The range of steel grades under the **EN 10219-1** standard—from the dependable **S235JRH** through the versatile **S355JOH/JEH** to the high-performance **S460MH**—provides the essential material solution for every deep foundation challenge. This European standard guarantees not only high **Mechanical Properties** (Yield Strength up to 460 MPa) but also critical **Impact Toughness** ($\text{J0}/\text{J2}$) and superior **Weldability** through strict control of the **Carbon Equivalent**.

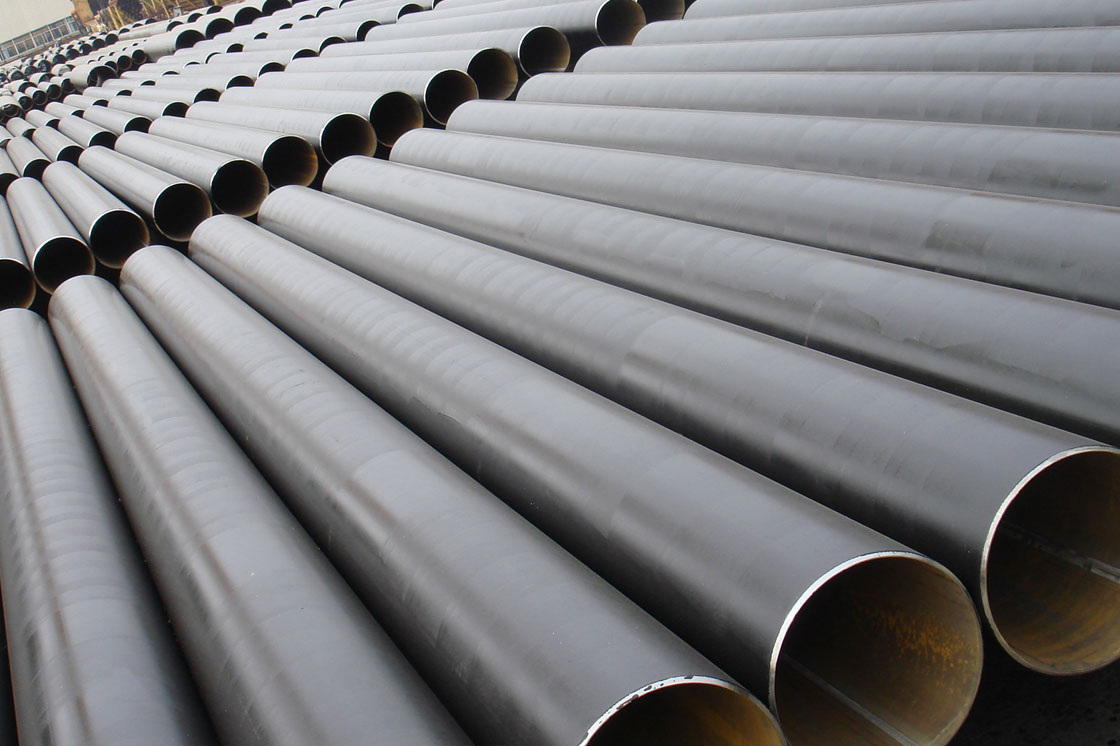

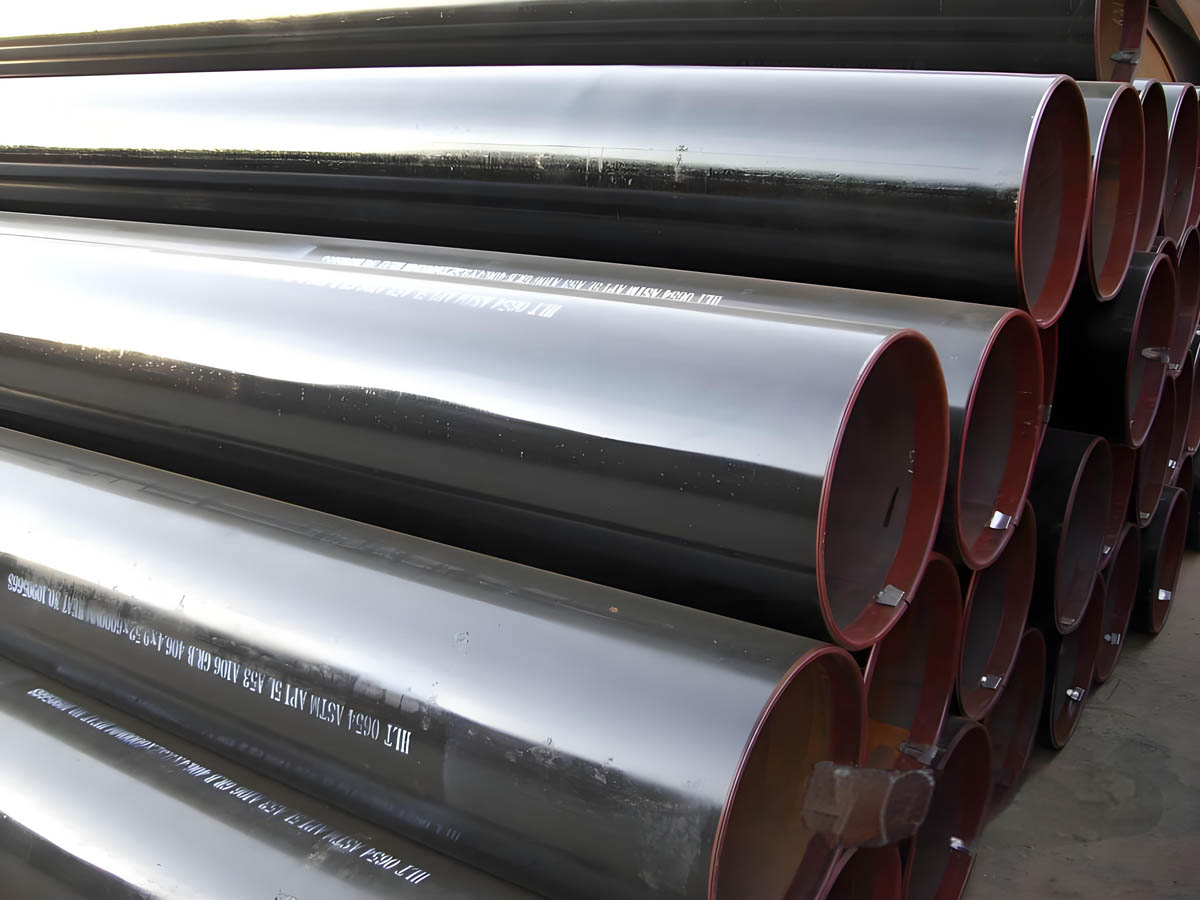

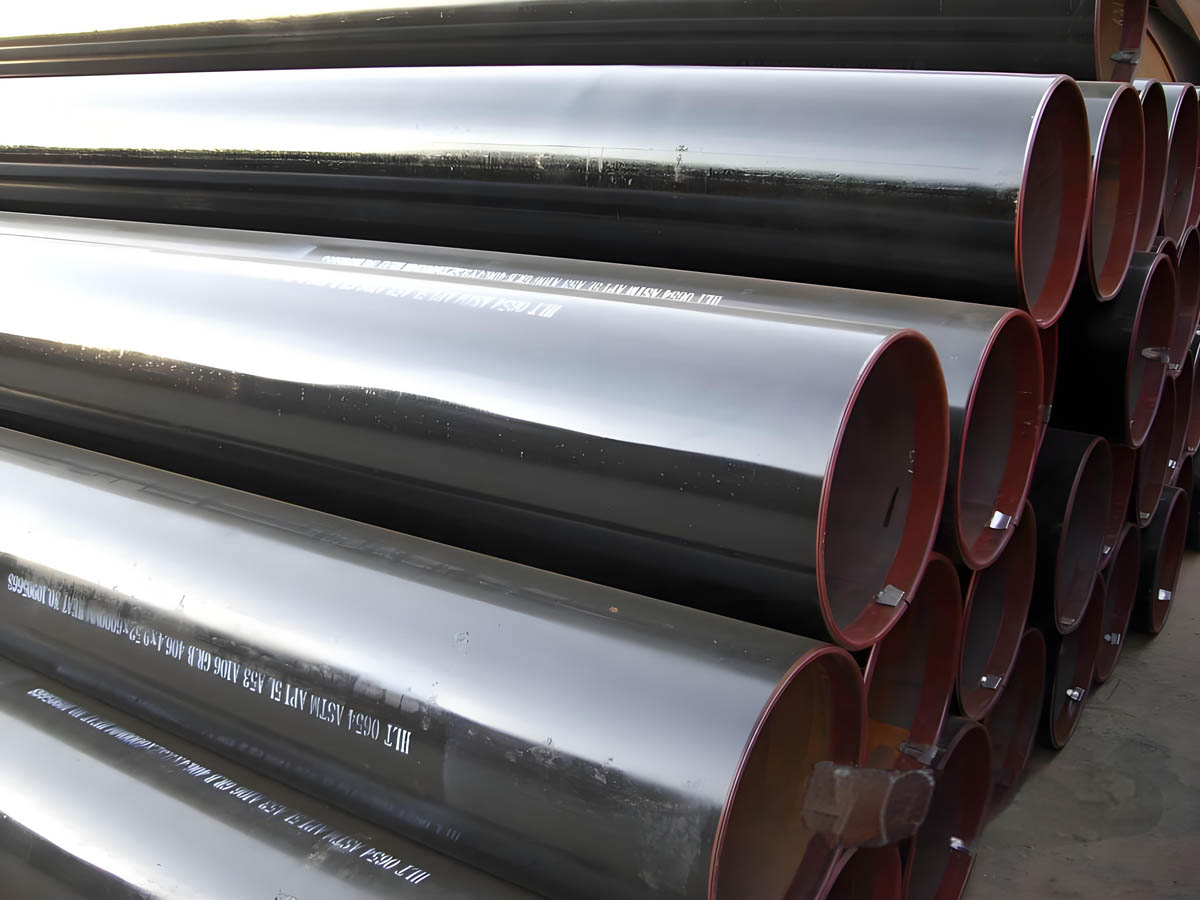

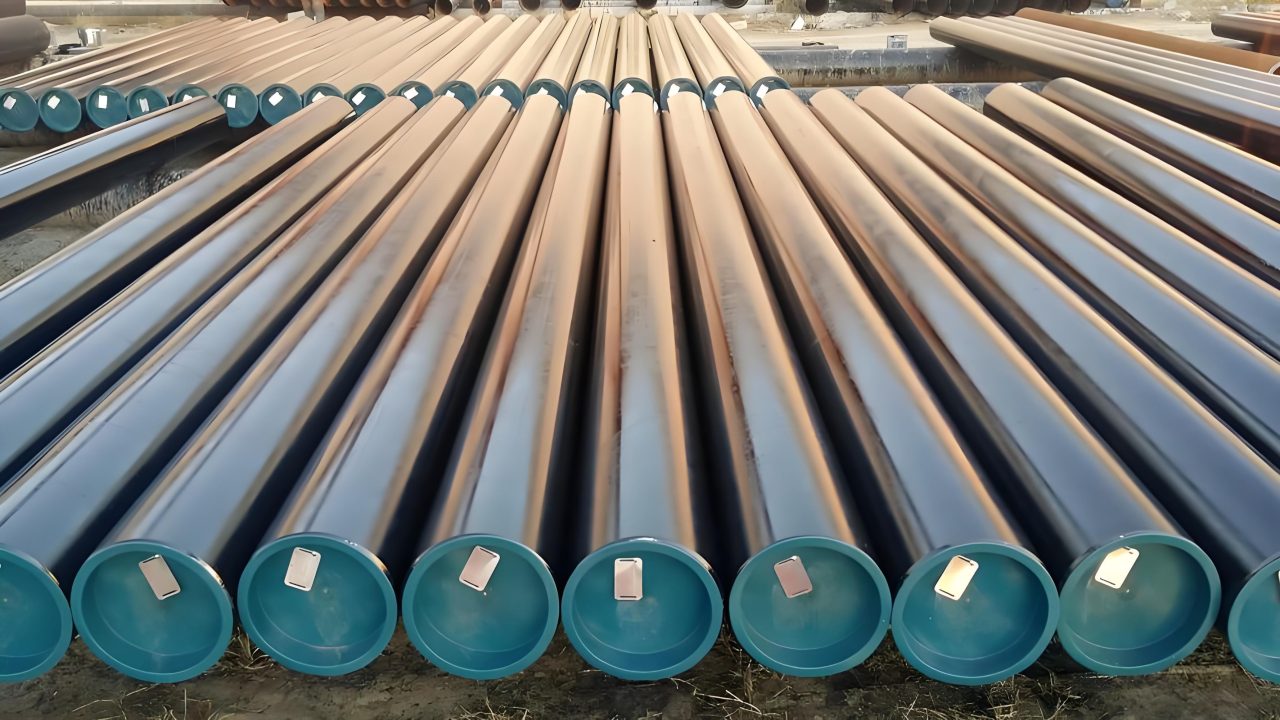

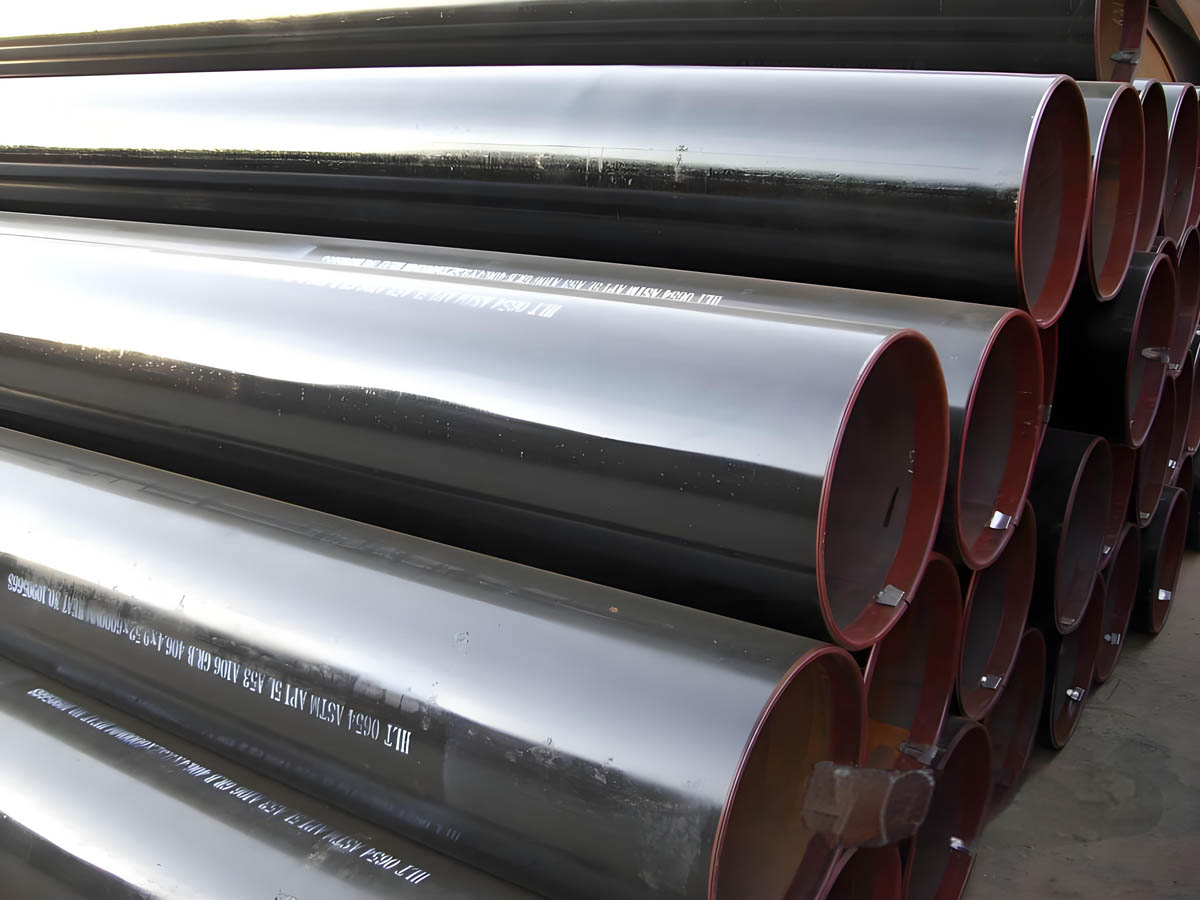

ERW Steel Pipe

The provided table and detailed analysis guide engineers in selecting the appropriate specification, with future innovations ensuring their continued relevance in industrial infrastructure.

