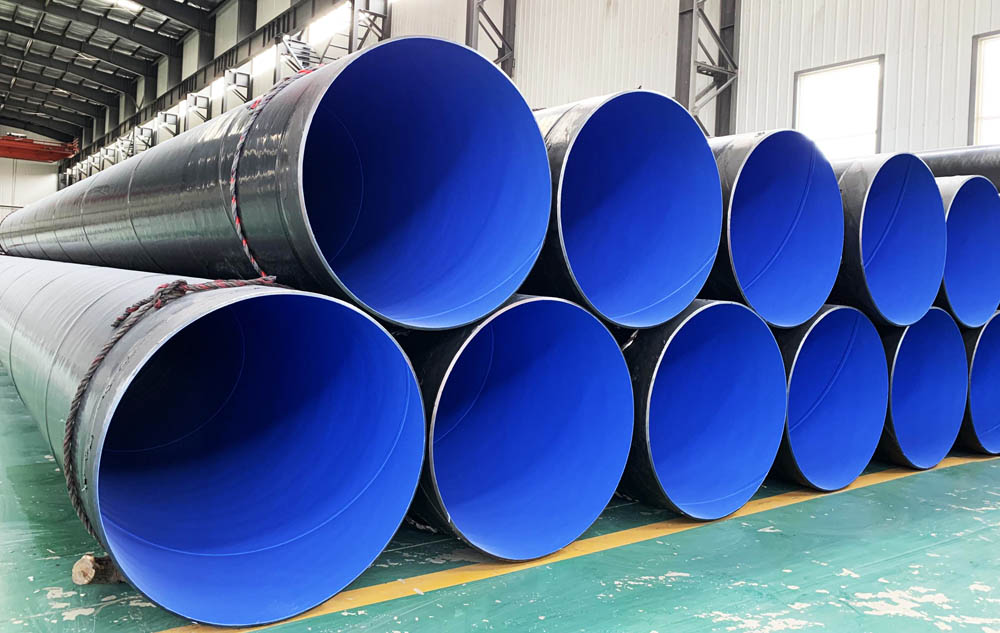

polyurethane insulation steel pipe

Steel Carrier Pipe Specifications

The steel carrier pipe forms the core of polyurethane insulation steel pipes, providing structural strength and fluid transport capacity. Its material and manufacturing standards are tailored to the pipeline’s diameter and application. For pipes with a nominal diameter (DN) of ≤150 mm, the carrier pipe is typically a 20# seamless carbon steel pipe conforming to the GB/T 8163-2018 standard. This standard ensures high tensile strength (≥410 MPa) and excellent weldability, making it ideal for smaller-diameter applications like underground hot water or chilled water supply. Seamless pipes are preferred in these sizes due to their uniform structure, which minimizes the risk of leaks under pressure.

For larger pipes with DN ≥200 mm, Q235 spiral welded carbon steel pipes are used, adhering to the GB/T 9711-2017 standard, commonly applied in oil and gas industries. Q235 steel offers a yield strength of ≥235 MPa and good ductility, suitable for high-volume transport over long distances, such as crude oil pipelines. Spiral welding allows for cost-effective production of large-diameter pipes while maintaining structural integrity. The choice of spiral welded pipes for larger diameters balances performance and economic considerations, reducing material costs by 10–15% compared to seamless alternatives.

Flexibility in standards is a key advantage, as the steel carrier pipe can also comply with international specifications like API 5L, ASTM A53, or DIN EN 10217, depending on customer requirements. For instance, API 5L pipes are widely used in crude oil pipelines due to their high resistance to corrosion and ability to withstand pressures up to 25 MPa. ASTM A53 pipes, available in seamless or welded forms, are common in district heating systems, offering reliable performance at temperatures up to 150°C. DIN standards ensure compatibility with European infrastructure projects, emphasizing precision and durability. This adaptability allows polyurethane insulation steel pipes to meet diverse global market needs, ensuring compliance with local regulations and project specifications.

