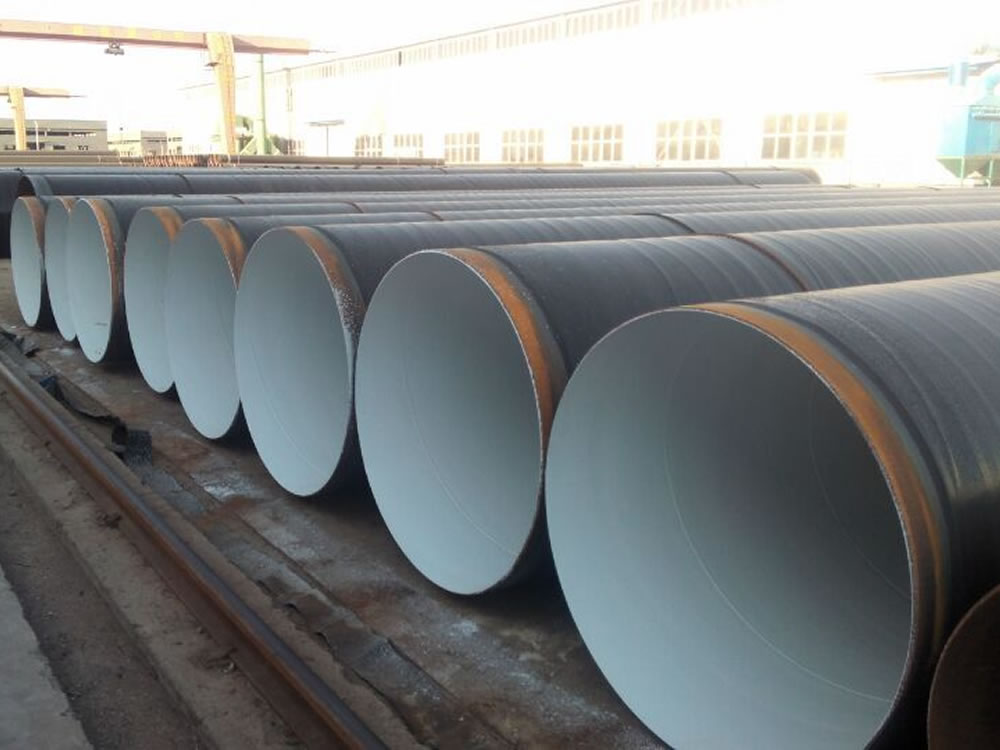

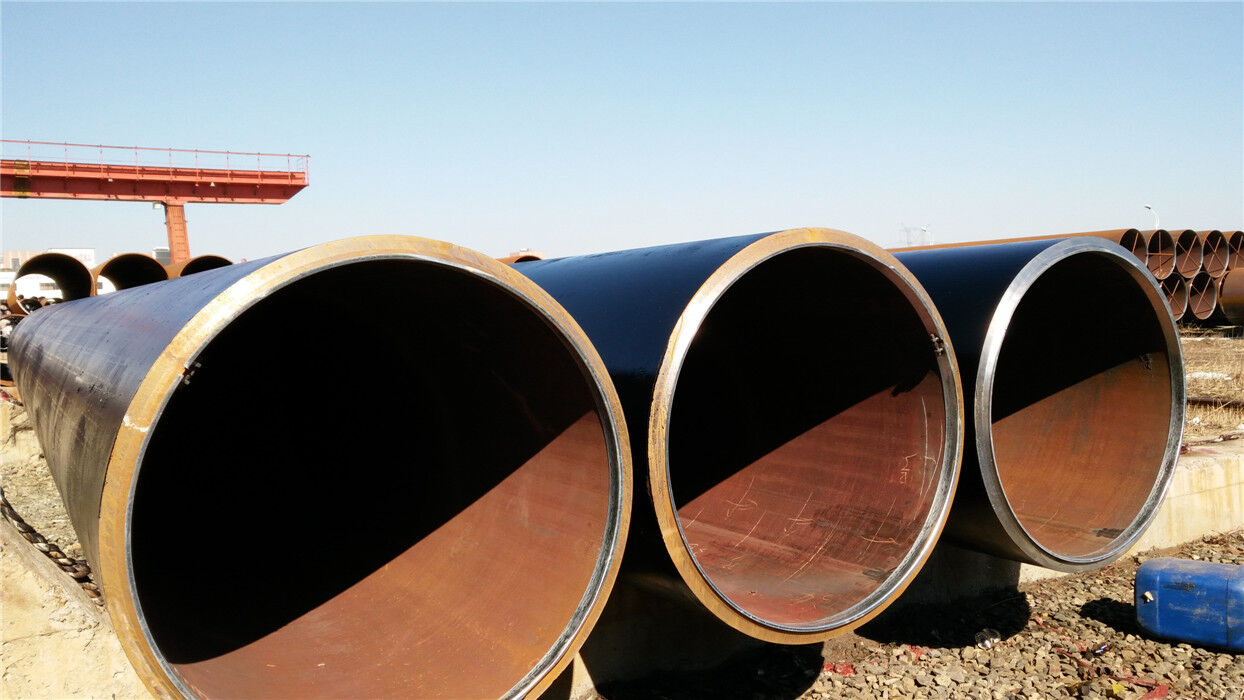

3LPE (Three-Layer Polyethylene) and 3LPP (Three-Layer Polypropylene) coatings are advanced pipe coating technologies used to protect steel pipes from corrosion, mechanical damage, and other environmental factors. These coatings are widely used in various industries, including oil and gas, water supply, and chemical processing.

