DIN 30670 3LPE Coated Steel Pipe

Engineering Endurance: The Definitive Guide to DIN 30670 3LPE Coated Steel Pipe

The Unyielding Challenge of Corrosion in Global Infrastructure

In the vast, subterranean and sub-aquatic networks that constitute the arteries of global energy and resource transport, the threat of corrosion is relentless and absolute. Pipelines, which carry everything from crude oil and natural gas to essential potable water, face an aggressive, ceaseless electrochemical assault from soil, moisture, and chemical agents. A failure in these systems—driven primarily by corrosion—is not merely an operational inconvenience; it is an event with catastrophic consequences, demanding immense environmental remediation, halting production, and incurring astronomical economic damage.

I. The Material Foundation: Why Steel Needs a Shield

The journey of the coated pipe begins with the base steel itself. The pipe must be robust enough to handle internal pressure and external loads while maintaining weldability and structural integrity throughout its operational life.

Base Steel Specifications: The Inner Strength

Our core steel pipes are manufactured to the highest international standards, typically API Specification 5L or ISO 3183, which govern the use of steel pipe in pipeline transportation systems. The choice of steel grade is critical, as it defines the pipe’s mechanical performance profile—specifically its Yield Strength and Tensile Strength.

Commonly specified grades range from X42 to X70, providing the high strength necessary for modern high-pressure pipelines. The steel fabrication process—whether Seamless (SMLS) for high-pressure uniformity, Longitudinal Submerged Arc Welded (LSAW) for thicker walls, or Helical Submerged Arc Welded (HSAW) for large diameters—is certified before the coating process even begins.

| Base Steel Grade (API 5L/ISO 3183) | Minimum Yield Strength (MPa) | Core Application Environment |

| Grade B / L245 | 245 | General low-pressure fluid conveyance. |

| X52 / L360 | 360 | Standard mid-range transmission for oil and gas. |

| X65 / L450 | 450 | High-pressure, high-stress pipelines. |

| X70 / L485 | 485 | Critical long-distance, high-pressure transmission lines. |

The Essential Pre-Coating Step: Surface Preparation

No anti-corrosion system, however advanced, can succeed without immaculate surface preparation. The bond between the steel and the initial coating layer is the ultimate point of failure or success.

The DIN 30670 standard mandates a meticulous process: the pipe surface must be abrasive blasted to a finish of Sa 2 1/2 (Near-White Metal) or even Sa 3 (White Metal). This intense cleaning removes all rust, mill scale, and residual contaminants, simultaneously creating a specific anchor pattern (surface roughness profile) that maximizes the mechanical and chemical grip for the first layer—the FBE. This single step is the non-negotiable prerequisite for the long-term adhesion that defines the 3LPE system’s endurance.

II. The Anatomy of Protection: The 3LPE System Explained

The Three-Layer Polyethylene (3LPE) coating is a composite armor, strategically designed to offer complementary forms of defense. It combines the chemical passivation of a thermoset resin with the unparalleled mechanical toughness of a thermoplastic polymer. This synergistic structure ensures that the system is greater than the sum of its parts.

Layer 1: Fusion Bonded Epoxy (FBE)—The Chemical Shield

The FBE layer is the primary corrosion defense. It is a dry, thermosetting powder applied electrostatically to the pipe, which has been pre-heated to a precise temperature. Upon contact, the powder melts, flows, and chemically bonds directly to the prepared steel surface.

- Mechanism: FBE forms a highly cross-linked polymer network, creating an exceptionally dense, pinhole-free shield. This strong chemical adhesion is vital for preventing Cathodic Disbondment (CD). CD occurs when water, under the influence of the pipeline’s cathodic protection system, penetrates the coating and attempts to lift it off the steel. The FBE’s robust chemical bond resists this electrochemical separation better than any other primary coating layer. Its typical thickness is carefully controlled in the range of micrometers ().

