In summary, the technical success of EN 10219 pipe relies on a deeply integrated relationship between the chemistry (controlled by $\text{CEV}$ for weldability and $\text{P}/\text{S}$ for toughness), the manufacturing process (cold forming for efficiency and work-hardening), and the final mechanical guarantees (yield strength and low-temperature impact energy). The progression from S235 to S355J2H is an engineering-driven pathway, providing a graded spectrum of performance that allows designers to precisely select the most efficient and safe material for any given structural task. The inherent structural efficiency of the hollow section form, combined with the excellent weldability and guaranteed toughness of these $\text{EN}$ grades, ensures their continued preeminence as the material of choice for the world's most vital structural works.

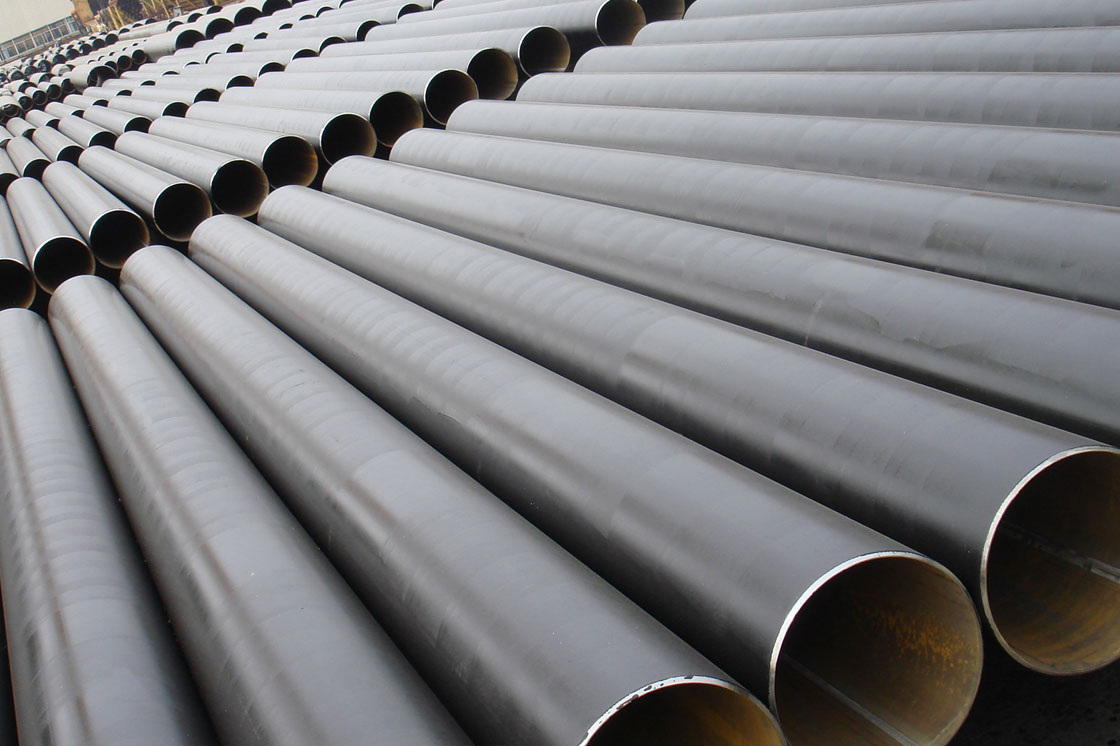

LSAW Steel Pipe

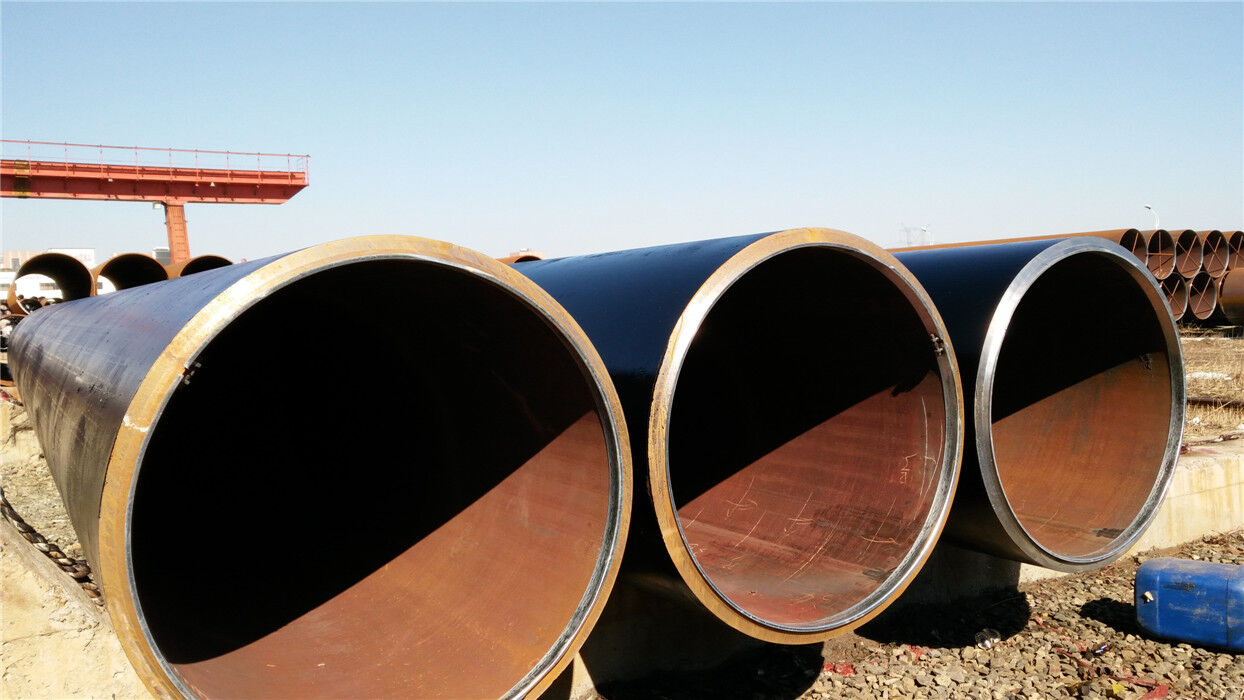

The pipe ends, which are left uncoated to facilitate field welding, require specific protection to maintain the cleanliness and integrity of the precisely machined bevels. The ends are protected with internal and external plastic or metal end caps to prevent physical damage, ingress of moisture, and internal contamination during storage and transit. For particularly long transit times, a temporary, easily removed corrosion inhibitor may be applied to the bare steel bevels to prevent surface rusting, ensuring the contractor receives a clean, ready-to-weld surface. This final logistical step closes the loop on Abtersteel’s commitment, ensuring that the high-integrity X60M PSL2 3PE LSAW pipe reaches the construction site in the same pristine, certified condition in which it left the factory.

The range of steel grades under the **EN 10219-1** standard—from the dependable **S235JRH** through the versatile **S355JOH/JEH** to the high-performance **S460MH**—provides the essential material solution for every deep foundation challenge. This European standard guarantees not only high **Mechanical Properties** (Yield Strength up to 460 MPa) but also critical **Impact Toughness** ($\text{J0}/\text{J2}$) and superior **Weldability** through strict control of the **Carbon Equivalent**.

Compared to Inconel 718 and Incoloy 901, API 5L BNS offers affordability over high-temperature performance. Relative to ASTM A671 CC60 CL22, it prioritizes sour service over low-temperature toughness, while API 5L X70 PSL2 provides higher strength but less inherent sour service suitability. The provided parameter table and tolerances aid engineering decisions. Future innovations in welding, coatings, and sustainability will enhance its utility, ensuring API 5L PSL2 BNS remains a cornerstone of reliable pipeline infrastructure in demanding environments.

