API 5L Grb lined pipe cover seamless or welded carbon steel line pipe which suitable for use in conveying gas and oil industry. Our factory can offer high quality API5L Grb line pipe to all of worlds with API certificate.API 5L grb ERW steel pipe is very common steel grade,usuallyy for psl1 grb pipe.

We can manufacture our line pipe according to the following standards:API 5L, Grades X42, X46, X52, X56, X60, X65, X70, X75 and X80 materials

Application

Line pipes are used for transporting petroleum, natural gas, industrial gases, oil, water and many other liquids. It can be applied to submarine, high and low temperature transportation, corrosive content transportation, etc.

Technical Specification

We can manufacture our line pipe with an outer diameter from 21.3mm to 914.4mm and with a wall thickness from 2.11mm to 59.54mm.

Materials

The line pipe can be made with different materials, including API 5L GR.B, X42, X52, X56,X60, X65, X70, X80.

Equipment Maintenance

Maintenance of the following items is included in the warranty range: brush paint, groove, pipe cap, galvanization, anticorrosion property, etc.

Packaging

The line pipe can be painted with different colors according to customers’ requirements. Plastic caps are provided to protect the two sharp ends. Our line pipes are supplied in 20 feet or 40 feet containers.

Service

We can ship our line pipes to customers directly.

ABTER is a China based line pipe manufacturer and supplier. Our main products include boiler steel tube, corrosion protection steel pipe, insulated pipeline, to name a few. All of our high quality products are offered at competitive prices. The full chain of manufacturing abrasion resistant steel pipe, SSAW steel pipe, etc. can be completed in China, even in one city. Lower manufacturing cost saves your purchasing cost. The detailed information of each product is shown in the corresponding product page.

API 5L PSL1 Pipeline

Standard: API 5L PSL 1, ISO 3183 PSL 1

Steel Grade: A, B, X42, X46, X52, X56, X60, X65, X70

API 5L PSL1 A ,API 5L PSL1 B ,API 5L PSL1 X42 ,API 5L PSL1 X46,API 5L PSL1 X52 ,API 5L PSL1 X56 ,API 5L PSL1 X60 line pipe.

Dimension:

1)seamless

OD: 21.3-762mm WT: 2-100mm L: 5.8m, 6m, 11.8m, 12m

2)HFW/ERW

OD: 21.3-508mm WT: 3.2-15.9mm L: 5.8m, 6m, 11.8m, 12m

3)LSAW

OD: 406.4-1422mm WT: 6.4-44.5mm L: 5.8m, 6m, 11.8m, 12m

4)SSAW

OD: 219.1-2540mm WT: 5.4-25.4mm L: 5.8m, 6m, 11.8m, 12m

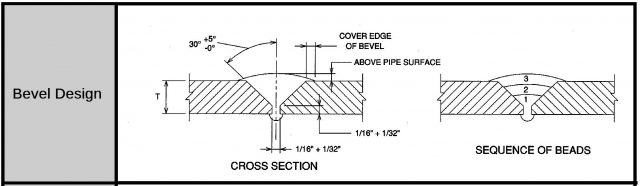

Ends deisgn:

1) Bevel the welding ends to an angle of 30°, +5°, -0°, with a root face of 1/16″, +/- 1/32″. The bevel shall form a V groove with an included angle of 60°+10/-0. The root opening shall be 1/16″, +/- 1/32″ according to ANSI B16.25.

2) Plain or straight ends.

3) Threaded ends with coupling or without coupling according to API Spec. 5B.

API 5L psl2 Line Pipe(Seamless or Welded)

Standard: API 5L PSL 2, ISO 3183 PSL 2

Steel Grade:

1) For seamless and welded pipes

BR, BN,BQ, X42N, X42Q, X46N, X46Q, X52N, X52Q, X56N, X56Q, X60N, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q

2) For welded pipes

BM, X42M, X46M, X52M, X56M, X60M, X65M, X70M, X80M, X90M, X100M, X120M

OD: NPS 1/2″ – 30″ (21.3-762mm)

WT: SCH 10-XXS (2-100mm)

Length: 5.8m, 6m, 11.8m, 12m or according to customers’ requirements.

Manufacturing Process: Hot Rolled, ERW, HFW, SSAW, LSAW, JOCE, UOE, RBE

Package: Beveled or straight ends with plastic caps or metal protectors, black painted, hexagonal bundled or loose packing.

Usage: Water Pipeline, Petroleum Pipeline, Gasoline Pipeline, Oil Termainal Pipeline, Oil Jetty Pipeline.

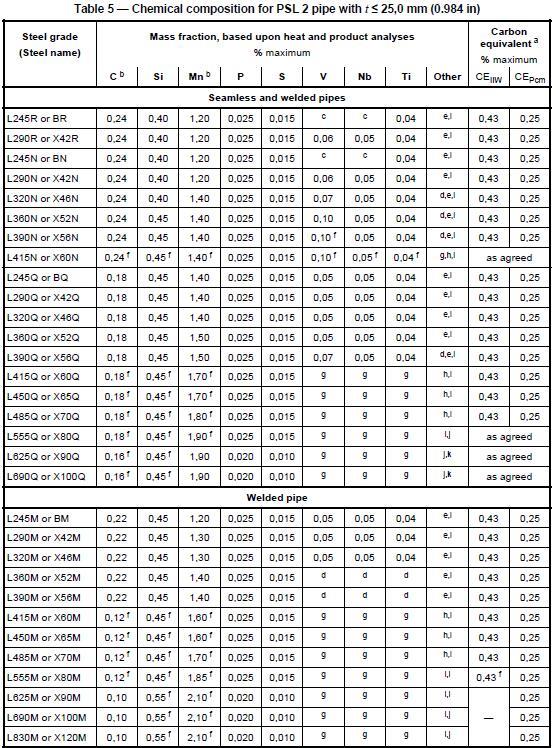

Chemical Composition Table for API 5L PSL2 Line Pipe:

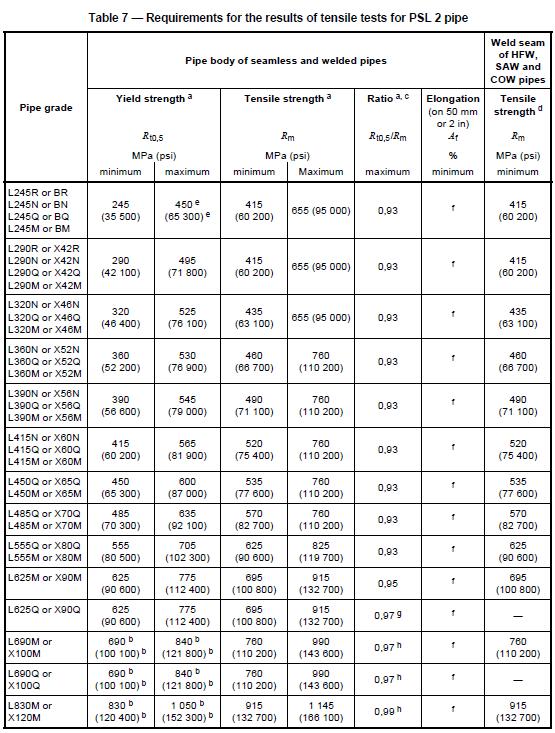

Mechanical Property Table for API 5L PSL2 Line Pipe: