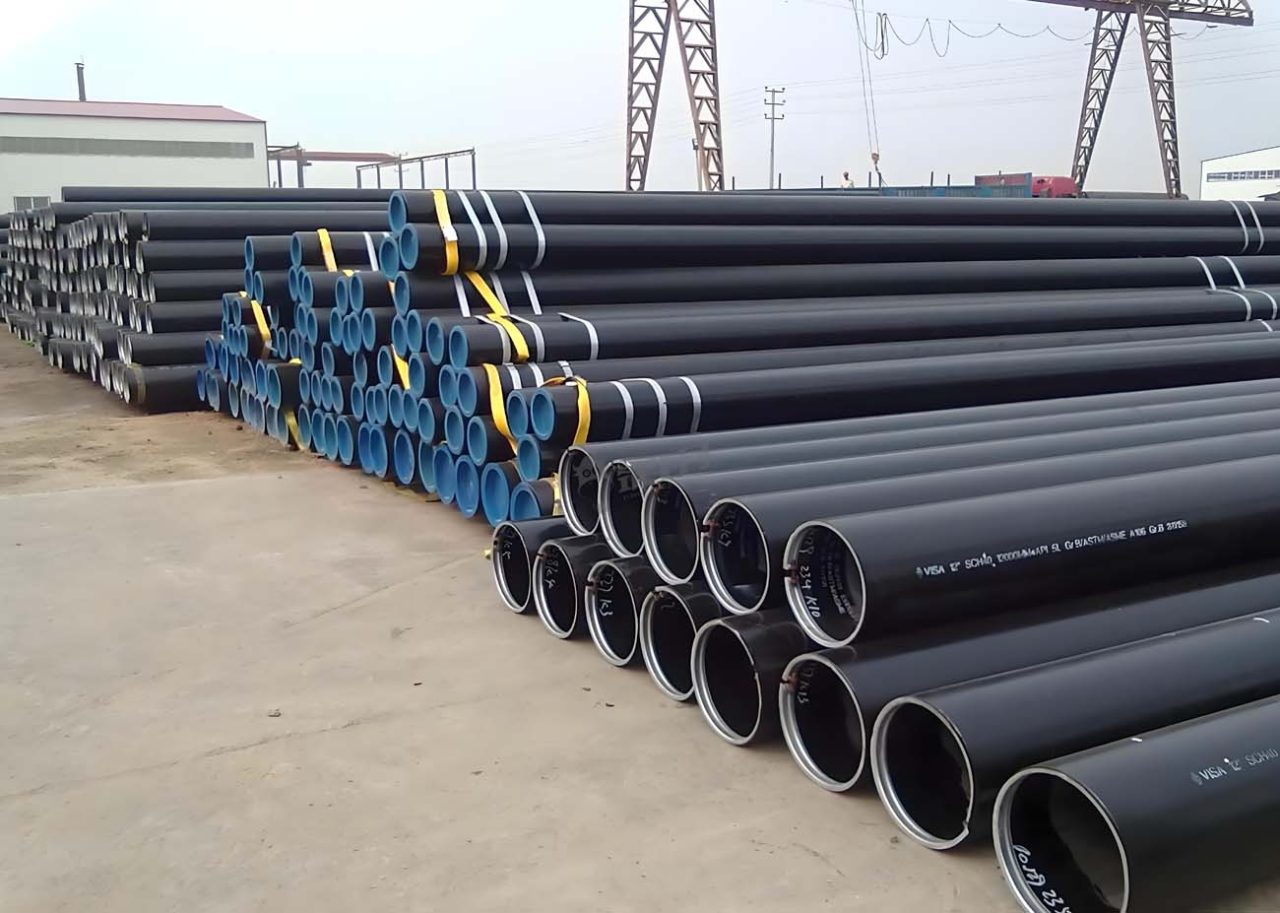

ASTM A106 seamless steel pipes are a reliable choice for high-temperature applications due to their robust mechanical properties and versatile manufacturing process. They are essential in various industrial sectors, ensuring durability and performance under extreme conditions.

ASTM A53, also referred to as ASME SA53, is a carbon steel alloy that is used for structural and low-pressure applications. This specification covers seamless and welded black and hot-dipped galvanized steel pipes intended for mechanical and pressure applications, as well as for ordinary uses in steam, water, gas, and air lines. The specifications for this alloy are set by ASTM International in the standard ASTM A53 / A53M.