ASTM A500 and A501 welded steel pipes are widely used in structural applications due to their strength, versatility, and reliability. These specifications ensure the pipes meet stringent quality and performance criteria, making them suitable for various construction and structural projects. Proper marking, certification, and testing ensure traceability and compliance, providing confidence in the use of these pipes in critical applications. By following appropriate handling, installation, and maintenance practices, the performance and longevity of ASTM A500 and A501 pipes can be effectively managed.

With abtersteel company commitment to adhering to the EN 10217-1 standard and its dedication to producing top-notch ERW welded pipes, customers can be confident in the performance and durability of the products they acquire. By choosing Baolai, industries can access a wide range of specifications and sizes to meet their specific project requirements.

The EN 10219 standard specifies the technical delivery conditions for cold-formed welded structural hollow sections of non-alloy and fine grain steels. Below are the specifications for various grades, including S235J0H, S275J0H, S275JRH, S275J2H, S355J0H, S355JRH, and S355J2H.

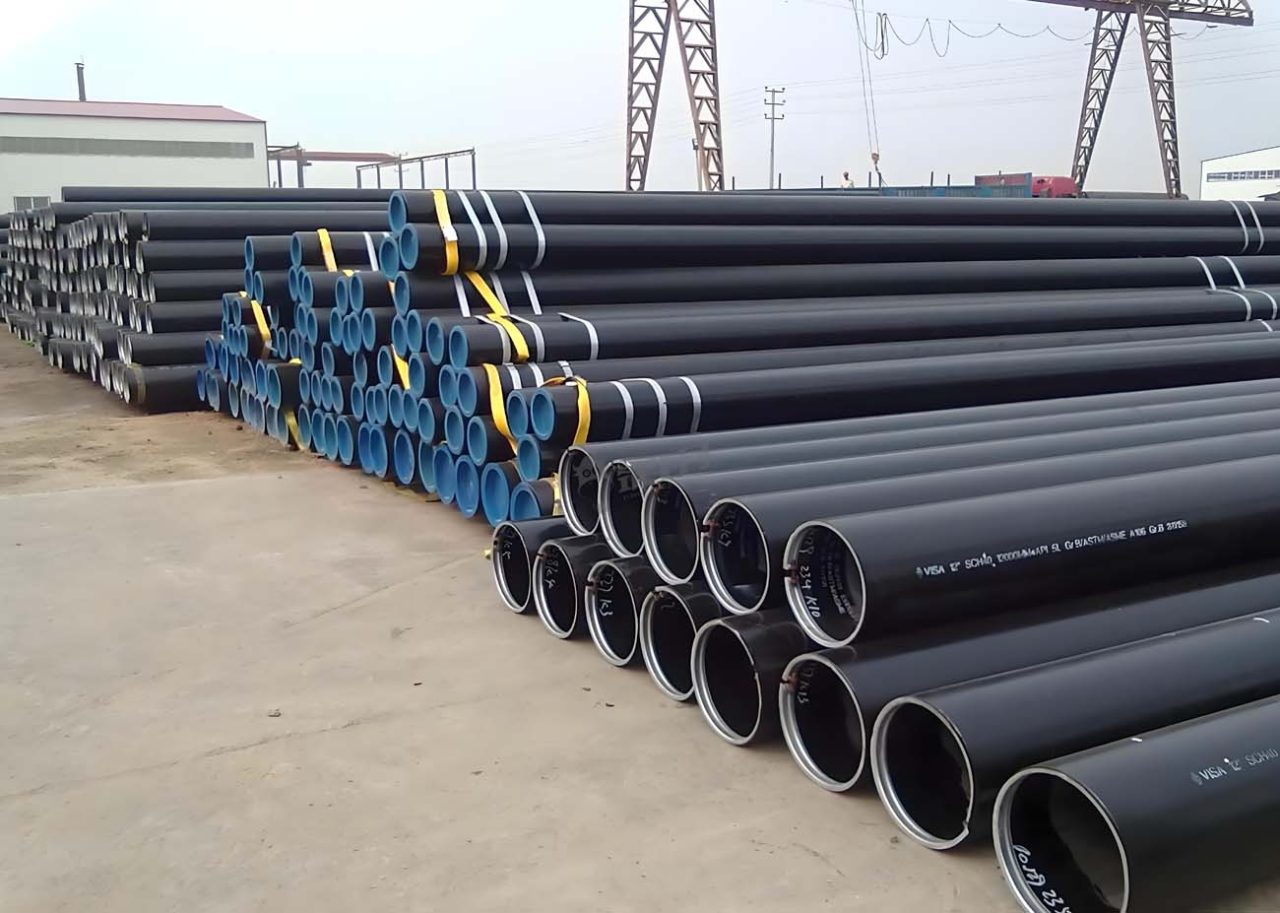

The API 5L specification covers seamless and welded steel line pipes for the petroleum and natural gas industries. The pipes are suitable for conveying gas, water, and oil. Electric-Resistance-Welded (ERW) pipes are one of the types specified under API 5L.

ASTM A252 Tubing Applications: Tubular steel pipe piles, structural support piles, cast-in-situ concrete piles. Products: Carbon steel seamless pipes, black steel pipe, stainless steel tubes, coating steel pipes.

ASTM A178 standard referes to electric-resistance-welded tubes with minimum-wall-thickness. Materials are carbon steel and carbon-manganese steel, ASTM A178 pipe and tube is to be used in boiler tubes, boiler flues, superheater flues and safe ends. Steel Grades A (low-carbon steel), C (medium-carbon steel), or D (carbon-manganese steel). Manufacturing processes must include heat treatment, welding after cooling. Crush test shall be performed if required by customer.

Conclusion HFI steel pipes are a reliable and efficient choice for a wide range of applications, offering high-quality welds and consistent dimensions. Their cost-effectiveness and versatility make them a popular option in industries such as oil and gas, construction, and automotive.