Layer 2: Copolymer Adhesive—The Molecular Bridge

Applied immediately after the FBE while the epoxy is still in its partially cured, gel state, the adhesive layer serves a singular, critical function: chemical coupling.

- Function: This layer is a modified polyethylene polymer designed to react chemically with the FBE below and the Polyethylene (PE) topcoat above. It bridges the inherent chemical incompatibility between the thermoset FBE and the thermoplastic PE. Without this intermediate layer, the outer shell would simply peel away from the primary corrosion barrier, rendering the mechanical protection useless. The efficiency of this adhesive dictates the system’s Peel Strength—a critical performance indicator under DIN 30670.

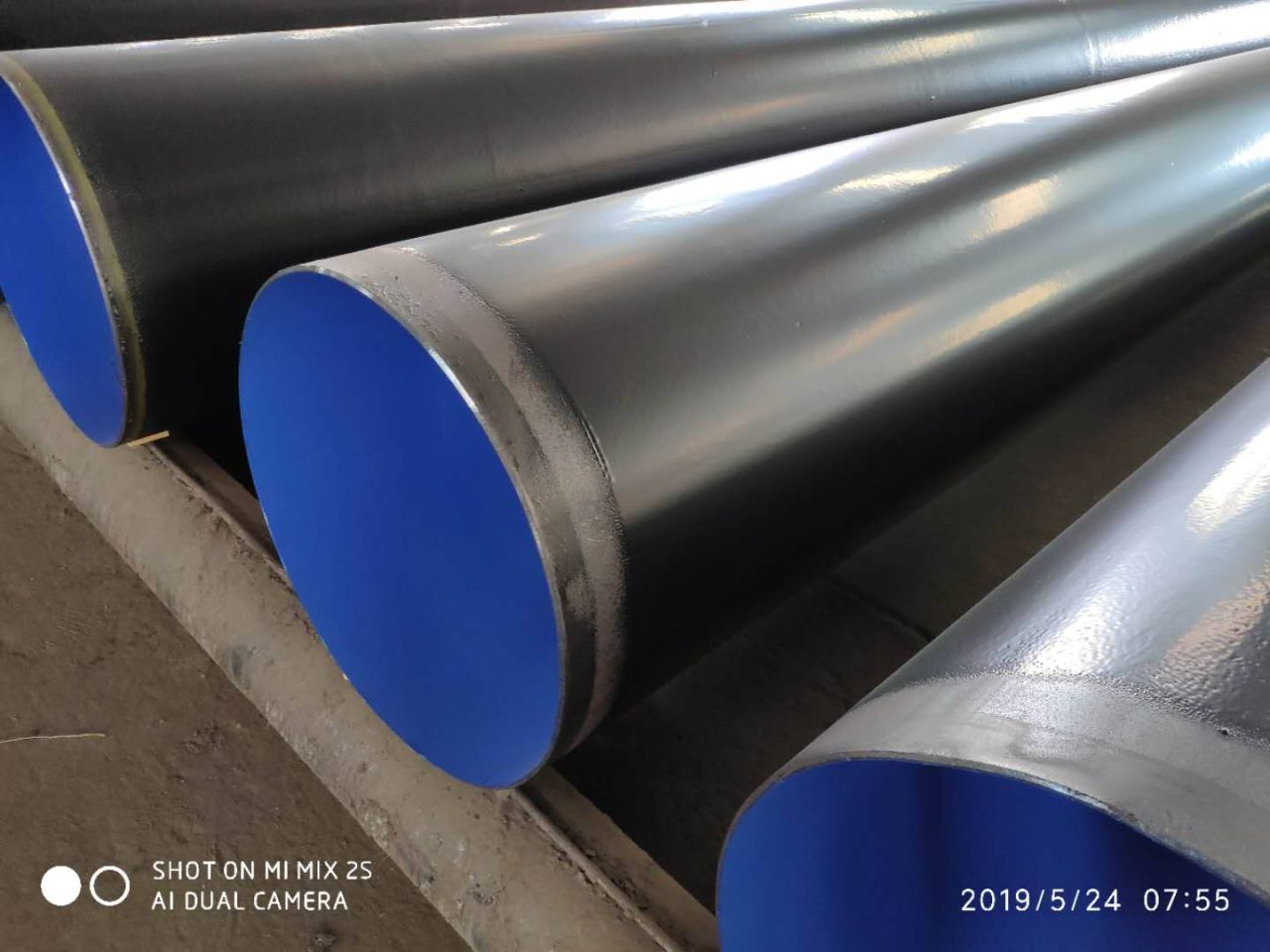

Layer 3: Extruded Polyethylene (PE)—The Mechanical Armor

The final layer is the physical, external defense system, providing the pipe with its superior mechanical durability.

- Toughness: Extruded PE is a thermoplastic material known for its exceptional resistance to abrasion, impact damage, soil stress, and hydrostatic pressure. This thick jacket protects the delicate FBE layer during transportation, aggressive handling during installation, and the decades of continuous contact with abrasive, shifting soil.

- Permeability and Electrical Resistance: Polyethylene itself possesses extremely low permeability to moisture and oxygen, and high electrical insulation properties. This reinforces the FBE layer, ensuring corrosive elements are physically deterred from reaching the steel substrate, which is a key factor in achieving the required Volume Resistivity mandated by the standard.

III. DIN 30670: The Standard of Non-Negotiable Performance

DIN 30670, titled “Polyethylene coatings for steel pipes and fittings,” is not merely a guideline; it is a rigid technical standard that transforms a three-layer process into a certified, predictable, high-performance product. Compliance ensures the coated pipe is fit for decades of demanding service across global energy networks.