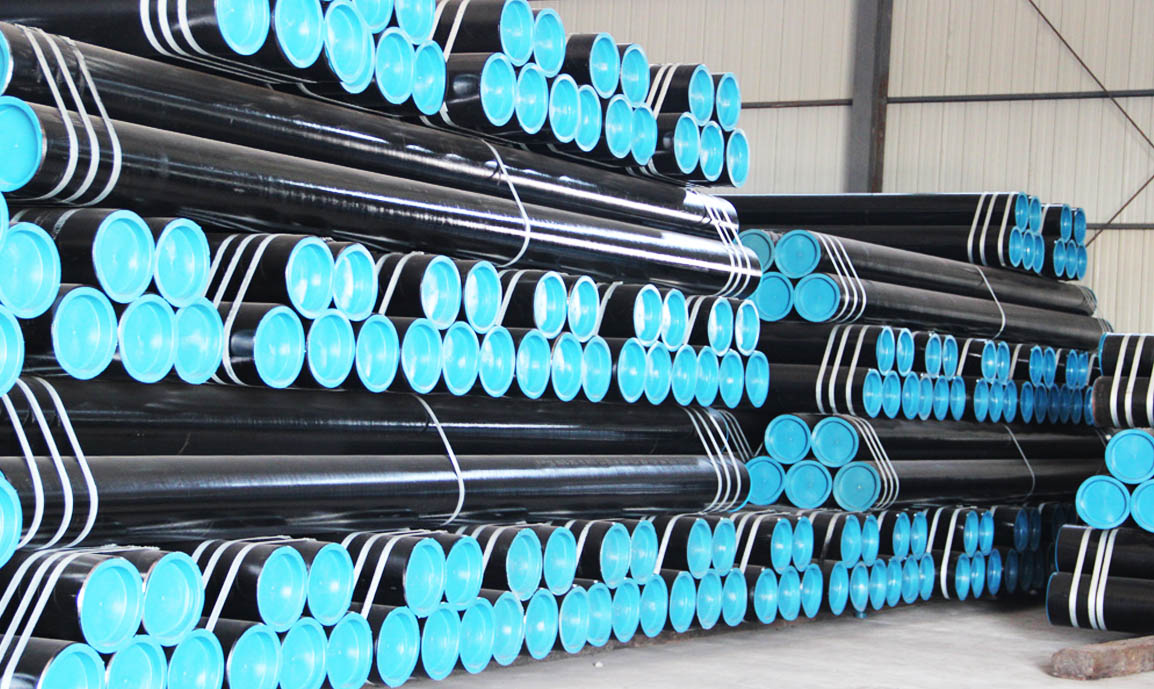

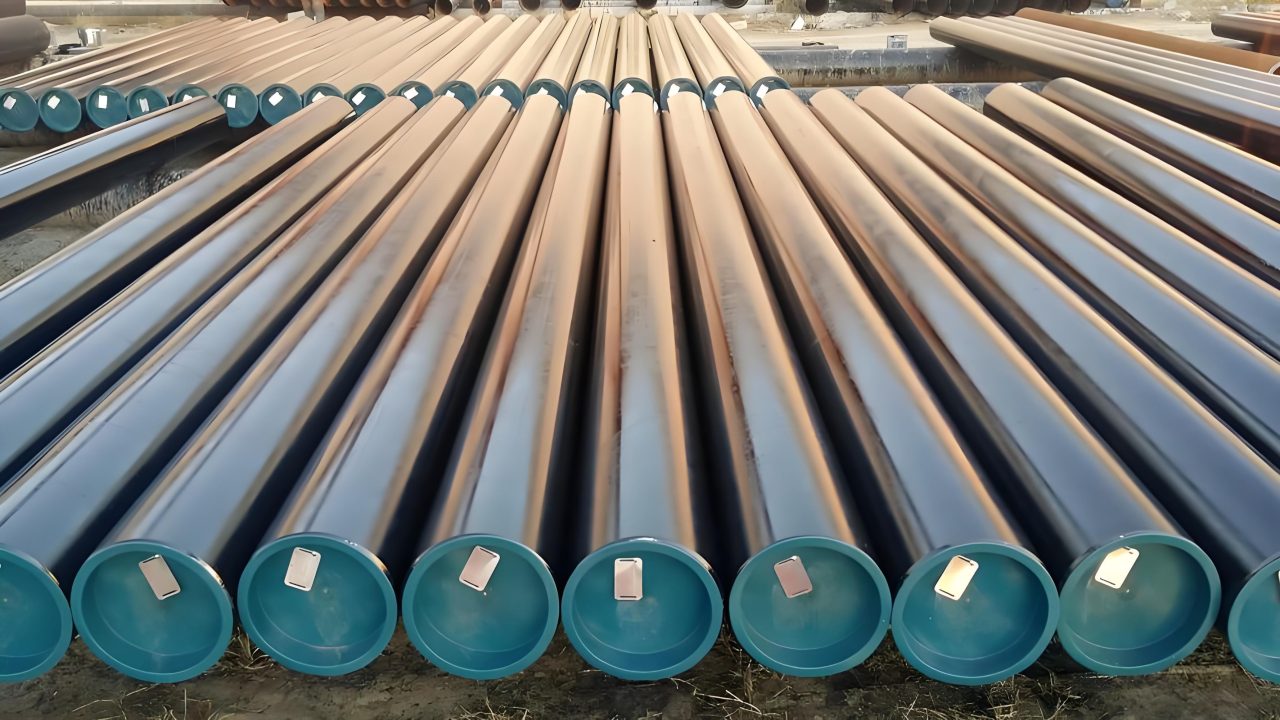

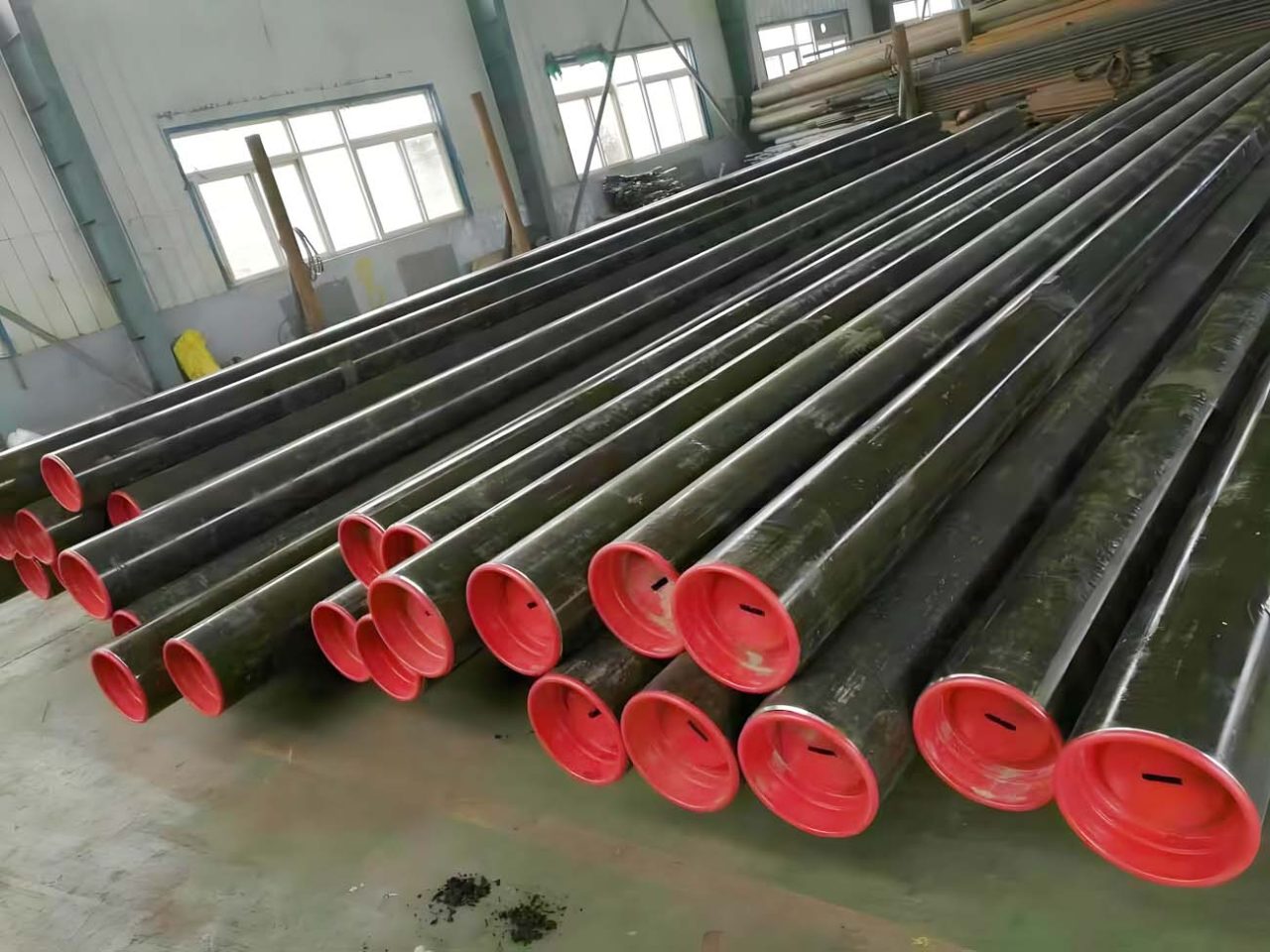

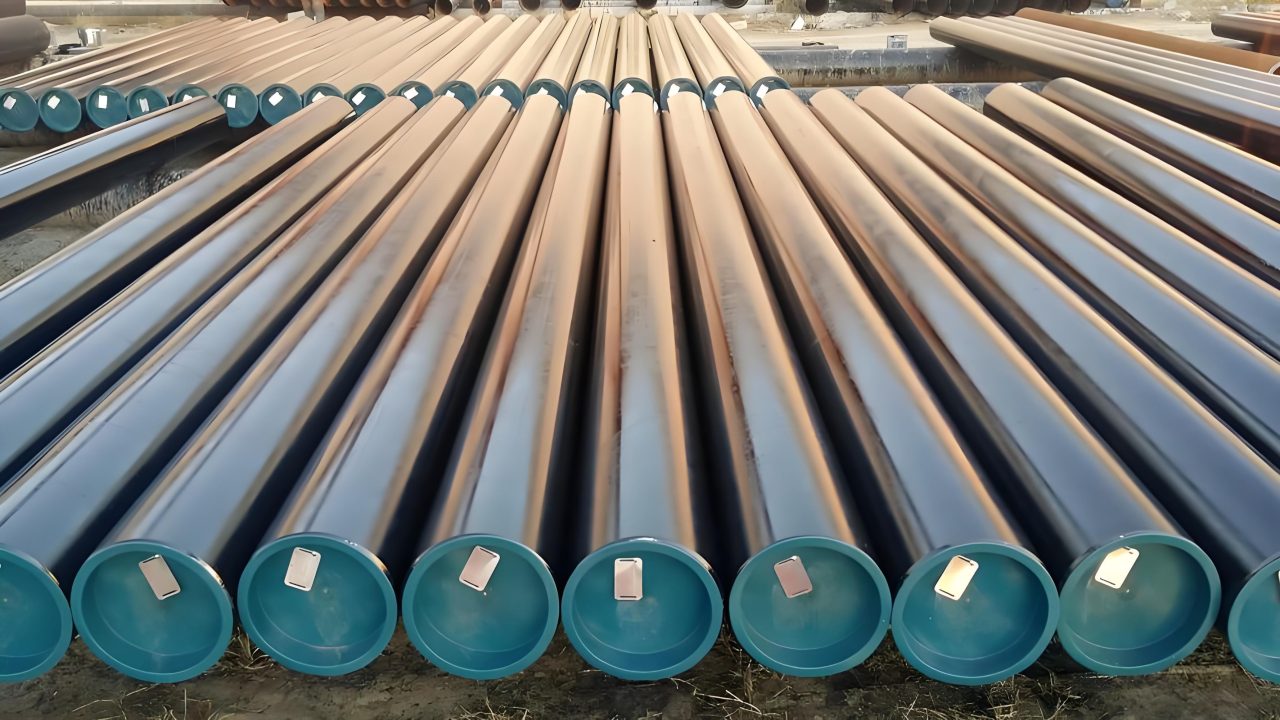

API 5L: Steel Pipes Specifications and Tolerances API 5L specifies standards for seamless and welded steel pipes used in pipeline transportation systems in the petroleum and natural gas industries.

JIS G3429 sets rigorous standards for seamless steel pipes used in high-pressure gas cylinders, ensuring they possess the necessary strength, toughness, and durability. By adhering to these standards, manufacturers can produce high-quality, reliable cylinders that safely store and transport gases under high pressure, meeting the demands of various industrial, medical, and safety applications.