Blog

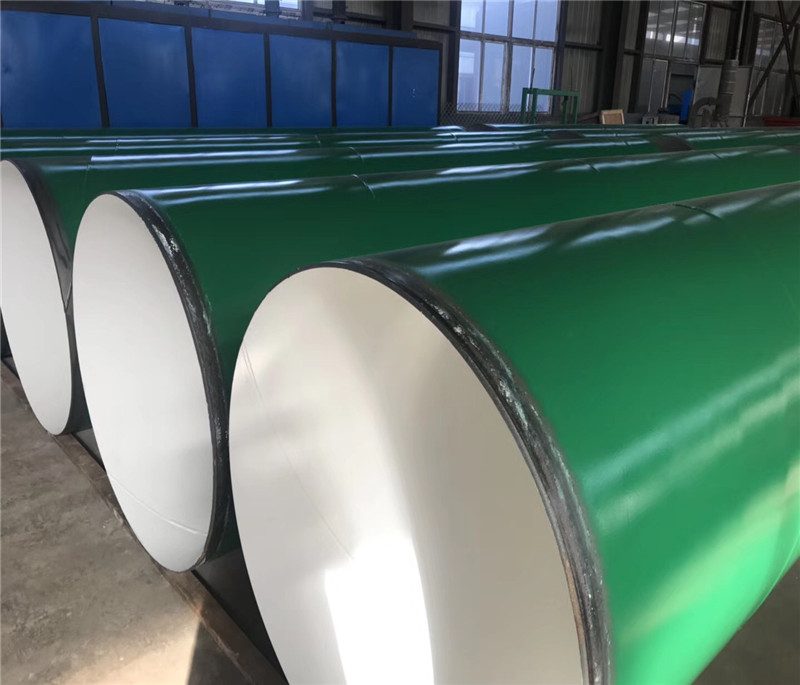

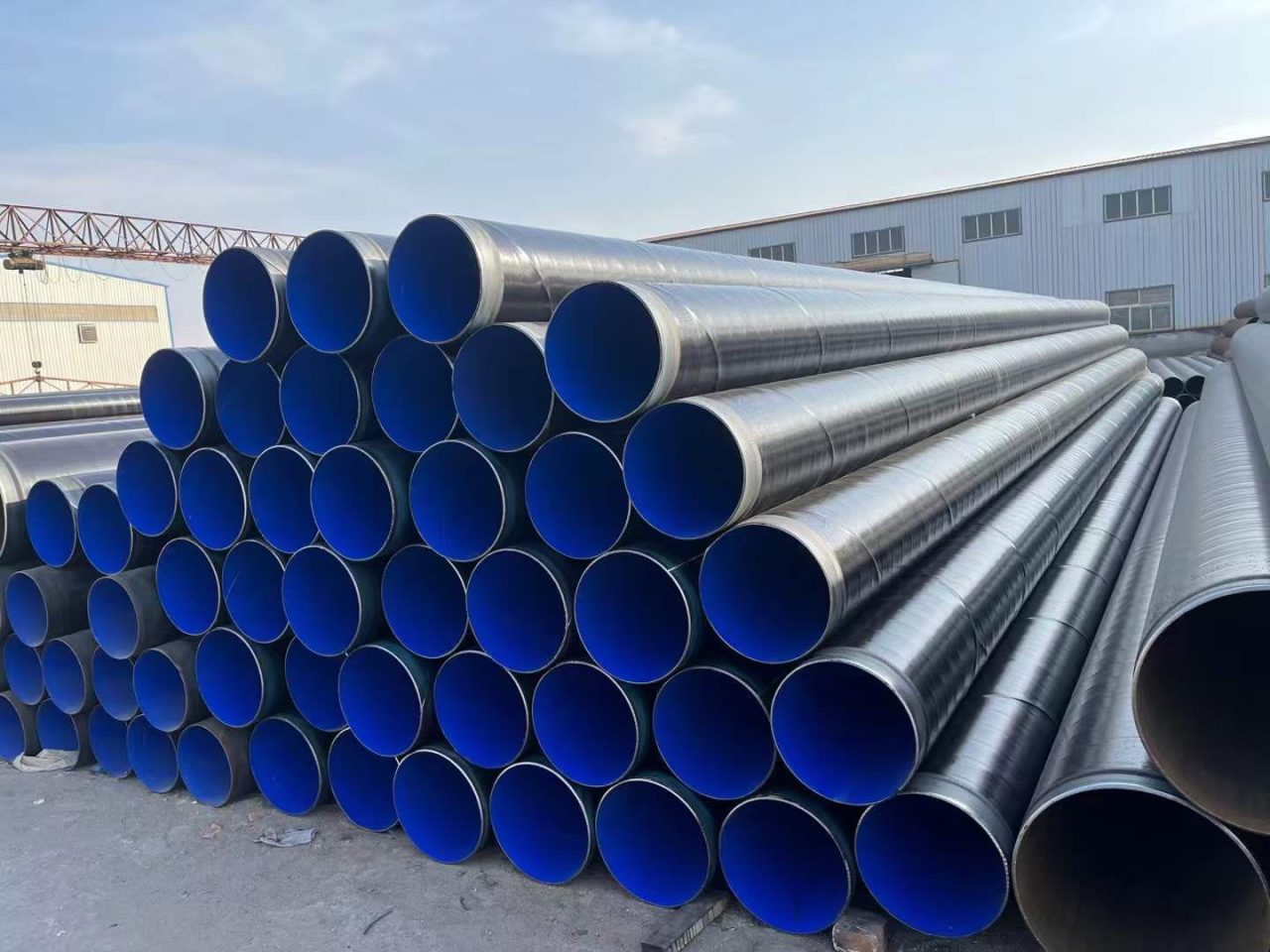

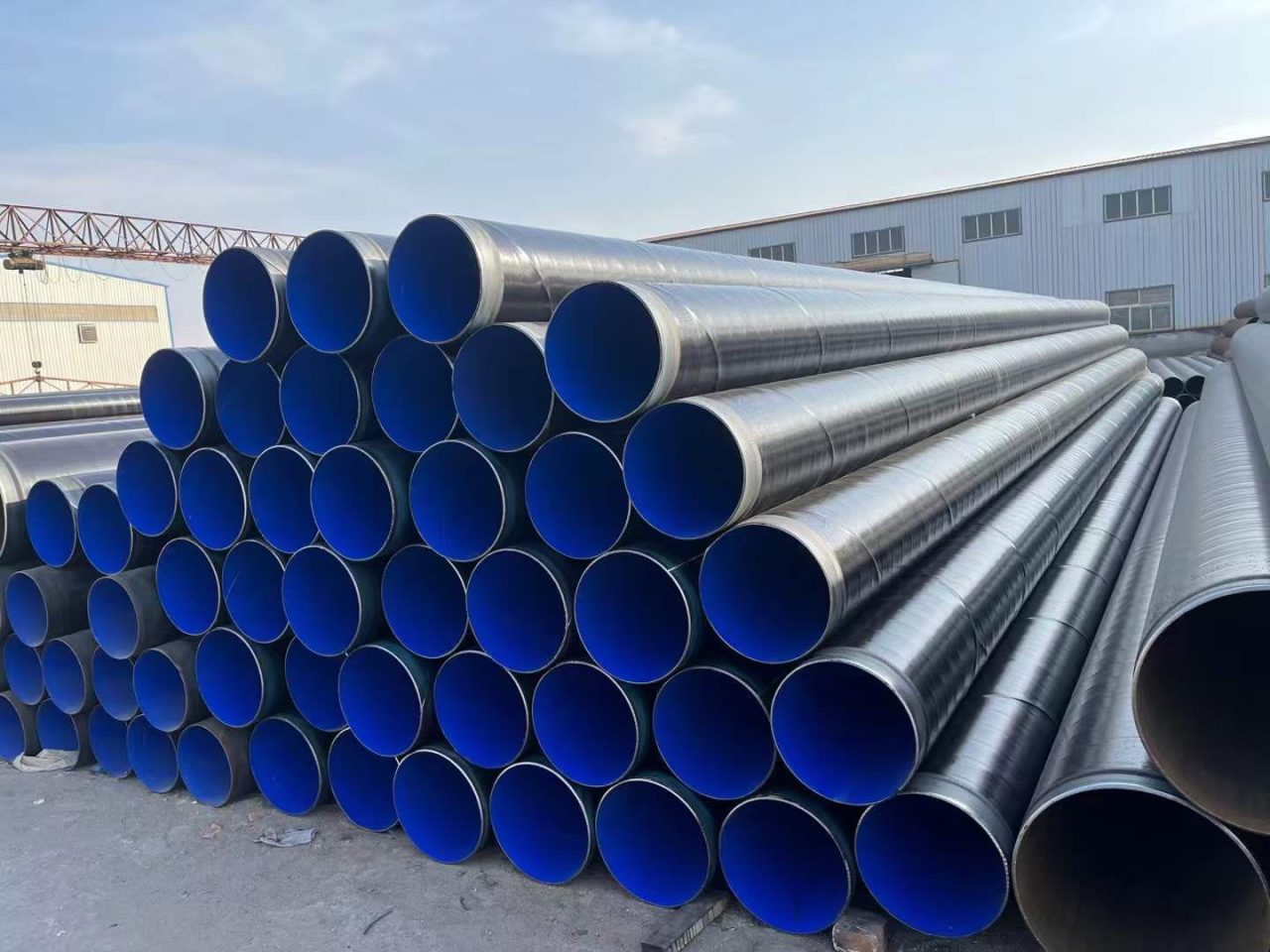

IPN8710 is an advanced anticorrosion coating designed for steel pipes, combining polyurethane resin, modified epoxy resin, asphalt, anti-rust pigments, and various additives. This coating provides exceptional corrosion resistance and durability, making it ideal for environments where steel pipes are exposed to water, gas, or other corrosive substances. By leveraging the benefits of IPN8710 coated pipes, industries can achieve enhanced pipeline integrity, reduced maintenance costs, and extended service life, ensuring safe and efficient operation in various water transport applications.