Compliance and Performance Metrics

The standard mandates specific performance parameters and testing protocols that directly address the most common causes of pipeline failure:

| Test Parameter | DIN 30670 Acceptance Criteria | Rationale for Importance |

| Cathodic Disbondment (CD) | Maximum |

Directly measures the FBE’s chemical bonding strength and its ability to resist failure under the influence of cathodic protection systems. |

| Peel Strength (Adhesion) | Ensures the fusion of the three layers (FBE/Adhesive/PE) is robust enough to withstand mechanical stress without separation. | |

| Impact Resistance | Tested at |

Verifies the PE jacket’s ability to resist damage from rocks and impacts during laying, backfilling, and handling. |

| Holiday Detection | Guarantees the coating is completely free of holidays (pinholes or breaks), as even a microscopic defect can initiate rapid localized corrosion. | |

| Volume Resistivity | Confirms the high electrical insulation quality of the PE layer, minimizing current drainage from the cathodic protection system. |

Operational Versatility: Temperature Classification

A critical aspect of DIN 30670 is the classification of the coating based on the maximum permissible operating temperature. This ensures the PE polymer does not soften, creep, or lose adhesion under thermal load:

- Class N (Normal): Designed for maximum operating temperatures up to

. Suitable for most water, sewage, and cold gas applications.

- Class M (Medium): Certified for temperatures up to

. Used in regions with higher ambient temperatures or moderately warm product transport.

- Class H (High): Approved for temperatures up to

. Essential for hot oil, hot gas lines, or sections near compressor stations where thermal degradation is a significant risk. For sustained service above

, 3-Layer Polypropylene (3LPP) is typically specified, but the 3LPE Class H represents the maximum thermal performance of the polyethylene system.

