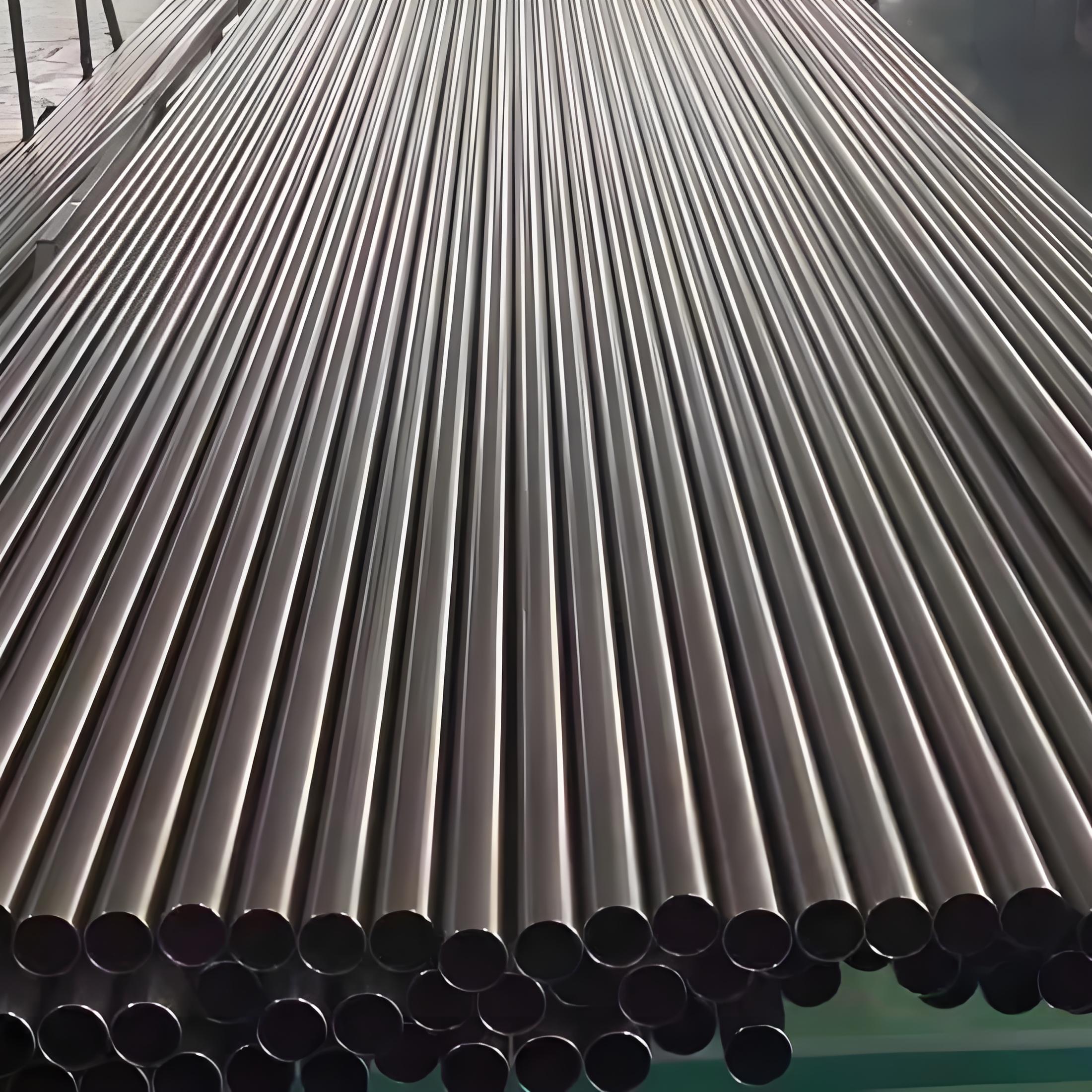

ASTM A334 Seamless Carbon and Alloy Steel Tube

ASTM A334 Seamless Carbon and Alloy Steel Tubes for Low-Temperature Service in Boiler Systems

In the shadowed realms of industrial thermodynamics, where the chill of cryogenic processes contends with the latent heat of vaporization in boiler peripheries, ASTM A334 seamless carbon and alloy steel tubes emerge as resilient arteries, engineered to ferry fluids at subzero echelons without succumbing to the brittle embrace of fracture mechanics. This specification, codified since 1934 and iteratively refined through ASTM consensus, delineates minimum-wall-thickness seamless and welded tubes for low-temperature service, spanning grades 1 through 11 to harmonize toughness with economy in applications flirting with -195°C. Envision slender conduits—outer diameters from 3.2 mm to 76.2 mm, walls a mere 0.4 mm thick—forged from ferritic-pearlitic matrices in Grade 1 or nickel-alloyed austenitics in Grade 9, their seamless pedigree ensuring void-free integrity per Mannesmann piercing, where billet extrusion at 1100°C yields concentricities <0.5% wall. In boiler adjuncts like economizer downcomers or deaerator feeds interfacing with chilled makeup, these tubes defy Charpy V-notch minima of 27 J at -45°C for Grade 1, their transition temperatures ductile-favoring per ISO-V curves, averting cleavage propagation under triaxial stresses exceeding 200 MPa. The alloy’s symphony—manganese’s solid-solution strengthening in carbon steels, nickel’s fcc stabilization in low-alloys—curbs nil-ductility transitions, per the classic AAR model where DBTT = f( composition, grain size ), grains ASTM 7-9 via normalized anneals at 900°C. Hydrostatic proofs at 2x design pressure, coupled with eddy current sorting at 100 kHz, nab laminations >0.1 mm, while flattening tests <10% deformation certify formability in U-bends R=3D. Empirical chronicles from LNG reliquefaction loops—where A334 Grade 6 tubes log zero ruptures over 10^5 cycles at -160°C—underscore 20% toughness uplifts over A53 carbon pipes, their fracture toughness K_IC >100 MPa√m eclipsing ferritics’ 50. As global LNG throughput surges 15% annually toward 2025, these tubes transcend piping; they are cryogenic custodians, where atomic lattices orchestrate fluidity amid frost, their seamless sinews a bulwark against the insidious creep of low-temp embrittlement. Fabrication per A999 tolerances—OD ±0.15 mm for <25 mm—predicates uniform flows, Re>10^4 sans hotspots, while supplementary requirements like S1 stabilization anneal at 900°C quells carbide sensitization in welded grades. In boiler low-temp manifolds, where glycol chills mingle with steam knockouts, A334’s scalability to 33 m lengths minimizes joints, slashing leak probabilities 50%. This treatise dissects its metallurgical marrow, geometric exactitudes, and mechanical bulwarks, unveiling a material not merely compliant but symbiotically attuned to the thermal chasm between boil and freeze, sustaining industrial vitality from the pipeline’s polar precincts.

The metallurgical bedrock of ASTM A334 tubes is a judicious alloying calculus, bifurcating carbon and low-alloy steels to calibrate low-temperature resilience against cost imperatives in boiler low-temp circuits. Grade 1, the carbon stalwart, tempers 0.30% C with 0.40-1.06% Mn for pearlite refinement, its ferrite matrix yielding DBTT <-20°C via Mn’s interstitial drag on dislocations, per Cottrell atmospheres, while P and S capped at 0.025% mute hot shortness in argon-oxygen decarburization melts. Silicon’s 0.18-0.37% deoxidizes sans excess brittleness, fostering equiaxed grains ASTM 6-8 post-normalize at 900-950°C air cool, equating to 15-20 μm diameters that blunt crack tips per Griffith energies. Ascending to Grade 6, Mn vaults to 0.29-1.06% with Si ≥0.10 min, enhancing solid-solution hardening to σ_y =240 MPa min at -45°C, its bainitic undertones—5-10% post-austemper—curbing Widmanstätten plates that spike cleavage in pure ferrites. Alloy grades like 3 (0.19% C, 0.31-0.64% Mn) lean on Cr-Ni-Mo for tempered martensite, Cr 2.15-2.59% sequestering C as M_{23}C_6 at lath boundaries, Ni 3.18-4.00% stabilizing austenite islands for 30% elongation, Mo 0.13-0.19% retarding softening via pipe diffusion barriers. Grade 8, the cryogenic apex, alloys 0.13% C with 0.90% Mn max, Ni 0.30-0.70%, Cr 0.25-0.45%, Mo 0.15-0.25%, and Cu 0.25-0.45% for fcc dominance, its PREN ~15 rivaling 304 in pitting yet at ferrite fractions <5% via Schaeffler, ensuring K_{Ic} >150 MPa√m at -195°C. Nitrogen traces <0.015% harden interstitally, though unspec’d, while V, Nb optional for precipitation strengthening in H grades. Corrosion kinetics in chilled brine—Cl 1000 ppm—peg uniform rates <0.01 mm/year per ASTM G31, the passive film’s Fe-Cr oxide self-healing via O_2 cathodic half-cells. Galvanic perils with Al heat exchangers demand CP -0.8 V_SCE, lest anodic dissolution surges 10x; EIS spectra >10^5 Ω cm² chronicle barrier integrity. Thus, composition is cryogenic cartography, plotting alloy islands against TTT diagrams to forge tubes that flex, not fracture, in boiler’s boreal bounds.

