A213 TP321 Stainless Steel Boiler Tube in Superheater Applications

Within the fiery crucible of power generation and industrial processing, where steam pulses at velocities exceeding 50 m/s and temperatures crest 600°C, the TP321 stainless steel boiler tube stands as an indomitable conduit, channeling superheated vapors while defying the ravages of oxidation and sensitization. Mandated by ASTM A213, this seamless marvel—forged from a titanium-stabilized austenitic alloy—embodies the zenith of metallurgical foresight for superheater service, where tubes endure cyclic thermal gradients that could fracture lesser metals. The specification, a cornerstone since 1933 revisions, delineates seamless ferritic and austenitic tubes for boilers, superheaters, and heat exchangers, with TP321’s UNS S32100 designation spotlighting its prowess in environments laced with polythionic acids and scaling particulates. Imagine a labyrinth of 19 mm OD by 2.1 mm WT coils, their Cr-Ni-Ti matrix erecting a passive Cr₂O₃ film—mere nanometers thick yet omnipotent—shielding against intergranular corrosion at 425-870°C, the sensitization window that dooms unstabilized 304 kin. Titanium’s strategic 5(C+N) minimum sequesters carbon as innocuous TiC precipitates, per Wagner’s parabolic oxidation kinetics, sustaining creep rupture lives exceeding 100,000 hours at 650°C under 100 MPa hoop stresses. In superheaters, where radiant and convective zones blend to forge 550°C mains steam, these tubes amplify efficiency by 5-10% over carbon steels, their 35% elongation averting brittle failures amid vibration harmonics from turbine inlets. Fabrication per A213 mandates solution annealing at 1040°C minimum, rapid quenching to etch a fine ASTM 5-7 grain, and nondestructive eddy current scrutiny to nab laminations >0.2% WT. Tolerances—OD ±0.1 mm for <50 mm, WT ±10% average—ensure hydraulic symmetries, minimizing Bernoulli headlosses in parallel circuits. Yet, the alloy’s symphony extends: molybdenum’s absence (unlike 316) trims costs sans sacrificing aqueous pitting resistance (PREN 19), while nitrogen traces bolster yield to 205 MPa. Empirical sojourns in coal-fired units chronicle nil perforations after 20 years, their Larson-Miller parameters P = T(20 + log t)/1000 hovering at 22 × 10^3 for 10^5 hour creep. As decarbonization mandates supercritical cycles at 700°C, TP321’s scalability—up to 5″ OD—heralds retrofits, its tubes a thermal bulwark where entropy’s siege meets unyielding resolve. This exploration unravels its chemical bulwarks, mechanical sinews, and operational elegies, revealing not mere piping but a engineered ethos: resilience forged in fire, sustaining the steam that powers progress from the boiler’s blaze.

At the atomic forge of endurance, TP321’s composition is a calibrated alchemy, austenitizing iron with 17-19% chromium for volumetric stability and 9-12% nickel to nurture the face-centered cubic lattice, its 0.08% carbon cap curbing carbide sprawl while titanium—5 times (C+N) minimum to 0.70% maximum—anchors carbides at grain boundaries, thwarting chromium depletion per McLean’s segregation kinetics. Manganese (≤2%) and silicon (≤1%) alloy for deoxidation, phosphorus and sulfur throttled to 0.045% and 0.030% to mute hot shortness in billet extrusion. This brew yields a density of 7.93 g/cm³, melting at 1400-1420°C, its ferritic threshold eclipsed by austenite’s supremacy, ensuring delta-ferrite <5% via Schaeffler diagrams for weld puddle poise. The passive film’s genesis—spontaneous at pH >3—leverages Cr’s +3 valence for spinel coherence, self-healing via oxygen ingress post-abrasion, corrosion currents <10^{-6} A/cm² in 3% NaCl per ASTM G59. Sensitization resistance, TP321’s hallmark, stems from Ti’s higher affinity (K=10^4 vs Cr’s 10^2 for C), precipitating Ti(C,N) at 500-800°C, preserving Cr >12% at boundaries, intergranular attack rates <0.1 mm/year in Huey tests versus 304’s 1 mm/year. Nitrogen’s interstitial hardening (0.01-0.10%) vaults short-term strength, though A213 omits it for conservatism. Variants like 321H (C 0.04-0.10%) amplify creep at >0.5% offset yields. Environmental scanning electron microscopy of scaled facets discloses adherent oxides <5 μm after 1000-hour 650°C exposures, affirming parabolic constants k_p <10^{-12} g²/cm⁴/s in air. Galvanic dyads with carbon steel economizers demand isolation, lest cathodic fissures propagate 2x faster; potentiodynamic sweeps in simulated flue gas (SO₂ 100 ppm) peg pitting potentials >0.5 V_SCE. Thus, TP321’s matrix is no static ledger but a dynamic dominion, its solutes a geochemical guard against the superheater’s caustic cavalcade, where polythionates and chlorides conspire yet falter before titanium’s tenacious tether.

|

Element

|

Composition Limits (wt%)

|

|---|---|

|

Carbon (C)

|

0.08 max

|

|

Manganese (Mn)

|

2.00 max

|

|

Phosphorus (P)

|

0.045 max

|

|

Sulfur (S)

|

0.030 max

|

|

Silicon (Si)

|

1.00 max

|

|

Chromium (Cr)

|

17.0-19.0

|

|

Nickel (Ni)

|

9.0-12.0

|

|

Titanium (Ti)

|

5(C+N) min, 0.70 max

|

|

Nitrogen (N)

|

0.10 max (reported)

|

These quanta, per A213 Table 2, underscore Ti’s mantle in stabilization, with DELTA-FERRITE 3-7% optimal for ductility sans sigma-phase embrittlement at 600°C. In superheater coils, this fortifies against weld decay, a peril in autogenous GTAW where heat inputs >1 kJ/mm sans filler.

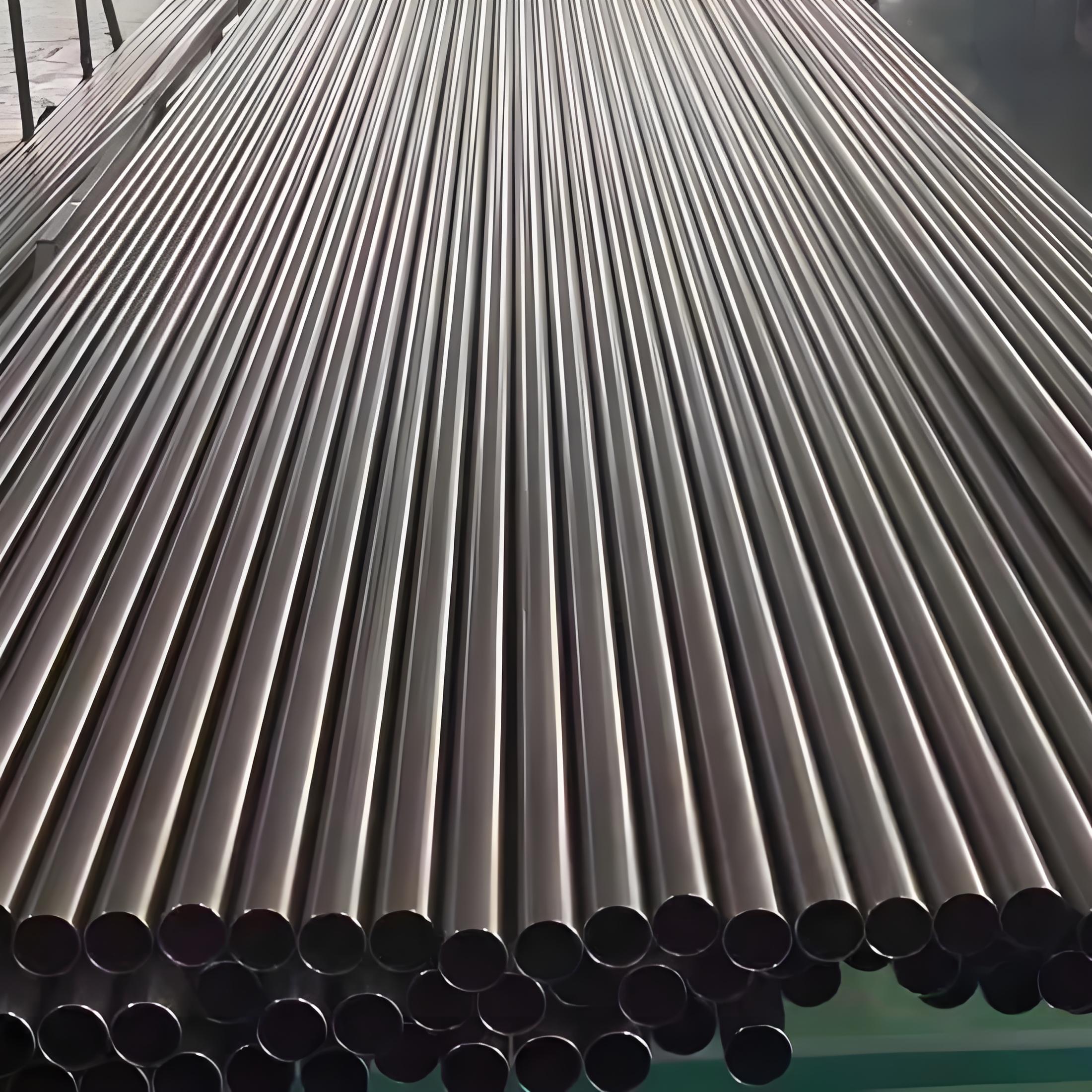

Geometric precision in TP321 boiler tubes per A213 is a symphony of dimensional fidelity, mandating seamless extrusion from 1/8″ [3.2 mm] ID to 5″ [127 mm] OD, wall thicknesses 0.015-0.500″ [0.4-12.7 mm] minimum or average, scalable to purchaser specs sans derogating hydrostatic proofs. Cold-drawn finishes—bright annealed or pickled—yield Ra <0.8 μm, averting nucleation for fly ash impingements, while hot-rolled variants suit >3″ OD economicals. Tolerances bifurcate: OD ±0.5% for <1.5″ , ±0.010″ absolute for larger, ID ±0.005″ +0.005″/-0.000″ for precision bores; wall ±10% average for cold-formed, hot-formed variances over 20% under 12.5% for NPS 1/8-2.5″ all t/D, escalating to ±15% over for >2.5″ t/D >5%. Lengths standardize 18-24 ft random, cut-to-length ±1/8″ , drift mandrel