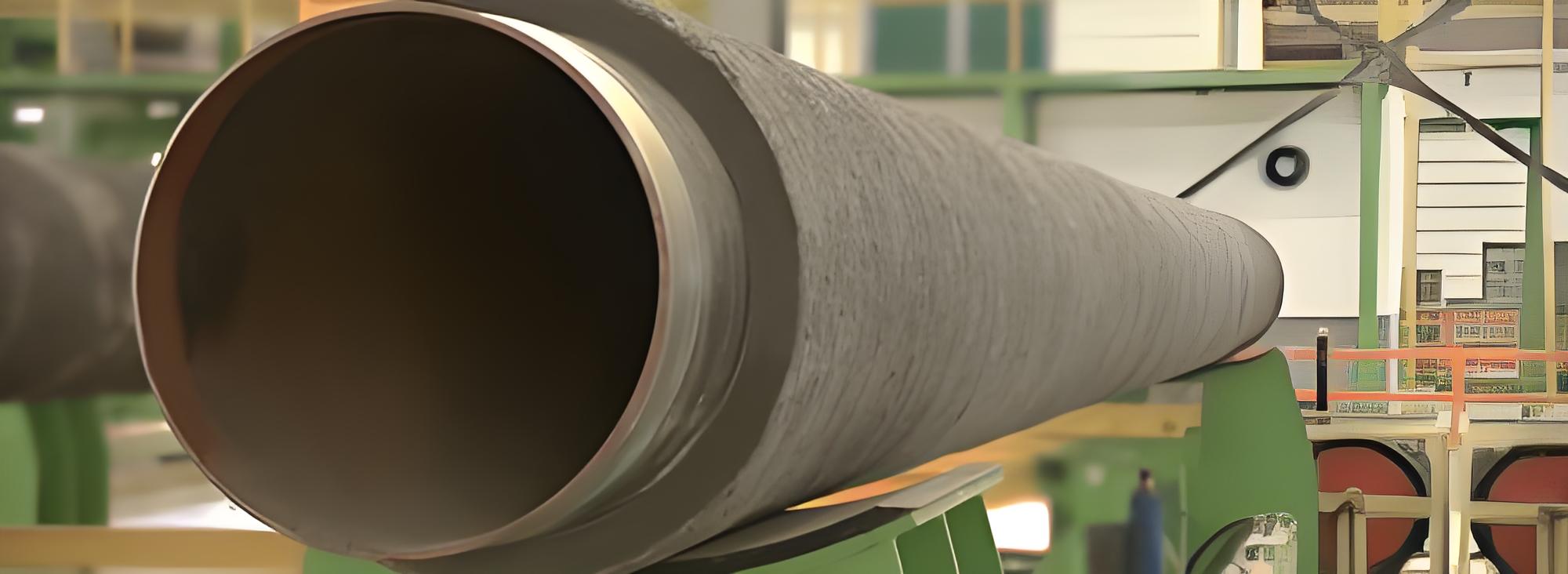

IV. The Manufacturing Process: Precision and Control

The transition from a bare steel pipe to a certified DIN 30670 product is a highly automated and meticulously controlled sequence, where deviations in temperature or timing can compromise the final product.

- Preparation (Heating and Blasting): The pipe is fed through an internal and external blast cleaner to achieve the required Sa 2 1/2 finish and anchor profile. It is then induction heated to the precise application temperature (typically

to

), which is vital for the FBE cure.

- FBE Application: The electrostatically charged FBE powder is sprayed onto the spinning, heated pipe. The heat ensures the powder melts, flows, and chemically cross-links into the primary protective film.

- Adhesive and PE Application: While the FBE is still in its gel state, the copolymer adhesive is applied, followed almost instantaneously by the thick PE layer, typically via side extrusion or a crosshead die. The heat from the pipe and the layers beneath fuses all three components into the single, monolithic composite structure.

- Curing and Cooling: The pipe is immediately quenched and cooled, typically in water, to set the polymer layers. This controlled cooling maintains the material’s properties and prevents thermal stress.

- Quality Inspection: This phase is non-negotiable. It involves comprehensive Holiday Detection across

of the surface, measurement of the coating thickness at multiple points (to ensure compliance with the diameter-based minimums), and laboratory testing of Peel Strength and Cathodic Disbondment on cut sections.

V. Strategic Advantages and Long-Term Value

The choice of DIN 30670 3LPE coated pipe represents a profound investment in asset integrity that translates directly into operational savings and environmental safety.