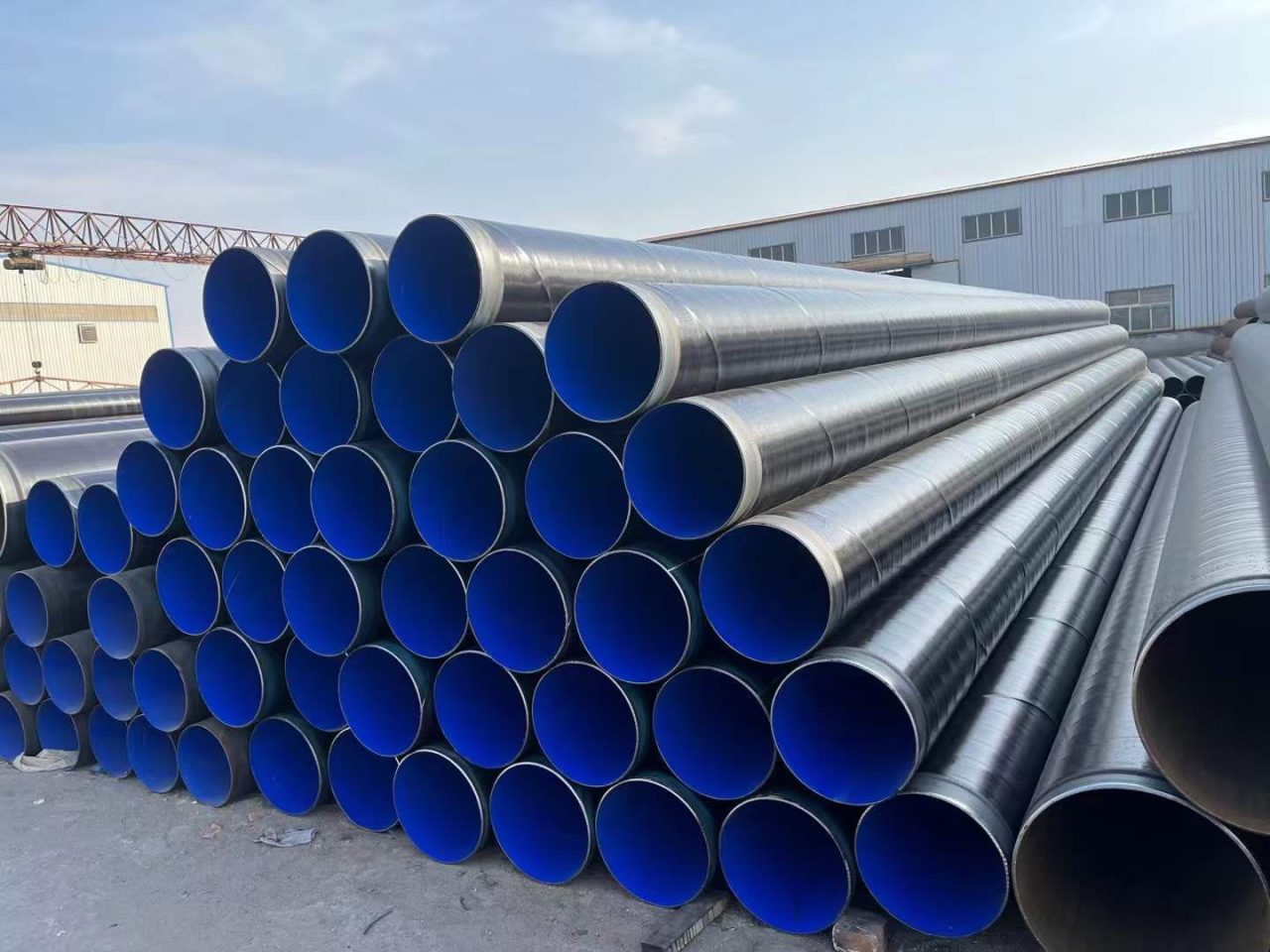

SAWH steel pipes are a fundamental component in infrastructure and industry, offering economical production and robust performance under pressure. Their unique helical welding process provides significant advantages in terms of strength and flexibility, making them suitable for a broad range of demanding applications from oil and gas transmission to structural projects.

SAWL steel pipes are a reliable choice for high-pressure and structural applications due to their strong, continuous longitudinal welds and versatility in manufacturing. When selecting these pipes, it’s essential to consider the specific requirements of your project, including the pressures involved and environmental conditions, to ensure the integrity and longevity of the pipeline system.

EN 10219 LSAW and DSAW steel pipes are essential in various structural and engineering applications due to their high strength, durability, and precise manufacturing processes. These pipes provide reliable performance in demanding environments, making them an excellent choice for construction, infrastructure, and mechanical applications.

ASTM A252 LSAW and DSAW steel pipes are excellent choices for piling foundations and structural supports due to their strength, durability, and high-quality manufacturing processes.

ASTM A53 LSAW steel pipes are a reliable choice for various industrial applications due to their strength, durability, and high-quality manufacturing process. Whether used in the transportation of fluids, structural projects, or mechanical systems, these pipes provide excellent performance and long-term reliability.

DSAW pipes are an excellent choice for demanding applications due to their manufacturing precision, strength, and versatility. Whether straight or spiral welded, these pipes meet stringent industry standards and are a reliable solution for transporting fluids and gases under high pressure.

LSAW steel pipes, whether produced through UOE, JCOE (Press Bending), or JCOE (Roll Bending) methods, are integral to various industrial applications due to their high strength, dimensional accuracy, and compliance with numerous international standards. Each manufacturing process has its unique advantages, making these pipes suitable for transporting fluids and gases, as well as for use in structural and engineering projects.

Longitudinally Submerged Arc Welding Pipe is subdivided into UOE, RBE, JCOE steel pipe according to its different forming methods. Longitudinal high-frequency welded steel pipe has the characteristics of relatively simple process and fast continuous production, and has wide use in civil construction,petrochemical, light industry and other sectors. Mostly used to transport low pressure fluids or made into various engineering components and light industrial products.