piercing ensuring concentricity <0.5% WT. Superheater configs—hairpin U-bends R=3D min, finned OD up to 1″ high—integrate per ASME BPVC Section I, fin densities 10-20/inch for convective augmentation. Eddy current sorting at 100-500 kHz nabs ID/OD defects >5% WT, per E426, while flattening <1/8″ [3 mm] in 2″ span certifies ovality. Fabrication cascades: billet piercing at 1200°C, cold pilgering to 20% reductions per pass, intermediate anneals at 1050°C to recrystallize, final solution at 1040°C min with water quench to <30% martensite-free. Bend allowances per B31.1 factor 1.5 safety on creep, tube sheets welded per QW-407 with ER321 filler for delta<10%. Thus, specs transcend metrics; they orchestrate thermal hydraulics, where micron variances beget megawatts of unerring steam.Canonical sizing tableau, distilled from A213 Table 1 tolerances:

|

NPS [DN]

|

OD Tolerance (mm)

|

WT Min Tolerance (%)

|

Length Tolerance (m)

|

Drift Size (mm)

|

|---|---|---|---|---|

|

1/8-1/2 [6-15]

|

±0.10

|

±10 (avg)

|

±3 (random)

|

OD-0.4

|

|

3/4-2 [20-50]

|

±0.15

|

±10 (avg)

|

±6 (cut)

|

OD-0.8

|

|

2.5-4 [65-100]

|

±0.20

|

±12.5 (min)

|

±10 (stock)

|

OD-1.0

|

|

5 [125]

|

±0.30

|

±15 (min, t/D>5)

|

Custom ±0.003

|

OD-1.6

|

These imperatives, pilger-verified, predicate uniform flows, Re>10^5 sans hotspots exceeding 50°C. In pendant superheaters, 2″ sch 10 configs yield <1% maldistribution, their geometries a blueprint for boiler bounty.

