Spiral Welded Steel Pipe – SSAW

SSAW Steel Pipe(Spiral Submerged Arc Pipe)

Sizes:

Out diameter:219mm-3620mm

Wall thickness: 5mm-25.4mm

Length: 3m-12m

Standard and Classfication of SSAW Steel Pipe

| Classfication | Standard | Main Products | ||||||||||||||

| Line Pipe | API 5L PSL1/2 | Line pipe | ||||||||||||||

| Casing | API 5CT/ ISO 11960 PSL1 | Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries | ||||||||||||||

| Steel Pipe for Fluid Service | ASTM A53 | Black and hot-hipped galvanized welded and seamless steel pipe | ||||||||||||||

| BS EN10217-2 | Welded steel tybes for pressure purposes – delivery technical conditions – part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties | |||||||||||||||

| BS EN10217-5 | Welded steel tybes for pressure purposes – delivery technical conditions – part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties | |||||||||||||||

| Steel Pipe for Ordinary Structure | ASTM A252 | Welded and seamless steel pipe piles | ||||||||||||||

| BS EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions | |||||||||||||||

| BS EN10219-2 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimmsions and sectional properties | |||||||||||||||

Chemical Analysis and Mechanical Properties of SSAW Steel Pipe

| Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

| C | Si | Mn | P | S | Tensile Strength(Mpa) | Yield Strength(Mpa) | ||

| API 5CT | h40 | – | – | – | – | 0.030 | 417 | 417 |

| J55 | – | – | – | – | 0.030 | 517 | 517 | |

| K55 | – | – | – | – | 0.300 | 655 | 655 | |

| API 5L PSL1 | A | 0.22 | – | 0.90 | 0.030 | 0.030 | 335 | 335 |

| B | 0.26 | – | 1.20 | 0.030 | 0.030 | 415 | 415 | |

| X42 | 0.26 | – | 1.30 | 0.030 | 0.030 | 415 | 415 | |

| X46 | 0.26 | – | 1.40 | 0.030 | 0.030 | 435 | 435 | |

| X52 | 0.26 | – | 1.40 | 0.030 | 0.030 | 460 | 460 | |

| X56 | 0.26 | – | 1.40 | 0.030 | 0.030 | 490 | 490 | |

| X60 | 0.26 | – | 1.40 | 0.030 | 0.030 | 520 | 520 | |

| X65 | 0.26 | – | 1.45 | 0.030 | 0.030 | 535 | 535 | |

| X70 | 0.26 | – | 1.65 | 0.030 | 0.030 | 570 | 570 | |

| API 5L PSL2 | B | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 415 | 415 |

| X42 | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 415 | 415 | |

| X46 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 435 | 435 | |

| X52 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 460 | 460 | |

| X56 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 490 | 490 | |

| X60 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 520 | 520 | |

| X65 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 535 | 535 | |

| X70 | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 | 570 | 570 | |

| X80 | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | 625 | 625 | |

| ASTM A53 | A | 0.25 | 0.10 | 0.95 | 0.050 | 0.045 | 330 | 330 |

| B | 0.30 | 0.10 | 1.20 | 0.050 | 0.045 | 415 | 415 | |

| ASTM A252 | 1 | – | – | – | 0.050 | – | 345 | 345 |

| 2 | – | – | – | 0.050 | – | 414 | 414 | |

| 3 | – | – | – | 0.050 | – | 455 | 455 | |

| EN10217-1 | P195TR1 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P195TR2 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 | |

| P235TR1 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P235TR2 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P265TR1 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| P265TR2 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10217-2 | P195GH | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10217-5 | P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10219-1 | S235JRH | 0.17 | – | 1.40 | 0.040 | 0.040 | 360 | 360 |

| S275JOH | 0.20 | – | 1.50 | 0.035 | 0.035 | 410 | 410 | |

| S275J2H | 0.20 | – | 1.50 | 0.030 | 0.030 | 410 | 410 | |

| S355JOH | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 470 | 470 | |

| S355J2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 | |

| S355K2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 | |

Machine of manufacturing ssaw steel pipe

Edge planing machine, edge milling machine, pipe cutting machine,butt welding machine, pinching machine, hydraulic testing machine.

