DIN 30678 is more than a standard; it is a testament to abtersteel company rigor and a blueprint for achieving exceptional longevity in pipeline infrastructure. The 3PE coating system it specifies represents the pinnacle of external corrosion protection technology

Blog

The provided table and detailed analysis guide engineers in selecting the appropriate specification, with future innovations ensuring their continued relevance in industrial infrastructure.

Alloy 309 and 309S welded pipes from our company excel in high-temperature service, backed by scientific analysis of properties and performance. Contact for custom solutions.

Compared to Inconel 718 and Incoloy 901, API 5L BNS offers affordability over high-temperature performance. Relative to ASTM A671 CC60 CL22, it prioritizes sour service over low-temperature toughness, while API 5L X70 PSL2 provides higher strength but less inherent sour service suitability. The provided parameter table and tolerances aid engineering decisions. Future innovations in welding, coatings, and sustainability will enhance its utility, ensuring API 5L PSL2 BNS remains a cornerstone of reliable pipeline infrastructure in demanding environments.

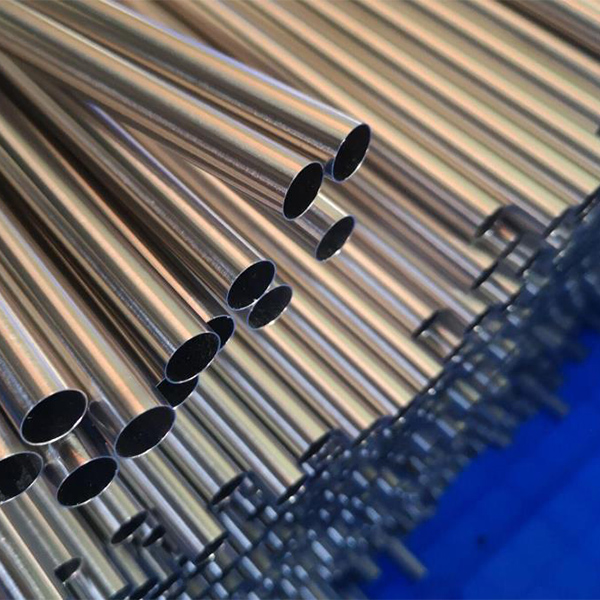

ASTM A270 304L stainless steel sanitary pipes are a cornerstone of fluid equipment in biopharmaceutical and sanitary applications, offering a balance of corrosion resistance, hygienic properties, and cost-effectiveness

316 stainless steel pipes represent the pinnacle of material engineering for juice and food processing applications, offering a unique combination of corrosion resistance, hygienic properties, and durability. Their ability to withstand acidic juices, aggressive cleaning agents, and high-pressure systems makes them indispensable in ensuring product safety and operational efficiency.

STH11 and STH12 are cost-effective for general-purpose cylinders, while STH21 and STH22 excel in high-pressure, high-temperature applications due to their Cr-Mo composition. Dimensional tolerances and chemical compositions are tightly controlled to ensure safety and performance.

Future trends in polyurethane insulation include the development of organic-inorganic composite foams, which improve mechanical strength and microbial resistance while maintaining thermal performance. Research into sustainable blowing agents, such as n-pentane, aims to reduce environmental impact without compromising insulation properties. Additionally, advancements in leakage detection systems and smart monitoring technologies will further enhance the reliability of polyurethane-insulated pipelines, making them a cornerstone of next-generation infrastructure.

Polyurethane insulation steel pipes require less frequent inspections and have lower maintenance costs due to their resistance to moisture and corrosion. Their compatibility with advanced leak detection systems further reduces downtime and repair expenses, making them a cost-effective choice for long-term infrastructure projects.

Scientific Analysis of Steel Pipes for Chemical Fertilizer Applications

Piping spool fabrication is a sophisticated process that combines engineering precision, materials science, and advanced manufacturing techniques to deliver high-quality, modular piping systems. By controlling key parameters like pipe diameter, material selection, and weld quality, fabricators ensure spools meet stringent industry standards like ASME B31.3 and API 1104. Advances in automation, digital tools, and sustainable practices are transforming the industry, enabling faster, greener, and more cost-effective production.

The JCOE forming method offers a superior balance of mechanical performance, residual stress control, and weld integrity compared to UOE and three-roll bending. While UOE remains preferable for high-volume, thin-walled pipes, JCOE is indispensable for heavy-wall, high-strength applications. Future advancements should focus on AI-driven press force optimization and hybrid forming techniques to further enhance efficiency.