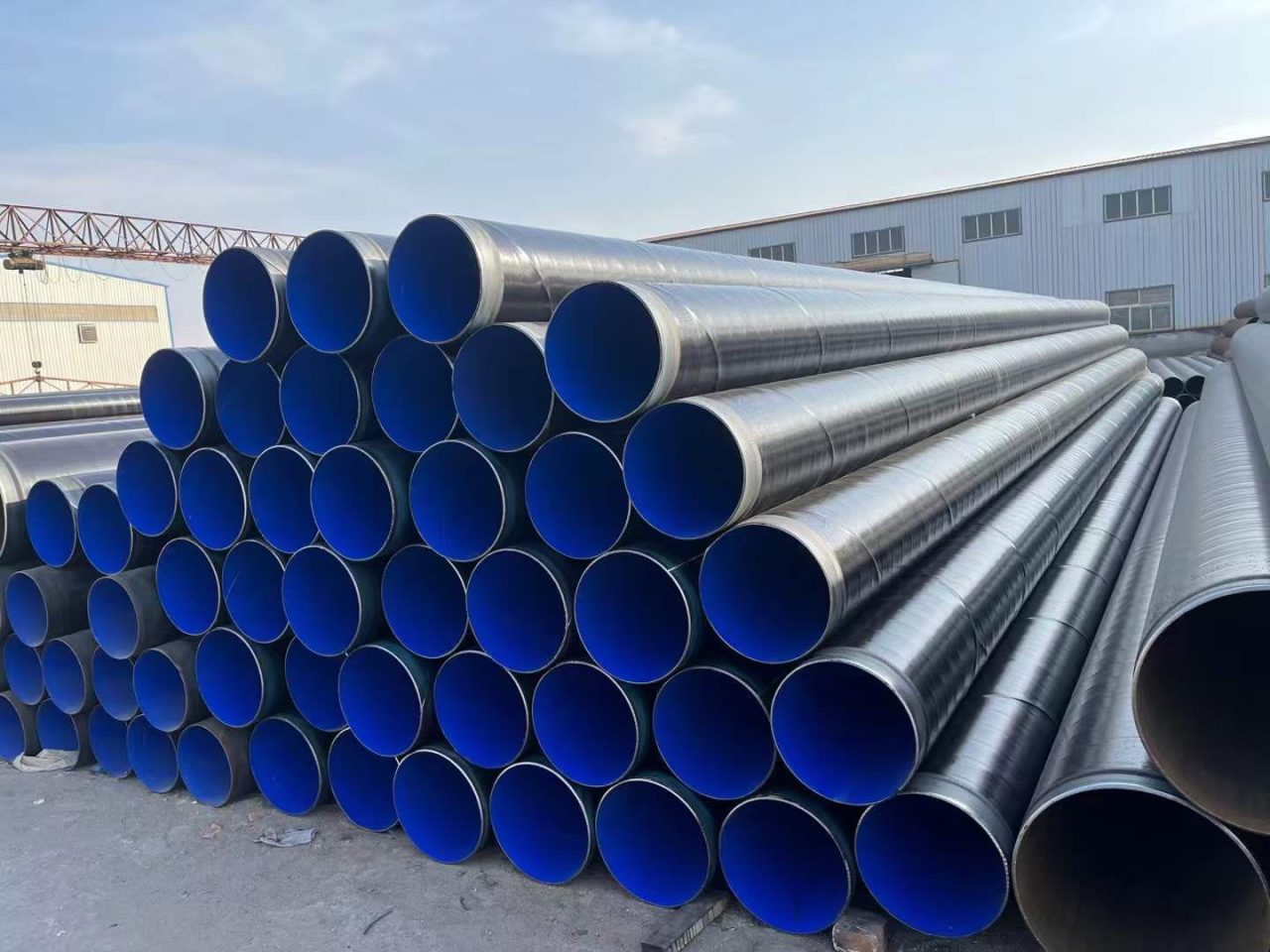

FBE coated pipes offer robust protection against corrosion and mechanical damage, making them ideal for a variety of industrial applications, including oil and gas pipelines, water pipelines, and more. Understanding the coating process, properties, and benefits can help in selecting the right coated pipe for specific needs, ensuring long-term performance and reliability in challenging environments.

Inconel 718, designated as UNS N07718 and Werkstoff Number 2.4668, is a high-strength, corrosion-resistant nickel chromium material used in the range from cryogenic temperatures up to long term service at 1200°F. The alloy is used extensively in aerospace, nuclear, and petrochemical industries due to its combination of high-temperature strength, excellent corrosion resistance, and ability to retain its properties under harsh conditions.

Alloy L-605 (UNS R30605 | Haynes 25) is a high-performance cobalt-based alloy known for its exceptional high-temperature strength, oxidation resistance, and wear resistance. It is widely used in demanding applications such as aerospace, gas turbines, chemical processing, and medical devices. By adhering to best practices in welding and fabrication, engineers and fabricators can ensure high-quality results and reliable performance in their intended applications.

