Heat-Expanded Seamless Steel Pipe – Process Core Principle and Technical Analysis

Core Principle and Technical Analysis of Heat-Expanded Seamless Steel Pipe Process

Core Principle and Technical Analysis of Medium and High Frequency Heat-Expanded Seamless Steel Pipe Process

As an undergraduate majoring in Pipeline Industry, mastering the core principle and technical points of the Guanzhong medium and high frequency heat-expanded seamless steel pipe process is the foundation of learning this major well, and also a necessary skill for engaging in work related to the pipeline industry in the future. During the course study and internship, I have conducted in-depth research and practice on the core principle, technical characteristics, key links and parameter control of this process. Combined with my personal understanding and internship experience, the following is a detailed elaboration of these contents, which will integrate some specific problems and solutions I encountered during the internship, making the technical analysis closer to actual production.

3.1 Core Principle of the Process

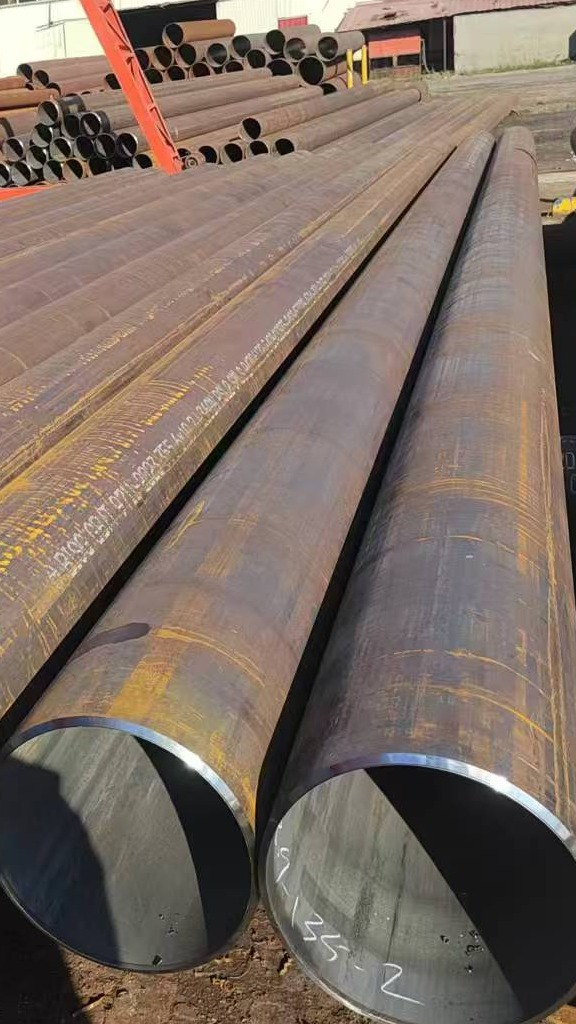

The Guanzhong medium and high frequency heat-expanded seamless steel pipe process is essentially a secondary thermal processing process for seamless steel pipes (mother pipes). Its core principle is: using the electromagnetic induction effect generated by intermediate frequency or high frequency current, the mother pipe is heated to the plastic deformation temperature range, and then under the support of the plug and the action of external force, the mother pipe undergoes radial expansion and axial extension, so as to obtain a seamless steel pipe (finished pipe) with larger diameter and thinner wall thickness, while ensuring that the dimensional accuracy, surface quality and mechanical properties of the finished pipe meet the engineering requirements.

Here I want to emphasize that many people are easy to confuse the Guanzhong medium and high frequency heat expansion process with the hot-rolled seamless steel pipe process. In fact, there are great differences between the two. Hot-rolled seamless steel pipes are directly rolled from steel billets without the need for mother pipes, while the Guanzhong medium and high frequency heat expansion process is a secondary processing of formed seamless steel pipes, which requires mother pipes as raw materials; the hot-rolled process is suitable for producing small and medium-diameter, thick-walled seamless steel pipes, while the heat expansion process is suitable for producing large-diameter, medium-thin-walled seamless steel pipes; moreover, the equipment investment of the heat expansion process is much lower than that of the hot-rolled process, and the production flexibility is stronger. It can quickly adjust product specifications according to market demand and produce steel pipes of different diameters and wall thicknesses. During the internship, I often saw the workshop produce finished pipes of different specifications by adjusting process parameters with mother pipes of different specifications according to customer orders. Sometimes, several different specifications of products can be produced in one day, which is the advantage of the heat expansion process.

Specifically, the core principle of the Guanzhong medium and high frequency heat expansion process can be divided into two parts: electromagnetic induction heating principle and plastic deformation principle.

