The choice between Inconel® X-750 (UNS N07750) and Nickel Alloy 600 depends largely on the specific requirements of the application: Choose Inconel X-750 for high-stress, high-temperature applications where mechanical strength, fatigue resistance, and creep resistance are critical (e.g., aerospace, nuclear, and gas turbines). Choose Nickel Alloy 600 for versatile corrosion resistance in general-purpose applications or where fabrication and cost-efficiency are more important (e.g., chemical processing, marine, and heat exchangers).

Blog

Hastelloy C276 alloy steel pipes, produced under ASTM B622 UNS N10276 standards, are indispensable in industries that demand high corrosion resistance and durability. With its exceptional properties, wide-ranging applications, and long lifespan, this material remains a top choice for critical applications. Investing in Hastelloy C276 ensures reliability and performance, even in the most challenging environments.

Hastelloy C-276 stands out as one of the most versatile and corrosion-resistant alloys available today. Its unique properties make it indispensable in industries where performance and reliability are paramount. From resisting aggressive acids in chemical plants to enduring the harsh conditions of marine environments, Hastelloy C-276 has proven its worth time and again. While its high cost and fabrication challenges may pose limitations, the benefits it offers far outweigh these drawbacks for critical applications.As global industries continue to push the boundaries of innovation, Hastelloy C-276 will remain a cornerstone material for demanding environments, ensuring safety, efficiency, and durability for years to come.

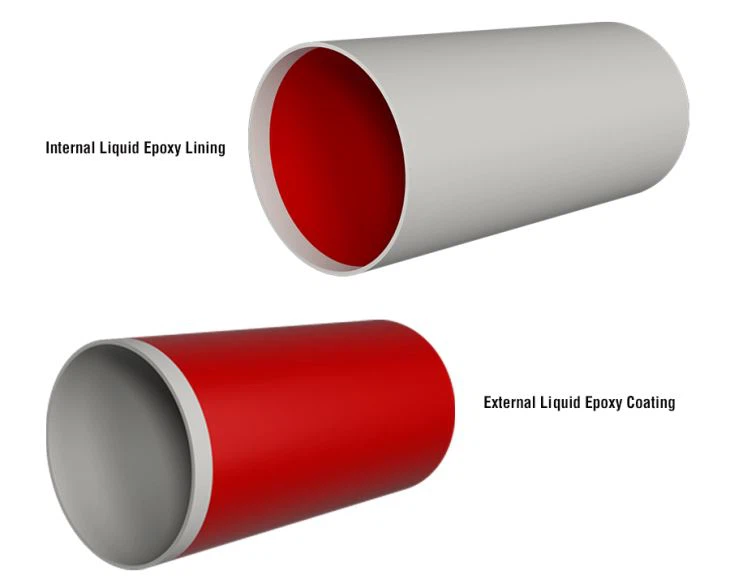

Liquid-epoxy coatings and linings are essential for protecting steel water pipes and fittings in water infrastructure systems. From their superior corrosion resistance to their adaptability for various applications, these coatings ensure the long-term performance and safety of pipelines. By adhering to proper application techniques, inspection protocols, and industry standards, project managers and engineers can maximize the benefits of epoxy coatings. Whether you're working on a potable water system or a wastewater project, liquid-epoxy coatings provide a durable, cost-effective, and environmentally friendly solution to meet the demands of modern water infrastructure.