Through rigorous quality control, continuous innovation, and a commitment to sustainability, our company ensures that our products meet the highest industry standards while addressing the evolving needs of global infrastructure. By comparing 3PE and FBE coatings to alternatives, addressing challenges proactively, and embracing future trends like nanocomposites and smart coatings, we solidify our position as a trusted leader in the pipeline industry. As the world grapples with the demands of energy transition, urbanization, and climate change, our 3PE coated and internal epoxy steel pipes offer a reliable, cost-effective, and sustainable solution. We invite our clients and partners to collaborate with us in building the infrastructure of tomorrow, powered by innovation and driven by excellence.

ASME SB338 Grade 7 titanium heat exchanger tubes, alloyed with palladium, offer unmatched corrosion resistance, thermal efficiency, and lightweight properties for demanding applications. Compliant with ASME SB338 and ASTM B338, these tubes excel in chemical processing, power generation, desalination, and marine heat exchangers. Their durability, enhanced by palladium, justifies their use despite higher costs. For technical data or quotes, contact suppliers like abtersteel.com

ASTM B861 titanium alloy seamless pipes are a premium choice for boiler applications, offering unmatched corrosion resistance, high-temperature strength, and lightweight properties. Compliant with ASTM B861 and ASME SB861, these pipes in grades like 2, 7, and 12 meet the demands of power generation, chemical processing, and marine boiler systems. Despite higher costs, their durability and performance justify their use in critical applications. For technical data or quotes, contact suppliers like abtersteel.com

For ASME B31.3, the design pressure should be the maximum pressure the system is expected to experience under normal or upset conditions, including any pressure relief or safety valve settings, with consideration for conservative design practices.

