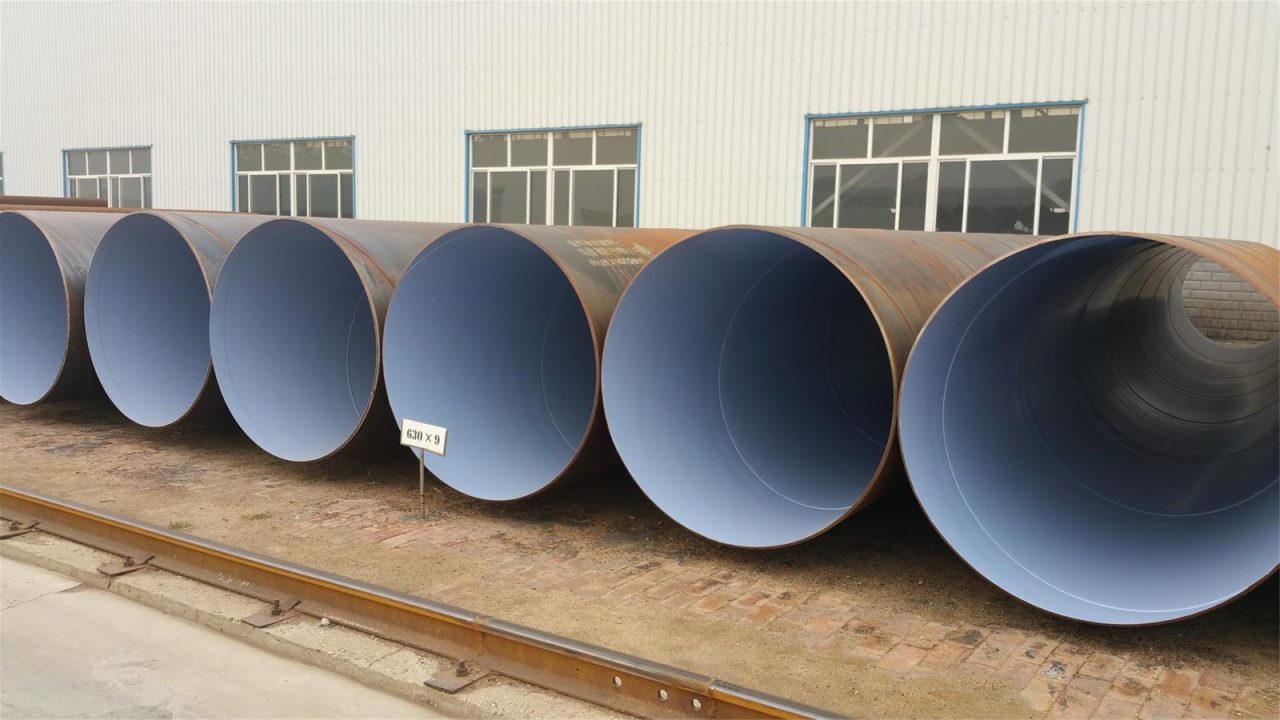

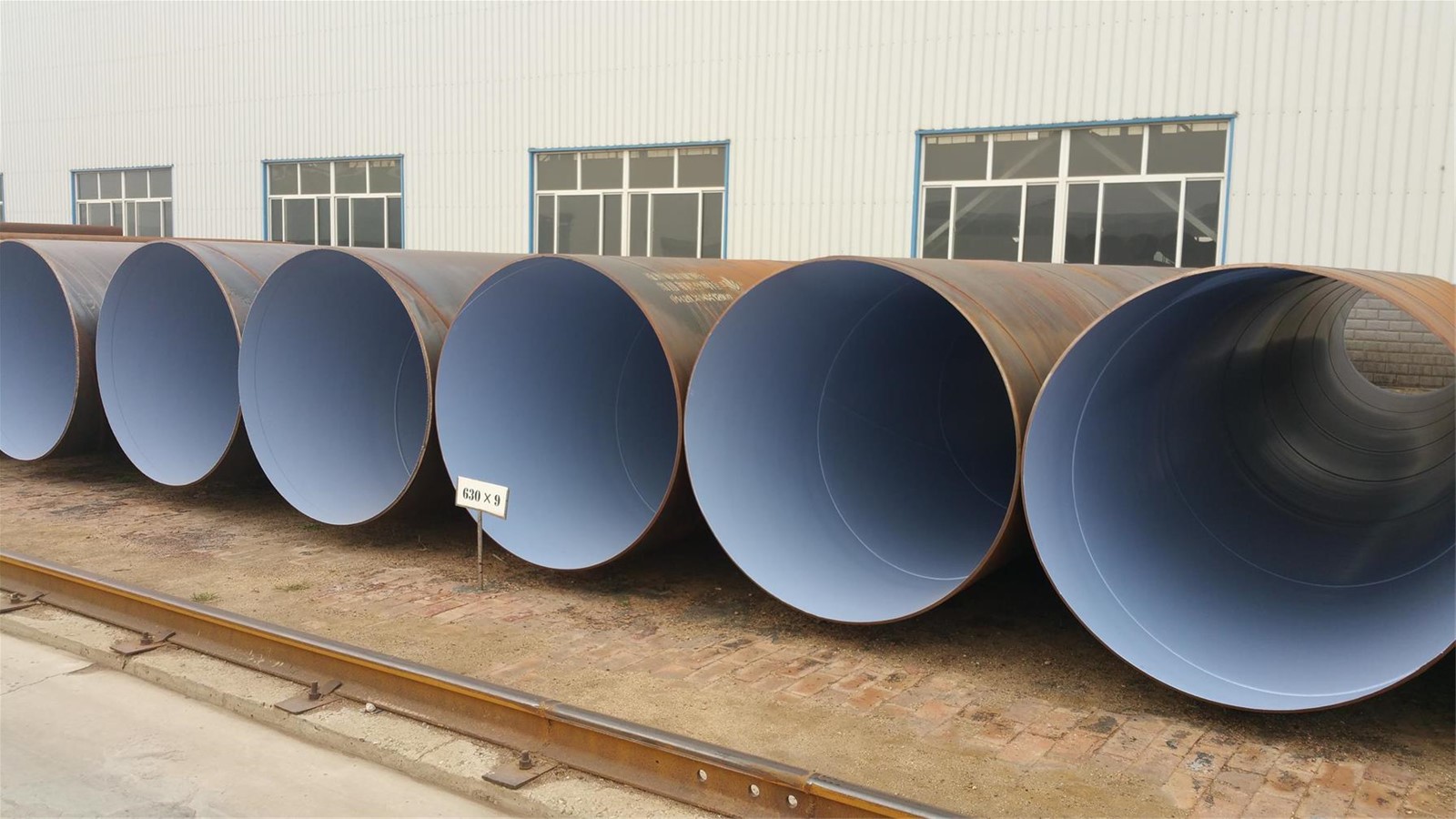

The API 5L Carbon Steel SSAW Pipe is a highly specialized piece of engineered infrastructure, a material solution fundamentally defined not by simple dimensional constraint or utility-grade corrosion protection, but by the relentless pursuit of high strength, reliable weld integrity, and exceptional fracture toughness, all necessary to ensure the safe, uninterrupted, and high-pressure conveyance of hydrocarbons, natural gas, or dense fluid slurries across vast geological and environmental landscapes. Unlike the familiar

SSAW Steel Pipe

The investment in API 5L Grade B Large Diameter SAW Steel Pipe is not merely a procurement decision; it is a strategic commitment to decades of predictable, high-volume fluid conveyance, underwritten by the most stringent certification system in the global pipeline industry

The range of steel grades under the **EN 10219-1** standard—from the dependable **S235JRH** through the versatile **S355JOH/JEH** to the high-performance **S460MH**—provides the essential material solution for every deep foundation challenge. This