EN10219 Steel Pipe Piles | S235JRH, S275JOH/J2H, S355JOH/JEH, S420MN, and S460MH Grades

The Backbone of European Construction: A Definitive Guide to EN 10219 Steel Pipe Piles

Unlocking High-Strength Foundation Solutions with S235JRH, S275JOH/J2H, S355JOH/JEH, S420MN, and S460MH Grades

1. Introduction: The European Standard for Structural Excellence in Deep Foundations

In the world of deep foundation engineering, the choice of material is the single most critical factor determining the structural integrity, longevity, and overall cost-efficiency of a project. For structures built across Europe and in regions that adhere to the stringent requirements of Eurocodes and harmonized European Norms (EN), the definitive standard for tubular steel piling is **EN 10219-1/2**. This specification governs cold-formed welded structural hollow sections, providing a robust, highly predictable, and globally recognized material framework for civil engineering masterpieces, from massive offshore wind farms and complex marine terminals to high-speed rail viaducts and towering urban developments.

Our commitment as a leading manufacturer in this highly specialized field is to transform high-quality European steel into foundation elements that are not merely compliant, but truly superior. We specialize in producing pipe piles from the full spectrum of relevant EN 10219 grades: from the versatile standard strength of **S235JRH** to the high-performance, thermo-mechanically treated grades like **S420MN** and **S460MH**. These grades, characterized by their minimum yield strength, specified impact energy, and controlled chemical composition (particularly the **Carbon Equivalent value**), offer engineers unparalleled flexibility in optimizing foundation design, achieving greater load-bearing capacity with less material, and ensuring superior weldability for critical field splices.

This comprehensive technical document serves as an exhaustive guide to the EN 10219 standard as applied to steel pipe piling. We will dissect the nuances of the grading system—explaining the significance of the ‘S’, the numerical yield strength, and the impact designations (\(\text{J0}\), \(\text{J2}\), \(\text{JR}\), \(\text{JKH}\), \(\text{JEH}\)). We will provide the essential Mechanical Property and Chemical Composition tables that underpin the standard, and we will elaborate on the sophisticated cold-forming and welding processes we employ to guarantee adherence to the exacting dimensional tolerances of EN 10219-2. Ultimately, understanding the power and precision inherent in these EN grades is the key to unlocking the full potential of high-strength, durable, and highly cost-effective deep foundations.

The transition from the standard foundation material of the past to the high-strength, low-weight solutions of today is driven by the efficiencies offered by grades like **S355** and **S460**. Utilizing these higher grades allows for the reduction of the required wall thickness or diameter for a given load, saving material cost, reducing transportation weight, and crucially, decreasing the energy required for pile driving. This shift is not just an engineering preference; it is an economic and environmental imperative, and our production capabilities are perfectly aligned to support this modern engineering mandate across all construction sectors.

2. Decoding the EN 10219 Standard: Grades, Properties, and Impact Toughness

EN 10219 is specifically designed for structural hollow sections formed at room temperature (cold-formed), which results in high precision and excellent surface finish. The designation system is systematic and provides immediate structural information, which is essential for design engineers working within the Eurocode framework.

2.1. The EN 10219 Grading System Explained

Every EN 10219 grade is a structural narrative, defining its strength, impact resistance, and material quality:

- S (Structural Steel): Indicates the steel is intended for structural purposes.

- Numerical Value (235, 275, 355, 420, 460): Defines the minimum specified Yield Strength (\(R_{\text{eH}}\)) in Newtons per square millimeter (\(\text{MPa}\)) for wall thicknesses up to \(16 \text{mm}\). For thicker sections, a slightly lower value may apply, which is a critical design consideration.

- JR, J0, J2 (Impact Toughness): Defines the minimum impact energy absorption in Joules (\(\text{J}\)) at a specific temperature, measured via the Charpy V-notch test.

- JR: \(\ge 27 \text{ J}\) at \(20^{\circ}\text{C}\) (Room Temperature).

- J0: \(\ge 27 \text{ J}\) at \(0^{\circ}\text{C}\).

- J2 / JEH: \(\ge 27 \text{ J}\) at \(-20^{\circ}\text{C}\). (Crucial for cold-weather applications or low-temperature exposure).

- H (Hollow Section): Simply designates the product as a hollow structural section.

