Schedule 40 Galvanized Steel Pipe for Water Pipeline

The Galvanized Steel Schedule 40 Pipe stands as an architectural pillar of conventional fluid transport, a design solution so ubiquitous in water pipeline infrastructure that its technical sophistication is often obscured by its sheer familiarity. Its continued dominance, even in the face of modern polymer and composite alternatives, is a testament to the optimized balance achieved between the raw, dependable strength of carbon steel and the elegant, self-sacrificial electrochemistry of the zinc coating. To truly comprehend this product requires a technical deconstruction that moves beyond its visual simplicity, delving into the rigorous standards—primarily ASTM A53, ASME B36.10M, and ASTM A123—that govern its material composition, geometric precision, and anti-corrosion efficacy. The engineering value proposition of this pipe is complex, residing not just in its ability to contain pressure, but in its designed longevity, a feature directly dependent on the calculated decay rate of its protective zinc layer.

The foundation of the pipe’s robust performance is laid by its material: low-carbon steel, most frequently certified as ASTM A53 Grade B. This grade is selected precisely because its chemical composition—controlled levels of carbon ($\text{C}$), manganese ($\text{Mn}$), sulfur ($\text{S}$), and phosphorus ($\text{P}$)—endows it with an ideal metallurgical profile: high ductility to withstand bending and forming, excellent weldability (for the common $\text{ERW}$ manufacturing process), and a guaranteed minimum Yield Strength ($\text{S}_y$) of $35,000 \text{ psi}$. This strength is not arbitrary; it is the cornerstone for pressure vessel design. For an $\text{A53}$ pipe intended for water service, this strength ensures that the pipe operates safely within the elastic region under typical hydrostatic loads, preventing permanent plastic deformation and guaranteeing that the pipe will resist the critical hoop stress, which is the circumferential tension induced by internal pressure, calculated conceptually through the Barlow formula. The manufacturing diversity permitted by $\text{A53}$—Type F (Furnace Butt Welded), Type E (Electric Resistance Welded), and Type S (Seamless)—allows manufacturers to select the most cost-effective method while maintaining the Grade B mechanical properties, though the subsequent Hot-Dip Galvanizing (HDG) process necessitates that any welded seam (Type E or F) must be meticulously treated—often normalized—to ensure a homogenous microstructure that can uniformly react with the molten zinc, preventing localized coating failure at the weld line.