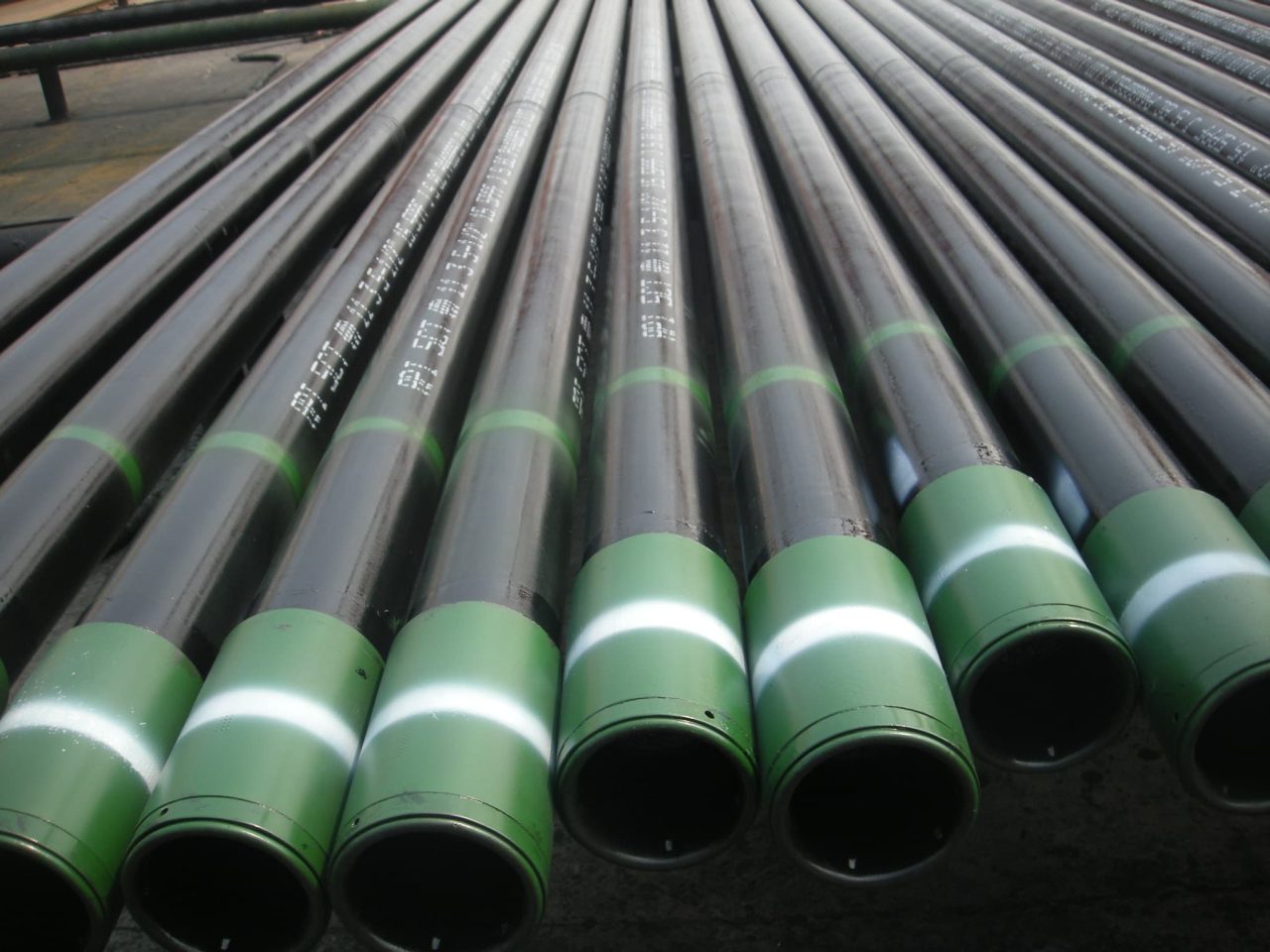

Abstract: The effect of tempering temperature after quenching at 920 ℃ on the microstructure and mechanical properties of a deep well oil casing steel was studied with the help of optical microscope (OM), scanning electron microscope (SEM), tensile testing machine and other equipment. The results show that the test steel is tempered at 500-600 ℃ to obtain tempered troostite, which has high strength, plasticity and toughness. The fluctuation range of strength-plasticity product is 20.5-22.1 GPa·%, and the fluctuation range of impact absorption energy is 94.6-100.3 J. When the tempering temperature is 550 ℃, the deep well oil casing test steel has the best comprehensive mechanical properties. At this time, the tensile strength is 978 MPa, the yield strength is 935 MPa, the strength-plasticity product is 22.1 GPa·%, and the impact absorption energy is 100.3 J. Keywords: oil casing steel; tempering temperature; microstructure; mechanical properties

Interpret and exceed complex technical specifications Maintain rigorous quality control across global supply chains Deliver mission-critical components on accelerated timelines Provide ongoing technical support throughout product lifecycle

In summary, Alloy 602 CA (2.4633, N06025) represents a pinnacle of materials engineering, blending exceptional properties with practical utility. Its standards ensure quality, its composition delivers performance, and its applications span critical industries. Whether in a chemical reactor, a power plant furnace, or a diesel engine, Alloy 602 CA proves its worth as a material built for the toughest challenges.

Incoloy 28 (UNS N08028 / W. Nr. 1.4563) alloy steel pipe stands out as a premier material for industries requiring exceptional corrosion resistance and mechanical strength. Its carefully engineered composition, adherence to stringent standards, and versatility in dimensions and forms make it a reliable choice for critical applications. The detailed tables provided—covering parameters, dimensions, testing, pressure ratings, chemical composition, and mechanical properties—offer a comprehensive resource for understanding and specifying this alloy. Whether used in chemical plants, oilfields, or marine systems, Incoloy 28 delivers unparalleled performance, ensuring safety and efficiency in the most demanding environments.

Large-diameter thick-walled seamless steel pipes, produced through advanced processes like hot piercing and heat treatment, offer exceptional strength and reliability. International grades from EN (e.g., 34CrMo4) and ASTM (e.g., A519 4140) alongside GB standards meet diverse needs, from hydraulic cylinders to energy infrastructure, ensuring performance under high pressure and stress.

For high-pressure hydraulic cylinders, seamless steel pipes such as ST52 (E355), SAE 4140 (42CrMo), 37Mn, and 34CrMo4 are widely used, adhering to standards like DIN 2391, ASTM A519, and GB 18248. These grades offer the necessary strength, toughness, and precision to ensure safety and performance under extreme pressures. Selection depends on specific pressure requirements, environmental conditions, and manufacturing processes like honing or heat treatment.

The welding of UNS N08825 pipelines demands a holistic approach integrating material science, process engineering, and stringent quality control. By optimizing TIG/MIG/SMAW parameters, mitigating defects through pre/post-weld treatments, and adhering to international standards, industries can leverage the alloy’s full potential in corrosive and high-temperature environments. Continuous advancements in welding technologies promise enhanced efficiency and reliability for future applications.

Welding Inconel 625 and P22 requires meticulous control of thermal gradients, filler selection, and post-weld treatments to address metallurgical incompatibilities. Industry standards and advanced processes (e.g., EBW, laser welding) enhance joint reliability in critical applications. Continuous innovation in welding technology will further optimize these dissimilar joints for extreme environments.

2205 duplex steel plate flat welding flange (HG/T 20592 DN40 PN10 PLRF) combines the corrosion resistance of the material with the lightweight advantages of the structure, and is suitable for medium and low pressure corrosive environments such as chemical industry and marine engineering. Its design must strictly follow the size and pressure specifications of HG/T 20592, and pay attention to the welding process and maintenance requirements during processing and use to ensure long-term reliability.

