DIN 2391 St45 Seamless Pipe – Advanced Assurance and Life-Cycle Performance

The Unseen Physics of Precision: Advanced Assurance and Life-Cycle Performance of DIN 2391 St45 Seamless Pipe

The previous analysis established the fundamental engineering integrity of the DIN 2391 Grade St45 Seamless Pipe, grounding its value in dimensional precision and the metallurgical excellence achieved through the NBK (Normalized Bright Annealed) condition. However, the true differentiation of this product in the ultra-competitive high-reliability mechanical sector—particularly within the sensitive domain of fluid power systems—lies not just in its static specification, but in its performance under dynamic stress, its ability to maintain fluid cleanliness, and the rigorous quality assurance protocols that ensure its operational longevity. To continue promoting this indispensable component, we must delve into the physics of its functional surfaces, its predicted fatigue life under pressure cycling, and the economic justification derived from its meticulous flaw control and component-level integration.

1. The Science of Surface Finish and Fluid Contamination Control

In a hydraulic or pneumatic system, the internal surface of the conduit acts as a critical interface that determines both energy efficiency and system life. For the DIN 2391 St45 tube, the cold-drawing process, followed by the NBK treatment, is specifically engineered to control the Surface Roughness ($\text{Ra}$ value) to a degree far surpassing general-purpose piping.

Roughness, Friction, and Energy Efficiency

The smoothness of the bore directly impacts the flow characteristics of the hydraulic fluid. According to the Darcy-Weisbach equation, the frictional head loss ($h_f$) is proportional to the friction factor ($f$), which itself is highly dependent on the relative roughness ($\epsilon/D_i$, where $\epsilon$ is the absolute roughness and $D_i$ is the inner diameter). In precision tubes destined for hydraulic service, the required $\text{Ra}$ value is typically engineered to fall well below $4 \mu\text{m}$, frequently achieving values of $1.6 \mu\text{m}$ or even $0.8 \mu\text{m}$ after final honing or polishing. This micro-level smoothness ensures the flow regime remains as close to laminar as possible across a wide range of operational velocities, minimizing the energy dissipated as heat due to internal shear stress and turbulence. The reduced friction translates directly into lower pump power requirements and, consequently, a measurable reduction in the system’s total energy consumption—a vital factor in large-scale industrial and mobile hydraulic applications where maximizing the overall system efficiency is paramount to operating cost control and compliance with stringent energy standards.

The Zero-Tolerance Policy on Contaminants

Beyond fluid mechanics, the internal surface purity is a safety-critical issue related to fluid cleanliness. Hydraulic fluid, which can operate at pressures exceeding $400 \text{ bar}$, must remain free of particulate contaminants. Any micro-level iron oxide scale, metallic debris, or residual drawing lubricant left inside the tube bore will be carried through the system, acting like sandpaper on the tight tolerances of modern high-performance components, such as servo valves with clearances measured in the single-digit micron range. This abrasive wear quickly degrades performance, increases leakage (internal and external), and ultimately leads to catastrophic component seizure.

To combat this, the manufacturing process for our St45 NBK tube includes specialized post-production protocols that exceed standard washing:

-

Chemical Passivation and Flushing: After the NBK process, the tubes undergo rigorous internal cleaning—often involving high-pressure aqueous flushing combined with specialized inhibitors or passivation agents—to chemically neutralize any potential acid residue from pickling and physically remove microscopic particulate matter.