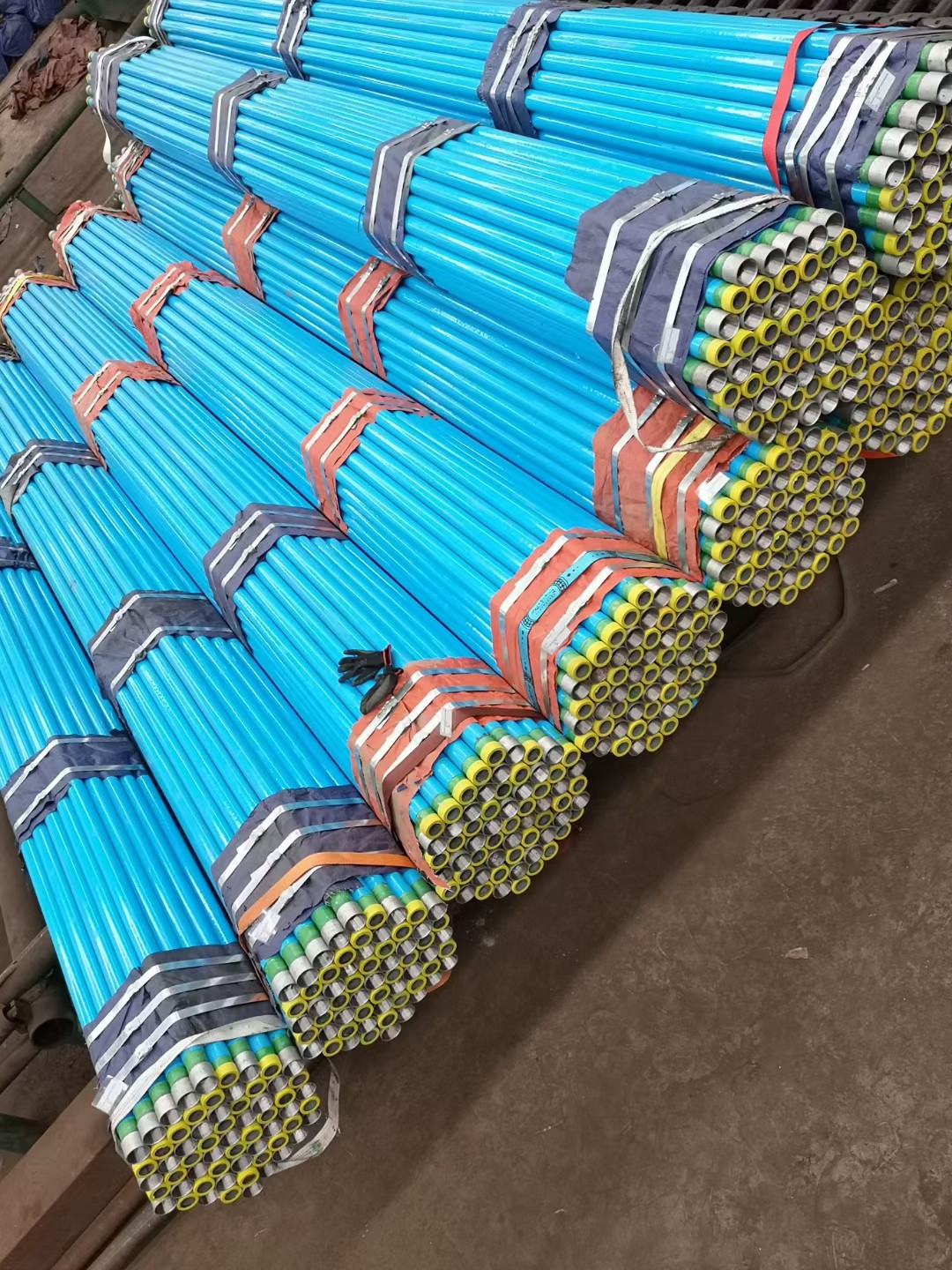

This metallurgical foundation is structurally quantified by the Schedule 40 ($\text{SCH 40}$) designation, a concept central to the pipe industry defined rigorously by the ASME B36.10M standard. The Schedule system is a brilliant simplification: it dictates the wall thickness ($\text{WT}$) as a function of the Nominal Pipe Size ($\text{NPS}$), ensuring that for a given size, the pipe’s internal volume and exterior dimension are predictable, regardless of the manufacturer. $\text{SCH 40}$ has historically been synonymous with “standard weight” pipe, embodying the economic sweet spot where the pipe possesses sufficient $\text{WT}$ to resist standard working pressures (typically under $300 \text{ psi}$ for water and compressed air) and sufficient external stiffness to resist handling damage and support its own weight over spans, without incurring the unnecessary cost and material weight of heavier sections like $\text{SCH 80}$ or $\text{SCH 160}$. The $\text{SCH 40}$ wall thickness is, therefore, the primary determinant of the pipe’s internal pressure rating and its crucial capacity to endure the mechanical rigors of threading, which is the most common joining method for this particular pipe class, a process that physically removes pipe material and thus reduces the effective wall thickness at the joint. The precise dimensional control dictated by the $\text{SCH 40}$ thickness, coupled with the $\text{ASTM A53}$ tolerance limits, ensures that the structural integrity remaining after threading is adequate to prevent failure, particularly at the highly stressed root of the thread.