The electromagnetic induction heating principle is the foundation of the Guanzhong medium and high frequency heat expansion process. When intermediate frequency and high frequency current pass through the induction coil, an alternating magnetic field will be generated. When the mother pipe is in the alternating magnetic field, an induced current (eddy current) will be generated inside the mother pipe. When the eddy current flows inside the mother pipe, it will be hindered by the resistance of the mother pipe itself, thus generating Joule heat and heating the mother pipe quickly. It should be noted here that the difference between intermediate frequency and high frequency mainly lies in the difference of current frequency: the frequency of intermediate frequency current is generally 1-10kHz, and the frequency of high frequency current is generally 10-50kHz. Different frequencies of current produce different electromagnetic induction effects and heating effects. Intermediate frequency heating is characterized by deep heating depth and uniform temperature, which is suitable for heating large-diameter and thick-walled mother pipes; high frequency heating is characterized by fast heating speed and small heat-affected zone, which is suitable for heating small-diameter and thin-walled mother pipes. This is the reason why the intermediate frequency and high frequency heat expansion processes complement each other as I mentioned earlier.

The principle of plastic deformation is the core of the Guanzhong medium and high frequency heat expansion process. When the mother pipe is heated to the plastic deformation temperature range (for ordinary carbon steel, generally 900-1100℃), the metal structure of the mother pipe will change, the grains will be refined, the plasticity will be significantly improved, and the brittleness will be reduced. At this time, under the support of the plug and the external force (expansion pressure), the mother pipe will undergo plastic deformation, radial expansion and axial extension, and finally form the finished pipe that meets the requirements. In this process, it is necessary to strictly control the heating temperature and deformation speed. If the heating temperature is too high, it will lead to serious oxidation of the mother pipe surface, coarse grains, and affect the mechanical properties of the finished pipe; if the heating temperature is too low, the plasticity of the mother pipe is insufficient, which is easy to break and cannot complete the expansion; if the deformation speed is too fast, it will lead to low dimensional accuracy and excessive wall thickness deviation of the finished pipe; if the deformation speed is too slow, it will reduce production efficiency and increase energy consumption.

During the internship, I encountered such a problem: once, the workshop produced DN800 finished pipes. Due to the carelessness of the operator, the temperature of the intermediate frequency heating furnace was adjusted to 1150℃, which exceeded the specified maximum temperature, resulting in excessive heating of the mother pipe, serious surface oxidation. Moreover, after expansion, the grains of the finished pipe were coarse, the mechanical performance test was unqualified, and it could only be scrapped. This incident also made me deeply realize the importance of process parameter control. Even a small parameter deviation may lead to product scrapping and economic losses.

3.2 Comparison and Technical Characteristics of Intermediate Frequency and High Frequency Heat Expansion Processes

Intermediate frequency heat expansion and high frequency heat expansion are two main forms of the Guanzhong medium and high frequency heat-expanded seamless steel pipe process. Both are based on the electromagnetic induction heating principle and plastic deformation principle, but due to the different current frequencies, there are obvious differences between the two in heating effect, technical characteristics, application scope and other aspects. During the internship, I stayed in the intermediate frequency heat expansion workshop and high frequency heat expansion workshop for a period of time, and had an intuitive understanding of the differences between the two processes. Combined with my personal practical experience, the following is a detailed comparative analysis of the two processes, as shown in Table 1.

| Comparison Items | Intermediate Frequency Heat Expansion Process (1-10kHz) | High Frequency Heat Expansion Process (10-50kHz) |

| Heating Principle | Eddy current generated by electromagnetic induction, deep heating depth, uniform temperature, large heat-affected zone | Eddy current generated by electromagnetic induction, fast heating speed, small heat-affected zone, mainly heating the surface |

| Heating Efficiency | Medium, generally 65%-75%, suitable for batch heating | High, generally 75%-85%, heating speed is 2-3 times faster than intermediate frequency |

| Applicable Mother Pipe Specifications | Large-diameter, thick-walled mother pipes (DN200-DN1500, wall thickness 8-30mm), such as DN300 and DN500 mother pipes commonly used during my internship | Small-diameter, thin-walled mother pipes (DN50-DN300, wall thickness 3-10mm) |

| Characteristics of Finished Pipes | Large diameter, uniform wall thickness, medium dimensional accuracy, general surface quality, stable mechanical properties, more oxide scale | Small diameter, thin wall thickness, high dimensional accuracy, good surface quality, less oxide scale, better mechanical properties |

| Production Efficiency | Medium, long heating time for single steel pipe (5-15min), suitable for mass production of large-diameter products | High, short heating time for single steel pipe (1-5min), suitable for mass production of small-diameter products |

| Energy Consumption Level | High, unit energy consumption 650-800kWh/ton of steel pipe, reduced to 650kWh/ton after the enterprise I interned in upgraded | Low, unit energy consumption 500-650kWh/ton of steel pipe |

| Equipment Investment | Large, high investment in intermediate frequency heating furnace, expansion equipment, etc., about 5-10 million yuan for one production line | Small, high-frequency heating furnace is small in size and low in cost, about 2-5 million yuan for one production line |

| Applicable Fields | Large-diameter transmission pipelines in petroleum chemical industry, municipal pipe network, energy power and other fields, such as central heating pipe network in Shaanxi region | Small-diameter precision pipelines in precision machinery, small chemical industry, medical equipment and other fields |

| Core Advantages | Strong production flexibility, can produce large-diameter and thick-walled finished pipes, stable mechanical properties, suitable for large-scale mass production | Fast heating speed, low energy consumption, high dimensional accuracy and good surface quality of finished pipes, suitable for precision product production |

| Existing Shortcomings | High energy consumption, general surface quality, more oxide scale, need subsequent finishing treatment; early excluded from the high-pressure boiler standard | Cannot produce large-diameter and thick-walled finished pipes, limited equipment power, insufficient heating depth |