-

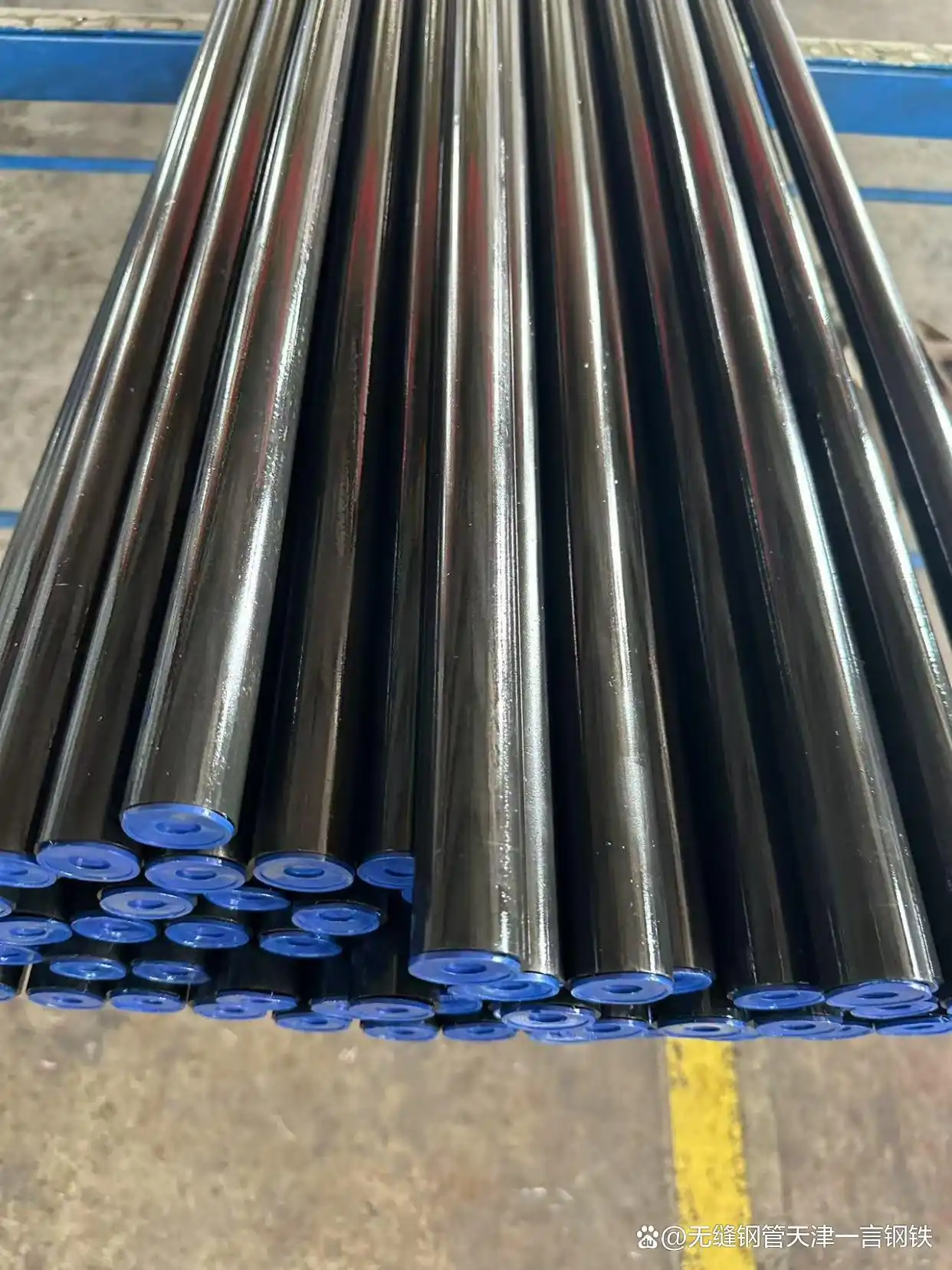

Internal Oiling and Capping: The tubes are immediately dried, internally coated with a volatile anti-corrosion oil, and sealed with plastic end caps. This crucial final step protects the pristine surface finish from atmospheric contamination (rust, dust, moisture) during storage and transport, preserving the factory-level cleanliness.

The ultimate measure of this cleanliness is compliance with global standards such as ISO 4406. High-end hydraulic component manufacturers demand that the supplied tube, after its final cleaning cycle, meets specific target codes (e.g., ISO $14/12/10$), which quantify the maximum allowable particle count per milliliter of fluid across specific size ranges ($\geq 4 \mu\text{m}, \geq 6 \mu\text{m}, \geq 14 \mu\text{m}$). Our commitment to this final, critical cleanliness validation ensures that our St45 tube is ready for immediate integration into sensitive hydraulic systems without the need for the customer to incur additional, expensive pre-installation flushing costs, cementing our tube as the benchmark for system readiness.

2. Advanced Mechanical Modeling and Fatigue Life Prediction

The true test of the St45 Seamless Pipe in hydraulic service is its resistance to fatigue failure caused by constant pressure cycling, where the pipe is repeatedly subjected to internal hoop stress followed by stress relief. Simple burst calculations based on static yield strength are insufficient; the design must be validated through rigorous fatigue life modeling.

The S-N Curve and Cyclic Stress Resistance

Fatigue life prediction relies heavily on the S-N curve (Wöhler curve), which plots the magnitude of the cyclic stress range (S) against the number of cycles (N) the material can withstand before failure. Because the St45 grade is manufactured via the seamless process and supplied in the stress-free NBK condition, its S-N curve exhibits a significantly higher fatigue limit compared to equivalent welded or highly stressed (BK condition) tubes.

-

Residual Stress Mitigation: The normalization step in the NBK treatment eliminates the tensile residual stresses that are naturally introduced during cold drawing. These residual stresses would otherwise add to the operating hoop stress, dramatically reducing the maximum allowable cyclic pressure and accelerating fatigue crack initiation. The stress-free nature of the NBK condition allows the material to utilize its full fatigue strength capacity.

-

Flaw Control and Stress Concentration: Fatigue failure invariably initiates at a stress concentration point, usually a flaw (a microscopic crack, an inclusion, or a sharp surface scratch). The extensive Non-Destructive Testing (NDT) procedures deployed during our manufacturing—including Eddy Current Testing (ET) to detect longitudinal defects and specialized ultrasonic inspection (UT) for heavy walls—are specifically designed to ensure the product enters service with a negligible flaw population. By reducing the size and frequency of flaws, we minimize the Stress Concentration Factor ($\text{K}_t$), thereby shifting the entire S-N curve upwards and to the right, dramatically increasing the predicted service cycles ($\text{N}$) before potential failure.