External Coating:

| Type | Standard |

| Single-Layer FBE Coating | SY/T 0315-2005, CAN/CSA Z245.20-2010, DEP 31.40.30.32-Gen-2011, ISO 21809-2-2007, API RP 5L9-2001 |

| Double-Layer FBE Coating | Q/CNPC 38-2002, CAN/CSA Z245.20-2010 |

| 2LPE/2LPP Coating | SY/T 0413-2002, GB/T 23257-2009, ISO 21809-1-2009 |

| 3LPE/3LPP Coating | SY/T 0413-2002, GB/T 23257-2009, DIN 30670-1991, CAN/CSA Z245.21-2010, ISO 21809-1-2009, NF A49-711-1992, NF A49-710-1988 |

| Insulation Coating | SY/T 0415-1996, CJ/T 114-2000, EN 253-1994 |

Internal Coating

Single-Layer FBE Coating

Standard: API RP 5L2-2002, DEP 31.40.30.35-Gen-2005

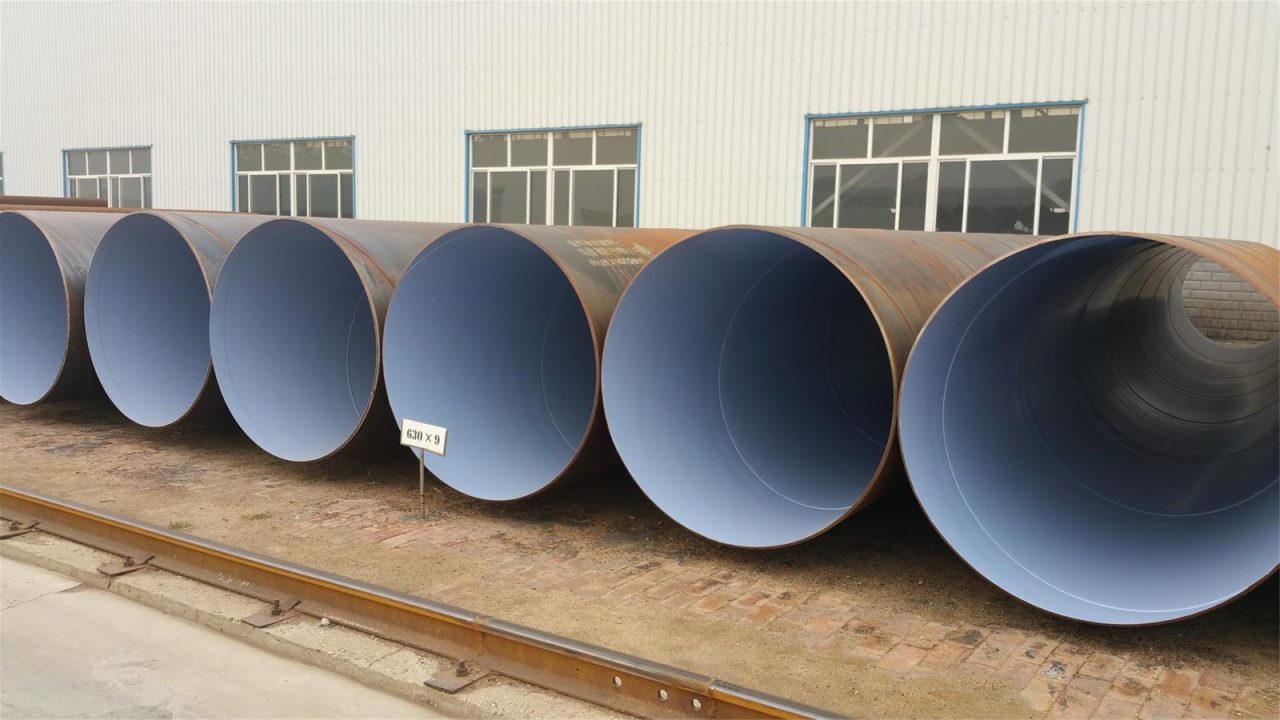

PE Coated SSAW Pipe

Type:PE Coated Pipe, 2PE Coated Pipe, 3PE Coated Pipe

Application: Used for for natural gas, petroleum, water & sewage, and pipe systems

Specification:OD: 219mm~2020mm

WT: 5mm~25mm

LENGTH: 4mtr, 6mtr, 12mtr, 18mtr, 21mtr

Coating Standard:DIN 30670, DIN 30671, DIN 30678, SY/T0413-2002 etc.