Table 1 Comparison Table of Intermediate Frequency and High Frequency Heat Expansion Processes

From the above comparison, we can clearly see that the intermediate frequency heat expansion and high frequency heat expansion processes have their own advantages and disadvantages. They are not alternative to each other, but complementary, forming the Guanzhong medium and high frequency heat-expanded seamless steel pipe process system together. In actual production, enterprises will choose the appropriate heat expansion process according to market demand, product specifications, customer requirements and other factors. For example, the enterprise I interned in mainly produces large-diameter heat-expanded seamless steel pipes, so it mainly adopts the intermediate frequency heat expansion process and is equipped with two intermediate frequency heat expansion production lines; while a small steel pipe enterprise next to it mainly produces small-diameter precision steel pipes, so it adopts the high frequency heat expansion process and is equipped with three high frequency heat expansion production lines.

In addition, during the internship, I also found that with the continuous upgrading of technology, the boundary between intermediate frequency and high frequency heat expansion processes is gradually blurring. For example, some enterprises have realized precise surface temperature control of the intermediate frequency heat expansion process by optimizing the structure of the induction coil and improving the heating method, reducing the generation of oxide scale and improving the surface quality of the finished pipe; while some enterprises have realized deep heating of the high frequency heat expansion process by increasing the power of the high frequency equipment, which can produce finished pipes with larger diameter and thicker wall thickness. This trend of technological integration has also become one of the important development directions of the Guanzhong medium and high frequency heat expansion process. At the same time, both intermediate frequency and high frequency heat expansion pay more and more attention to the control of pipe blank quality and deformation zone temperature. By reasonably selecting deformation parameters and strengthening finished product inspection, the product quality is ensured to meet the standard requirements.

3.3 Key Process Links and Technical Control Points

The production process of the Guanzhong medium and high frequency heat-expanded seamless steel pipe process mainly includes seven core links: raw material inspection, mother pipe pretreatment, induction heating, expansion forming, cooling, finishing and finished product inspection. Each link has its key technical control points. Any problem in any link will affect the quality of the finished pipe. During the internship, I participated in the work of these seven links and had a deep understanding of the technical control points of each link. Combined with my personal practical experience, the following is a detailed elaboration of the key technical control points of each link, which will integrate some problems and solutions I encountered during the internship, making the technical analysis closer to actual production.

3.3.1 Raw Material Inspection

Raw material inspection is the first line of defense of the Guanzhong medium and high frequency heat expansion process, and also the foundation to ensure the quality of finished pipes. The raw material of the Guanzhong medium and high frequency heat expansion process is seamless steel pipe (mother pipe). The quality of the mother pipe directly determines the quality of the finished pipe. If the mother pipe has defects such as cracks, inclusions and excessive wall thickness deviation, even if the subsequent process parameters are well controlled, it is impossible to produce qualified finished pipes. During the internship, my first post was raw material inspection. My daily work was to inspect the incoming mother pipes. The main inspection items included: specification model, material, wall thickness deviation, surface quality and mechanical properties of the mother pipe.

Specifically, there are three key technical control points for raw material inspection: first, material inspection. It is necessary to ensure that the material of the mother pipe meets the production requirements. For example, to produce Q355 heat-expanded seamless steel pipes, the material of the mother pipe must also be Q355, and Q235 mother pipes cannot be used instead, otherwise the mechanical properties of the finished pipe will be unqualified. During the internship, I encountered a case of inconsistent material: a batch of incoming mother pipes was marked as Q355, but after spectral analysis, it was found that the actual material was Q235, which did not meet the production requirements. We returned this batch of mother pipes to the supplier in time to avoid quality problems in subsequent production. Second, wall thickness deviation inspection. The wall thickness deviation of the mother pipe must be controlled within the allowable range (generally ±5%). If the wall thickness deviation of the mother pipe is too large, the wall thickness deviation of the finished pipe after expansion will also be too large, which cannot meet the engineering requirements. We used ultrasonic thickness gauges to measure multiple points at different parts of the mother pipe to ensure uniform wall thickness. Third, surface quality inspection. It is necessary to check whether the surface of the mother pipe has defects such as cracks, scratches, oxide scale and inclusions. If there are these defects, it needs to be polished. It can enter the next process only after passing the treatment; if the defects are too serious to be treated, it needs to be scrapped. For example, once, we found that the surface of a batch of mother pipes had many scratches with depth exceeding 0.5mm. After polishing, they still could not be eliminated, so this batch of mother pipes had to be scrapped.

