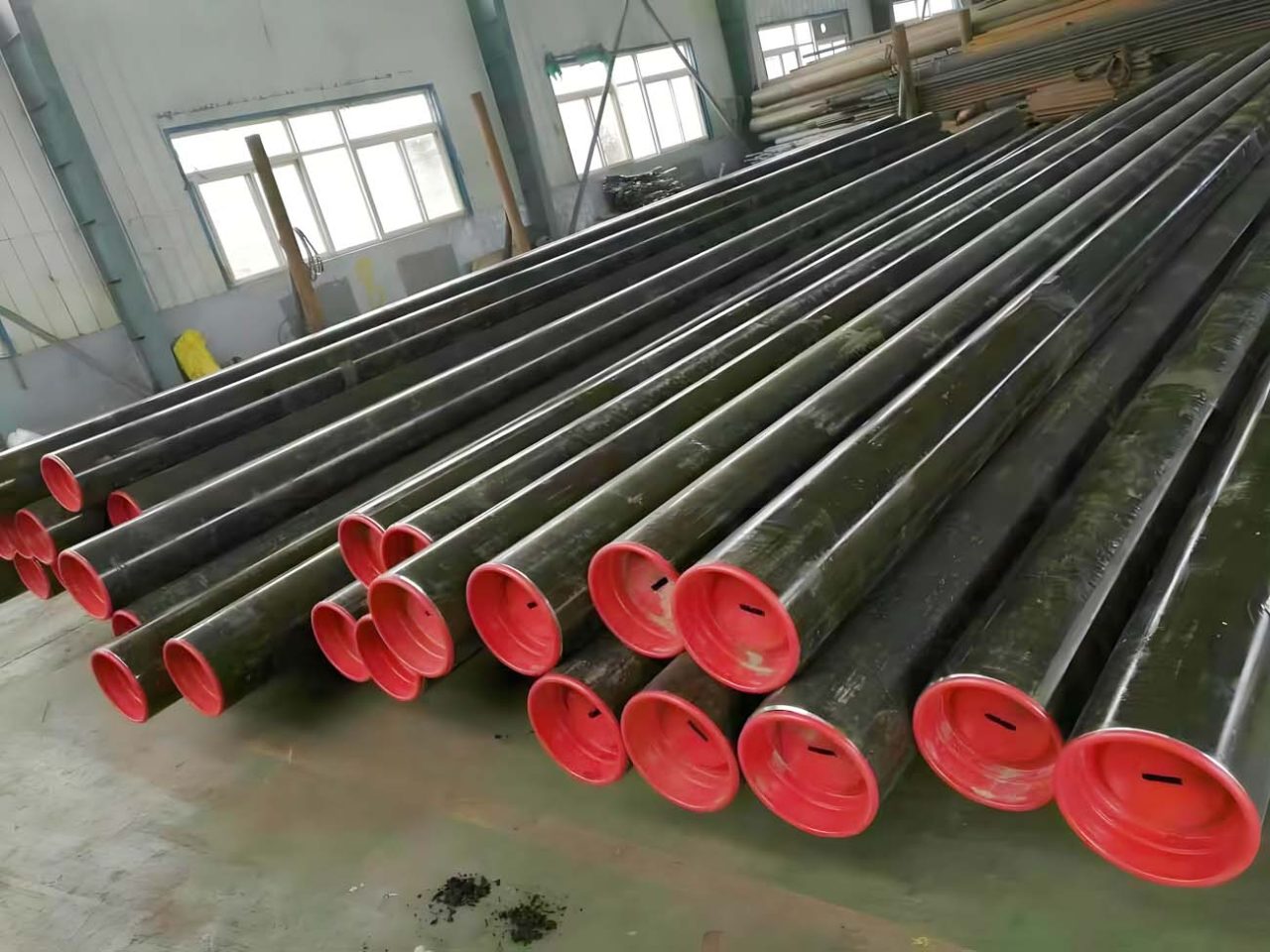

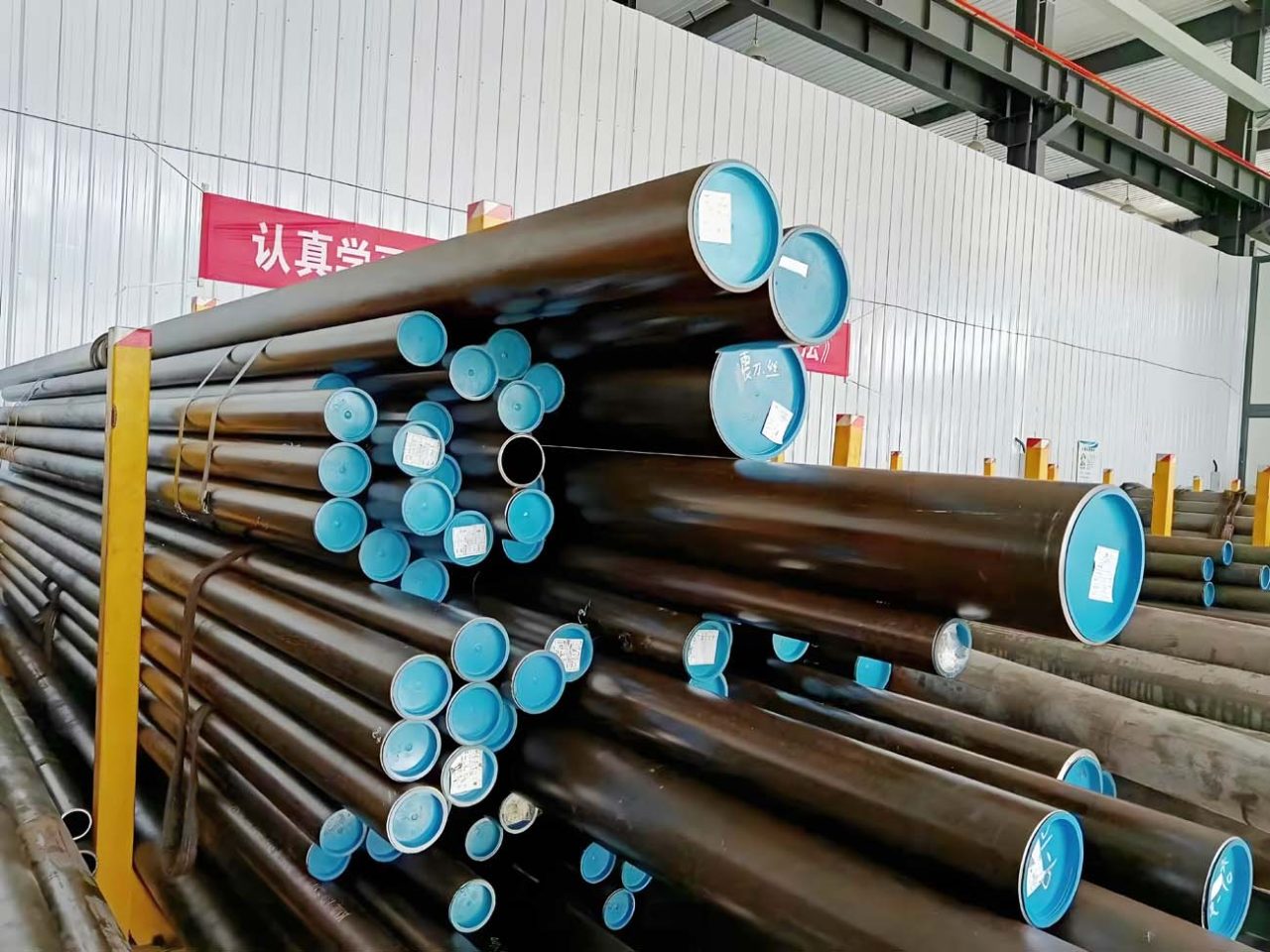

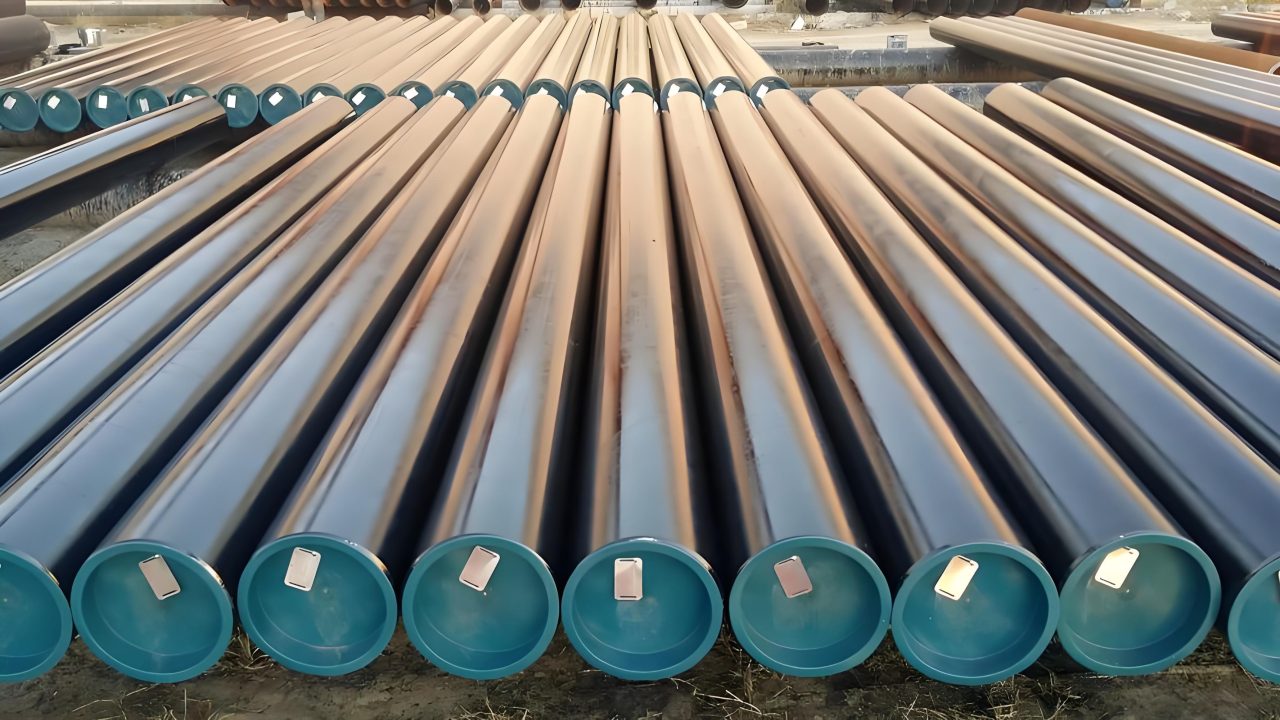

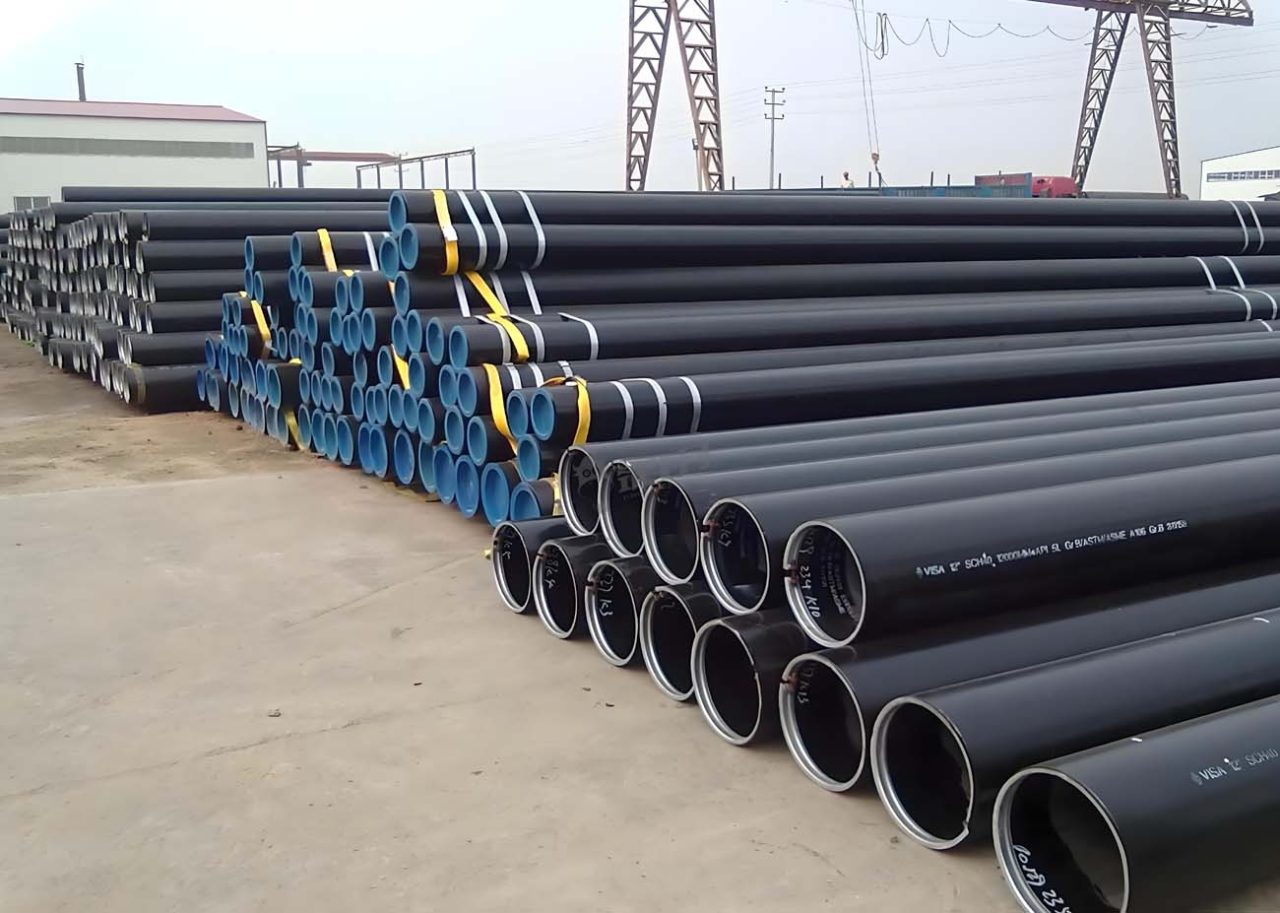

The pipe ends, which are left uncoated to facilitate field welding, require specific protection to maintain the cleanliness and integrity of the precisely machined bevels. The ends are protected with internal and external plastic or metal end caps to prevent physical damage, ingress of moisture, and internal contamination during storage and transit. For particularly long transit times, a temporary, easily removed corrosion inhibitor may be applied to the bare steel bevels to prevent surface rusting, ensuring the contractor receives a clean, ready-to-weld surface. This final logistical step closes the loop on Abtersteel’s commitment, ensuring that the high-integrity X60M PSL2 3PE LSAW pipe reaches the construction site in the same pristine, certified condition in which it left the factory.

API 5L

Compared to Inconel 718 and Incoloy 901, API 5L BNS offers affordability over high-temperature performance. Relative to ASTM A671 CC60 CL22, it prioritizes sour service over low-temperature toughness, while API 5L X70 PSL2 provides higher strength but less inherent sour service suitability. The provided parameter table and tolerances aid engineering decisions. Future innovations in welding, coatings, and sustainability will enhance its utility, ensuring API 5L PSL2 BNS remains a cornerstone of reliable pipeline infrastructure in demanding environments.

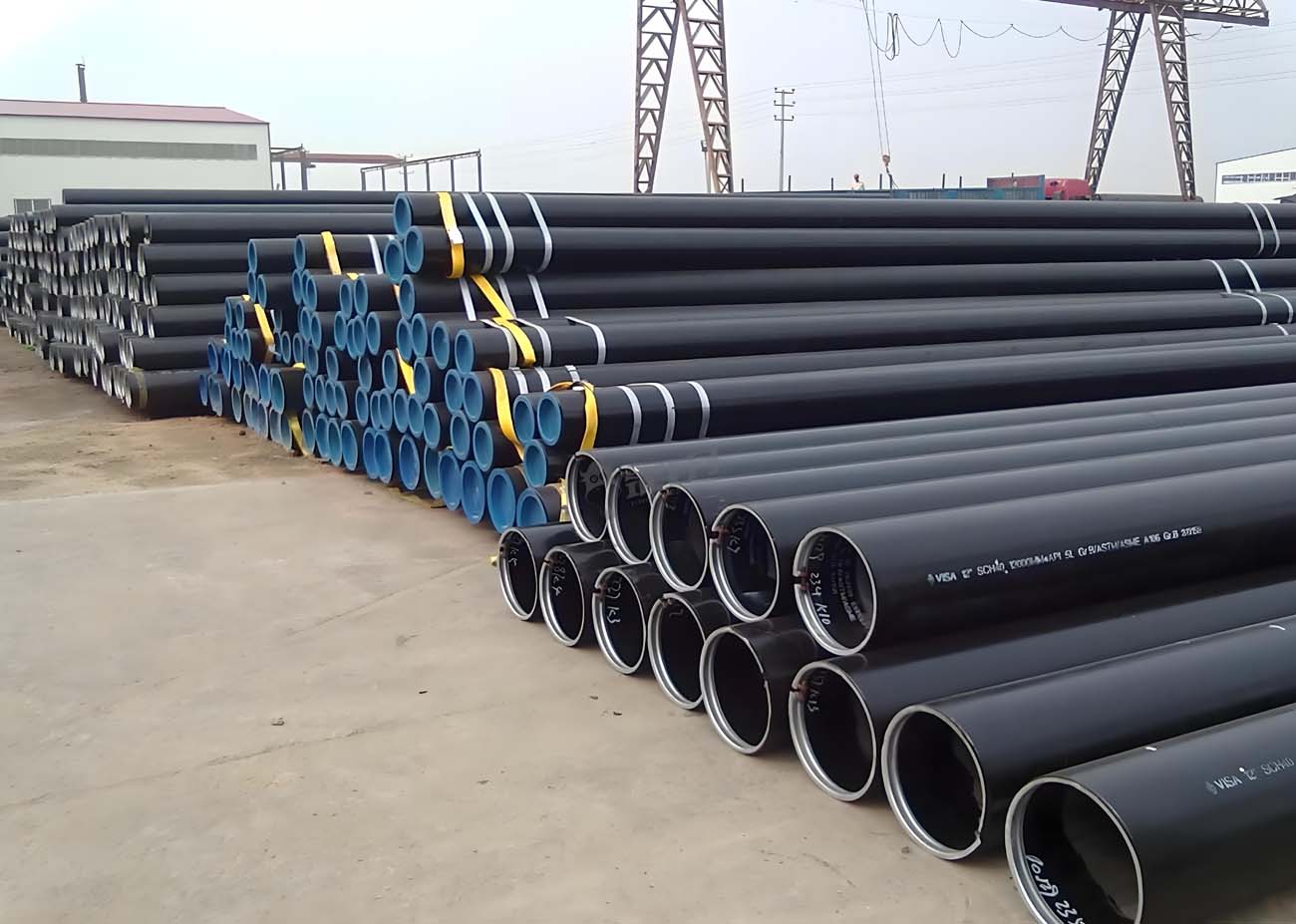

API 5L: Steel Pipes Specifications and Tolerances API 5L specifies standards for seamless and welded steel pipes used in pipeline transportation systems in the petroleum and natural gas industries.