Pipe Type: Submerged Arc Welded (LSAW/SSAW), Electrci Resistance Welded

Surface:Two Layer Polyethylene Coating (2mm~4.5mm)

FBE Coated SSAW Pipe

Type: FBE (Fusion Bond Epoxy) Coated Pipe, Epoxy Coated Carbon Steel Pipe

Application:Used for natural gas, petroleum, water & sewage, and pipe systems

Specification: OD: 219mm~2020mm

WT: 5mm~25mm

LENGTH: 4mtr, 6mtr, 12mtr, 18mtr, 21mtr

Coating Standard: DIN 30670, DIN 30671, DIN 30678, SY/T0413-2002 etc.

Surface:One Layer / Double Layer FBE anti-corrosive coating powder (200um~800um)

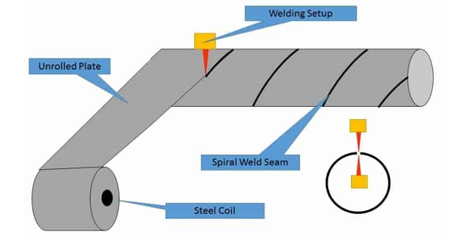

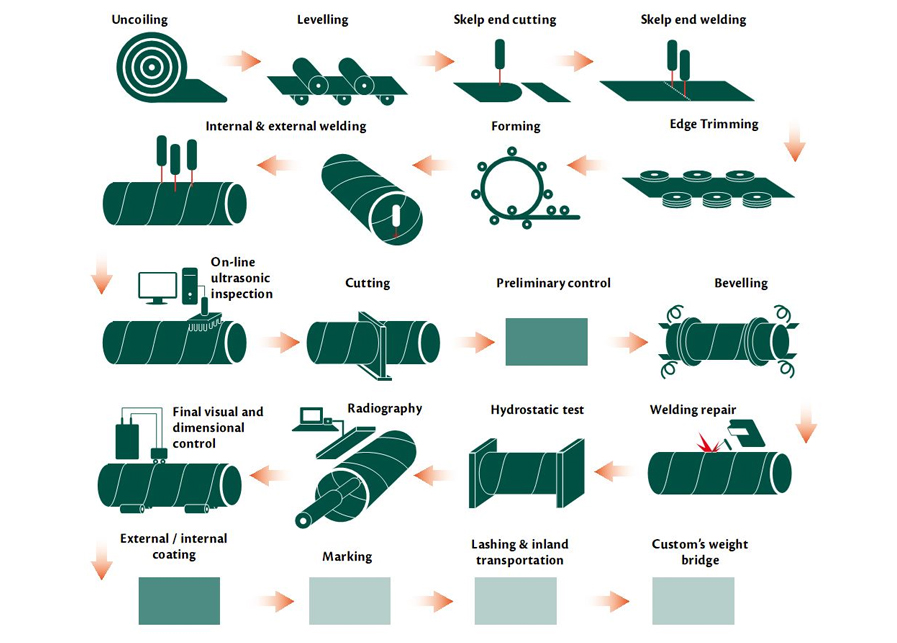

Spiral Steel Pipe Manufacturing Process

SSAW Pipe (Spiral Submerged Arc-Welding Pipe), also called HSAW pipe, welding line shape like a helix. It is using the same welding technology of Submerged Arc-Welding with LSAW pipe. Differently SSAW pipe is spiral welded where the LSAW is longitudinally welded. Manufacturing process is rolling the steel strip, to make the rolling direction have an angle with the direction of the pipe center, forming and welding, so the welding seam is in a spiral line.