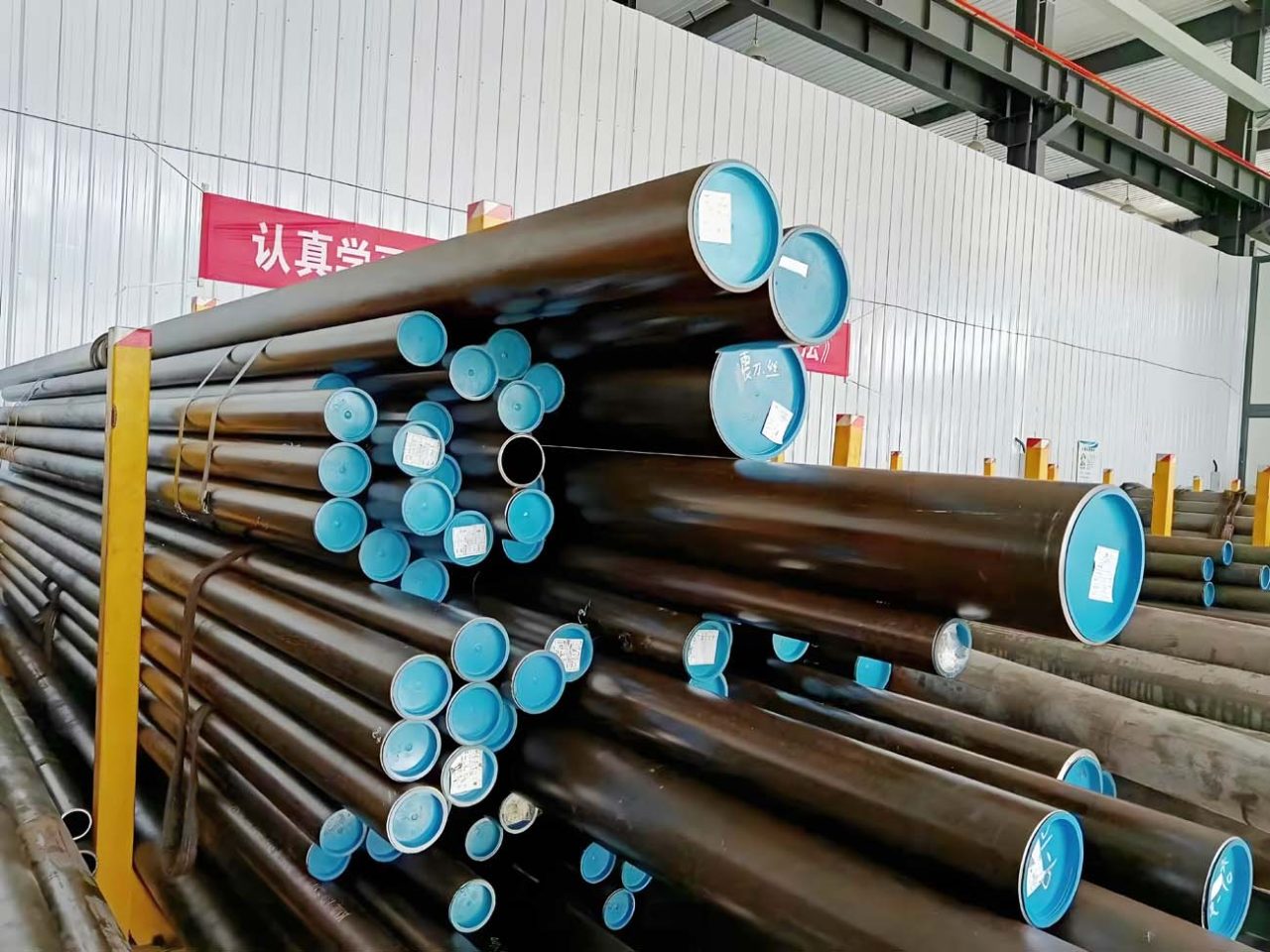

Mechanical steel tubes are essential for a variety of industrial applications requiring high strength, precision, and durability. The choice of material—whether carbon steel, alloy steel, or stainless steel—depends on the specific requirements of the application, such as mechanical properties, corrosion resistance, and ease of machining.