Nickel 201 (UNS N02201) is a versatile material known for its excellent corrosion resistance, good mechanical properties, and high thermal and electrical conductivity. It is suitable for a wide range of applications, especially in chemical processing, electronics, aerospace, and food processing industries. By adhering to best practices in welding and fabrication, engineers and fabricators can ensure high-quality results and reliable performance in their intended applications.

Nickel Alloy 52 (UNS N14052) is a versatile material known for its controlled thermal expansion properties, making it ideal for applications requiring precision, such as in electronics and aerospace industries. It offers a good balance of mechanical and physical properties, making it suitable for various demanding applications. By adhering to best practices in welding and fabrication, engineers and fabricators can ensure high-quality results and reliable performance in their intended applications.

Nickel 200 (UNS N02200) is a versatile material with excellent corrosion resistance, mechanical properties, and conductivity. It is widely used across various industries, including chemical processing, electronics, aerospace, and food processing. By adhering to best practices in welding and fabrication, engineers and fabricators can ensure high-quality results and reliable performance in their applications.

Alloy HX (UNS N06002) offers excellent high-temperature strength and oxidation resistance, making it suitable for demanding industrial applications such as aerospace, industrial furnace components, and chemical processing. By adhering to best practices and understanding the specific requirements of this alloy, engineers and fabricators can ensure high-quality results and reliable performance in various high-temperature and corrosive environments.

Nickel Alloy 800, 800H, and 800HT (UNS N08800/N08810/N08811) offer excellent strength and resistance to oxidation and carburization at high temperatures, making them suitable for demanding industrial applications. By adhering to best practices and understanding the specific requirements of these alloys, engineers and fabricators can ensure high-quality results and reliable performance in various environments, including chemical processing, petrochemical and refining, power generation, and nuclear power industries.

Nickel Alloy 825 (UNS N08825 / WNR 2.4858) is a versatile alloy with excellent resistance to corrosion and high-temperature stability. Its favorable welding and fabrication characteristics make it a preferred choice for demanding industrial applications. By adhering to best practices and understanding the specific requirements of this alloy, engineers and fabricators can ensure high-quality results and reliable performance in various environments such as chemical processing, oil and gas, pollution control, and nuclear power.

Nickel 690 (UNS N06690 / WNR 2.4642) is a versatile alloy with excellent welding and fabrication characteristics. By adhering to best practices and understanding the specific requirements of this alloy, engineers and fabricators can ensure high-quality results in various industrial applications. Its robustness in resisting corrosion and maintaining mechanical integrity at high temperatures makes it a preferred choice for demanding environments.

INCONEL Alloy 625 (UNS N06625 / WNR 2.4856) is a highly versatile alloy widely used across various industries due to its exceptional mechanical properties, outstanding corrosion resistance, and excellent fabricability. It is particularly well-suited for high-stress and high-temperature applications in aerospace, marine, chemical processing, oil and gas, and power generation sectors.

Alloy 600, also known as Inconel 600, is a nickel-chromium alloy renowned for its exceptional resistance to high-temperature corrosion and oxidation.

Alloy 400 is a nickel-copper alloy known for its excellent corrosion resistance and high strength across a wide temperature range. It is particularly effective in reducing and oxidizing environments and offers good mechanical properties at sub-zero temperatures.

Alloy C276 is a highly versatile nickel-molybdenum-chromium alloy with excellent corrosion resistance in a wide range of severe environments. It is particularly known for its resistance to pitting, stress-corrosion cracking, and oxidizing atmospheres.