Longevity and Mechanical Toughness

The combination of chemically anchored FBE and the physically tough PE jacket results in an anti-corrosion system engineered for a service life exceeding 50 years. This system offers far superior resistance to handling damage and soil stress than traditional bituminous, coal tar, or even thinner single-layer epoxy systems. This resilience is crucial in minimizing expensive integrity digs and repairs over the life of the pipeline.

Environmental Stewardship

By guaranteeing leak prevention, the 3LPE system plays a direct role in environmental protection. Its robust structure minimizes the risk of product leakage (oil, gas, or chemicals) into the surrounding soil and groundwater, protecting delicate ecosystems and maintaining regulatory compliance. Furthermore, the modern PE coatings themselves are inert, stable, and environmentally safe, unlike some older coating chemistries.

Compatibility with Cathodic Protection (CP)

The coating works synergistically with the pipeline’s CP system. The high electrical resistance of the PE/FBE layers minimizes the current draw required for effective cathodic protection, allowing the CP system to operate more efficiently and cost-effectively over vast distances. The high CD resistance ensures that the protective barrier remains intact, acting as the front line of defense while the CP system handles small, unavoidable coating defects.

VI. Comprehensive Technical Specifications

Our manufacturing capability covers the full range of pipe sizes and standards required for global pipeline infrastructure.

Available Pipe Sizes and Coating Thicknesses

The required total coating thickness (tmin) is directly proportional to the pipe’s Outer Diameter (OD), ensuring consistent mechanical defense across all pipeline dimensions as per DIN 30670 Annex C.

| Outer Diameter (OD) Range (mm) | Minimum Wall Thickness (mm) | Nominal Total Coating Thickness (mm) | Minimum Total Coating Thickness () (mm) |

Note: All listed thicknesses exclude the height of the surface profile created during blast cleaning.

Anticorrosive Coating Material Composition

The integrity of the 3LPE system relies on the careful specification of its component materials to ensure seamless fusion and performance compliance with the DIN 30670 standard.

| Layer | Primary Material Type | Primary Function | Typical Thickness Range ( |

DIN 30670 Compliance Check |

| Layer 1 | Fusion Bonded Epoxy (FBE) | Anti-Corrosion Barrier, Adhesion to Steel | Cathodic Disbondment, Cross-linking | |

| Layer 2 | Co-Polymer Adhesive | Chemical Bonding Agent (FBE to PE) | Peel Strength, Fusion Integrity | |

| Layer 3 | Extruded Polyethylene (PE) | Mechanical/Physical Protection, Insulation | Impact Resistance, Water Permeability |

Technical Appendix: Engineering Formulas for 3LPE Integrity

To fully appreciate the science behind the DIN 30670 standard, one must examine the key mathematical and electrochemical principles that govern both corrosion and coating performance. These formulas are the bedrock of our quality control and engineering design, ensuring the pipe meets its predicted service life.

I. Corrosion Control and Cathodic Protection Efficacy

The 3LPE coating works synergistically with the pipeline’s Cathodic Protection (CP) system, where the coating minimizes current demand and the CP system protects against corrosion at inevitable, small coating defects (holidays).

1. Pitting Resistance Equivalent Number (PREN)

Although the corrosion resistance of the steel is secondary to the coating, the base metal’s quality is vital. The $\mathbf{PREN}$ is commonly used for stainless steels, but its principle applies to low-alloy steel specifications (like API 5L) to measure the steel’s inherent resistance to localized attack, determined by alloying elements:

In typical API 5L carbon steel, the percentages of $\text{Cr}, \text{Mo}$, and $\text{N}$ are minimal, resulting in a low $\text{PREN}$. This low value underscores the critical necessity of the high-performance 3LPE coating to provide the primary defense against pitting.