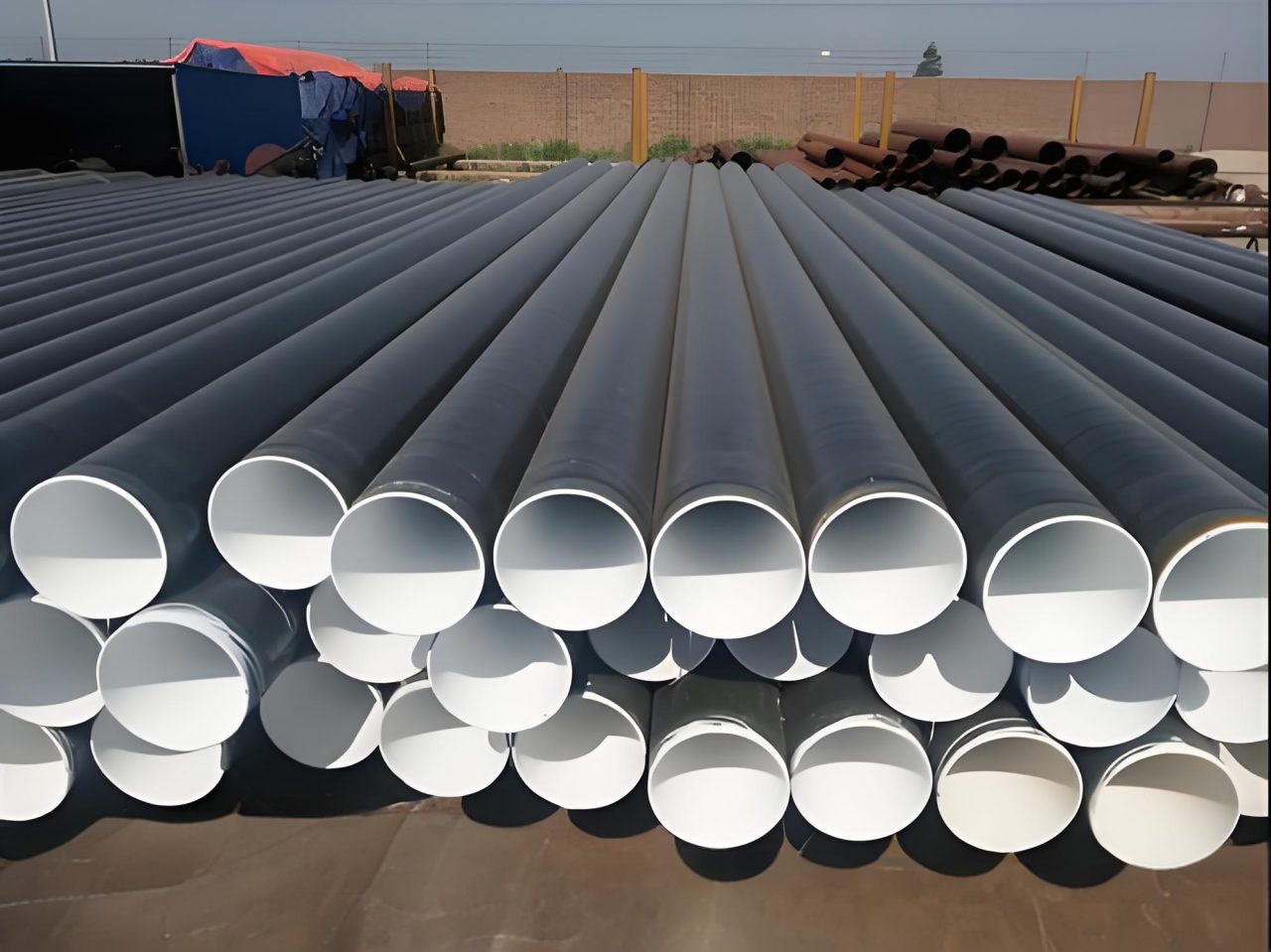

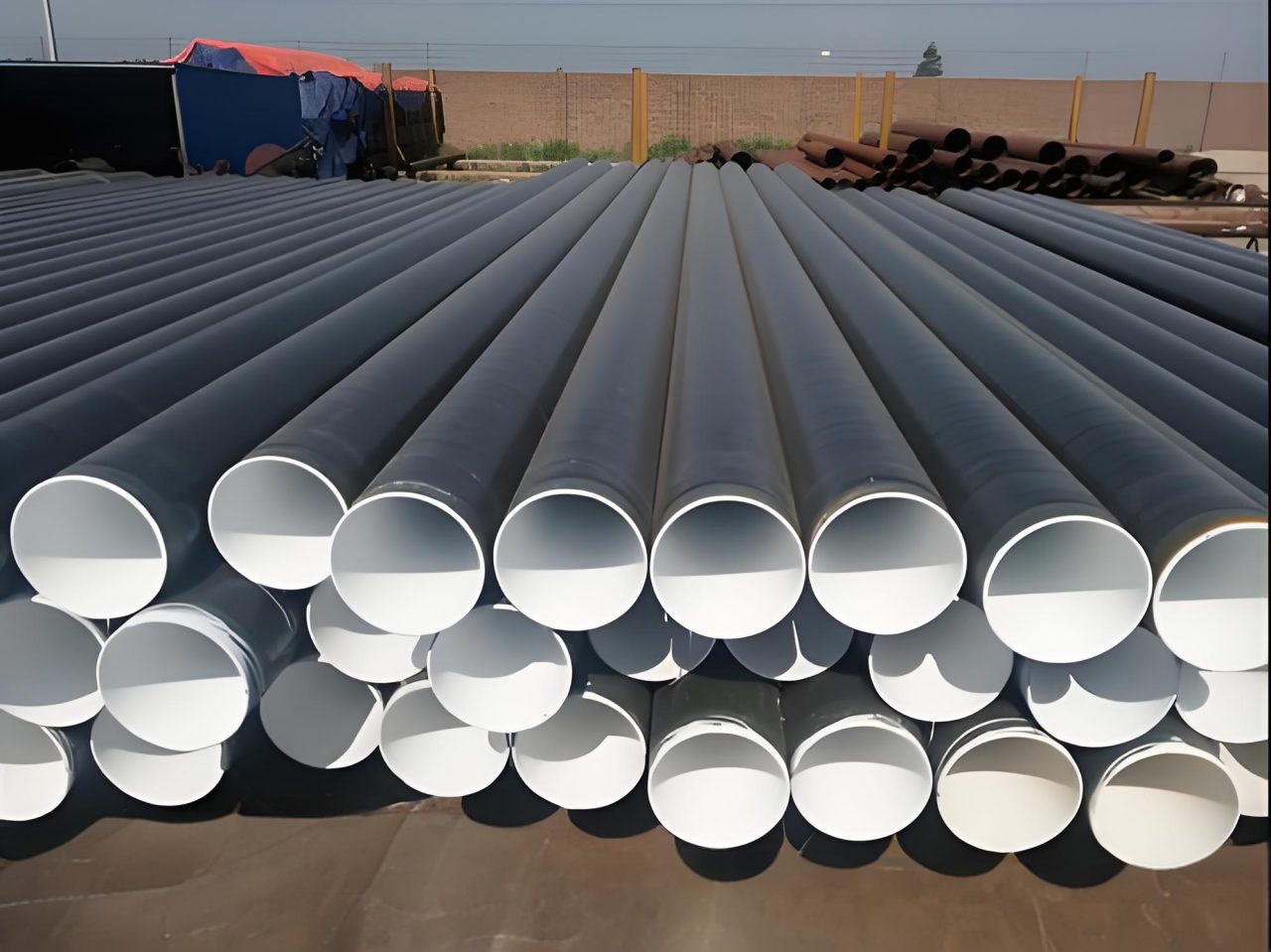

Seamless steel fluid pipes are vital components in many industrial systems, offering unmatched strength, durability, and reliability. By understanding their characteristics, manufacturing processes, materials, standards, and applications, industries can select the appropriate seamless pipes to ensure efficient and safe fluid transport.