Here I want to emphasize that the raw material inspection link must not be careless. Many enterprises have produced a large number of unqualified products and caused huge economic losses because they ignored the raw material inspection. The enterprise I interned in has very strict requirements on raw material inspection, established a complete raw material inspection system. Each batch of incoming mother pipes must be inspected, and can be put into storage only after passing the inspection. Moreover, the inspection records must be retained throughout the process to facilitate subsequent quality traceability. At the same time, for mother pipes used in high-end products, electric arc furnace, LF refining and VD vacuum degassing triple process will also be adopted to ensure the purity of molten steel, control the S and P content below 0.015%, and lay a good foundation for the subsequent heat expansion process.

3.3.2 Mother Pipe Pretreatment

Mother pipe pretreatment is an important link of the Guanzhong medium and high frequency heat expansion process. Its purpose is to remove impurities such as oxide scale, oil stain and rust on the surface of the mother pipe, adjust the dimensional accuracy of the mother pipe, and prepare for subsequent induction heating and expansion forming. The quality of mother pipe pretreatment directly affects the effect of induction heating and the surface quality of the finished pipe. If there are oil stains, rust and other impurities on the surface of the mother pipe, the heating will be uneven during heating, and the impurities will adhere to the surface of the finished pipe, affecting the surface quality; if the dimensional accuracy of the mother pipe does not meet the requirements, the dimensional accuracy of the finished pipe after expansion will also be affected.

Mother pipe pretreatment mainly includes three steps: polishing, straightening and degreasing. Each step has its key technical control points. First, polishing. It is mainly to remove oxide scale, rust and scratches on the surface of the mother pipe. The surface of the polished mother pipe should be smooth and flat without obvious defects, and the surface roughness should be controlled at Ra≤12.5μm. We used automatic polishing machines at that time, the polishing speed was controlled at 10-15m/min, and the polishing pressure was controlled at 0.3-0.5MPa to ensure the polishing effect. If the oxide scale on the surface of the mother pipe is thick, it needs to be sandblasted first, then polished. Second, straightening. It is mainly to adjust the straightness of the mother pipe to ensure that the straightness of the mother pipe meets the requirements (straightness deviation per meter ≤1mm). If the mother pipe is bent, the force will be uneven during expansion, and the finished pipe will have problems such as ellipse and excessive wall thickness deviation. We used a hydraulic straightener, the straightening pressure was controlled at 10-20MPa. The straightened mother pipe should be tested for straightness, and the unqualified ones should be straightened again. Third, degreasing. It is mainly to remove oil stains on the surface of the mother pipe. Oil stains will affect the effect of induction heating, and harmful gases will be generated during heating, polluting the environment. We used alkaline degreasing agent, the degreasing temperature was controlled at 50-60℃, the degreasing time was controlled at 10-15min. After degreasing, the mother pipe should be washed with water to remove the residual degreasing agent on the surface, then dried to ensure that the surface of the mother pipe is dry and free of moisture.

During the internship, due to carelessness, I sent a mother pipe to the heating furnace without thorough degreasing treatment. As a result, during heating, the oil stains on the surface of the mother pipe burned, producing a lot of black smoke, which not only polluted the environment, but also caused uneven heating of the mother pipe. After expansion, many black spots appeared on the surface of the finished pipe, which could only be scrapped. This incident made me deeply realize that every step of the mother pipe pretreatment link must be operated in strict accordance with the requirements, and there can be no slightest carelessness. At the same time, for products that need overall heat treatment after expansion, the quality of mother pipe pretreatment will also affect the heat treatment effect, and then affect the mechanical properties of the finished pipe.

3.3.3 Induction Heating

Induction heating is the core link of the Guanzhong medium and high frequency heat expansion process, and also the link with the greatest difficulty in technical control. Its core task is to heat the mother pipe to the plastic deformation temperature range, and ensure uniform heating and stable temperature, so as to provide good plastic conditions for subsequent expansion forming. The quality of induction heating directly determines the mechanical properties, dimensional accuracy and surface quality of the finished pipe, and is the “soul” of the entire process. During the internship, I spent a long time learning the operation and parameter control of the induction heating link, followed the workshop master to learn how to adjust the heating power, heating time, how to control the heating temperature, and accumulated a lot of valuable practical experience.

The key technical control points of induction heating are mainly three: first, heating temperature control, second, heating speed control, third, temperature uniformity control.