- N/M (Process Condition): For the higher strength grades, ‘N’ denotes normalized/normalized rolled, while ‘M’ denotes thermo-mechanically rolled. These processes are key to achieving high strength (e.g., \(420/460 \text{ MPa}\)) while maintaining excellent toughness and weldability, particularly for the **S420MN** and **S460MH** grades we manufacture.

For piling applications, the minimum yield strength is essential for carrying axial loads and resisting driving forces. However, the impact toughness designation (\(\text{J0}\), \(\text{J2}\)) provides assurance that the pile will not suffer brittle fracture in colder climates or under dynamic loading conditions, a level of detail often exceeding other international piling specifications.

2.2. Mechanical Property Requirements (Table 1)

The minimum mechanical performance is defined by the following key parameters. Note that \(R_{\text{eH}}\) (Upper Yield Strength) is the basis for the grade name, and \(R_{\text{m}}\) (Tensile Strength) provides the measure of ultimate strength. The high \(\text{S420}\) and \(\text{S460}\) grades showcase superior performance, allowing for significant material optimization in foundation design.

| Table 1: EN 10219-1 Mechanical Property Requirements (Minimum, for \(t \le 16 \text{mm}\)) | |||

|---|---|---|---|

| Steel Grade | Minimum Yield Strength (\(R_{\text{eH}}\)) (\(\text{MPa}\)) | Minimum Tensile Strength (\(R_{\text{m}}\)) (\(\text{MPa}\)) | Minimum Elongation (%) |

| S235JRH | 235 | 360 – 510 | 26 |

| S275J0H/J2H | 275 | 410 – 560 | 24 |

| S355J0H/JEH | 355 | 510 – 680 | 22 |

| S420MN/MH* | 420 | 500 – 640 | 19 |

| S460MH* | 460 | 540 – 720 | 17 |

*Note: The high-strength grades (\(\text{S420}\), \(\text{S460}\)) often employ M (Thermo-mechanically rolled) or N (Normalized) processing to achieve high yield strength while maintaining excellent weldability and toughness.

The high yield strength of \(\text{S355}\), \(\text{S420}\), and \(\text{S460}\) is the key differentiator. Utilizing these grades allows the structural engineer to design foundations with a significantly reduced steel mass while achieving the same axial load capacity. This is particularly advantageous for large-scale projects, minimizing the volume of steel to be purchased, transported, and driven, leading to a substantial reduction in the overall foundation budget. The relationship between yield strength and ultimate tensile strength also ensures that there is a predictable reserve of strength beyond the design load, critical for long-term structural reliability.

3. Chemical Composition and the Critical Carbon Equivalent (\(\text{CEV}\))

The European standard, unlike some others, places significant emphasis on controlling the chemical composition, not just to achieve mechanical properties, but primarily to ensure excellent weldability. For cold-formed structural sections like pipe piles, especially the higher strength grades that require field splicing, controlled chemistry is a non-negotiable factor. The most critical control measure is the maximum permissible **Carbon Equivalent Value** (\(\text{CEV}\)).

3.1. Chemical Composition Requirements (Table 2)

EN 10219 sets maximum percentage limits for key alloying elements. These limits are tighter for higher strength steels (like \(\text{S355}\) and \(\text{S460}\)) to ensure that despite their increased strength, their welding characteristics remain favorable. The control of Phosphorus (\(\text{P}\)) and Sulfur (\(\text{S}\)) is essential to minimize the risk of solidification cracking (hot tearing) during both the mill welding process and critical field splicing operations.

| Table 2: EN 10219-1 Chemical Composition (Maximum % by Mass, Heat Analysis) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Steel Grade | C max. | Mn max. | P max. | S max. | Cu max. | Nb max. | V max. | CEV max. |

| S235JRH | 0.22 | 1.60 | 0.040 | 0.040 | 0.55 | – | – | 0.35 |

| S275J0H/J2H | 0.20 | 1.60 | 0.035 | 0.035 | 0.55 | – | – | 0.40 |

| S355J0H/JEH | 0.20 | 1.70 | 0.035 | 0.035 | 0.55 | – | – | 0.45 |

| S420MN/MH | 0.20 | 1.70 | 0.030 | 0.025 | 0.55 | 0.05 | 0.12 | 0.50 |

| S460MH | 0.20 | 1.80 | 0.030 | 0.025 | 0.55 | 0.05 | 0.12 | 0.53 |

3.2. The Significance of Carbon Equivalent Value (\(\text{CEV}\))

The most important chemical control in EN 10219 is the maximum \(\text{CEV}\). The **Carbon Equivalent** is a calculation used to predict the weldability and the tendency of a steel to harden upon rapid cooling (quench hardening). The \(\text{CEV}\) is calculated using the formula:

A lower \(\text{CEV}\) indicates superior weldability, requiring less pre-heating and simplifying on-site welding procedures. For higher strength steels like **S420MN** (\(\text{CEV max } 0.50\)) and **S460MH** (\(\text{CEV max } 0.53\)), strict \(\text{CEV}\) control is crucial. These grades achieve high strength through a combination of chemistry and specialized processing (M or N). By limiting the \(\text{CEV}\), the standard guarantees that despite their high strength, the steel can be reliably welded in the field for splicing, a task typically performed under challenging conditions. Our manufacturing process guarantees the delivered material falls well within these maximum \(\text{CEV}\) limits, providing the contractor with maximum assurance and simplified welding requirements.

4. Manufacturing Excellence: Cold-Forming and High-Integrity Welding

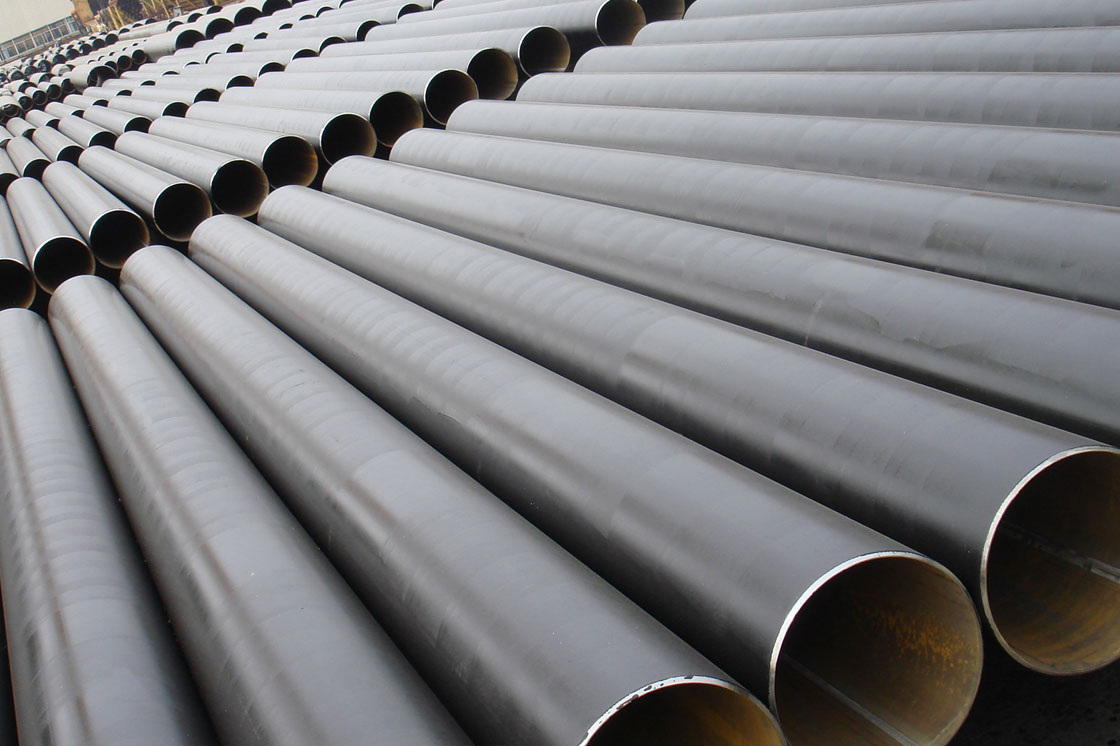

Our process of producing EN 10219 pipe piles leverages the advantages of **cold forming** and combines it with advanced fusion welding techniques to create a dimensionally precise and structurally sound product. The difference between cold-formed and hot-formed (EN 10210) hollow sections is significant in terms of residual stress and the sharp geometry of the corner sections, though for large diameter piling (which are often near-circular), the primary benefit is the precise control over the final geometry.