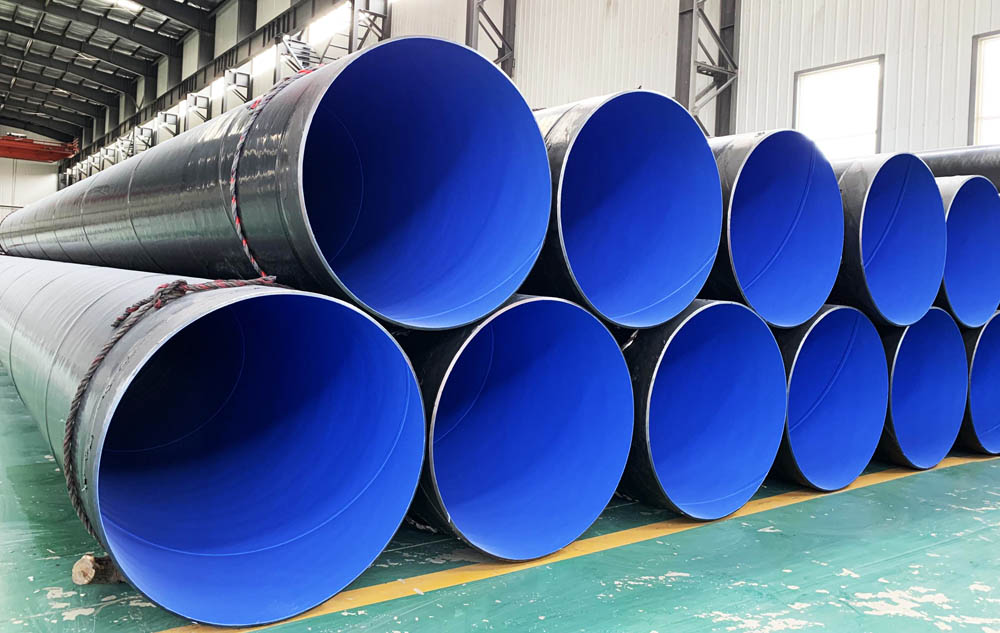

The transformative stage is the application of the Galvanization process, which is the pipe’s technical commitment to longevity in the aqueous environment. Governed by ASTM A123/A153, the Hot-Dip Galvanizing ($\text{HDG}$) process is a meticulous metallurgical sequence: cleaning (pickling), fluxing, and immersion in molten zinc ($\sim 450^{\circ}\text{C}$). The result is not a mere surface paint, but a true fusion-bonded composite coating composed of distinct $\text{Iron-Zinc ($\text{Fe-Zn}$) alloy layers}$ ($\Gamma_1, \delta, \zeta$) nearest the steel substrate, capped by a ductile layer of relatively pure zinc ($\eta$). The scientific brilliance of this system lies in its inherent sacrificial protection mechanism: when the pipe is exposed to water containing dissolved oxygen and electrolytes, the zinc, being anodic relative to the steel, preferentially corrodes. This electrochemical action generates a flow of protective current (electrons) to the exposed steel cathode, preventing the iron from oxidizing and forming rust. This self-healing ability is vital in water pipelines where minor construction damage, abrasion from suspended solids, or localized failure points are inevitable. The minimum coating thickness, measured in ounces per square foot or microns, is the direct mathematical predictor of the pipe’s lifespan, establishing the economic viability of the entire water infrastructure project based on the calculated corrosion consumption rate of the zinc in that specific water chemistry.

The performance of this galvanized $\text{SCH 40}$ pipe in a water pipeline environment introduces specific, challenging chemical variables. The presence of dissolved oxygen ($\text{DO}$) is the primary driver of corrosion, but the pipe’s longevity is further challenged by the water’s $\text{pH}$ and alkalinity. In neutral or slightly alkaline water ($\text{pH} 7.5 \text{ to } 12$), the zinc forms a stable, insoluble zinc carbonate layer that passivates the surface and slows the corrosion rate of the zinc itself—a key factor extending the pipe’s service life. However, if the water is very acidic ($\text{pH} < 6.5$) or extremely pure and soft (lacking stabilizing minerals), the zinc coating can dissolve rapidly, leading to the early onset of base steel corrosion, manifesting internally as tuberculation (buildup of iron oxide) and externally as accelerated general corrosion. Furthermore, the presence of corrosive agents like chlorides ($\text{Cl}^-$) and sulfates ($\text{SO}_4^{2-}$) can disrupt the protective passivation layer, accelerating the consumption of the zinc shield. The structural analysis of this pipe, therefore, must inherently include a detailed water chemistry assessment to accurately predict the long-term $\text{C}$-factor (hydraulic roughness coefficient) and the point at which the internal iron corrosion will begin to significantly reduce the effective flow diameter and hydraulic performance, a technical decline that must be factored into the pipeline’s economic design life.

The practical integrity of the pipeline hinges significantly on the joining method, with the mechanical process of threading being the default choice for the $\text{SCH 40}$ dimension due to its ease of field execution and reliance on standard fittings. The threading operation, however, poses a significant technical challenge: the physical removal of material for the $\text{NPT}$ (National Pipe Thread Taper) cuts through the entire $\text{HDG}$ coating, exposing the base $\text{A53}$ steel at the most highly stressed region of the joint. While the adjacent zinc coating provides sacrificial protection to the thread flanks, the exposed steel is still vulnerable. Therefore, rigorous installation protocol demands the application of a zinc-rich cold galvanizing paint or compound immediately after threading to partially restore the protective barrier, acknowledging that this field-applied coating is metallurgically inferior to the original $\text{HDG}$ bond but is essential to maintain local corrosion resistance. In contrast, when $\text{SCH 40}$ pipe is welded (often necessary for larger diameters or higher pressures), the intense heat completely vaporizes the zinc coating for several inches around the weld zone. This requires a much more extensive cleaning and subsequent re-coating process with specialized high-zinc content paints to prevent immediate weld zone corrosion, reinforcing the technical and economic advantage of threading for lower-pressure galvanized systems.

