Large Diameter SAW Steel Pipe

The API 5L Grade B Large Diameter SAW Steel Pipe stands as a foundational product within the global energy and infrastructure sectors, a technical manifestation of the critical need to efficiently and safely transport massive volumes of fluids—often low-pressure natural gas, crude oil, or water slurries—where high flow capacity, dictated by large diameter, is prioritized over the extreme pressure containment capabilities characteristic of higher $\text{API 5L}$ grades like $\text{X65}$ or $\text{X80}$. The selection of Grade B ($\text{Gr. B}$) is a deliberate economic and engineering choice, specifying a minimum Specified Minimum Yield Strength ($\text{SMYS}$) of $35,000$ psi, which is the lowest standardized strength level within the $\text{API 5L}$ family, positioning the pipe for applications where the design pressure is moderate but the sheer volume and scale of the project necessitate the immense size and manufacturing efficiency afforded by the SAW (Submerged Arc Welding) process. This seemingly low strength belies the technical rigor of the $\text{API 5L}$ standard, which ensures that even this base-level grade is subjected to far more rigorous testing, dimensional control, and quality assurance protocols than standard structural pipe, guaranteeing a level of reliability essential for any long-haul pipeline.

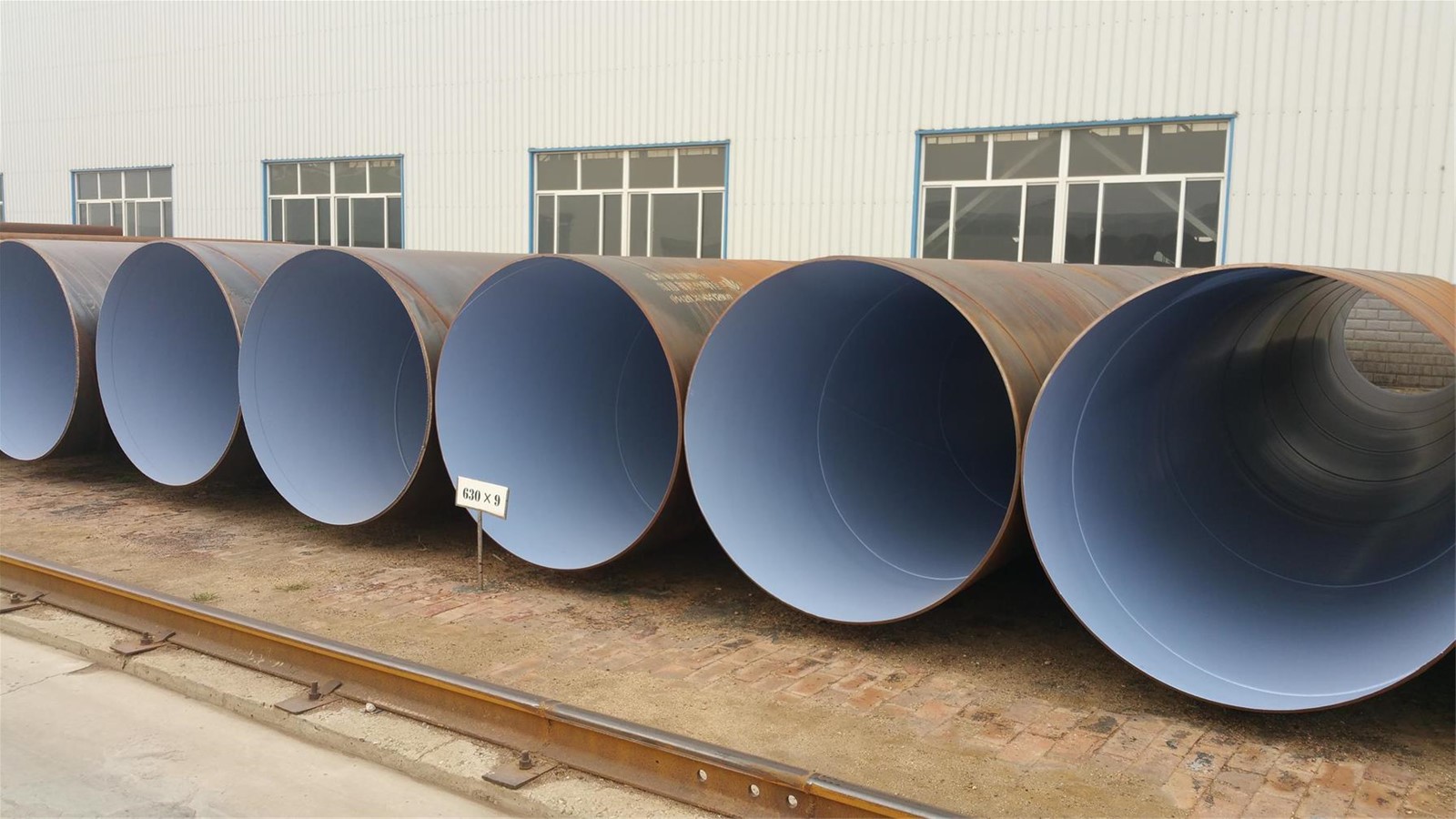

The crucial defining characteristic of this product lies in the Large Diameter SAW manufacturing process, which overwhelmingly favors either the LSAW (Longitudinal Submerged Arc Welded) method, typically achieved through the complex UOE (U-ing, O-ing, and Expanding) or JCOE (J-ing, C-ing, O-ing, and Expanding) forming processes, or the SSAW (Spiral Submerged Arc Welded) method, the economic advantage of both methods being their capability to efficiently create pipe sections with diameters frequently exceeding $\text{NPS 24}$ up to $\text{NPS 60}$ or larger, often involving substantial wall thicknesses ($\text{WT}$). The $\text{LSAW}$ process, which involves cold forming steel plate (cut from wider $\text{TMCP}$ or conventionally rolled sheet) into a cylindrical shape and welding the single, straight seam internally and externally using the high-energy, high-deposition **Submerged Arc Welding ($\text{SAW}$) ** technique, results in a uniform microstructure and excellent dimensional stability, but requires massive hydraulic presses and substantial capital investment. Conversely, the $\text{SSAW}$ process utilizes narrower steel coil, spirally winding it to form the pipe and welding the helical seam, offering greater dimensional flexibility and lower input material cost, though introducing the unique complexity of a weld seam that runs at an angle to the primary stress axes, a distinction that must be carefully managed through continuous $\text{NDT}$ (Non-Destructive Testing) for both methods to ensure the absolute integrity of the large-volume weld zone.

The metallurgical foundation of the API 5L Grade B material, while simpler than the micro-alloyed, high-$\text{TMCP}$ steels used for $\text{X}$ grades, is still governed by strict Chemical Composition limits mandated by $\text{API 5L}$, focusing primarily on ensuring excellent weldability in the mill $\text{SAW}$ process and, critically, during subsequent field welding where pipe segments are joined under variable weather conditions. The carbon ($\text{C}$) content is typically limited to a maximum of $0.26\%$, and the sulfur ($\text{S}$) and phosphorus ($\text{P}$) residuals are tightly controlled to low levels ($\text{S} \le 0.015\%, \text{P} \le 0.030\%$) to minimize the risk of internal defects like segregation and the susceptibility to hydrogen-induced cracking ($\text{HIC}$), a potential failure mode, particularly in large, high heat-input $\text{SAW}$ welds. The calculated **Carbon Equivalent ($\text{CEq}$) ** of the $\text{Gr. B}$ steel is a key technical metric, intentionally kept low to ensure that the steel remains highly compatible with the high-deposition, low-hydrogen environment of the $\text{SAW}$ process, a prerequisite for achieving the robust, high-integrity fusion required across the extensive length of the large-diameter weld seam.

