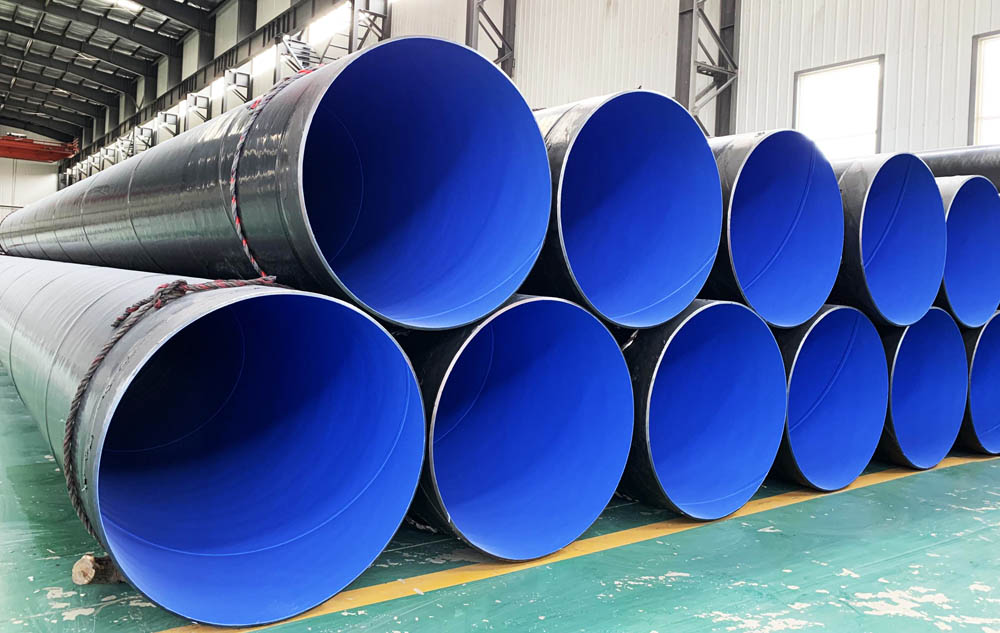

Anti-corrosion Pipeline

Corrosion prevention of pipes refers to measures to slow down or prevent corrosion and deterioration of pipes under the chemical or electrochemical action of the internal and external media or by the metabolic activities of microorganisms. Why do seamless steel pipes need to be anticorrosive? Seamless steel pipe is a relatively high-end steel pipe. After all, the raw material is iron, which will also rust, which will affect the service life in the pipeline. Therefore, the anticorrosion of seamless steel pipe is also a process that must be done before pipeline construction. For seamless steel pipe It is mainly used for 3pe anticorrosion or epoxy coal tar anticorrosion.

polyurethane insulation steel pipe

Polyurethane insulation steel pipes require less frequent inspections and have lower maintenance costs due to their resistance to moisture and corrosion. Their compatibility with advanced leak detection systems further reduces downtime and repair expenses, making them a cost-effective choice for long-term infrastructure projects.

API 5L X60M 3PE LSAW Pipe (PSL21,PSL2)

The pipe ends, which are left uncoated to facilitate field welding, require specific protection to maintain the cleanliness and integrity of the precisely machined bevels. The ends are protected with internal and external plastic or metal end caps to prevent physical damage, ingress of moisture, and internal contamination during storage and transit. For particularly long transit times, a temporary, easily removed corrosion inhibitor may be applied to the bare steel bevels to prevent surface rusting, ensuring the contractor receives a clean, ready-to-weld surface. This final logistical step closes the loop on Abtersteel’s commitment, ensuring that the high-integrity X60M PSL2 3PE LSAW pipe reaches the construction site in the same pristine, certified condition in which it left the factory.

Schedule 40 Galvanized Steel Pipe for Water Pipeline

The Galvanized Steel Schedule 40 Pipe stands as an architectural pillar of conventional fluid transport, a design solution so ubiquitous in water pipeline infrastructure that its technical sophistication is often obscured by its sheer familiarity. Its continued dominance, even in the face of modern polymer and composite alternatives, is a testament to the optimized balance achieved between the raw, dependable strength of carbon steel and the elegant, self-sacrificial electrochemistry of the zinc coating