Heating temperature control is the core of the induction heating link. Different materials of mother pipes have different plastic deformation temperature ranges, which must be strictly controlled within the corresponding temperature range, not too high or too low. For example, the plastic deformation temperature range of ordinary carbon steel (20#, Q235) is 900-1100℃, that of Q355 high-strength steel is 950-1150℃, and that of 304 stainless steel is 1050-1200℃. If the heating temperature is too high, it will lead to serious oxidation of the mother pipe surface, coarse grains, even burnout, affecting the mechanical properties and surface quality of the finished pipe; if the heating temperature is too low, the plasticity of the mother pipe is insufficient, which is easy to break and cannot complete the expansion. During the internship, we used infrared thermometers to monitor the surface temperature of the mother pipe in real time, and measured the internal temperature of the mother pipe with thermocouples every 5 minutes to ensure that the temperature was controlled within the specified range. At the same time, for the intermediate frequency induction heating push-type process, although it is local heating, the intelligent temperature control system can effectively ensure the stable temperature of the deformation zone and avoid the adverse impact of temperature fluctuation on the expansion deformation.

Heating speed control is also very important. If the heating speed is too fast, it will lead to too high surface temperature and too low internal temperature of the mother pipe, resulting in the phenomenon of “burned outside but raw inside” and poor temperature uniformity; if the heating speed is too slow, it will reduce production efficiency, increase energy consumption, and lead to too much oxide scale on the mother pipe surface. Generally speaking, the heating speed of intermediate frequency heat expansion is controlled at 50-100℃/min, and that of high frequency heat expansion is controlled at 100-200℃/min. The heating speed of mother pipes of different specifications and materials needs to be adjusted appropriately. For example, the heating speed of large-diameter and thick-walled mother pipes should be slower to ensure sufficient internal heating; the heating speed of small-diameter and thin-walled mother pipes can be faster to improve production efficiency. During the internship, I once caused a DN500, 15mm wall thickness mother pipe to appear the phenomenon of “burned outside but raw inside” due to too fast heating speed. The surface temperature reached 1150℃, but the internal temperature was only 850℃, which could not be expanded and had to be reheated, which not only wasted electric energy, but also delayed the production progress.

Temperature uniformity control is another key point of the induction heating link. The temperature of the mother pipe must be uniform, and there should be no local overheating or local low temperature. Otherwise, during expansion, the plastic deformation of the mother pipe will be uneven, leading to defects such as ellipse, excessive wall thickness deviation and surface cracks of the finished pipe. To ensure temperature uniformity, we mainly took three measures: first, optimize the structure of the induction coil. According to the specification of the mother pipe, design a suitable induction coil to ensure uniform gap between the coil and the mother pipe (generally 5-10mm); second, adopt segmental heating method, divide the mother pipe into multiple heating segments, and control the temperature of each heating segment respectively to ensure uniform overall temperature; third, drive the mother pipe to rotate through mechanical devices during heating, so that all parts of the mother pipe can be heated uniformly. During the internship, I once encountered the problem of uneven temperature of the mother pipe. The temperature of one side of a mother pipe reached 1050℃, while the temperature of the other side was only 950℃. After expansion, the finished pipe appeared obvious ellipse, and the wall thickness deviation exceeded the allowable range, which could only be scrapped. Later, we found that it was caused by the uneven gap between the induction coil and the mother pipe. After adjusting the gap, the temperature uniformity was significantly improved. At the same time, for the intermediate frequency heat expansion process, the temperature uniformity can also be effectively improved by adjusting the distribution of heating power, ensuring stable expansion deformation.

3.3.4 Expansion Forming

Expansion forming is the core forming link of the Guanzhong medium and high frequency heat expansion process. Its purpose is to make the mother pipe undergo radial expansion and axial extension under the support of the plug and the action of external force when it is in the plastic deformation state, so as to obtain the required finished pipe specifications. The quality of expansion forming directly determines the dimensional accuracy, wall thickness deviation and shape accuracy of the finished pipe, and is one of the key links of the entire process. During the internship, I followed the workshop master to learn the operation of the expansion forming link, understood the working principle and parameter control points of the expansion equipment, and personally participated in the auxiliary work of expansion forming.

The key technical control points of expansion forming are mainly four: first, plug selection, second, expansion speed control, third, expansion pressure control, fourth, expansion ratio control.

Plug selection is the foundation of expansion forming. The material, shape and size of the plug must match the specification and material of the mother pipe. The material of the plug is generally high-temperature resistant and high-strength alloy materials, such as H13 die steel and 3Cr2W8V alloy steel, which can withstand the action of high temperature and high pressure and avoid plug deformation or damage. The shape of the plug is mainly conical plug and spherical plug. The conical plug is suitable for expansion of large-diameter and thick-walled mother pipes, and the spherical plug is suitable for expansion of small-diameter and thin-walled mother pipes. The size of the plug should be designed according to the specification of the finished pipe to ensure that the diameter of the finished pipe after expansion meets the requirements. During the internship, I once selected the wrong plug size, resulting in the diameter of a DN800 finished pipe being too small to meet the customer’s requirements, so it had to be expanded again, wasting manpower and material resources. At the same time, the surface of the plug should be smooth to avoid scratching the inner surface of the mother pipe and affecting the inner surface quality of the finished pipe.