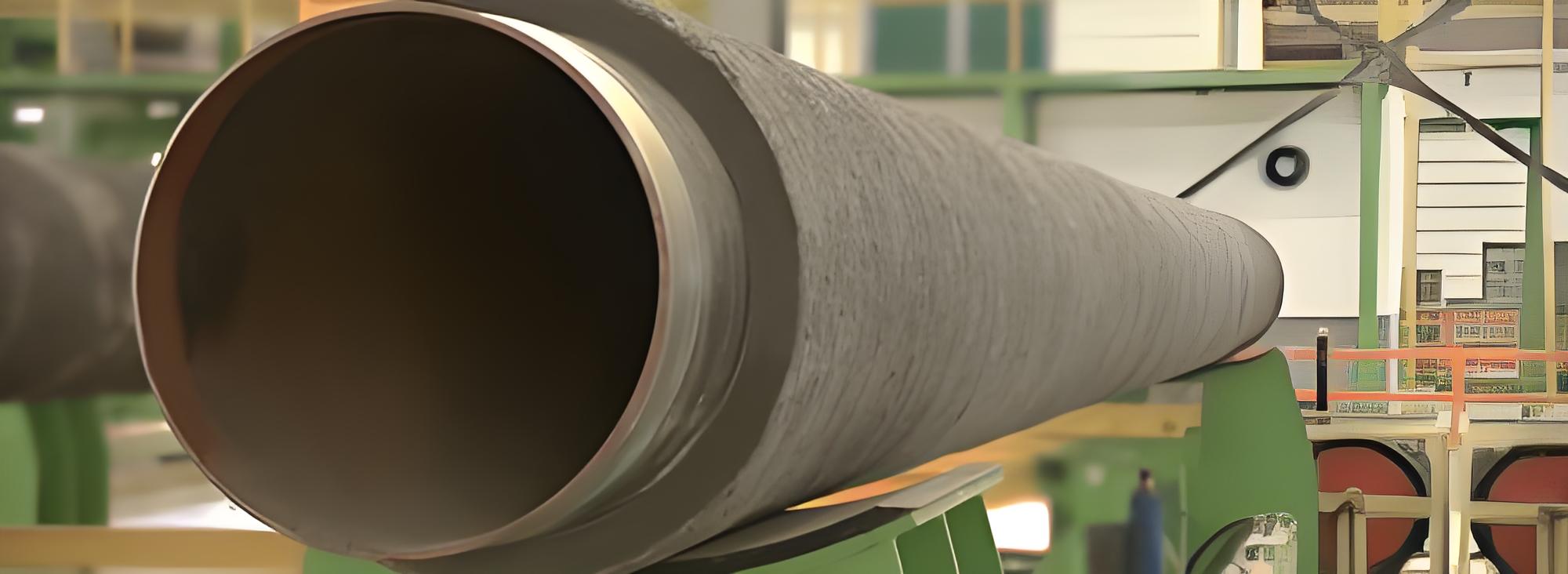

SAWH steel pipes are a fundamental component in infrastructure and industry, offering economical production and robust performance under pressure. Their unique helical welding process provides significant advantages in terms of strength and flexibility, making them suitable for a broad range of demanding applications from oil and gas transmission to structural projects.

SAWL steel pipes are a reliable choice for high-pressure and structural applications due to their strong, continuous longitudinal welds and versatility in manufacturing. When selecting these pipes, it’s essential to consider the specific requirements of your project, including the pressures involved and environmental conditions, to ensure the integrity and longevity of the pipeline system.

SSAW steel pipes offer a practical solution for a range of applications that require durable, large-diameter, and long-length pipes. While they have certain limitations in terms of precision and potential for defects, their cost-effectiveness and strength make them a popular choice in various industries. For specific applications, it is crucial to select the appropriate grade and comply with the relevant standards to ensure safety and efficiency.

EN 10219 LSAW and DSAW steel pipes are essential in various structural and engineering applications due to their high strength, durability, and precise manufacturing processes. These pipes provide reliable performance in demanding environments, making them an excellent choice for construction, infrastructure, and mechanical applications.

ASTM A252 LSAW and DSAW steel pipes are excellent choices for piling foundations and structural supports due to their strength, durability, and high-quality manufacturing processes.

ASTM A53 LSAW steel pipes are a reliable choice for various industrial applications due to their strength, durability, and high-quality manufacturing process. Whether used in the transportation of fluids, structural projects, or mechanical systems, these pipes provide excellent performance and long-term reliability.

DSAW pipes are an excellent choice for demanding applications due to their manufacturing precision, strength, and versatility. Whether straight or spiral welded, these pipes meet stringent industry standards and are a reliable solution for transporting fluids and gases under high pressure.

