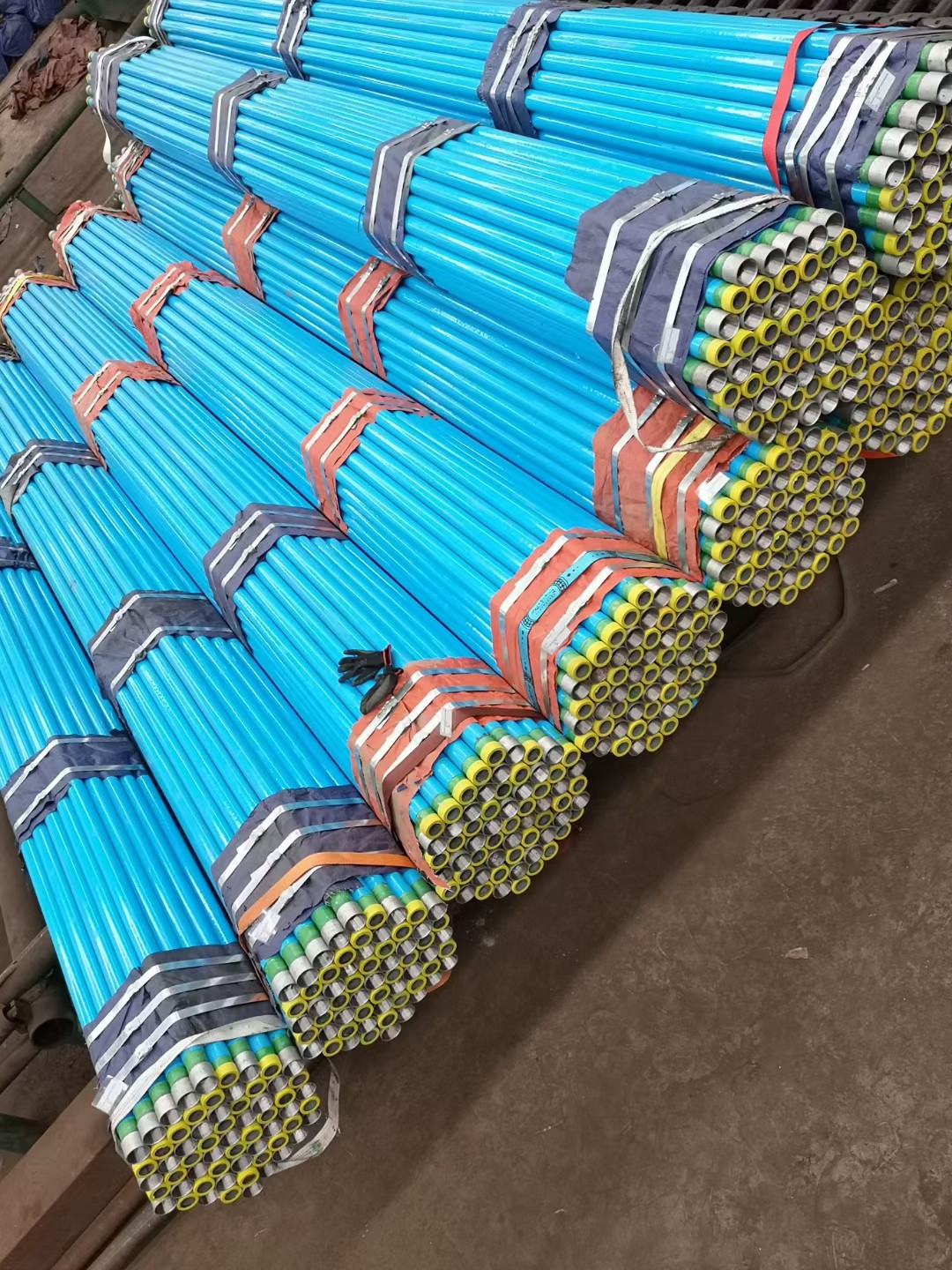

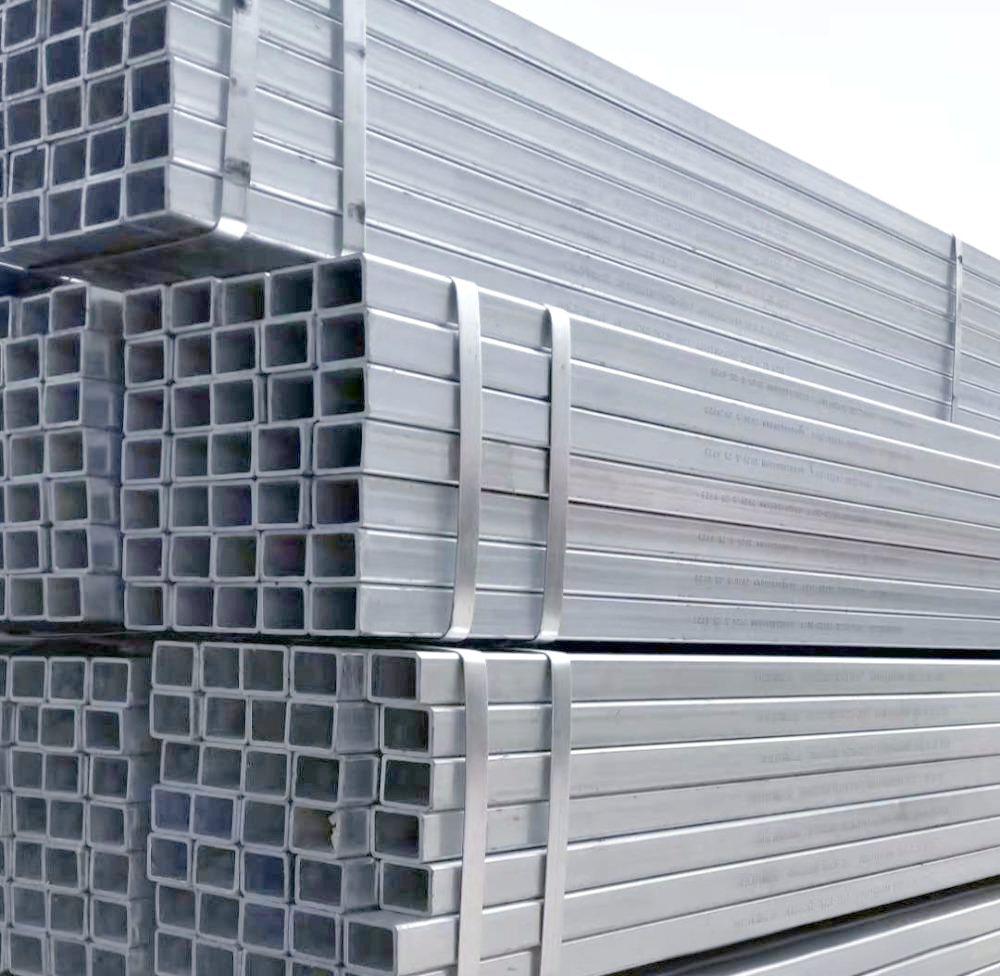

Galvanized steel Hollow Section for for Structural Frames

When we consider the skeletal integrity of modern architecture—the hidden frames within towering skyscrapers, the robust supports of industrial warehouses, or the precision-engineered modules of solar racking—we are fundamentally discussing the science of the Square Hollow Section (SHS). Specifically, when these sections are forged from grades like S235, S275, or S355 and armored with a galvanized coating, they represent a peak intersection of metallurgical durability and geometric efficiency. At our manufacturing facilities, we don’t just produce steel; we engineer structural solutions that balance the cold, hard numbers of Yield Strength ($R_{eH}$) and Tensile Strength ($R_m$) with the practical demands of site-specific longevity.

The Geometry of Strength: Why Square Hollow Sections?

The Square Hollow Section is a marvel of symmetry. Unlike an I-beam or a C-channel, which possess “strong” and “weak” axes, the SHS provides nearly uniform resistance to torsion and multi-axial loading. When a structural frame is subjected to wind loads or seismic shifts, the square profile distributes stress evenly across its four walls. This inherent balance makes it the premier choice for columns and unbraced members.

By utilizing cold-forming techniques according to EN 10219, we ensure that the grain structure of the steel remains tight, enhancing the surface finish—which is critical for the subsequent galvanization process. A smoother surface allows for a more uniform zinc-iron alloy layer, preventing the “shadowing” or “pinholing” that can occur in inferior alloys.

Chemical Metallurgy: The Foundation of Performance

The performance of a structural frame begins at the atomic level. The transition from S235JR to S355JR isn’t merely a label change; it is a meticulous adjustment of carbon equivalents and micro-alloying elements.

Table 1: Chemical Composition Analysis (Mass Fraction %)

| Grade | Standard | C (max) | Si (max) | Mn (max) | P (max) | S (max) | N (max) | Cu (max) |

| S235JR | EN 10025-2 | 0.17 | — | 1.40 | 0.035 | 0.035 | 0.012 | 0.40 |

| S235J0 | EN 10025-2 | 0.17 | — | 1.40 | 0.030 | 0.030 | 0.012 | 0.40 |

| S235J2 | EN 10025-2 | 0.17 | — | 1.40 | 0.025 | 0.025 | — | 0.40 |

| S275JR | EN 10025-2 | 0.21 | — | 1.50 | 0.035 | 0.035 | 0.012 | 0.40 |

| S355JR | EN 10025-2 | 0.24 | 0.55 | 1.60 | 0.035 | 0.035 | 0.012 | 0.55 |

In our production, we pay close attention to the Carbon Equivalent Value (CEV). While the table shows maximum limits, our proprietary smelting control targets the “sweet spot” of the range. For instance, in S355JR, the higher Manganese (Mn) content (up to 1.60%) acts as a solid-solution strengthener, while Silicon (Si) is controlled to ensure optimal reactivity during the hot-dip galvanizing process (the Sandelin effect), ensuring the zinc coating isn’t brittle or excessively thick.

Mechanical Integrity and Temperature Resilience

The distinction between “JR,” “J0,” and “J2” is often misunderstood as a simple quality tier, but it is actually a vital safety parameter regarding Charpy V-notch impact energy.

- JR (27J @ +20°C): Ideal for indoor structures or temperate climates.

- J0 (27J @ 0°C): Necessary for external structures in regions with mild winters.

- J2 (27J @ -20°C): Essential for sub-zero environments to prevent brittle fracture.

Table 2: Mechanical Properties and Energy Absorption

| Grade | Yield Strength ReH (min, MPa) | Tensile Strength Rm (MPa) | Elongation A (min, %) | Impact Req. (Charpy V) |

| S235JR | 235 | 360–510 | 26 | 27 J @ +20°C |

| S235J0 | 235 | 360–510 | 26 | 27 J @ 0°C |

| S235J2 | 235 | 360–510 | 26 | 27 J @ −20°C |

| S275JR | 275 | 410–560 | 23 | 27 J @ +20°C |

| S355JR | 355 | 470–630 | 22 | 27 J @ +20°C |

Our S355JR sections offer a significant weight-to-strength advantage. By utilizing a higher yield strength (355 MPa), engineers can specify thinner wall thicknesses without sacrificing load-bearing capacity, leading to lighter structures and reduced shipping costs—a critical factor for large-scale international projects.

Galvanization: The Barrier and Galvanic Shield

The “Galvanized” aspect of our Square Hollow Sections is not a mere paint job; it is a metallurgical bond. Through a hot-dip process, we create a series of zinc-iron alloy layers topped with a pure zinc outer layer.

- Barrier Protection: The coating isolates the steel from corrosive oxygen and moisture.

- Sacrificial Anodic Protection: If the section is scratched or cut during installation, the surrounding zinc will corrode preferentially to the steel, “healing” the wound through galvanic action.

We strictly adhere to EN ISO 1461 or ASTM A123 standards, typically providing a coating thickness of 55μm to 85μm, depending on the material thickness. This ensures a maintenance-free service life exceeding 50 years in C3 (Urban/Industrial) environments.

Global Standards and Quality Compliance

Our supply chain is built on the universality of engineering. Whether your project specifies European, American, or Japanese standards, our Square Hollow Sections are cross-certified to meet the rigorous demands of global procurement.

- Europe (EN 10219 / EN 10025): The gold standard for structural integrity and dimensional tolerances ($T < 10\%$, $O < 2\%$).

- USA (ASTM A500): Focuses on cold-formed welded tubing, ensuring the ductility required for seismic applications.

- China (GB/T 6728): Aligning domestic high-capacity production with international performance metrics.

We provide full Mill Test Certificates (MTC) to EN 10204 3.1 as a standard practice, offering our clients 100% traceability from the iron ore to the finished, galvanized section.

Why Partner With Us?

In the competitive landscape of structural steel, the difference lies in the execution of detail. Our company integrates the entire production cycle. By controlling the cold-forming process and the galvanizing bath in the same facility, we eliminate the risks of “pickling embrittlement” and ensure that the internal surfaces of the hollow sections are as well-protected as the external ones.

Our S355JR sections are specifically favored for high-load applications because we maintain a tighter tolerance on “Corner Radius” than the standard requires. A tighter radius allows for easier welding and better fitment in complex structural junctions.

When you choose our galvanized Square Hollow Sections, you aren’t just buying steel; you are investing in a structural foundation that is scientifically optimized for strength, chemically protected against the elements, and certified to the world’s most demanding standards.

To provide a deeper technical perspective, we must examine the intersection of material science and structural economics. Transitioning from a standard grade like S235JR to a high-strength grade like S355JR isn’t just about meeting a safety coefficient; it is a strategic decision that affects the entire lifecycle of a structural project.

The Physics of Strength-to-Weight Optimization

When designing a structural frame, the primary goal is to resist bending moments and axial compression. The formula for the design strength of a section is fundamentally tied to its Yield Strength ($f_y$).

For a given load $F$, the required cross-sectional area $A$ can be simplified as:

By utilizing S355JR ($f_y = 355\text{ MPa}$) instead of S235JR ($f_y = 235\text{ MPa}$), you increase the material strength by approximately 51%. In practical application, this allows for a reduction in wall thickness of the Square Hollow Section (SHS) while maintaining the same load-bearing capacity.

Comparative Table: Weight Savings Analysis

Example: 100x100mm Square Hollow Section

| Requirement | S235JR Selection | S355JR Selection | Improvement |

| Wall Thickness | 6.0 mm | 4.0 mm | -33% Thickness |

| Weight per Meter | 17.1 kg/m | 11.7 kg/m | ~31% Lighter |

| Load Capacity | Baseline | Equivalent | Neutral |

The “Ripple Effect” of Weight Reduction:

- Lower Logistics Costs: You can fit 30% more linear meters of steel on a single truck or shipping container.

- Foundation Savings: Lighter superstructures require less massive concrete footings, reducing overall site costs.

- Ease of Installation: Lighter sections allow for smaller cranes and faster manual handling on-site.

The Metallurgy of the Galvanized Layer

A common technical concern in structural frames is the “Sandelin Effect.” During hot-dip galvanizing, the silicon (Si) and phosphorus (P) content in the steel dictates the reaction between the iron and the molten zinc.

In our production of S275JR and S355JR, we maintain strict “Category A” or “Category L” silicon levels (typically $Si \le 0.03\%$ or $0.14\% < Si \le 0.25\%$). This ensures:

- Aesthetic Uniformity: A smooth, silver finish rather than a dark, brittle grey.

- Adhesion: A robust metallurgic bond that won’t flake off during the thermal expansion and contraction of the structural frame.

- Ductility: A coating that can withstand minor structural deflections without cracking.

Fracture Mechanics: The “JR” vs “J2” Distinction

For projects in cold climates or those subject to dynamic loading (like crane rails or bridges), the impact energy requirement is the most critical parameter. This is measured via the Charpy V-Notch test.

If an S235JR section is used in an environment that drops to -20°C, the steel may cross the “ductile-to-brittle transition” temperature. Under a sudden load, the steel could snap like glass rather than deforming. By specifying S235J2, our customers ensure the material remains ductile and safe even in extreme winter conditions, as it is certified to absorb 27 Joules of energy at -20°C.

Execution Standards and Compliance

Our facility ensures that every Square Hollow Section leaves with a comprehensive Mill Test Certificate (MTC) according to EN 10204 3.1. This document is the “DNA” of your steel, detailing:

- Heat Number: Tracking the steel back to the specific furnace batch.

- Chemical Analysis: Verification of C, Mn, Si, P, and S levels.

- Mechanical Testing: Actual results for Yield, Tensile, and Elongation.

- Coating Thickness: Magnetic induction test results for the zinc layer (e.g., average 85μm).

Beyond the standard specs, we focus on Dimensional Precision. According to EN 10219-2, the tolerance for “Out-of-Squareness” is $\pm 1\%$. Our internal quality control tightens this to $\pm 0.5\%$. This precision is vital for automated welding robots and modular construction, where a 1mm deviation can lead to significant alignment issues over a 20-meter frame.

We don’t just supply a commodity; we supply an engineered component. Our galvanized S355JR SHS is the “high-performance” choice for modern infrastructure.

Would you like me to generate a specific Loading Table for various spans using our S355JR Square Hollow Sections to help with your current structural design?