Expansion speed control is the core of expansion forming. If the expansion speed is too fast, it will lead to uneven plastic deformation of the mother pipe, resulting in defects such as ellipse, excessive wall thickness deviation and surface cracks of the finished pipe; if the expansion speed is too slow, it will reduce production efficiency, increase energy consumption, and lead to too much oxide scale on the mother pipe surface, affecting the surface quality. Generally speaking, the expansion speed of intermediate frequency heat expansion is controlled at 50-100mm/min, and that of high frequency heat expansion is controlled at 100-150mm/min. The expansion speed of mother pipes of different specifications and materials needs to be adjusted appropriately. For example, the expansion speed of mother pipes with hard material and thick wall thickness should be slower to ensure sufficient plastic deformation; the expansion speed of mother pipes with soft material and thin wall thickness can be faster to improve production efficiency. During the internship, I once caused a Q355 material mother pipe to have surface cracks during expansion due to too fast expansion speed, which could only be scrapped.

Expansion pressure control is also very important. Expansion pressure is the power to promote the plastic deformation of the mother pipe. If the pressure is too high, it will lead to excessive wall thickness deviation, surface bulging, even fracture of the mother pipe; if the pressure is too low, it cannot promote sufficient plastic deformation of the mother pipe, and the diameter of the finished pipe after expansion is too small to meet the requirements. The magnitude of expansion pressure mainly depends on the material, specification, wall thickness and expansion ratio of the mother pipe. Generally speaking, the expansion pressure of intermediate frequency heat expansion is controlled at 15-25MPa, and that of high frequency heat expansion is controlled at 10-15MPa. During the internship, we monitored the expansion pressure in real time through pressure sensors, and adjusted the pressure in time according to the deformation of the mother pipe to ensure stable expansion pressure. At the same time, for the intermediate frequency induction heating push-type expansion process, the control of push pressure is also very critical. The push pressure and expansion pressure must be properly matched to ensure uniform and stable expansion deformation and avoid defects.

Expansion ratio control is another key point of expansion forming. Expansion ratio refers to the ratio of the diameter of the finished pipe to the diameter of the mother pipe. If the expansion ratio is too large, it will lead to excessive plastic deformation of the mother pipe, resulting in defects such as excessive wall thickness deviation, surface cracks and fracture; if the expansion ratio is too small, it cannot make full use of the plasticity of the mother pipe, the production efficiency is low, and the energy consumption is increased. Generally speaking, the expansion ratio of the Guanzhong medium and high frequency heat expansion process is controlled between 1.2 and 2.0. Different mother pipes of different materials and specifications have different limits on the expansion ratio. For example, the maximum expansion ratio of ordinary carbon steel mother pipes can reach 2.0, while the maximum expansion ratio of stainless steel mother pipes can only reach 1.8, because although the plasticity of stainless steel is good, excessive deformation is easy to cause cracks. During the internship, I once tried to expand a DN500 mother pipe to DN1000, with an expansion ratio of 2.0. As a result, the mother pipe cracked severely during the expansion process, and the wall thickness deviation of the local part exceeded 8%, which far exceeded the allowable range of the standard. The finished pipe could only be scrapped, causing certain economic losses to the enterprise. This incident made me deeply realize that the control of the expansion ratio is crucial, and we must strictly follow the process requirements and not blindly pursue the expansion effect to increase the expansion ratio at will.

In addition, during the expansion forming process, the fit between the plug and the mother pipe also needs to be paid attention to. If the fit is too tight, it will increase the friction between the plug and the inner wall of the mother pipe, easily scratching the inner surface of the mother pipe and increasing the resistance of expansion; if the fit is too loose, the plug cannot effectively support the mother pipe, leading to uneven deformation of the mother pipe and affecting the dimensional accuracy of the finished pipe. During the internship, we usually adjust the fit gap between the plug and the mother pipe to 0.5-1.0mm according to the wall thickness of the mother pipe, which can effectively avoid the above problems. To sum up, the expansion forming link is a comprehensive technical link, which requires the operator to have rich practical experience and strict control of each parameter to ensure the quality of the finished pipe.

3.3.5 Cooling

Cooling is an indispensable key link after the expansion forming of the Guanzhong medium and high frequency heat-expanded seamless steel pipe process. Its core purpose is to cool the finished pipe after high-temperature expansion to room temperature or a specified temperature, stabilize the metal structure of the finished pipe, improve its mechanical properties, and avoid deformation or cracks of the finished pipe due to natural cooling at room temperature. The cooling effect directly affects the mechanical properties, dimensional stability and surface quality of the finished pipe. If the cooling process is not properly controlled, all the previous efforts will be wasted, and the qualified finished pipe will become unqualified.