European standard guarantees not only high **Mechanical Properties** (Yield Strength up to 460 MPa) but also critical **Impact Toughness** ($\text{J0}/\text{J2}$) and superior **Weldability** through strict control of the **Carbon Equivalent**.

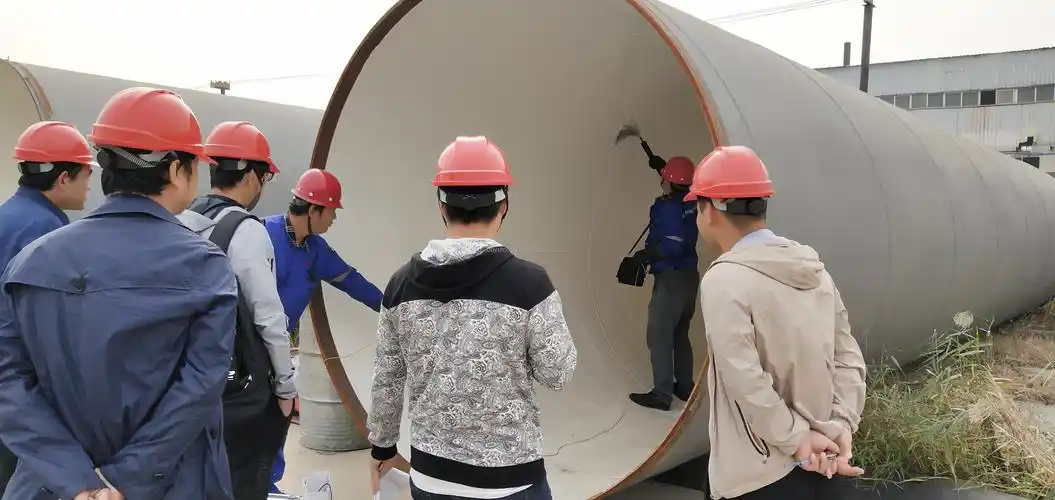

SSAW steel pipes offer a practical solution for a range of applications that require durable, large-diameter, and long-length pipes. While they have certain limitations in terms of precision and potential for defects, their cost-effectiveness and strength make them a popular choice in various industries. For specific applications, it is crucial to select the appropriate grade and comply with the relevant standards to ensure safety and efficiency.

SSAW steel pipe, also known as spiral submerged arc welded steel pipe, is a spiral welded steel pipe produced by double-sided submerged arc welding. Spiral welded pipes are formed using narrower sheets or hot rolled coils, which greatly reduces their production costs. The spiral welding process allows the production of large diameter pipes suitable for transporting large quantities of oil and gas.