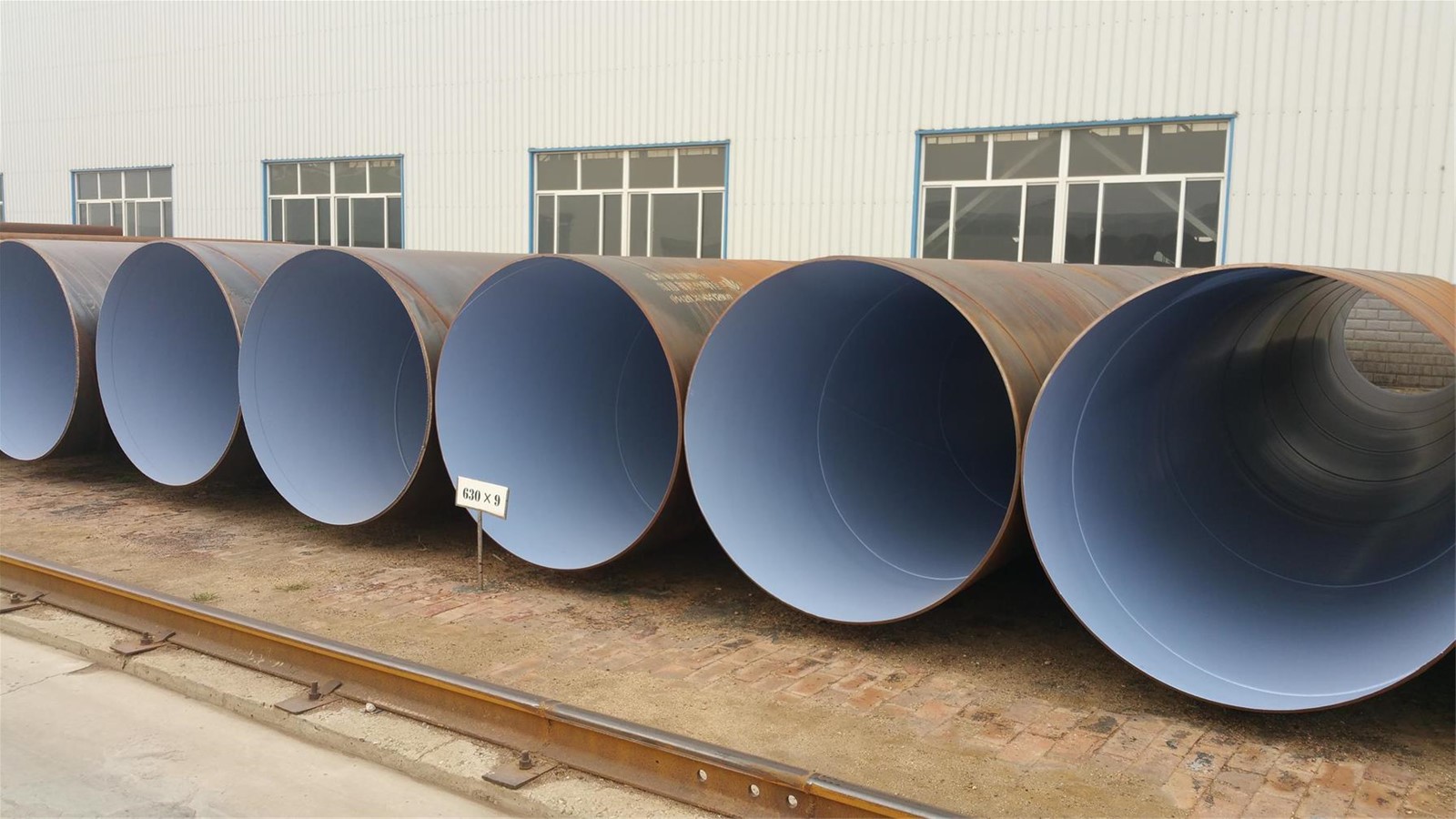

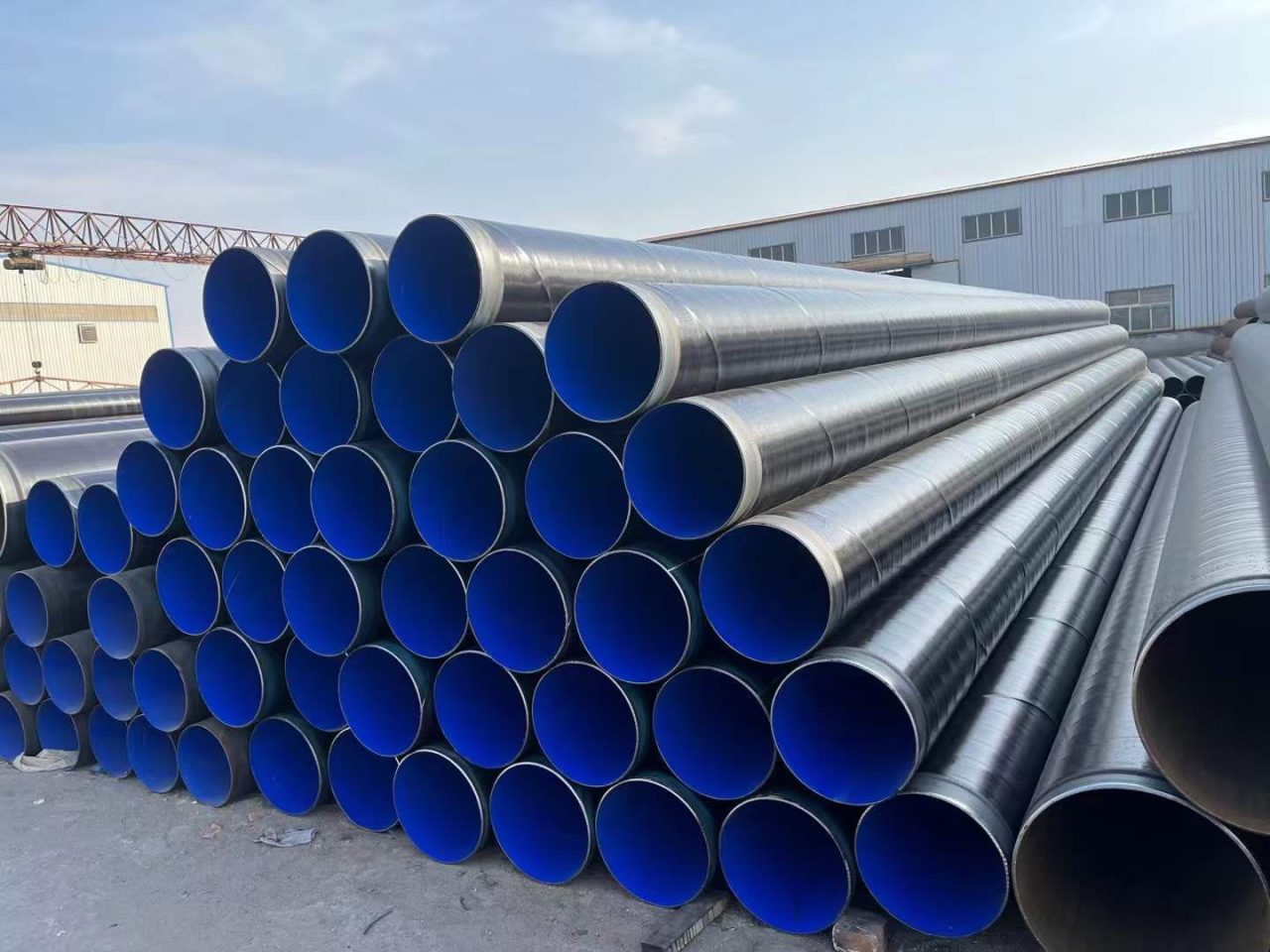

EFW steel pipes are a reliable choice for applications that require large-diameter, high-strength pipes with excellent weld integrity. Their manufacturing process ensures robust and consistent quality, making them suitable for demanding industries like oil and gas, petrochemicals, and large-scale water supply systems. While they may come at a higher cost compared to ERW and HFW pipes, their superior