Boiler Steel Pipes are critical components in many industrial applications, providing reliable performance under extreme conditions. By adhering to strict quality standards and understanding the key properties and classifications of these tubes, industries can ensure the safe and efficient operation of their thermal systems.

Structural seamless steel pipes are critical components in numerous industries due to their strength, durability, and versatility. These pipes are manufactured without seams, providing a uniform structure that can withstand high pressure and mechanical stress. This makes them suitable for mechanical and pressure applications and ordinary uses in steam, water, gas, and air lines. They are also ideal for welding and forming operations involving coiling, bending, and flanging, subject to certain qualifications.

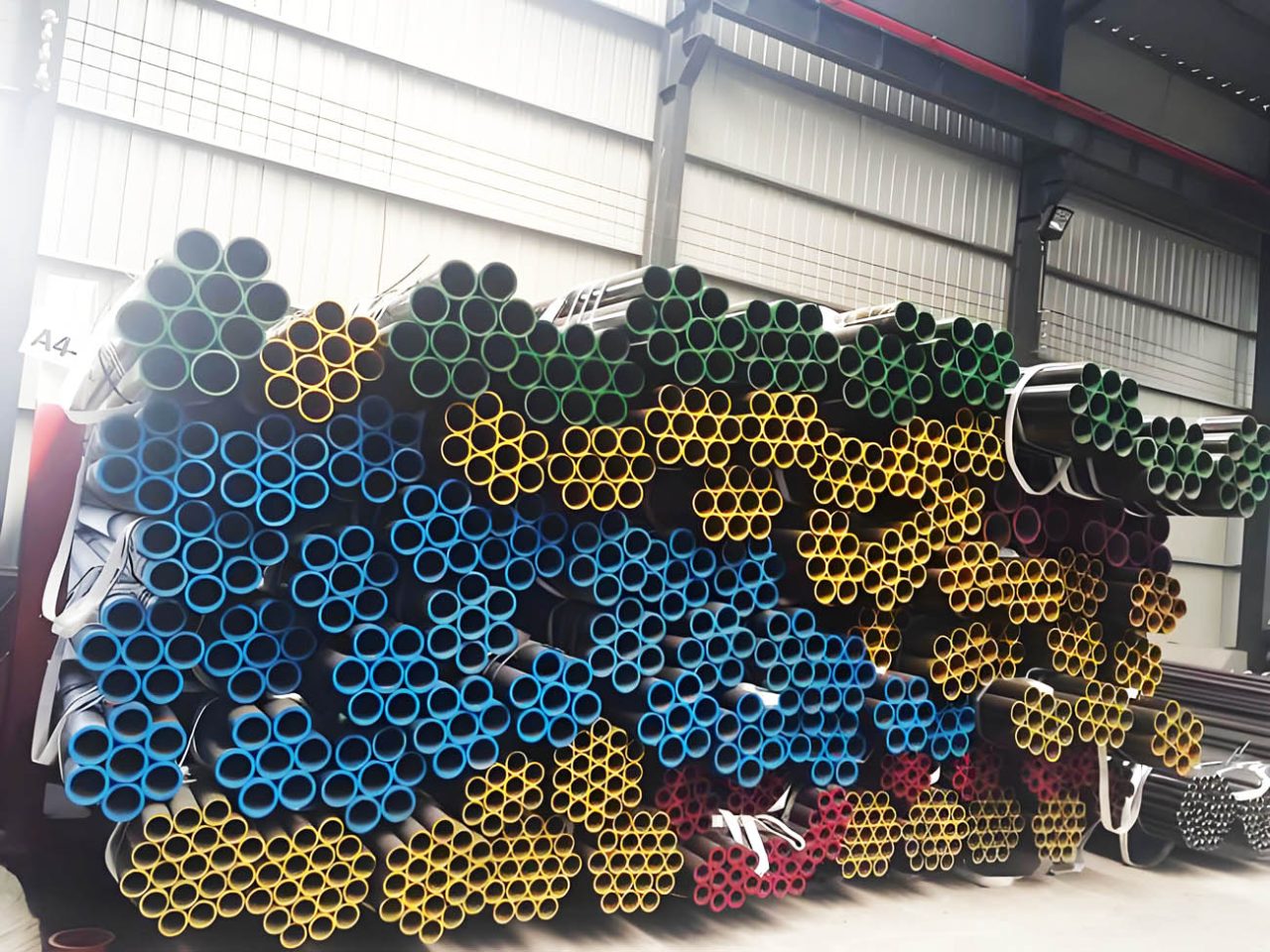

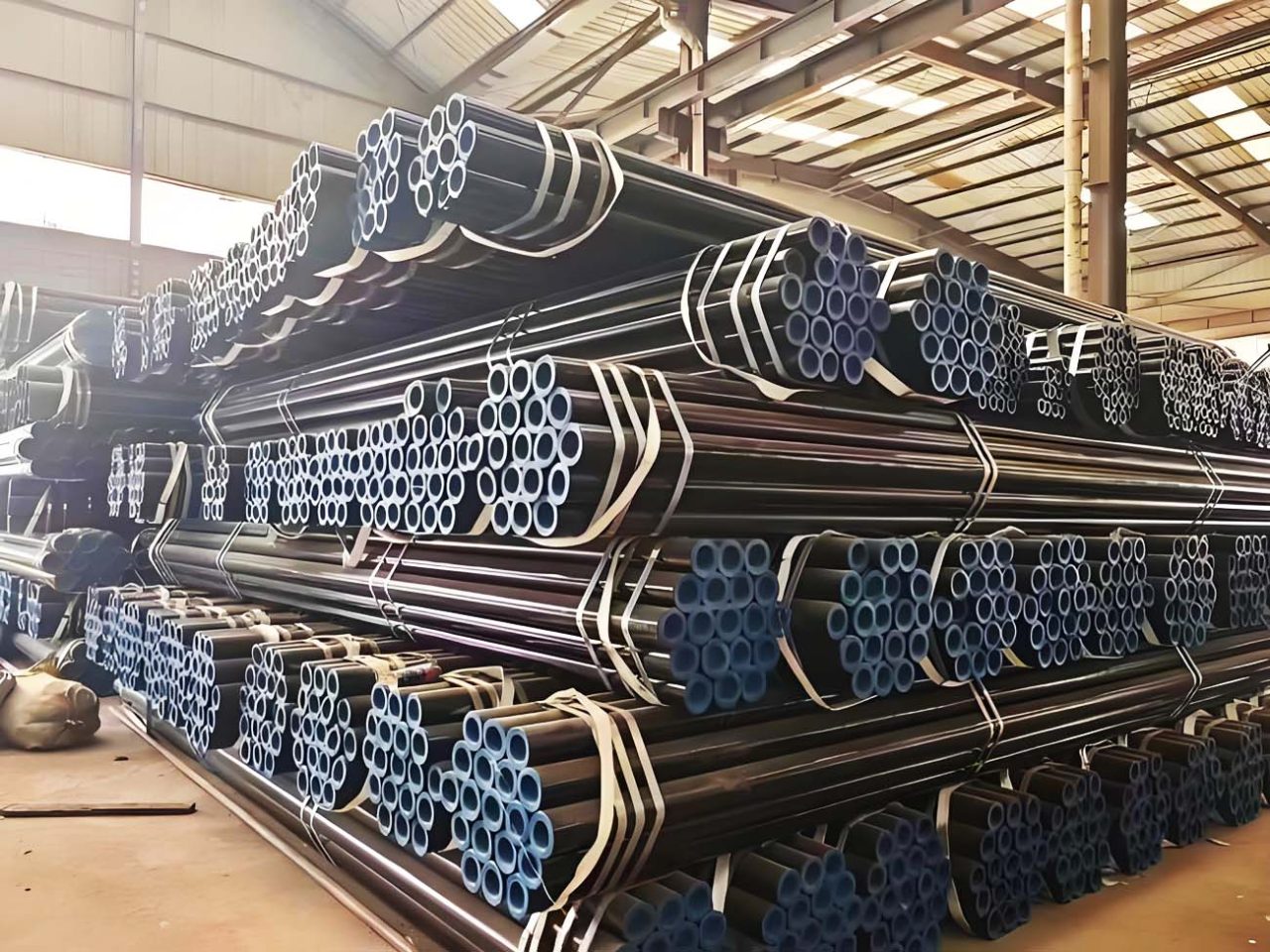

Product Name: seamless pipe, seamless steel pipe, seamless carbon steel pipe, carbon seamless steel pipe,Seamless Line pipe Application: For converying gas, water & oil for Fluids Transmission Size: OD: 10.3-1219.2mm WT: 1.65-60mm LENGTH: 5.8/6/11.8/12m

Carbon steel seamless pipe is used in a range of applications in all different industries, including petrochemical, environmental, energy, and more. Thanks to more than 100 years of combined experience and vast knowledge across multiple industries, we can help match you with the right product for your unique application. Our friendly, knowledgeable customer service representatives will listen to your needs and can offer suggestions to get you products that meet your requirements.