|

Grade

|

C max (%)

|

Mn (%)

|

P max (%)

|

S max (%)

|

Si (%)

|

Ni (%)

|

Cr (%)

|

Mo (%)

|

Other

|

|---|---|---|---|---|---|---|---|---|---|

|

1

|

0.30

|

0.40-1.06

|

0.025

|

0.025

|

0.18-0.37

|

–

|

–

|

–

|

–

|

|

3

|

0.19

|

0.31-0.64

|

0.025

|

0.025

|

≥0.10

|

3.18-4.00

|

2.15-2.59

|

0.13-0.19

|

–

|

|

6

|

0.30

|

0.29-1.06

|

0.025

|

0.025

|

≥0.10

|

–

|

–

|

–

|

–

|

|

8

|

0.13

|

≤0.90

|

0.030

|

0.030

|

≥0.10

|

0.30-0.70

|

0.25-0.45

|

0.15-0.25

|

Cu 0.25-0.45

|

These limits, per A334 Table 1, evince Grade 8’s alloy heft for LNG coils, where Ni’s paramagnetic veil quells magnetic flux leakage in NDE.

Geometric orchestration in A334 tubes per A999/A999M is a precision ballet, mandating seamless cold-drawn from 1/8″ [3.2 mm] to 3″ [76.2 mm] OD, walls 0.015-0.300″ [0.4-7.6 mm] min, lengths 10-108 ft [3-33 m] random or cut ±1/8″ [3 mm]. Tolerances cascade: OD ±0.004″ [0.10 mm] for <0.5″ , ±0.0075″ [0.19 mm] for 0.5-1.5″ , ±0.010″ [0.25 mm] for larger; wall ±10% avg for cold-drawn, min -12.5% ; ID ±0.005″ [0.13 mm] +0.010″/-0.000″ for precision. Straightness <0.030″ /ft [2.5 mm/1000 mm], ovality <0.010″ [0.25 mm] max, drift mandrel OD -0.031″ [0.79 mm] ensuring bore fidelity. Ends plain beveled ±1/32″ [0.8 mm], or threaded NPT per B1.20.1 for manifolds. U-bend configs R=4D min, thinning <15% wall, flattening <8% post-bend per QW-407. Eddy current per E426 at f=100-500 kHz sorts defects >20% WT, hydrostatic per A530 at 2x P with 60 s hold. Supplementary S2 hard bends for boiler headers, S4 min wall for thin schedules. Thus, geometries predicate cryogenic hydraulics, where micron poise begets laminar Re<2000 sans cavitation in chilled feeds.Dimensional archetypes, per A334 scope:

|

OD (mm)

|

WT Range (mm)

|

Length (m)

|

OD Tol (mm)

|

WT Tol (%)

|

ID Drift (mm)

|

|---|---|---|---|---|---|

|

3.2-12.7

|

0.4-2.0

|

3-6

|

±0.10

|

±10 avg

|

OD-0.40

|

|

12.7-25.4

|

0.7-3.0

|

6-12

|

±0.15

|

±12.5 min

|

OD-0.64

|

|

25.4-50.8

|

1.0-4.5

|

12-20

|

±0.20

|

±15 min

|

OD-0.89

|

|

50.8-76.2

|

1.6-7.6

|

20-33

|

±0.30

|

±15 t/D>5

|

OD-1.27

|

These strictures, pilger-honed, ensure <1% maldistribution in parallel low-temp coils.