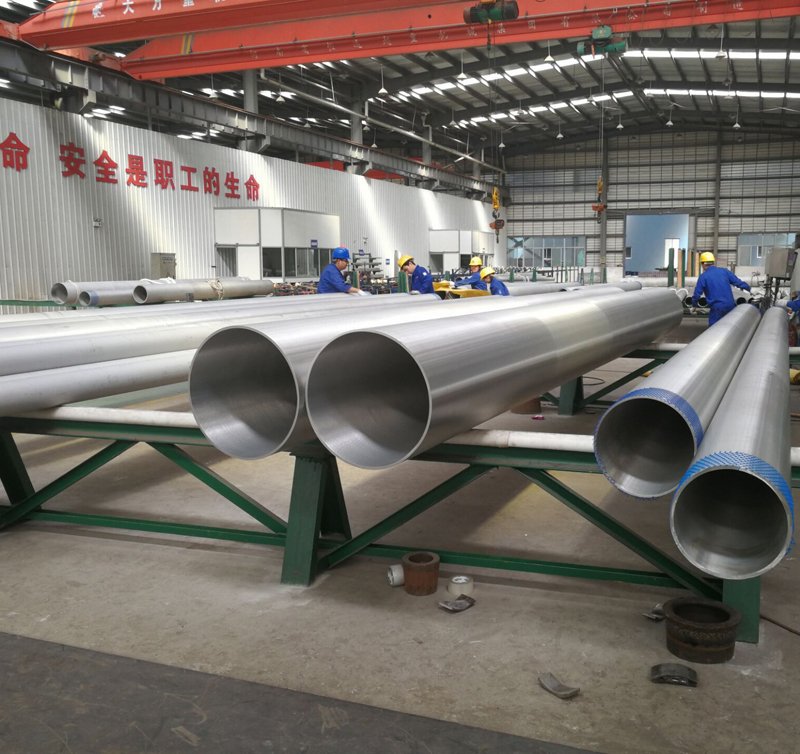

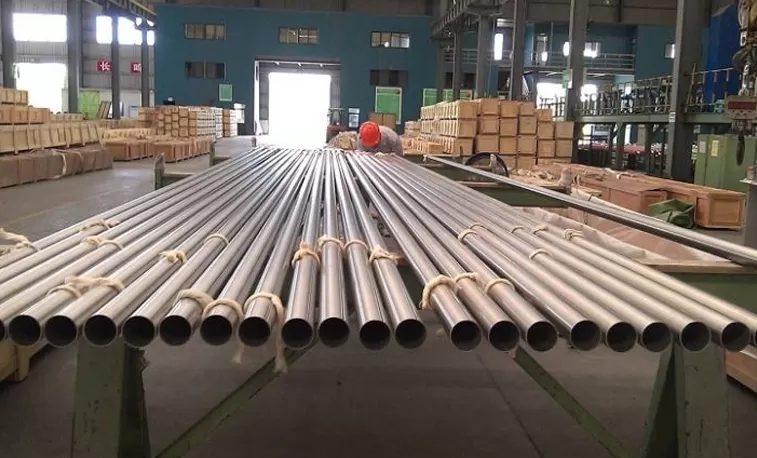

LSAW steel pipes, whether produced through UOE, JCOE (Press Bending), or JCOE (Roll Bending) methods, are integral to various industrial applications due to their high strength, dimensional accuracy, and compliance with numerous international standards. Each manufacturing process has its unique advantages, making these pipes suitable for transporting fluids and gases, as well as for use in structural and engineering projects.

ASTM A500 and A501 welded steel pipes are widely used in structural applications due to their strength, versatility, and reliability. These specifications ensure the pipes meet stringent quality and performance criteria, making them suitable for various construction and structural projects. Proper marking, certification, and testing ensure traceability and compliance, providing confidence in the use of these pipes in critical applications. By following appropriate handling, installation, and maintenance practices, the performance and longevity of ASTM A500 and A501 pipes can be effectively managed.

With abtersteel company commitment to adhering to the EN 10217-1 standard and its dedication to producing top-notch ERW welded pipes, customers can be confident in the performance and durability of the products they acquire. By choosing Baolai, industries can access a wide range of specifications and sizes to meet their specific project requirements.

The EN 10219 standard specifies the technical delivery conditions for cold-formed welded structural hollow sections of non-alloy and fine grain steels. Below are the specifications for various grades, including S235J0H, S275J0H, S275JRH, S275J2H, S355J0H, S355JRH, and S355J2H.

The API 5L specification covers seamless and welded steel line pipes for the petroleum and natural gas industries. The pipes are suitable for conveying gas, water, and oil. Electric-Resistance-Welded (ERW) pipes are one of the types specified under API 5L.