4.1. The Cold-Forming Process and Dimensional Accuracy

Cold forming involves shaping the flat steel plate or coil into the final tubular section at ambient temperature. This process introduces work hardening, particularly in the corners (for square/rectangular sections), which can slightly increase the yield strength in these areas. For circular pipe piles, the roll-forming process achieves exceptional concentricity and straightness. EN 10219-2 dictates rigorous dimensional and mass tolerances. For pipe piling, maintaining tight tolerances on:

- Outside Diameter (\(\text{OD}\)): Crucial for fitting driving shoes and connecting to other foundation components.

- Wall Thickness (\(\text{WT}\)): Ensuring the thickness never falls below the specified minimum is vital for structural capacity and corrosion allowance, especially given the strict \(R_{\text{eH}}\) requirements.

- Straightness and Length: Essential for successful alignment during driving and field splicing, preventing refusal or buckling under the immense force of the pile hammer.

Our commitment involves utilizing continuous laser and ultrasonic monitoring systems during the roll-forming and sizing stages to ensure adherence to these tight dimensional requirements, often surpassing the standard’s minimums to provide a product with inherently enhanced structural reliability.

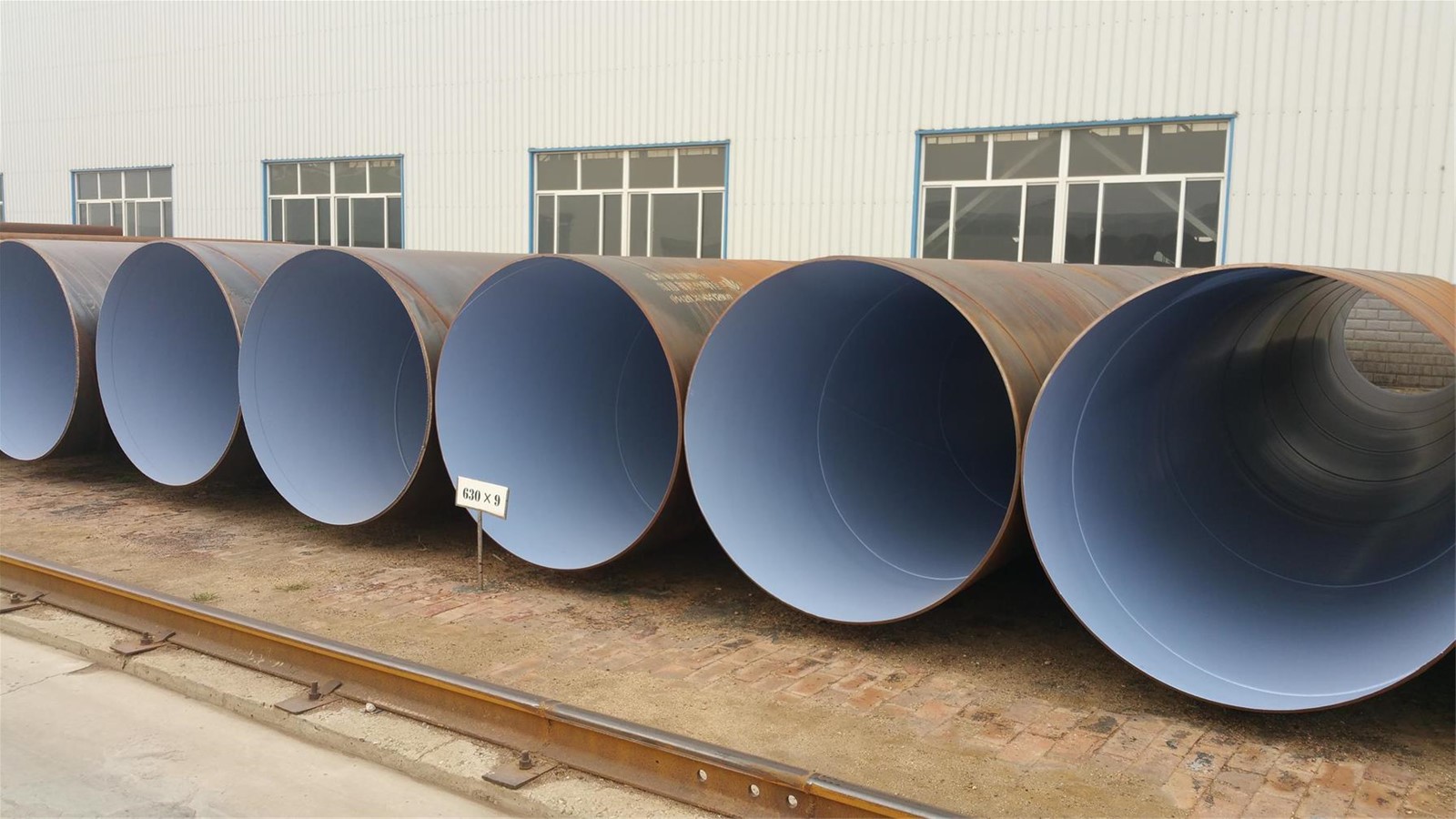

4.2. Double Submerged Arc Welding (\(\text{DSAW}\)) for Piling Integrity

For high-integrity structural pipe piles, we predominantly use the **Double Submerged Arc Welding (\(\text{DSAW}\))** technique. This is crucial because SAW ensures deep, full-penetration fusion along the weld seam. The plate edges are joined and welded both internally and externally beneath a flux blanket, protecting the molten metal and producing a clean, high-strength weld. The weld metal and the Heat-Affected Zone (\(\text{HAZ}\)) are rigorously controlled to ensure their mechanical properties, including impact toughness, meet or exceed the requirements of the parent material, whether it be **S235JRH** or the high-strength **S460MH**.

This attention to weld quality is directly tested through the EN 10219 requirements, which demand specific non-destructive testing (\(\text{NDT}\)) to confirm the integrity of the seam. This verification is essential for pipe piles, as the weld line is under constant dynamic and static stress throughout the pile’s life. We also implement continuous monitoring of welding parameters—voltage, amperage, travel speed, and heat input—to maintain process consistency and metallurgical soundness across every meter of the pipe seam.