The key technical control points of the cooling link are mainly three: first, cooling method selection, second, cooling speed control, third, cooling uniformity control. During the internship, I learned that the cooling method of the finished pipe is mainly determined by the material of the finished pipe and the requirements of mechanical properties, and the common cooling methods include natural cooling, air cooling, water cooling and spray cooling.

Natural cooling is the simplest cooling method, which only needs to place the finished pipe after expansion on the cooling platform and let it cool naturally at room temperature. This method has the advantages of low cost and no additional equipment investment, but the cooling speed is slow, the production efficiency is low, and the metal structure of the finished pipe is easy to be coarse, which is only suitable for ordinary carbon steel finished pipes with low mechanical performance requirements. Air cooling is to use a fan to blow air to the finished pipe to accelerate the heat dissipation of the finished pipe. The cooling speed is faster than natural cooling, and the cooling effect is more uniform. It is suitable for Q355 and other high-strength steel finished pipes. Water cooling is to immerse the finished pipe in cold water or spray cold water on the surface of the finished pipe to cool it quickly. The cooling speed is the fastest, which can effectively refine the grains of the finished pipe and improve its hardness and strength. It is suitable for stainless steel and other alloy steel finished pipes. However, water cooling also has certain risks. If the cooling speed is too fast, it will lead to excessive internal stress of the finished pipe, resulting in surface cracks or even fracture.

Cooling speed control is the core of the cooling link. Different materials of finished pipes have different requirements for cooling speed. For ordinary carbon steel finished pipes, the cooling speed can be appropriately slower, generally controlled at 50-80℃/min, to avoid excessive internal stress; for high-strength steel and stainless steel finished pipes, the cooling speed needs to be faster, generally controlled at 80-120℃/min, to refine the grains and improve mechanical properties, but it cannot be too fast. During the internship, I once made a mistake in adjusting the water cooling speed: when cooling 304 stainless steel finished pipes, I adjusted the water flow too large, resulting in the cooling speed reaching 150℃/min. As a result, many fine cracks appeared on the surface of the finished pipe, which could only be scrapped. The workshop master told me that for stainless steel finished pipes, the maximum cooling speed should not exceed 120℃/min, otherwise it will cause excessive internal stress and cracks.

Cooling uniformity control is also very important. The finished pipe must be cooled uniformly, and there should be no local rapid cooling or local slow cooling. Otherwise, the internal stress of the finished pipe will be uneven, leading to deformation, ellipse or cracks. To ensure cooling uniformity, we mainly took three measures: first, when using air cooling or spray cooling, the fan or spray nozzle should be evenly arranged to ensure that all parts of the finished pipe can be cooled uniformly; second, during the cooling process, the finished pipe should be turned regularly to avoid uneven cooling caused by the contact between the finished pipe and the cooling platform; third, the temperature of the cooling medium (air or water) should be kept stable, and the temperature difference should not be too large. During the internship, we used a temperature sensor to monitor the temperature of the cooling water in real time, and adjusted the water flow in time to keep the water temperature stable at 20-30℃.

3.3.6 Finishing

Finishing is the link to improve the surface quality and dimensional accuracy of the finished pipe after cooling, and also the last processing link before the finished pipe leaves the factory. Its core purpose is to remove the defects such as oxide scale, scratches, burrs and uneven ends on the surface of the cooled finished pipe, adjust the dimensional accuracy and straightness of the finished pipe, and make the finished pipe meet the standard requirements and customer needs. The quality of finishing directly affects the appearance quality and market competitiveness of the finished pipe. During the internship, I participated in the finishing link for a period of time, mainly responsible for the polishing and end trimming of the finished pipe.

The finishing link mainly includes four steps: polishing, end trimming, straightening and rust prevention treatment. Each step has its key technical control points. First, polishing. The purpose of polishing is to remove the oxide scale, scratches and burrs on the inner and outer surfaces of the finished pipe, make the surface of the finished pipe smooth and flat, and improve the surface quality. The polishing of the outer surface mainly uses an automatic polishing machine, and the polishing of the inner surface uses a special inner surface polishing tool. The polishing speed and pressure need to be strictly controlled: the polishing speed is generally 15-20m/min, and the polishing pressure is 0.4-0.6MPa. If the polishing pressure is too large, it will scratch the surface of the finished pipe; if the pressure is too small, the oxide scale and scratches cannot be completely removed.

Second, end trimming. After expansion and cooling, the two ends of the finished pipe may have unevenness, burrs or excessive length, which need to be trimmed. The end trimming mainly uses a cutting machine to cut the two ends of the finished pipe to the specified length, and then uses a grinding machine to grind the end face to make it flat and smooth, without burrs. The length deviation of the finished pipe after trimming must be controlled within ±3mm, and the perpendicularity of the end face and the pipe axis must meet the requirements (perpendicularity deviation ≤0.5mm/m). During the internship, I once trimmed the end of a DN800 finished pipe too short due to carelessness, resulting in the length of the finished pipe not meeting the customer’s requirements, so it had to be scrapped. This incident made me realize that the end trimming link must be careful and strictly follow the specified length.