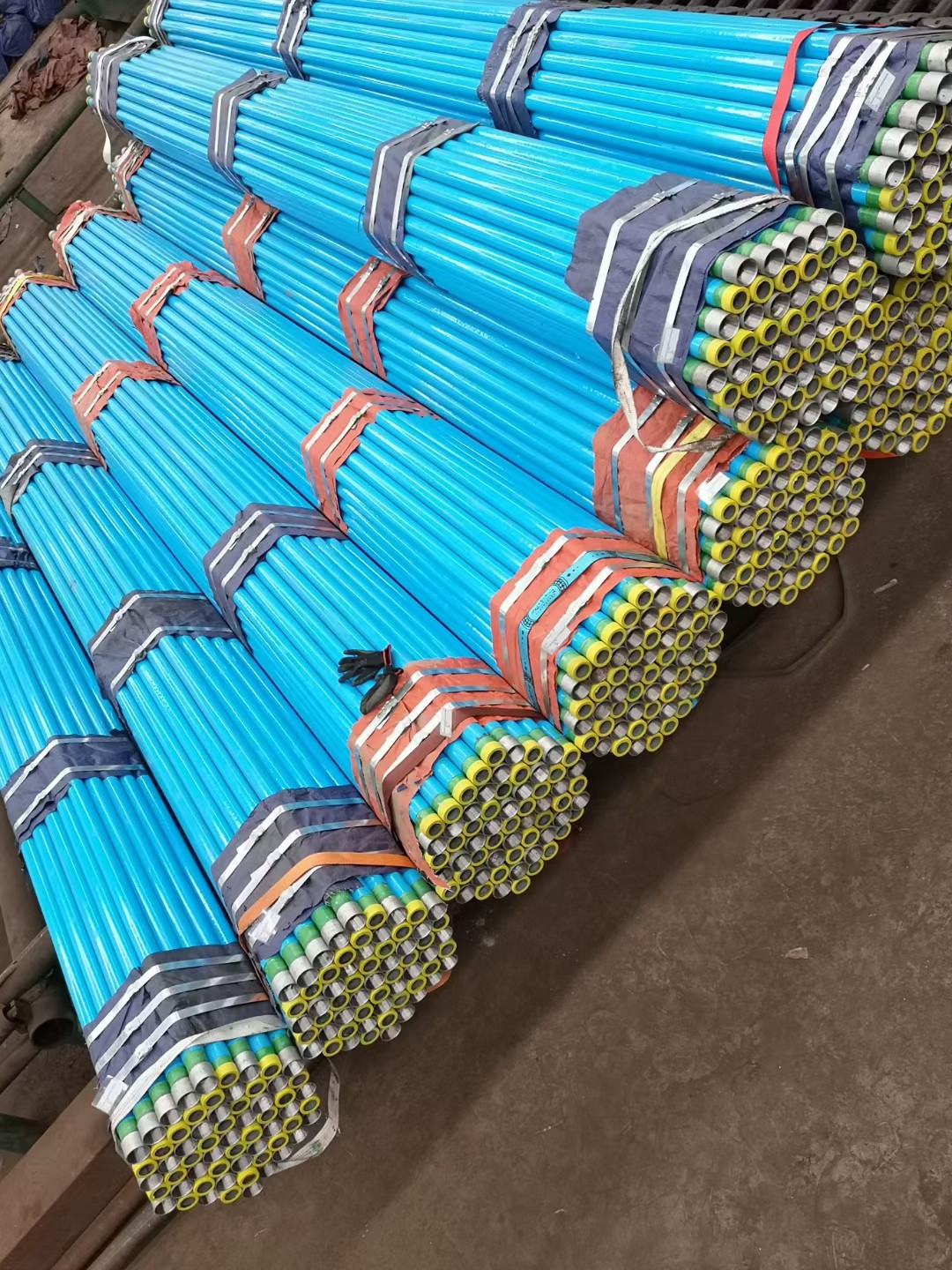

Epoxy-coated steel pipes are essential for ensuring the durability, safety, and efficiency of water supply, drainage, and dredging systems. By complying with international standards and offering superior corrosion resistance, epoxy-coated pipes deliver exceptional performance in harsh operating conditions.

Duplex 2205 (UNS S32205) steel pipe is a high-performance material that offers a blend of strength, corrosion resistance, and durability. Ideal for use in challenging environments like oil and gas, marine applications, and chemical processing, it outperforms standard austenitic steels in many areas. However, its higher cost and welding challenges may make it less ideal for less demanding applications.