The steel carrier pipe’s surface is often treated to enhance adhesion with the polyurethane foam insulation layer. Processes like sandblasting to a Sa 2.5 cleanliness level remove mill scale and rust, improving bonding strength by 20–30%, as per ISO 8501-1 standards. Proper surface preparation is critical to prevent delamination, which could compromise thermal efficiency or lead to corrosion under insulation (CUI). By combining robust materials and customizable standards, the steel carrier pipe ensures the reliability and longevity of the entire piping system, supporting applications from urban heating networks to remote oilfields.

Polyurethane Insulation Layer Properties

The insulation layer is the heart of polyurethane insulation steel pipes, delivering exceptional thermal performance. Composed of CFC-free rigid polyurethane foam sourced from reputable manufacturers like BASF or Bayer, this layer ensures environmental compliance by avoiding ozone-depleting substances. The foam is produced using advanced blowing agents like n-pentane, which have a near-zero global warming potential (GWP), aligning with regulations such as the EU’s F-Gas Regulation (517/2014). This eco-friendly formulation maintains the foam’s high insulation efficiency, making it suitable for sustainable infrastructure projects.

The foam’s density is a critical parameter, with a minimum of ≥60 kg/m³, as specified. Higher densities enhances compressive strength (≥0.3 MPa), allowing the insulation to withstand mechanical stresses in underground or high-pressure applications. Compared to lower-density foams (35–40 kg/m³) used in less demanding systems, the ≥60 kg/m³ density ensures durability in harsh environments, such as crude oil pipelines, where soil loads or thermal expansion may occur. The closed-cell structure, with a cell closure rate of 92–95%, minimizes water absorption to ≤0.2 kg/m², protecting the steel carrier pipe from corrosion and maintaining insulation performance over decades.

Thermal conductivity is another standout feature, with values ≤0.033 W/(m·K) at 50°C, significantly lower than mineral wool (0.035–0.045 W/(m·K)) or fiberglass (0.033–0.048 W/(m·K)). This low conductivity reduces heat loss by up to 40% in district heating systems, translating to energy savings of 300–500 kWh per kilometer annually, based on typical urban network data. The foam is applied using high-pressure foaming machines, which inject the polyurethane mixture between the steel carrier pipe and outer jacket. This process ensures uniform thickness (30–100 mm, depending on the application) and eliminates voids, enhancing thermal efficiency and structural integrity.

The foaming process is tightly controlled to achieve consistent quality. Parameters like mixing temperature (20–25°C), pressure (100–150 bar), and curing time (20–30 minutes) are optimized to produce a foam with minimal defects. Post-foaming inspections, such as those outlined in EN 253, verify density, thermal conductivity, and adhesion to the steel pipe and outer jacket. The result is an insulation layer that delivers reliable performance across a wide temperature range (-50°C to 150°C), making it ideal for applications from chilled water supply to hot water distribution in district heating networks.

Outer Jacket Specifications

The outer jacket of polyurethane insulation steel pipes provides essential protection against environmental factors, ensuring the longevity of the insulation and carrier pipe. Two primary materials are used: high-density polyethylene (HDPE) pipe jackets or galvanized steel jackets. HDPE is the most common choice due to its corrosion resistance, flexibility, and cost-effectiveness. The HDPE undergoes corona treatment, a surface activation process that increases its surface energy from 30 mN/m to 38–42 mN/m, improving adhesion to the polyurethane foam by 25–30%, as per ASTM D2578 standards. This strong bond prevents delamination, even under thermal cycling or mechanical stress.

The HDPE jacket has a minimum polyethylene density of ≥940 kg/m³, ensuring high tensile strength (≥20 MPa) and impact resistance. This density also contributes to the jacket’s impermeability, with water absorption rates below 0.05%, protecting the insulation layer from moisture ingress in underground installations. The jacket’s thickness typically ranges from 2–5 mm, depending on the pipe diameter and environmental conditions. For example, thicker jackets (4–5 mm) are used in crude oil pipelines to withstand soil loads and abrasion, while thinner jackets (2–3 mm) suffice for district heating systems in urban settings.