The ultimate functional requirement of this large pipe is its ability to contain pressure, quantified by the Tensile Requirements of $\text{API 5L Gr. B}$, which specify a minimum $\text{SMYS}$ of $35,000 \text{ psi}$ and a minimum Specified Minimum Tensile Strength ($\text{SMTS}$) of $60,000 \text{ psi}$. These values are not arbitrary; they are the basis for calculating the safe operating pressure via the Barlow formula ($\text{P} = 2 \text{t} \times \text{SMYS} \times \text{E} \times \text{F} / \text{OD}$), where $\text{P}$ is pressure, $\text{t}$ is wall thickness, $\text{E}$ is the joint efficiency factor, $\text{F}$ is the design factor, and $\text{OD}$ is the outer diameter. Even for $\text{Gr. B}$, this calculation mandates that the pipe’s material strength, coupled with its wall thickness, is sufficient to contain the hydrostatic pressure such that the resultant hoop stress remains well within the elastic limit, ensuring the pipe does not experience plastic deformation during routine operation or during the critical Hydrostatic Test. The mandatory $\text{API 5L}$ testing protocols ensure that the strength requirements are verified not only on the base metal but also across the entire width of the SAW weld seam, often through specialized transverse tensile tests that ensure the weld metal and the heat-affected zone ($\text{HAZ}$) do not fall below the $\text{SMTS}$ of the parent material, a key verification of the manufacturing quality.

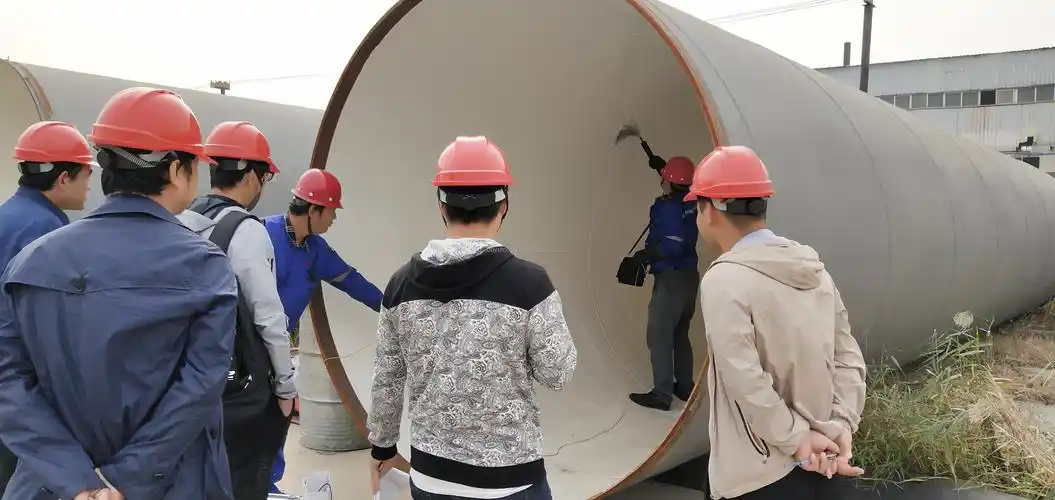

The challenge of manufacturing Large Diameter Pipe introduces complex constraints related to Dimensional Tolerance and Geometry, which are as critical to pipeline integrity as the material strength itself. The sheer scale of the pipe makes controlling ovality (the difference between maximum and minimum $\text{OD}$) and straightness extremely difficult, yet these parameters are critical for successful field fit-up and welding. Excessive ovality makes aligning the adjacent pipe ends for girth welding impossible without major force, leading to non-uniform weld gaps and potential root pass defects. Similarly, the pipe’s end squareness and the precise configuration of the bevel angle are crucial, as deviations directly affect the quality and integrity of the field weld, which must perform reliably under the constant stress of the pipeline. The $\text{API 5L}$ specification sets strict limits on these tolerances, and the large diameter $\text{SAW}$ pipe must be measured and qualified using specialized gauges and scanning equipment to ensure every meter meets the standard, preventing downstream construction delays and costly re-work in the field, a practical technical mandate that underpins the entire logistical success of the pipeline project.

Furthermore, the integrity of the $\text{SAW}$ weld seam, regardless of whether it is $\text{LSAW}$ or $\text{SSAW}$, is confirmed by rigorous **$100\%$ Non-Destructive Testing ($\text{NDT}$) ** protocols, a fundamental safety layer of the $\text{API 5L}$ standard. This typically involves using **Automatic Ultrasonic Testing ($\text{AUT}$) ** to scan the entire volume of the weld seam, seeking to detect internal defects like lack of fusion, slag inclusions, or internal porosity that could compromise the pipe’s burst strength or lead to fatigue failure. For $\text{LSAW}$ pipe, the straight, predictable weld line simplifies $\text{AUT}$, while $\text{SSAW}$ requires more complex, angled transducer arrangements to account for the spiral path. Additionally, $\text{Radiographic Testing ($\text{X-ray}$ or $\text{Gamma Ray}$) ** is often mandated, particularly at the pipe ends, to verify the weld quality in areas prone to start/stop defects, providing volumetric confirmation of soundness. The combination of these $\text{NDT}$ techniques ensures that the large, high-heat $\text{SAW}$ weld is essentially flaw-free before the pipe leaves the mill, a non-negotiable requirement for a product intended to contain high-pressure, often hazardous, fluids over decades of service.