Third, straightening. Although the mother pipe has been straightened during the pretreatment link, the finished pipe may still have slight deformation during expansion and cooling, so it needs to be straightened again during the finishing link. The straightening method is the same as that of the mother pipe pretreatment, using a hydraulic straightener, and the straightening pressure is controlled at 8-15MPa. The straightness of the finished pipe after straightening must meet the requirements (straightness deviation per meter ≤0.8mm), which is stricter than that of the mother pipe. For high-precision finished pipes, we also use a precision straightener to further improve the straightness.

Fourth, rust prevention treatment. Rust prevention treatment is to prevent the finished pipe from rusting during storage and transportation, and extend its service life. The rust prevention treatment method mainly depends on the use environment of the finished pipe: for finished pipes used in ordinary environments, we use anti-rust oil to coat the inner and outer surfaces of the finished pipe; for finished pipes used in humid or corrosive environments, we use galvanizing or painting treatment to improve the corrosion resistance. During the internship, we usually use a sprayer to spray anti-rust oil evenly on the surface of the finished pipe, and ensure that the anti-rust oil covers the entire surface without missing parts. At the same time, we also need to control the thickness of the anti-rust oil, which is generally 0.1-0.2mm. If the thickness is too large, it will affect the subsequent use of the finished pipe; if the thickness is too small, it cannot play a good anti-rust role.

3.3.7 Finished Product Inspection

Finished product inspection is the last line of defense to ensure the quality of the Guanzhong medium and high frequency heat-expanded seamless steel pipe, and also the key link to ensure that the finished pipe meets the standard requirements and customer needs. Its core purpose is to comprehensively inspect the dimensional accuracy, surface quality, mechanical properties and other indicators of the finished pipe after finishing, and screen out unqualified products to avoid unqualified products flowing into the market. During the internship, my last post was finished product inspection, and I learned a lot of professional knowledge and operation skills related to finished product inspection.

The key technical control points of the finished product inspection link are mainly three: first, inspection items and standards, second, inspection methods, third, unqualified product handling. The inspection items of the finished pipe mainly include four categories: dimensional accuracy inspection, surface quality inspection, mechanical properties inspection and chemical composition inspection. Each inspection item has clear national standards or industry standards, which must be strictly implemented.

Dimensional accuracy inspection mainly includes diameter, wall thickness, length, straightness, ovality and other indicators. The diameter inspection uses a caliper or a diameter measuring instrument to measure multiple points at different positions of the finished pipe, and the diameter deviation must be controlled within ±1% of the nominal diameter; the wall thickness inspection uses an ultrasonic thickness gauge to measure multiple points, and the wall thickness deviation must be controlled within ±5%; the length, straightness and ovality inspection are carried out according to the corresponding standards. Surface quality inspection mainly uses visual inspection and magnifying glass inspection to check whether the surface of the finished pipe has defects such as cracks, scratches, oxide scale, burrs and corrosion. If there are defects, it needs to be reprocessed; if the defects are too serious, it needs to be scrapped.

Mechanical property testing mainly includes tensile strength, yield strength, elongation, and impact toughness. The testing method involves taking samples from the finished pipe according to standard requirements and testing them on a universal testing machine and an impact testing machine. The test results must meet the requirements of the corresponding material standards. For example, the tensile strength of Q355 hot-expanding seamless steel pipe must be ≥355MPa, and the elongation must be ≥21%. Chemical composition testing mainly examines the content of elements such as C, Si, Mn, S, and P in the finished pipe to ensure that its chemical composition meets the requirements of the material standards. The testing method mainly uses spectral analysis, which is rapid and accurate.

During the internship, I once detected a batch of Q355 finished pipes with unqualified tensile strength: the tensile strength of the sample was only 340MPa, which was lower than the standard requirement of 355MPa. We immediately reported this situation to the workshop director, and the workshop organized technical personnel to investigate the reason. Finally, it was found that the heating temperature during the induction heating link was too low, resulting in insufficient plastic deformation of the mother pipe and unqualified mechanical properties of the finished pipe. The batch of finished pipes was all scrapped, and the relevant operators were trained and educated. This incident made me deeply realize that the finished product inspection link is crucial, which can timely find unqualified products and avoid greater economic losses.

For unqualified products, we must strictly handle them in accordance with the enterprise’s quality management system: unqualified products that can be reprocessed (such as slight scratches, excessive wall thickness deviation) are sent back to the corresponding link for reprocessing, and they can leave the factory only after passing the inspection again; unqualified products that cannot be reprocessed (such as cracks, unqualified mechanical properties) are scrapped, and the scrapped products are recycled and reused as raw materials to avoid waste. At the same time, we must record all inspection results in detail, including qualified products and unqualified products, so as to facilitate subsequent quality traceability and process optimization.