Monel K-500 is a high-performance nickel-copper-based alloy with excellent corrosion resistance and mechanical properties, suitable for a variety of industrial applications. Its good welding properties and processability make it have high flexibility in the manufacturing process. Through appropriate heat treatment processes, its performance can be further improved and the needs of different working conditions can be met.

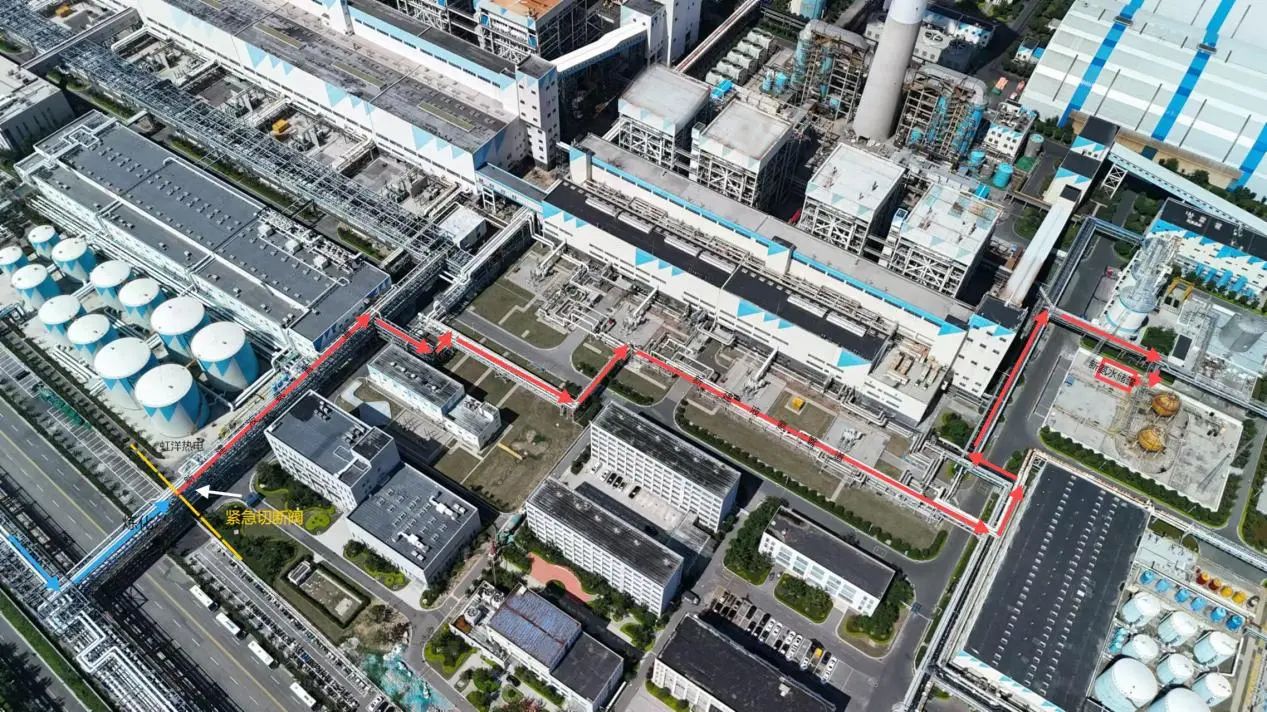

Through the welding practice of more than 400 dyne ports in the gasification section of the Liuguo Chemical Ammonia Synthesis Device, it is shown that the above welding process can completely ensure the welding quality. Judging from the result of the passing rate of 96%, it is sufficient. Prove this.

To sum up, Nickel 200's surface treatment technology includes methods such as pickling, bright annealing and polishing surfaces. These technologies have their unique advantages and room for improvement in different application scenarios.

Nickel 200 (UNS N02200/WS 2.4060) is a high-purity nickel alloy pipeline material. It performs excellently in corrosive media treatment, electronics and aerospace, but its high-temperature applications need to be carefully selected. Its welding pipe standard ASTM B725 clearly defines the size and process requirements. The supplier needs to match the carbon content (select Nickel 200 or 201) and surface treatment method according to the specific working conditions.

Perforated casing pipes are widely used in both oil & gas and water well applications. They play a crucial role in enabling efficient fluid flow, protecting the wellbore, and ensuring the overall longevity of the well. The pipe’s perforations (holes) allow for controlled inflow or outflow of fluids while preventing the collapse of the wellbore, which can be caused by external pressures. This article provides a comprehensive look at Perforated Casing Pipes, including their specifications, materials, types, mechanical properties, and applications in the oil, gas, and water well industries.