2. Current Density Demand for CP

A pipeline’s total current demand ($\mathbf{I}_{\text{total}}$) is directly related to the integrity of the coating. A high-quality 3LPE coating drastically reduces the exposed metal area ($\mathbf{A}_{\text{bare}}$), minimizing power consumption:

Where:

- $I_{\text{total}}$ is the required total protective current (Amperes).

- $A_{\text{bare}}$ is the total area of coating defects/holidays ($\text{m}^2$).

- $i_{\text{prot}}$ is the protective current density required for the bare steel (typically $0.02 \text{ A/m}^2$ in soil).

The low rate of Cathodic Disbondment specified by DIN 30670 (e.g., $\le 7 \text{ mm}$ radius) ensures that $A_{\text{bare}}$ remains exceptionally small throughout the pipeline’s decades-long service life.

II. Coating Performance and Integrity Calculations

The physical quality metrics mandated by DIN 30670 can be expressed through formulas related to thickness, peel strength, and mechanical energy absorption.

1. Thickness Calculation Based on Diameter (DIN 30670 Annex C)

The standard requires the total minimum coating thickness ($\mathbf{t}_{\text{min}}$) to scale with the pipe’s Outer Diameter (OD), ensuring structural integrity is maintained even on large pipelines:

Where $\mathbf{t}_{\text{nom}}$ is the nominal target thickness, and $\mathbf{t}_{\text{min}}$ is determined by the specific OD range of the pipe, ranging from $1.8 \text{ mm}$ up to $3.3 \text{ mm}$ for the largest pipes. This formula ensures a manufacturing tolerance buffer of $0.2 \text{ mm}$ above the required minimum.

2. Peel Strength Test (Adhesion Verification)

The **Peel Strength ($\mathbf{P}$)** test is a crucial measure of the fusion integrity between the three layers. It is expressed as force per unit width:

Where:

- $P$ is the peel strength (Newtons per centimeter, $\text{N/cm}$).

- $F_{\text{peak}}$ is the maximum tensile force recorded during the test (Newtons).

- $w$ is the width of the coating strip tested (centimeters).

DIN 30670 mandates a minimum $\mathbf{P}$ value (e.g., $\ge 35 \text{ N/cm}$ at $23^\circ\text{C}$), directly quantifying the robust chemical bond provided by the copolymer adhesive layer.

3. Impact Resistance Energy (Verification of Mechanical Durability)

The impact resistance test verifies the mechanical strength of the $\mathbf{PE}$ jacket by measuring the maximum energy ($\mathbf{E}$) the coating can absorb without developing a holiday:

Where:

- $E$ is the impact energy (Joules, $\text{J}$).

- $m$ is the mass of the falling weight ($\text{kg}$).

- $g$ is the acceleration due to gravity ($\approx 9.81 \text{ m/s}^2$).

- $h$ is the drop height (meters).

The standard requires the coating to withstand a specified minimum $\mathbf{E}$ (which varies by pipe size and wall thickness) without the high-voltage holiday detector registering a fault. This mathematical requirement translates directly into the field, ensuring the pipe survives the inevitable physical stresses of handling and backfilling.

III. Operational and Service Life Calculation

The ultimate goal of the 3LPE coating is to extend the asset’s useful life. While predicting absolute service life involves complex probability models, the **Coating Deterioration Factor ($\mathbf{D}_{\text{coat}}$)** is a critical metric:

The high adhesion and low water permeability of the DIN 30670 3LPE system minimize $\mathbf{D}_{\text{coat}}$, establishing a certified foundation for long-term pipeline integrity that is indispensable for any major infrastructure investment.

Conclusion: The Ultimate Assurance of Asset Integrity

The DIN 30670 3LPE Coated Steel Pipe is a certified solution for the future of pipeline integrity. It is the product of precise metallurgical sourcing, meticulous surface preparation, and a carefully controlled, triple-stage fusion process. By guaranteeing compliance with the stringent requirements of the DIN 30670 standard, particularly in adhesion, impact resistance, and thermal stability, we eliminate the guesswork from pipeline protection.