5. Quality Control, Testing, and \(\text{CE}\) Marking

Compliance with EN 10219 and its accompanying Eurocodes requires a documented system of rigorous quality control, culminating in the mandatory **\(\text{CE}\) Marking**, which signifies that the product conforms to all applicable European health, safety, and environmental protection standards and is fit for its intended structural use.

5.1. Mechanical Testing and Inspection Frequency

Testing is performed on samples taken from the material, typically one sample per heat/batch depending on the production volume, to confirm the material’s properties:

- Tensile Testing: Verifies the actual Yield Strength (\(R_{\text{eH}}\)) and Tensile Strength (\(R_{\text{m}}\)) against the required minimums (e.g., \(355 \text{ MPa}\) for \(\text{S355}\)). This is the absolute verification of the pile’s load-bearing capacity.

- Charpy V-notch Impact Testing: Required for all grades from \(\text{S275J0H}\) upwards, this test is performed at the specified temperature (\(0^{\circ}\text{C}\) for \(\text{J0}\), \(-20^{\circ}\text{C}\) for \(\text{J2}\)) to confirm the material’s ability to absorb energy without brittle fracture. For piling in cold or seismic regions, the \(\text{J2H}\) or \(\text{JEH}\) designation (e.g., **S355JEH**) is often non-negotiable, providing assurance against cold-induced failure.

- Chemical Analysis: Confirmed via a ladle analysis certificate for every heat of steel, verifying that the chemical composition, particularly the critical \(\text{CEV}\), falls within the permissible maximums specified in Table 2.

5.2. Non-Destructive Testing (\(\text{NDT}\)) of Welds

As per EN 10219 and relevant European standards for structural components, the weld integrity is verified using:

- Ultrasonic Testing (\(\text{UT}\)): Typically applied to \(100\%\) of the weld length in high-stress fusion-welded pipes, \(\text{UT}\) detects internal discontinuities.

- Visual and Dimensional Inspection: Continuous checks of the weld bead profile, geometry, and the overall dimensional compliance (\(\text{OD}\), \(\text{WT}\), Straightness) with EN 10219-2 tolerances.

The entire quality process is documented through a **Mill Test Certificate (\(\text{MTC}\))**, typically issued as an EN 10204 Type 3.1 certificate, which provides the full traceability required for compliance with Eurocodes and regulatory bodies across the continent.