The CFD analysis of water flow inside buttweld elbow pipes reveals that the normal-edged elbow pipe outperforms the sharp-edged elbow pipe in terms of flow efficiency, energy consumption, and structural integrity. Key findings include:

ASTM A210 Grade A1 Seamless Tube shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. The offered ASTM A210 GR A1 CS Seamless Tubes is availed in diverse sizes and other related specifications, to meet requirements of our prominent clients.ASME SA 210 Gr.A1 Boiler Pipes that is designed according to set industry standards. As per the needs and requirements of our clients, we are involved in providing ASME SA 210 Gr. A1 Boiler Tubes. Buy ASTM A210 Grade A1 Boiler Tubes at reasonable cost from us.

When selecting between seamless and welded high nickel alloy pipes, consider factors such as pressure requirements, corrosion resistance, cost, and size availability to ensure that you choose the right type of pipe for your project. For more information or assistance in selecting the right pipe, consult with a materials specialist or supplier who can help guide you through the decision-making process.

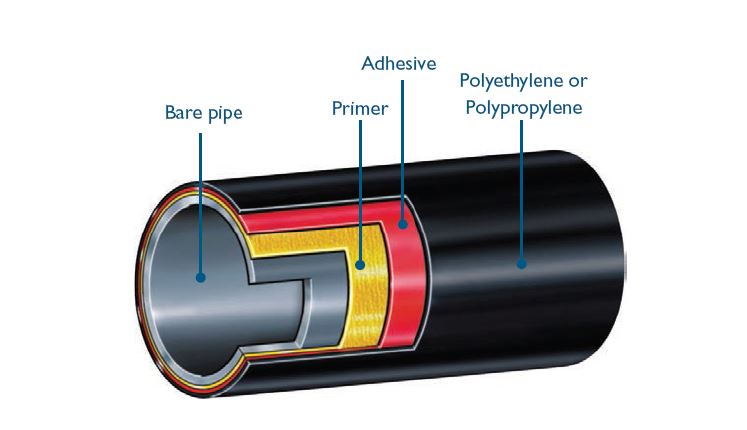

Both 3LPP and 3PE coatings provide excellent protection for steel pipelines, but they are designed for different operating conditions. 3LPP coatings, with their high-temperature resistance and superior mechanical strength, are ideal for pipelines in harsh environments or those transporting hot fluids. On the other hand, 3PE coatings, with their cost-effectiveness and good flexibility, are better suited for pipelines in moderate environments where temperature and mechanical stress are lower.

Welded joints in ASTM A335 P5 alloy steel pipes are susceptible to various forms of corrosion, particularly in harsh environments. The welding process, heat-affected zone, and post-weld heat treatment all play critical roles in determining the corrosion behavior of the material. By employing proper welding techniques,

By following these guidelines, operators can effectively manage the integrity of corroded pipes, ensuring continued safe operation in challenging environments.

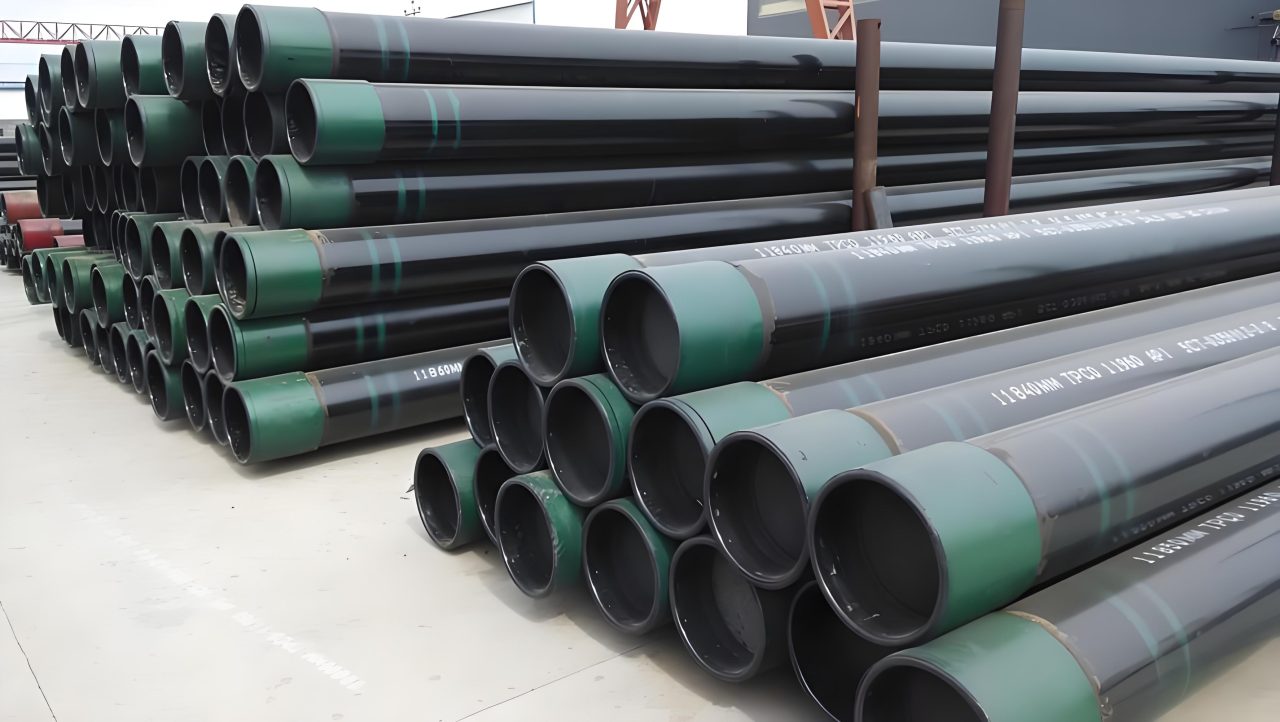

The casing pipe market is poised for growth and transformation as it adapts to evolving industry demands and technological advancements. While challenges such as raw material price volatility and supply chain disruptions persist, the market's resilience and innovation capacity offer significant opportunities for growth. As we approach 2025, the focus on sustainability, smart technologies, and advanced materials will shape the future of the casing pipe market, ensuring its continued relevance and contribution to the global energy landscape.

Connection technology for casing pipes is a critical component of well construction, ensuring the safe and efficient operation of oil and gas wells. From traditional threaded and welded connections to advanced mechanical and smart technologies, the industry continues to innovate to meet the demands of increasingly challenging environments. By selecting the appropriate connection technology and adhering to best practices, operators can optimize well performance, enhance safety, and extend the lifespan of their wells.

The phases of drilling, casing, and tubing are integral to the successful development of an oil or gas well. Each phase requires careful planning, precise execution, and adherence to safety and environmental standards. By understanding and effectively managing these phases, operators can optimize production, minimize risks, and ensure the longevity of the well. As technology advances, new techniques and materials continue to enhance the efficiency and safety of these operations, contributing to the ongoing evolution of the oil and gas industry.

Well casing pipe damage poses significant challenges to the integrity and efficiency of wells. Understanding the causes of damage and employing appropriate repair technologies are essential for maintaining safe and effective operations. From corrosion and mechanical stress to seismic activity and abrasive wear, various factors can contribute to casing damage. By utilizing a combination of traditional repair methods and advanced technologies, operators can effectively address these issues and extend the lifespan of their wells. Additionally, implementing preventive measures and best practices can help minimize the risk of damage and ensure the continued success of well operations. As technology continues to evolve, new solutions and materials will further enhance the ability to prevent and repair well casing pipe damage, contributing to the sustainability and safety of the oil and gas industry.

In summary, while both coating and lining are essential for protecting pipelines, they serve distinct purposes and are applied in different contexts. Coating focuses on external protection, shielding pipes from environmental factors, while lining addresses internal protection, safeguarding pipes from the substances they carry. Both processes offer significant benefits, including corrosion resistance, enhanced flow efficiency, and extended service life. As technology continues to advance, the effectiveness and sustainability of coating and lining methods are expected to improve, ensuring the continued reliability and safety of pipeline systems across various industries.

hot dipped galvanized tubes Scaffolding pipes,pre galvanized steel tubes,GI pipes and tubes, hot dipped pipes and tubes play more good role on the outdoor using such as bridge pipes, warehouse, street lamp, and telegraph poles, and also for the liquid pipes, useful widely. pre-galvanized steel pipes used in Construction / building materials steel pipe, Scaffolding pipe, Solar structure component steel pipe, Fence post steel pipe, Greenhouse frame steel pipe.