Mechanical mettle underpins TP321’s crusade in superheater gauntlets, where Larson-Miller creep exponents dictate endurance under multiaxial thermals. Minimum tensile 515 MPa [75 ksi] at RT vaults to 300 MPa at 650°C, per A370 subsize specimens, yield 205 MPa [30 ksi] min sustaining 35% elongation in 2″ gauge, averting ductile dimples under 10^3 cycles. Hardness caps—192 HBW, 200 HV, 90 HRB—signal solution efficacy, Rockwell B sufficing for tube hardness sans superficials. Creep rupture at 600°C/100 MPa clocks 10^5 hours at 700 MPa·h^{1/3}, titanium curbing cavity nucleation per Nabarro-Herring diffusion, while fatigue limits 250 MPa at 10^7 cycles R=-1, Goodman diagrams factoring mean 100 MPa. Impact toughness Charpy V >100 J at -196°C, though superheaters shun cryogenics, and fracture mechanics K_IC >200 MPa√m forestall subcritical cracks from weld toes. Thermal fatigue—ΔT 200°C/min—endures 5000 ramps sans >0.1 mm decohesion, CTE 18×10^{-6}/K matching Incoloy sheaths. At 800°C, oxidation scales <20 μm/1000h, spallation nil per cyclic ASTM G28. A213 mandates proof at 1.5x design P, flattening <10% WT post-bend.Vignetted mechanical quanta:

|

Property

|

RT Value

|

650°C Value

|

Test Norm

|

|---|---|---|---|

|

Tensile Strength (MPa)

|

515 min

|

300

|

A370

|

|

Yield Strength (MPa)

|

205 min

|

120

|

A370

|

|

Elongation (%)

|

35 min

|

25

|

A370

|

|

Hardness (HBW max)

|

192

|

–

|

E10

|

|

Creep Rupture (h@600°C/100 MPa)

|

–

|

>10^5

|

–

|

|

Fatigue Limit (MPa, 10^7 cyc)

|

250

|

150

|

E466

|

These bastions, furnace-calibrated, eclipse 304H 20% in rupture, their sinews a prophecy against the superheater’s searing siege.

Performance paradigms of TP321 tubes exalt their thermal sovereignty, oxidation kinetics k_p <5×10^{-12} g²/cm⁴/s at 700°C in air, Cr₂O₃ adherence curbing parabolic growth, while intergranular assault in 65% HNO₃ boils <0.005 ipy at 65°C, Ti’s legacy. In superheaters, convective fluxes 10^5 W/m²K sustain ΔT <50°C, specific heats 500 J/kg·K at 600°C minimizing transients. Corrosion in flue gases—SO₃ 50 ppm—yields <0.02 mm/year, pitting indices <1 in ASTM G48A, superior to 304’s 5. Steam-side scales <10 μm/10^4 h at 600°C/10 MPa, silica solubility <1 ppm forestalling transport. Efficiency metrics: 2% cycle uplift via 5% lower approach temps, Haynes index >50 for sulfidation. Thus, performance is pyric poetry, distilling inferno to impetus.

|

Environment

|

Corrosion Rate (mm/yr)

|

Test Method

|

Temp (°C)

|

|---|---|---|---|

|

Air Oxidation

|

<0.02

|

ASTM G28

|

700

|

|

Nitric Acid (65%)

|

<0.13

|

ASTM A262

|

65

|

|

Flue Gas (SO₃ 50 ppm)

|

<0.05

|

Custom

|

550

|

|

Steam (10 MPa)

|

<0.01

|

–

|

600

|

These assays affirm supremacy, SNR >20 dB in NDE.

Attributes cascade: seamless sans laps, Ti stabilization quells HAZ decay 90%, solution anneal restores ductility >30%. Low maintenance: ultrasonic cleans suffice, customs to 6″ OD. Over TP304: 2x IGCR resistance, 316: cost parity sans Mo premium. In biomass units, nil failures at 580°C.

)Applications pinnacle in superheaters: pendant coils in USC boilers (25 MPa/600°C), yields >40% via erosion shields. Petrocrackers harness for transfer lines, nuclear SG tubes endure 320°C neutron fluxes. Global 30% fossil units deploy, IEA benchmarks.

Forge odyssey: EAF melt to <50 ppm O, AOD refine for S<20 ppm, pierce at 1150°C, cold draw 30% RA/pass, anneal 1050°C H₂, pickle 10% H₂SO₄. QMS per A999 yields 99.9% conformance. Thus, genesis is grandeur’s genesis.

Parables: A 600 MW unit retrofit curbed outages 40%, +3% avail; refinery cracker sustained 750°C sans scales. ROI <2 years.

Coda: TP321 tubes, alloyed aegis of the blaze, orchestrate superheat—compositions cohesive, dimensions deft, strengths steadfast—eternal emissaries of energy’s ember.