The final structural proof and assurance of the API 5L Gr. B Large Diameter SAW Pipe is the mandatory, non-destructive Hydrostatic Test. Every single length of pipe is filled with water and pressurized to a level significantly exceeding its $\text{MAOP}$. This test is a crucial mechanical filter, proving the pipe’s elastic strength and revealing any existing flaws in the $\text{SAW}$ weld or the body that are close to the critical size, guaranteeing that the pipe can withstand the design pressure with a high margin of safety. While $\text{Gr. B}$ steel has a lower $\text{SMYS}$ compared to $\text{X}$ grades, its wall thickness is often large enough to achieve the required pressure capacity, and the Hydrostatic Test confirms that this design choice is structurally sound, making the test the ultimate seal of quality for the final large diameter product.

The investment in API 5L Grade B Large Diameter SAW Steel Pipe is not merely a procurement decision; it is a strategic commitment to decades of predictable, high-volume fluid conveyance, underwritten by the most stringent certification system in the global pipeline industry. Our product leverages the immense dimensional capacity inherent in the Submerged Arc Welded (SAW) manufacturing process—the proven backbone for large diameter transmission lines—and combines it with the strategically cost-effective Grade B material, creating a solution that is perfectly optimized for projects where flow capacity is king and operational pressure is moderate. This is the intelligent engineering choice, eschewing the unnecessary expense and fabrication complexity of higher-strength $\text{X}$ grades where the design pressure does not warrant them, thereby delivering the maximum return on investment without compromising the non-negotiable standards of safety and structural integrity demanded by the $\text{API 5L}$ specification. The large diameter capability, whether achieved through the linear precision of LSAW or the material efficiency of SSAW, guarantees that your project achieves the desired throughput, minimizing the frictional head loss and the long-term pumping energy consumption, making the initial investment a powerful predictor of operational efficiency and financial sustainability across the entire lifecycle of the pipeline.

The foundational strength of our offering lies in the **Grade B ($\text{SMYS} = 35,000 \text{ psi}$) ** material, a metallurgical masterpiece of cost-efficiency meticulously controlled to meet the demanding parameters of $\text{API 5L}$ despite its position as the entry-level grade. Our commitment to maintaining an ultra-low **Carbon Equivalent ($\text{CEq}$) ** ensures that every length of our large diameter pipe possesses exceptional weldability, a critical factor that dramatically reduces the complexity, time, and defect rate during the high-stakes field girth welding process, minimizing installation risk and accelerating project schedules. This guaranteed, repeatable weld quality is further reinforced by the inherent reliability of the $\text{SAW}$ process itself, which utilizes a massive, protected arc to deposit high-quality, high-volume weld metal, forming a seam that is consistently stronger and more ductile than the parent material, a technical assurance that is subsequently validated by the unyielding rigor of **$100\%$ Non-Destructive Testing ($\text{NDT}$) **. Every millimeter of the extensive $\text{SAW}$ seam is scanned by Automatic Ultrasonic Testing ($\text{AUT}$), eliminating volumetric defects and guaranteeing a flaw-free pressure boundary that meets or exceeds the uncompromising standards of the American Petroleum Institute, giving our clients absolute, verifiable confidence in the integrity of the pipe they bury.