Each type of scaffold tube and pipe offers distinct advantages and is selected based on the specific requirements of the construction project, including factors such as load capacity, environmental conditions, and budget constraints. By choosing the appropriate material, construction professionals can ensure the safety and efficiency of their scaffolding systems.

Scaffolding Pipe is a vital component of the construction industry, providing safe access to elevated work areas and supporting the efficient completion of projects. Understanding the necessity of Scaffolding Pipe, how it is assembled, the materials used in its construction, and the processes involved in inspecting it for safety is essential for ensuring the safety and success of construction projects. By adhering to best practices and safety standards, construction professionals can minimize risks and create a safe working environment for all involved.

The design of application pressure for chemical pipelines is influenced by a combination of chemical properties, flow rate requirements, friction loss, material selection, and environmental conditions. By carefully considering these factors, engineers can ensure the safe and efficient transport of chemical substances, minimizing risks and maintaining the integrity of the pipeline.

Casing pup joints are essential components in the construction and operation of oil and gas wells. They allow for precise adjustment of the casing string length, ensuring proper placement of downhole equipment and alignment with wellhead components. Selecting the appropriate pup joints based on diameter, material grade, and thread type is crucial for maintaining well integrity, safety, and efficient operation.

Couplings are short lengths of pipe used to connect 2 joints of tubing or casing. They come with painted colour codes on their external surface to indicate their grades. Couplings are manufactured according to API 5CT and 5B specifications.

Drill pipe is a steel pipe with thread at the end, which is used to connect the surface equipment of the drilling rig to the drilling and grinding equipment or the bottom hole equipment at the bottom of the drilling. Drill pipe can be divided into three categories: kelly, drill pipe and heavy drill pipe. Drill collar is located at the bottom of the drill string and is the main component of the lower drill tool assembly. Its main feature is that the wall thickness is larger, and it has greater gravity and rigidity. In order to facilitate tripping work, elevator grooves and slip grooves can be processed on the outer surface of the inner thread of the drill collar. Drill collars are generally divided into three types: spiral drill collars, non-magnetic drill collars, and integral drill collars.