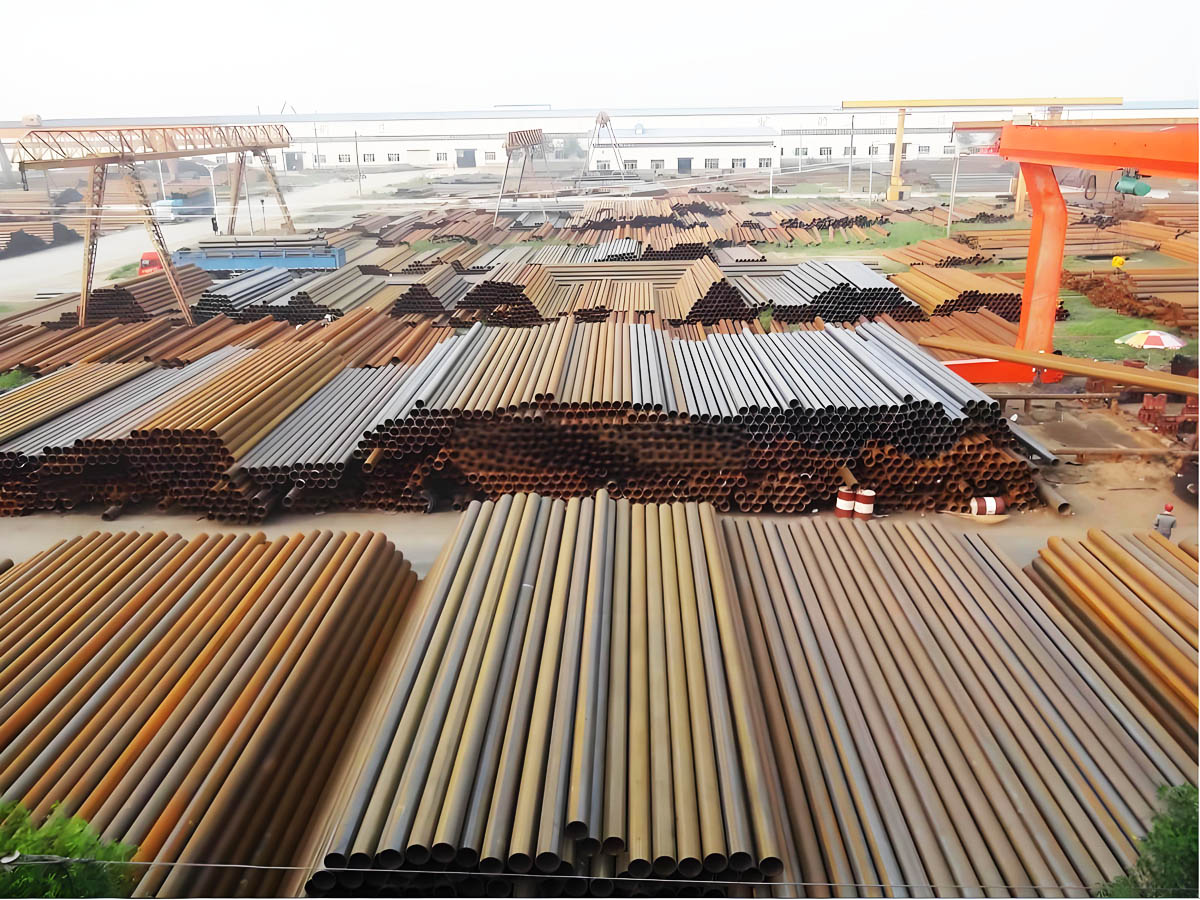

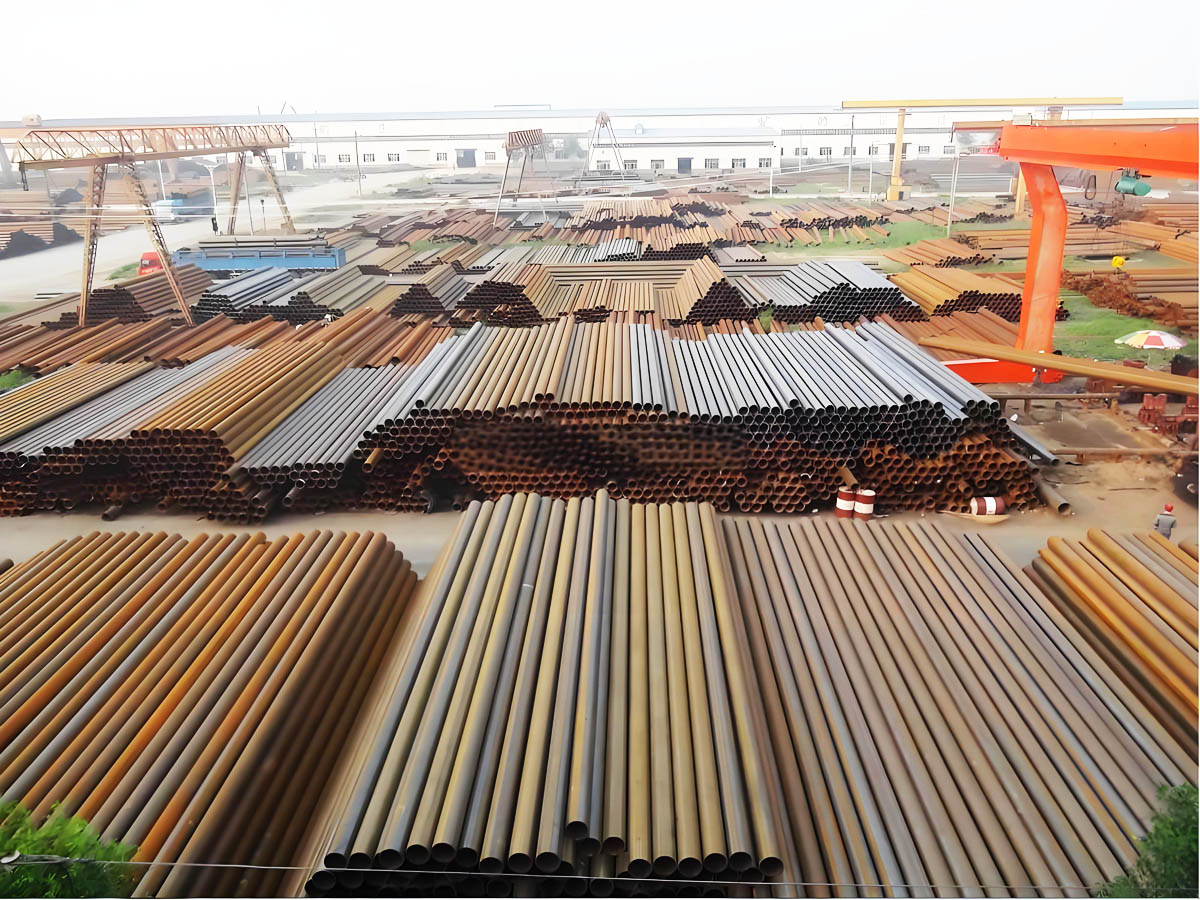

ASTM A252 Tubing Applications: Tubular steel pipe piles, structural support piles, cast-in-situ concrete piles. Products: Carbon steel seamless pipes, black steel pipe, stainless steel tubes, coating steel pipes.

ASTM A178 standard referes to electric-resistance-welded tubes with minimum-wall-thickness. Materials are carbon steel and carbon-manganese steel, ASTM A178 pipe and tube is to be used in boiler tubes, boiler flues, superheater flues and safe ends. Steel Grades A (low-carbon steel), C (medium-carbon steel), or D (carbon-manganese steel). Manufacturing processes must include heat treatment, welding after cooling. Crush test shall be performed if required by customer.