Furthermore, the operational security of our large diameter $\text{Gr. B}$ pipe is ultimately confirmed by the non-negotiable Hydrostatic Test, a process that transcends simple quality control to become the pipeline’s final, structural Proof of Concept. Each pipe section is individually subjected to internal pressures significantly exceeding the final operating pressure, effectively placing every element—the $\text{Gr. B}$ body steel, the $\text{SAW}$ seam, and the end geometry—under maximum design stress. This rigorous testing filters out any potential flaws or weaknesses, ensuring that the material has achieved its full **Specified Minimum Yield Strength ($\text{SMYS}$) ** guarantee, and providing the ultimate assurance that the pipe will perform reliably under the sustained loads of service for its entire design life. . This commitment to pressure-testing every single length translates directly into risk mitigation for our clients, providing an auditable, quantifiable safety standard that is the hallmark of $\text{API 5L}$ excellence. The impeccable dimensional control of our large diameter product, covering ultra-tight tolerances on ovality, end squareness, and $\text{OD}$, ensures that this structural integrity translates seamlessly into smooth, rapid, and defect-free field installation, providing the necessary precision that high-volume construction projects demand, positioning our API 5L Grade B Large Diameter SAW Steel Pipe as the technically superior and economically advantageous choice for tomorrow’s essential infrastructure.

Structured Technical Specification Data: API 5L Grade B Large Diameter SAW Steel Pipe

| Category | Technical Specification | Typical Requirements & Standards | Technical Significance |

| Material Grade | API 5L Grade B (Gr. B) | $\text{API Specification 5L}$. Common for lower pressure service. | $\text{SMYS}$ (Specified Minimum Yield Strength) Min. $35,000 \text{ psi}$ (240 $\text{MPa}$). Provides base-level pressure containment capacity. |

| Manufacturing Method | SAW (Submerged Arc Welded) | $\text{LSAW}$ (Longitudinal) or $\text{SSAW}$ (Spiral) processes used. | Essential for economically producing Large Diameter Pipe ($\text{NPS 24+}$) with high $\text{WT}$ and high-quality weld seams. |

| Dimensions | Large Diameter, Various WT | $\text{OD}$ typically $\ge \text{NPS 24}$. **Wall Thickness ($\text{WT}$) ** varies based on design pressure requirements. | Large size maximizes flow capacity for high-volume transmission lines. $\text{WT}$ is chosen to meet $\text{MAOP}$ based on $\text{Gr. B}$ strength. |

| Governing Standard | API Specification 5L | Defines material grades, $\text{NDT}$, testing (Hydrostatic, Flattening, Tensile), and dimensional tolerances. | The international standard for line pipe, ensuring safety and integrity in fluid transmission. |

| Chemical Composition | Controlled $\text{CEq}$ | $\text{C}$ Max $0.26\%$. $\text{Mn}$ Max $1.20\%$. $\text{P}$ Max $0.030\%$. $\text{S}$ Max $0.030\%$. | Low $\text{CEq}$ ensures good weldability during the high-heat $\text{SAW}$ process and facilitates easy field welding. |

| Heat Treatment Req. | As-Welded or Normalized | Typically supplied in the $\text{As-Welded}$ condition. Normalizing or stress relief may be required for specific service conditions. | Minimizes residual stresses and ensures the $\text{SAW}$ weld $\text{HAZ}$ microstructure is sound and free from hard zones. |

| Tensile Requirements | SMYS & SMTS | $\text{SMYS}$ Min $35,000 \text{ psi}$. $\text{SMTS}$ Min $60,000 \text{ psi}$. Elongation Min. $23\%$. | Guarantees the necessary strength and ductility for pressure containment and resistance to mechanical failure. |

| Application | Line Pipe (Moderate Pressure) | Transport of water, natural gas, crude oil, and slurry where large flow capacity is required. | Optimized for long-distance, high-volume transmission under moderate pressure and external loads. |

| Features | High Flow Capacity, Weld Integrity | $\text{Features:}$ Excellent $\text{SAW}$ weld quality, high dimensional control, proven $\text{NDT}$ certification. | The large diameter provides immense capacity; $\text{SAW}$ welding ensures the $\text{API 5L}$ integrity for the entire pipe length. |

| Tolerance of $\text{OD}$ and $\text{WT}$ | API 5L Dimensional Tolerances | Ovality and Straightness are tightly controlled. $\text{WT}$ tolerance is typically $\pm 10\%$. $\text{OD}$ tolerance is tight ($\pm 0.5\%$). | Tight control of $\text{OD}$ and ovality is critical for efficient and defect-free field welding fit-up of large pipe sections. |