For a hydraulic tube operating at a maximum pressure $P_{\max}$ and minimum pressure $P_{\min}$, the resultant cyclic hoop stress ($\sigma_H$) is applied thousands or millions of times over its lifespan. Our engineering assurance provides clients with validated fatigue data based on the tight dimensional control and NBK condition of the St45, allowing them to confidently design systems to meet stringent life-cycle requirements (e.g., meeting 10 million cycles for automotive applications). This precision in material performance modeling ensures that our St45 seamless pipe contributes to the highest safety and reliability standards in the industry.

3. Tapping, Machinability, and Component Integration

The ultimate measure of the St45 tube’s utility is its ease of integration into complex mechanical assemblies. The tight dimensional control and material homogeneity are prerequisites for subsequent critical fabrication processes, such as machining, tapping, and final surface finishing.

Machinability and Weldability of St45

The controlled low-carbon, medium-manganese chemistry of the St45 steel results in excellent Machinability. It is ductile enough to prevent excessive tool wear during drilling, tapping (for mounting points or connections), and turning, yet hard enough to provide a clean, sharp shear surface. This balance is crucial for manufacturers who integrate the tube into complex components:

-

Threaded Connections: The consistent wall thickness and material properties ensure that when threads are tapped directly into the tube wall (for fittings or sensors), the thread root strength is uniform, preventing uneven stress distribution and leakage.

-

Swaging and Flaring: The high ductility afforded by the NBK condition is vital for severe cold forming. Flaring the end of the tube to accept coupling connections, or swaging the diameter for specialized fittings, requires the material to undergo high localized deformation without cracking—a performance level that only the stress-free, homogenized grain structure of the NBK St45 can guarantee reliably.

The Ideal Substrate for Surface Finishing

In many applications, the DIN 2391 tube is utilized as the base material for a piston rod or a hydraulic cylinder bore, requiring an extremely hard, wear-resistant final surface. This final surface is typically achieved through subsequent processing, most commonly Hard Chrome Plating or Honing.

-

Chrome Plating Substrate: Chrome plating requires a clean, dimensionally stable substrate for perfect adhesion and uniform deposit thickness. The inherent smoothness and scale-free surface of the NBK tube reduce the need for extensive pre-plating grinding and polishing. Furthermore, the high dimensional accuracy (low ovality) ensures the chrome layer is deposited uniformly, maximizing its wear resistance and longevity.

-

Honing and Skiving: When the tube acts as the cylinder barrel, the internal diameter must be honed or skived to an exceptionally smooth, mirror-like finish (often $\text{Ra} \leq 0.4 \mu\text{m}$) to create the optimal bearing and sealing surface for the piston. The excellent concentricity of the seamless St45 tube ensures that the honing tool maintains consistent cutting pressure around the circumference, yielding a truly cylindrical bore essential for uniform sealing and minimal frictional resistance throughout the cylinder stroke.

The ability of the St45 seamless pipe to serve as a reliable, high-precision base for subsequent high-cost finishing operations is a fundamental driver of its economic viability and market dominance in the cylinder manufacturing sector.

4. Traceability, Future Trends, and Auditable Quality Assurance

The superiority of the DIN 2391 Grade St45 product is fundamentally assured by an uncompromising system of internal traceability and quality management that satisfies the most stringent global audit requirements, particularly those required by the aerospace and automotive supply chains (e.g., ISO/TS 16949).

Full Life-Cycle Traceability

Our manufacturing system ensures complete Life-Cycle Traceability of every single length of St45 seamless pipe. The unique identifier (Heat Lot or LMA code) applied to the pipe tracks its journey from the initial steel melt and chemical analysis through every subsequent processing stage:

-

Billet Piercing and Hot Rolling.

-

Acid Pickling and Cold Drawing Passes (including intermediate heat treatments).

-

Final NBK Normalizing and Bright Annealing.

-

Non-Destructive Testing (ET/UT) results.

-

Final Dimensional Inspection and Certification (3.1 Certification).

This auditable record provides customers in safety-critical industries with the absolute assurance that the material chemistry, mechanical properties, and heat treatment history of the installed tube are fully compliant with the specification, ensuring regulatory acceptance and minimizing potential liability risks stemming from material failure.

The Value Proposition

The DIN 2391 Grade St45 Seamless Pipe, supplied in the NBK condition, represents the pinnacle of precision steel tube engineering. Its excellence is a calculated outcome of advanced metallurgical control, severe cold-work plasticity, and meticulous thermal processing. Its functional superiority is validated by its proven ability to:

-

Maximize hydraulic system efficiency by minimizing internal friction.

-

Safeguard sensitive components by eliminating fluid contaminants.

-

Ensure structural longevity through superior fatigue resistance and stress-free state.

-

Provide the ideal, dimensionally perfect substrate for subsequent high-precision finishing.

This product is not merely a steel conduit; it is an engineered component, designed and assured to be the low-friction, high-endurance heart of any critical mechanical or fluid power system, delivering long-term reliability and significant life-cycle cost advantages through its commitment to absolute precision.