The essential $\text{Tolerance of Thickness Schedules}$ is a critical metric for quality assurance. The $\text{ASTM A53}$ standard permits a negative wall thickness tolerance of up to $-12.5\%$ from the nominal $\text{SCH 40}$ dimension. While this tolerance ensures the minimum pressure rating is met, high-quality projects often specify a tighter tolerance (e.g., $-8\%$ or less) to ensure the pipe’s structural rigidity and, critically, to guarantee that the remaining material at the thread root is maximized. Any excessive reduction in wall thickness due to manufacturing variability directly compromises the pipe’s collapse resistance and its ultimate ability to contain pressure under high stress. The quality control process must also incorporate detailed checks on the galvanization itself, adhering to $\text{ASTM A123}$ through tests like the Preece Test (rarely used now) or, more commonly, magnetic thickness gauges and adhesion tests (hammering/bending) to verify that the coating thickness is uniform and the fusion-bond is mechanically sound, ensuring that the critical $\text{Fe-Zn}$ alloy layers are present and fully intact before the pipe is accepted for installation in a long-term water pipeline system. The successful long-term application of the $\text{SCH 40}$ galvanized pipe is thus an elaborate interplay between standardized geometry, guaranteed mechanical properties, and a highly nuanced electrochemical defense system.

Structured Technical Specification Data: Schedule 40 Galvanized Steel Pipe for Water Pipeline

| Category | Technical Specification | Typical Requirements & Standards | Technical Significance for Water Pipeline |

| Material Grade (Base) | Carbon Steel | ASTM A53/A53M Grade B (Seamless/Welded) or ASTM A106 Grade B (Seamless). | Provides base structural strength ($\text{S}_y$) and ductility; low-carbon content ensures optimal galvanization reaction. |

| Dimensions/Size Range | ASME B36.10M Schedule 40 ($\text{SCH 40}$) | Defines $\text{WT}$ relative to $\text{NPS}$ (Nominal Pipe Size). $\text{SCH 40}$ is the “Standard Weight” pipe. | Thickness provides the required internal pressure rating, structural stiffness, and adequate material allowance for threading. |

| Coating Specification | Hot-Dip Galvanized ($\text{HDG}$) | ASTM A123/A153. Minimum coating mass/thickness based on pipe steel thickness (e.g., $610 \text{ g/m}^2$ minimum average mass). | The standard guarantees a thick, fusion-bonded $\text{Fe-Zn}$ coating, providing long-term sacrificial cathodic protection against internal and external corrosion. |

| Governing Standard | Base: $\text{ASTM A53/A106}$. Geometry: $\text{ASME B36.10M}$. Finish: $\text{ASTM A123/A153}$. | Compliance across all three standards ensures material strength, dimensional predictability, and durable corrosion resistance. | |

| Chemical Composition | ASTM A53 Grade B Limits | $\text{C}$ Max $\le 0.30\%$. $\text{Mn}$ Max $\le 1.20\%$. $\text{P}$ Max $\le 0.035\%$. $\text{S}$ Max $\le 0.035\%$. | Controlled composition ensures high weld quality ($\text{Type E}$) and minimizes impurities that could interfere with the $\text{Fe-Zn}$ metallurgical bond during galvanizing. |

| Heat Treatment Req. | As-Formed / Stress Relief | $\text{Type E}$ (ERW): Weld seam typically requires full heat treatment (normalizing) to restore microstructural integrity prior to galvanizing. | Ensures a homogenous microstructure and eliminates residual stresses that could cause cracking during the high-temperature $\text{HDG}$ process. |

| Tensile Requirements | ASTM A53 Grade B | Yield Strength ($\text{S}_y$): Min $35,000 \text{ psi}$ (240 MPa). Tensile Strength ($\text{S}_u$): Min $60,000 \text{ psi}$ (415 MPa). | Provides the necessary structural capacity to withstand internal hoop stress, external loads, and the substantial tensile forces encountered during installation. |

| Application | Water Transport Systems | Potable water lines, industrial process water, fire suppression systems, and non-critical steam/air conveyance. | The pipe is optimized for environments where moisture and oxygen are present, demanding corrosion control alongside reliable pressure containment. |

| Features | Sacrificial Protection, Durability, Threadability | Key Features: Sacrificial $\text{Zn}$ layer; Robust $\text{SCH 40}$ wall thickness; High $\text{C}$-factor initially; Compatible with standard $\text{NPT}$ fittings. | The $\text{Zn}$ coating ensures local protection of scratches and exposed threads, greatly extending service life compared to plain carbon steel. |

| Tolerance of Thickness Schedules | ASTM A53/A106 Wall Tolerance | Negative $\text{WT}$ Tolerance: $-12.5\%$ of nominal $\text{SCH 40}$ thickness. | Ensures that the minimum required structural wall thickness is maintained for pressure rating and thread strength, even with manufacturing variability. |