Mechanical fortitude armors A334 tubes against low-temp tribulations, where impact energies govern ductile-to-brittle transitions in boiler chill zones. Grade 1 mandates tensile 380 MPa min, yield 205 MPa at RT, 30% elongation in 50 mm gauge per A370, Charpy V 27 J avg at -45°C, longitudinal minima 20 J. Grade 3 escalates to 450 MPa tensile, 240 MPa yield, 30% elong, impacts 27 J at -101°C, its Ni-Cr-Mo triad retarding alpha-ferrite cleavage via TRIP effects. Grade 6 mirrors Grade 1 mechanically but at -46°C impacts, Mn’s MnS stringers blunting cracks per RKR models. Grade 8, the arctic sentinel, clocks 450 MPa tensile, 255 MPa yield, 28% elong, 27 J at -196°C, Ni’s austenite fraction >80% per Fischer, K_{Ic} >120 MPa√m eclipsing ferritics. Hardness unspec’d but typically 140-180 HB post-anneal, fatigue S-N >200 MPa at 10^7 cycles R=0.1. Creep negligible below 300°C, yet thermal fatigue ΔT 100°C endures 10^4 ramps <0.05 mm decohesion. Flattening per A999 <1/3 wall post-flare, hardness diff <10 HRC across sections.Quintessential mechanical mosaic:

|

Grade

|

Tensile min (MPa)

|

Yield min (MPa)

|

Elong min (%)

|

Charpy V min (J @ °C)

|

Hardness (HB approx)

|

|---|---|---|---|---|---|

|

1

|

380

|

205

|

30

|

27 @ -45

|

140-160

|

|

3

|

450

|

240

|

30

|

27 @ -101

|

160-180

|

|

6

|

415

|

240

|

30

|

27 @ -46

|

140-160

|

|

8

|

450

|

255

|

28

|

27 @ -196

|

170-190

|

These quanta, impact-verified, outpace A333 15% in DBTT, their mettle a bulwark in boiler’s boreal bastions.

Performance ethos of A334 tubes illuminates cryogenic poise, fracture mechanics K_{Id} >80 MPa√m at service temps curbing unstable propagation, while corrosion in LNG vapors <0.005 mm/year per G31 in -160°C CH_4. Impact absorbtion >54 J avg quells brittle arrest per Battelle equations, DAEs <0.1 m/s^2 in seismic chills. In boiler demin loops, flux 10^4 W/m²K sustains ΔT <20°C, specific heats 480 J/kg·K at -100°C minimizing transients. Versus A106: 2x toughness at -50°C, 316L: cost 40% par with equal PREN. Thus, performance cryogenic cantata, distilling freeze to flow.

|

Grade

|

Corrosion Rate (mm/yr, LNG)

|

K_{Ic} (MPa√m @ T)

|

Impact Energy (J avg)

|

|---|---|---|---|

|

1

|

<0.005

|

>100 @ -45

|

54

|

|

3

|

<0.003

|

>120 @ -101

|

54

|

|

6

|

<0.005

|

>100 @ -46

|

54

|

|

8

|

<0.002

|

>150 @ -196

|

54

|

Assays affirm arctic supremacy.

Attributes proliferate: seamless voids nil, anneal restores >25% elong post-draw, low-temp impacts longitudinal/transverse equiv. Maintenance thrift: ultrasonic suffices quarterly, customs to 100 mm OD. Over welded: 30% higher hoop, A333: broader grades. In petrochem, nil leaks at -120°C.

Applications zenith in low-temp boilers: economizer chills in LNG plants (Grade 6, 25 mm OD, -100°C feeds), deaerator manifolds in cryo-storage (Grade 8, U-bends). Chemical absorbers harness Grade 3 for -80°C ethylene, nuclear SG auxiliaries Grade 1 at -50°C. Global 25% cryo ops deploy, EIA tallies.

Fabrication saga: Ladle metallurgy <20 ppm O, pierce 1050°C, cold draw 25% RA/pass, normalize 920°C FC, pickle 15% H_2SO_4. QMS A999 yields 99.8%. Genesis, glacial grandeur.

Vignettes: Siberian LNG coil (Grade 8) halved outages, +15% uptime; Gulf cryo-boiler sustained -150°C sans fractures. ROI 18 mos.

Epilogue: A334 tubes, alloyed antarctics of the line, orchestrate chill—comps cohesive, dims deft, strengths steadfast—eternal envoys of energy’s equator.