Galvanized steel jackets are an alternative for applications requiring additional mechanical protection, such as aboveground pipelines exposed to impact or vandalism. The steel is coated with a zinc layer (70–100 µm thick) to prevent corrosion, meeting standards like ASTM A653. While galvanized steel is more robust, it is heavier and costlier than HDPE, increasing installation costs by 15–20%. Its use is typically limited to high-risk environments, such as chemical plants or coastal areas with high salinity.

Both jacket types are designed to withstand environmental challenges, including UV radiation, temperature fluctuations, and chemical exposure. HDPE jackets are often UV-stabilized with carbon black additives, extending their service life to 30–50 years in outdoor applications. Galvanized steel jackets require periodic inspections to ensure the zinc coating remains intact, as corrosion can compromise protection over time. The choice between HDPE and galvanized steel depends on factors like installation location, budget, and maintenance capabilities, with HDPE being the preferred option for most underground applications due to its balance of performance and cost.

Applications and Performance Analysis

Polyurethane insulation steel pipes are engineered for a wide range of applications, leveraging their superior thermal insulation and durability. One primary use is in underground hot water and chilled water supply systems, where they maintain fluid temperatures with minimal energy loss. In hot water systems operating at 80–120°C, the low thermal conductivity (≤0.033 W/(m·K)) of the polyurethane foam reduces heat loss to 1–2%, compared to 8–10% for traditional pipelines. Chilled water systems, operating at 5–10°C, benefit from the foam’s resistance to condensation, preventing corrosion and maintaining cooling efficiency.

District heating and cooling networks are another key application. In urban settings, these pipes deliver hot or cold water over long distances, serving residential and commercial buildings. For example, a district heating network in Stockholm, Sweden, uses polyurethane-insulated pipes to achieve an energy efficiency of 90%, reducing CO2 emissions by 200 tons annually per 10 km of pipeline. The ability to customize pipe sizes (DN 6–1220 mm) and insulation thicknesses ensures compatibility with varying flow rates and temperature requirements, making these pipes a cornerstone of modern urban infrastructure.

Crude oil pipelines represent a demanding application, where polyurethane insulation maintains oil viscosity by preventing temperature drops over long distances. In arctic environments, such as the Sakhalin-II pipeline in Russia, these pipes operate at temperatures as low as -40°C, with insulation thicknesses of 80–100 mm ensuring oil temperatures remain above 50°C. The HDPE jacket’s resistance to soil corrosion and the steel carrier pipe’s compliance with API 5L standards ensure reliability under high pressures (10–20 MPa) and harsh conditions.

Other heat insulation pipelines, such as those in chemical processing or geothermal energy systems, also benefit from polyurethane insulation. In geothermal applications, the pipes handle fluids at 100–150°C, with the foam’s compressive strength and low water absorption ensuring performance in high-pressure, moist environments. Comparative studies, such as those in the Journal of Energy Engineering, show that polyurethane-insulated pipes reduce energy costs by 20–30% compared to mineral wool or fiberglass in these applications, due to their superior thermal efficiency and durability.

Specification Summary Table

The following table summarizes the key specifications for polyurethane insulation steel pipes, based on the provided details:

| Component | Specification | Standard/Material | Application Notes |

|---|---|---|---|

| Steel Carrier Pipe | DN ≤150: 20# seamless; DN ≥200: Q235 spiral welded | GB/T 8163, GB/T 9711, API 5L, ASTM A53, DIN | Hot/chilled water, crude oil pipelines |

| Insulation Layer | CFC-free PU foam, density ≥60 kg/m³, thermal conductivity ≤0.033 W/(m·K) | BASF/Bayer, foamed by machine | District heating/cooling, thermal insulation |

| Outer Jacket | HDPE (density ≥940 kg/m³, corona treated) or galvanized steel | ASTM D2578, ASTM A653 | Underground/aboveground protection |

| Applications | Hot/chilled water, district heating/cooling, crude oil, heat insulation pipelines | – | Energy-efficient fluid transport |

This table provides a concise reference for engineers and project managers, highlighting the materials, standards, and applications that define the performance of polyurethane insulation steel pipes.