6. Piling Applications and Structural Advantages of High-Strength EN Grades

The broad range of strengths offered by EN 10219 allows engineers to precisely match the material to the structural demand. Utilizing high-strength grades like **S420MN** and **S460MH** unlocks significant engineering advantages in specific application areas, guided by the principles of Eurocode 3 (EN 1993) and Eurocode 7 (EN 1997).

6.1. High-Strength Efficiency: S420 and S460 in Action

The primary benefit of using high-strength pipe piles is material optimization. Since the axial load capacity is directly related to the yield strength (\(R_{\text{eH}}\)), switching from \(\text{S235}\) to \(\text{S460}\) allows the required cross-sectional area (\(A\)) to be approximately halved for the same load, assuming stability constraints are met. This means:

- Reduced Wall Thickness (\(\text{WT}\)): Lighter piles require less driving energy and are more economical to transport and handle.

- Smaller Diameter: A smaller \(\text{OD}\) can be used, minimizing the volume of soil displaced and potentially reducing foundation costs where space is limited.

These benefits are particularly pronounced in:

- Offshore/Marine Structures: Piles for wind turbine foundations and oil and gas jackets require enormous load-bearing capacity in a confined footprint. The high strength of **S460MH** minimizes weight, which is critical for complex offshore handling and installation logistics.

- Deep-Driven Foundations: Where extreme depths are required, **S420MN** and **S460MH** resist buckling during severe driving conditions more effectively than lower grades, preventing costly pile damage or refusal.

- Seismic Zones: The combination of high strength and guaranteed low-temperature toughness (e.g., \(\text{J2}/\text{JEH}\)) makes these grades ideal for resilient structures designed to withstand significant dynamic forces and energy absorption without brittle failure.

6.2. Foundation Versatility: Compression, Tension, and Lateral Loads

EN 10219 pipe piles serve multiple roles in a foundation system:

- Compression Piles: The steel acts to carry the axial load, often filled with concrete to maximize the composite capacity, leveraging the superior \(R_{\text{eH}}\) of the steel.

- Tension/Uplift Piles: Used in jetties or areas subject to high wind/water pressure, the steel’s high tensile strength (\(R_{\text{m}}\)) is crucial for resisting uplift forces, often utilizing friction or rock anchors to resist extraction.

- Lateral Piles: Utilized in retaining structures or to resist ship impact, the high section modulus (\(Z\)) of the large diameter piles provides the necessary stiffness and bending resistance.

The inherent geometry of the circular hollow section offers excellent lateral stiffness and minimizes drag in water or soil, which is a major advantage over open sections, further cementing the role of EN 10219 pipe piles as the material of choice for complex structural needs.

7. Installation, Splicing, and Corrosion Protection in the European Context

Effective installation relies on careful planning, optimized field procedures, and absolute confidence in the material’s properties, particularly its ability to be reliably spliced and protected from environmental degradation. The controlled chemistry of EN 10219 grades is fundamental to simplifying the on-site work.

7.1. Guaranteed Field Weldability and Splicing

Piles must often be field-spliced to achieve the required depth. The strict control over the **Carbon Equivalent (\(\text{CEV}\))** in EN 10219 steels directly translates to simpler, more reliable field welding. Lower \(\text{CEV}\) means less pre-heating is required, faster welding times, and reduced risk of hydrogen-induced cracking in the heat-affected zone, especially for the high-strength grades. Our piles are delivered with pre-machined bevels, ready for full-penetration butt welding, ensuring that the field splice achieves \(100\%\) of the pile’s structural capacity as required by Eurocode 3 for structural continuity.

For applications where welding is impossible or impractical, we supply mechanical splicing systems specifically engineered to maintain the axial and shear capacity of the corresponding EN grade, providing an alternative that accelerates installation time without compromising the structural integrity guaranteed by the S classification.

7.2. Managing Driving Stress and Pile Dynamics

The high yield strength of grades like **S355JEH** or **S460MH** is the primary defense against pile damage during driving. The pipe must withstand the compressive shock wave generated by the hammer without plastic deformation (local buckling). We provide essential engineering support, including wave equation analysis (\(\text{WEAP}\)) studies, to select the correct pile hammer, cushion material, and driving criteria to ensure that the maximum driving stress remains safely below the \(R_{\text{eH}}\) of the specified EN grade, protecting the material integrity and guaranteeing successful pile set.

7.3. Corrosion Protection Systems

In highly corrosive environments (marine, contaminated ground), the durability of the foundation requires dedicated protection. Our manufacturing capability includes the application of specialized anti-corrosion systems compliant with relevant European standards (e.g., EN ISO 12944):

- Protective Coatings: High-build epoxy, polyurethane, or coal tar epoxy coatings applied to specific zones (splash zone, buried zone) in controlled factory environments for maximum adhesion and lifespan.

- Cathodic Protection (\(\text{CP}\)) Integration: The pipe piles are often designed to integrate seamlessly with impressed current or sacrificial anode \(\text{CP}\) systems, which are essential for long-term corrosion mitigation in seawater and highly conductive soils.

- Corrosion Allowance: For lower-risk environments, the structural design often utilizes a slightly thicker wall than structurally required, leveraging the excess material as a ‘corrosion allowance’ over the project’s design life.

8. Commercial Excellence and Sustainability

The choice of EN 10219 steel pipe piles is an economically sound decision supported by superior logistics and an inherent commitment to environmental responsibility, particularly within the European regulatory framework.

8.1. Total Cost of Ownership (\(\text{TCO}\)) Advantage

While the initial cost of high-strength steel (\(\text{S420}/\text{S460}\)) may be higher than lower-grade alternatives, the **total installed cost and \(\text{TCO}\) are often significantly lower**. This is achieved through:

- Reduced Mass: Using a lower steel tonnage for the same load, minimizing raw material and freight costs.

- Faster Installation: High yield strength reduces driving refusal rates and enables faster pile advancement.

- Simplified Welding: The guaranteed low \(\text{CEV}\) simplifies and accelerates field splicing.

The structural longevity and minimal maintenance requirements inherent in these high-quality, fully traceable, and certified EN-grade steels provide superior long-term economic returns compared to many alternative foundation solutions.

8.2. Sustainability and European Green Standards

Steel is a champion of the circular economy, boasting exceptional recyclability. Our EN 10219 pipe piles contribute positively to project sustainability profiles:

- High Recycled Content: European steel mills often utilize a high percentage of recycled ferrous scrap, reducing the embodied carbon of the steel.

- End-of-Life Recyclability: At the end of the structure’s service life, the steel piles can be readily extracted and recycled without loss of material properties, minimizing landfill burden.

- Efficiency of Design: The use of high-strength steel (\(\text{S460}\)) means fewer foundation units or less mass is required, aligning perfectly with modern sustainable design principles focused on material optimization.

8.3. Our Commitment to Excellence Beyond the Norm

We pride ourselves on an organizational culture that views the EN 10219 standard as the floor, not the ceiling. Our internal quality assurance systems operate on tighter dimensional tolerances for wall thickness and straightness than mandated by EN 10219-2, providing an enhanced safety margin and greater ease of installation for our clients. From the continuous verification of the **J2H** impact toughness to the precise control of the \(\text{CEV}\) in every heat of **S460MH**, we guarantee a pipe pile that is structurally sound, dimensionally perfect, and ready to meet the most demanding requirements of deep foundation engineering globally.

9. Conclusion: Securing the Future with EN 10219 Pipe Piles

The range of steel grades under the EN 10219-1 standard—from the dependable **S235JRH** through the versatile **S355JOH/JEH** to the high-performance **S460MH**—provides the essential material solution for every deep foundation challenge. This European standard guarantees not only high Mechanical Properties (Yield Strength up to \(460 \text{ MPa}\)) but also critical Impact Toughness (\(\text{J0}/\text{J2}\)) and superior Weldability through strict control of the **Carbon Equivalent**.

Our role as a specialized manufacturer is to seamlessly translate these demanding specifications into a tangible product. By utilizing advanced cold-forming and \(\text{DSAW}\) techniques, maintaining rigorous \(\text{NDT}\) protocols, and providing comprehensive EN 10204 Type 3.1 certification and **\(\text{CE}\) Marking**, we deliver pipe piles that minimize risk, maximize efficiency, and ensure the structural integrity required by Eurocodes.

For structural engineers, project managers, and procurement specialists seeking a foundation solution that combines high load capacity, superior weldability, dimensional precision, and environmental responsibility, our **EN 10219 pipe piles** are the definitive choice. Partner with us to secure the foundations of your next critical project with European excellence and engineering assurance.