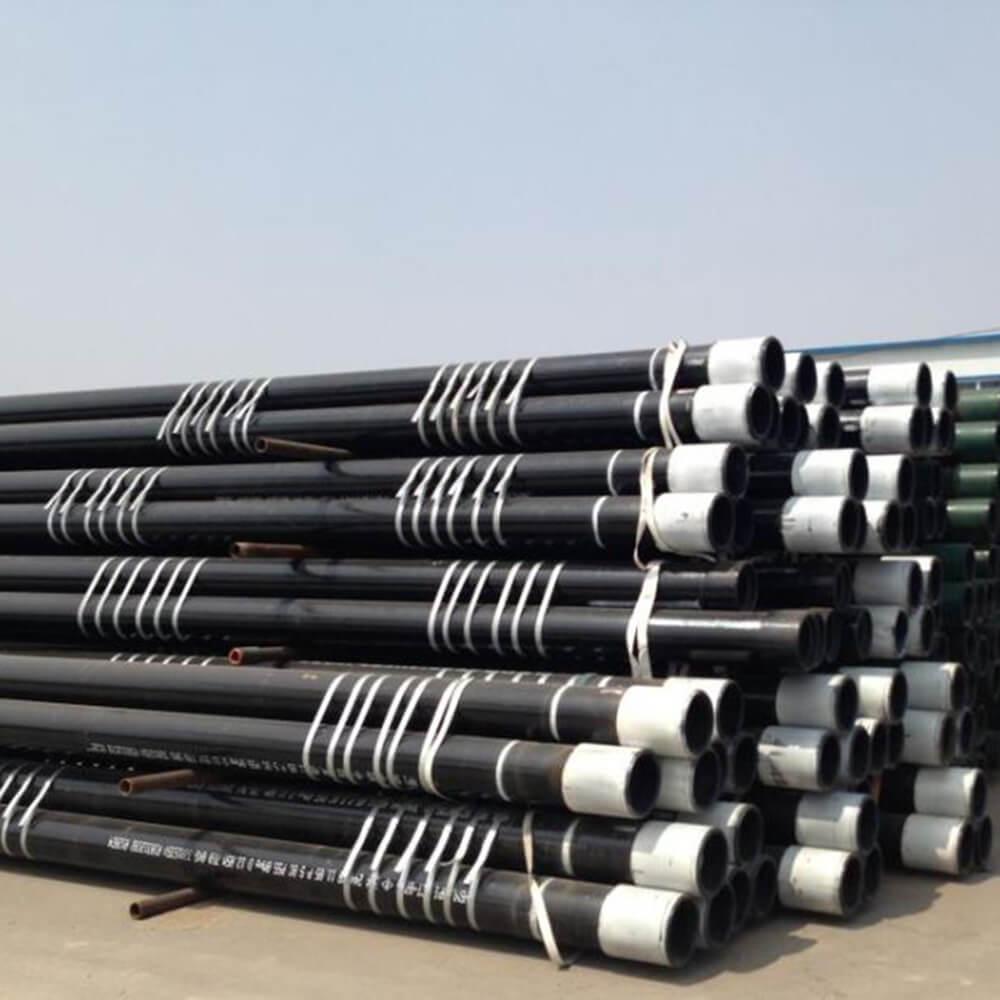

Slotted pipe are used for oil and gas wells. Steel casing pipes and tubing are applied to furnishing and installing cased tunnels, where they indicate to pass other utilities or obstructions without open excavation. Steel casing pipes and tube have smooth wall and a minimum yield strength of 35,000 psi. Corrosion-proofing water-based paint is applied on the outside pipe surface to protect against atmospheric corrosion during transportation and storage.

Petroleum special pipes are mainly used for drilling oil and gas wells and oil and gas transportation. Oil casing is mainly used to support the wellbore during driling and after completion to ensure the normal operation of the wholewell, Oil casing is the lifeline to maintain oil well operation. Because of the different aeolodical conditions.the stress state of underground is complex, and the comprehensive action of tension, compression, bending and torsion stresses acts on the pipe body, which puts forward higher requirements for the quality of casing itself.

oil casing And Seamless Pipe, Seamless 5ct Petroleum Casing Pipe, Petroleum Casing Pipe, Petroleum Tubing, Oil Casing Pipe, Casing & Tubing, Smls Steel pipes And Casing Tubing, API 5ct Oil Casing Pipe, API 5ct Oilfield Tubing, API 5CT V150 Petroleum Casing Pipe, Grade V150 Oil Well Drilling Tube

API 5CT Q125 oil well casing pipe and tubing is a type of steel pipe with special threads that are used in petroleum well drilling. The API 5CT Q125 oil well casing pipe and tubing is mainly used to protect the well wall from damage in order to ensure the normal operation of the well. The API 5CT Q125 oil well casing pipe and tubing are made of high-quality steel pipes. There are two types of API 5CT Q125 oil well casing pipes: casing pipes and tubing pipes

P110 API casing or tubing is a relatively common one in Oil drilling. Because of the low steel grade of P110, it is used for shallow oil and gas extraction. Due to its low price among other grades of steel, it enjoys broader applications. P110 API casing or tubing is widely used in the extraction of natural gas and coalbed methane, and can be commonly found in shallow wells, geothermal wells, and water wells.

OD: 4-1/2“ to 20“/ 114.3mm to 508mm Wall Thickness: 5.21 - 16.13 mm Thread: STC.BTC.LTC Length: R1(4.88-7.62M). R2(7.62-10.36M). R3(10.36-14.63Meters) Standard: API 5CT Grade: J55, K55, M65, N80,N80-1, N80-Q, L80-1, L80-9Cr, L80-13Cr, C90, C95, T95, P110, Q125