Structures Steel Pipe

Our product range includes not only carbon steel pipe for machine structures, alloy steel pipe, carbon steel material for machine structures, and alloy steel material for machine structures that conform to ASTM, but also a wide range of high-strength steel pipe products made to our own quality standards using a wide range of manufacturing methods, including seamless pipe, electric resistance welded (ERW) pipe, and hot finished ERW pipe.

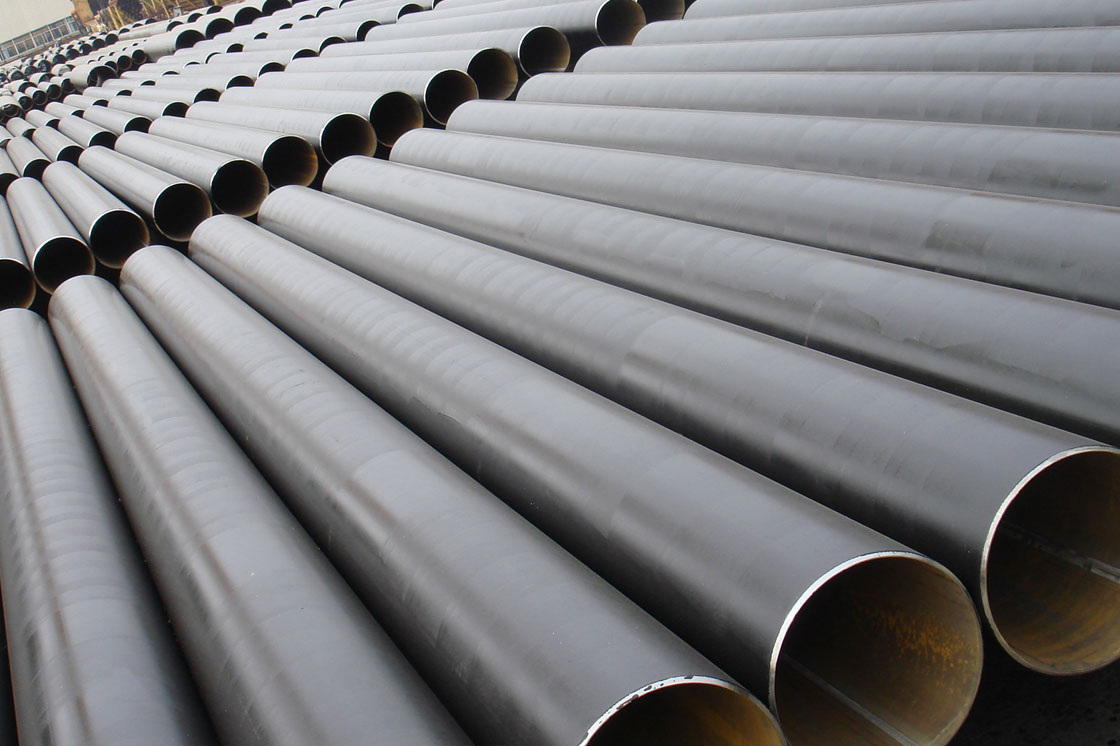

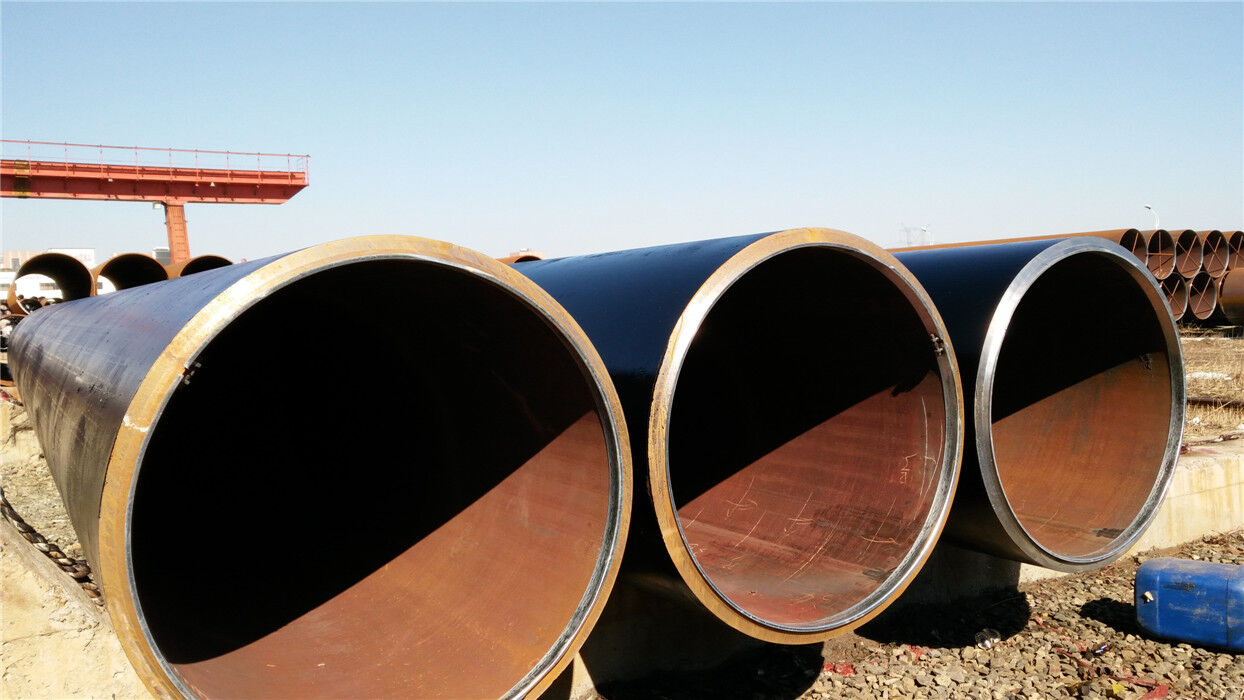

LSAW Steel Pipe (Longitudinally Submerged Arc Welding Pipe)

Longitudinally Submerged Arc Welding Pipe is subdivided into UOE, RBE, JCOE steel pipe according to its different forming methods. Longitudinal high-frequency welded steel pipe has the characteristics of relatively simple process and fast continuous production, and has wide use in civil construction,petrochemical, light industry and other sectors. Mostly used to transport low pressure fluids or made into various engineering components and light industrial products.

LSAW steel pipes

LSAW steel pipes, whether produced through UOE, JCOE (Press Bending), or JCOE (Roll Bending) methods, are integral to various industrial applications due to their high strength, dimensional accuracy, and compliance with numerous international standards. Each manufacturing process has its unique advantages, making these pipes suitable for transporting fluids and gases, as well as for use in structural and engineering projects.

DSAW Pipe

DSAW pipes are an excellent choice for demanding applications due to their manufacturing precision, strength, and versatility. Whether straight or spiral welded, these pipes meet stringent industry standards and are a reliable solution for transporting fluids and gases under high pressure.

ASTM A53 LSAW Steel Pipe

ASTM A53 LSAW steel pipes are a reliable choice for various industrial applications due to their strength, durability, and high-quality manufacturing process. Whether used in the transportation of fluids, structural projects, or mechanical systems, these pipes provide excellent performance and long-term reliability.

ASTM A252 LSAW & DSAW Steel Pipe

ASTM A252 LSAW and DSAW steel pipes are excellent choices for piling foundations and structural supports due to their strength, durability, and high-quality manufacturing processes.