mechanical properties and ability to handle high-pressure conditions justify their use in critical applications.

Both ERW and HFW steel pipes have their unique advantages and applications. ERW pipes are suitable for general purposes where cost-effectiveness and adequate strength are required. In contrast, HFW pipes are preferred for applications demanding superior weld quality and higher strength, especially in the oil and gas industry and high-pressure fluid transport systems. The choice between ERW and HFW will depend on the specific requirements of the project, including the mechanical stress, pressure conditions, and budget constraints.

ERW steel pipes are an essential component in various industrial applications, providing a reliable and economical solution for fluid transportation and structural uses. The specifications provided ensure that these pipes meet stringent industry standards and customer requirements.

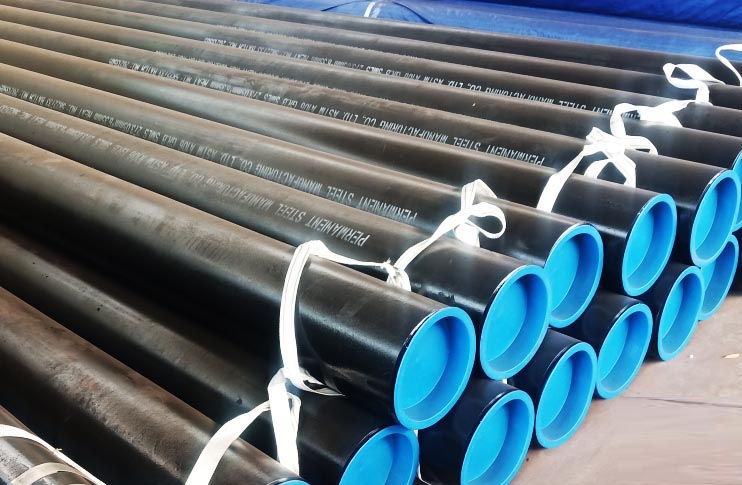

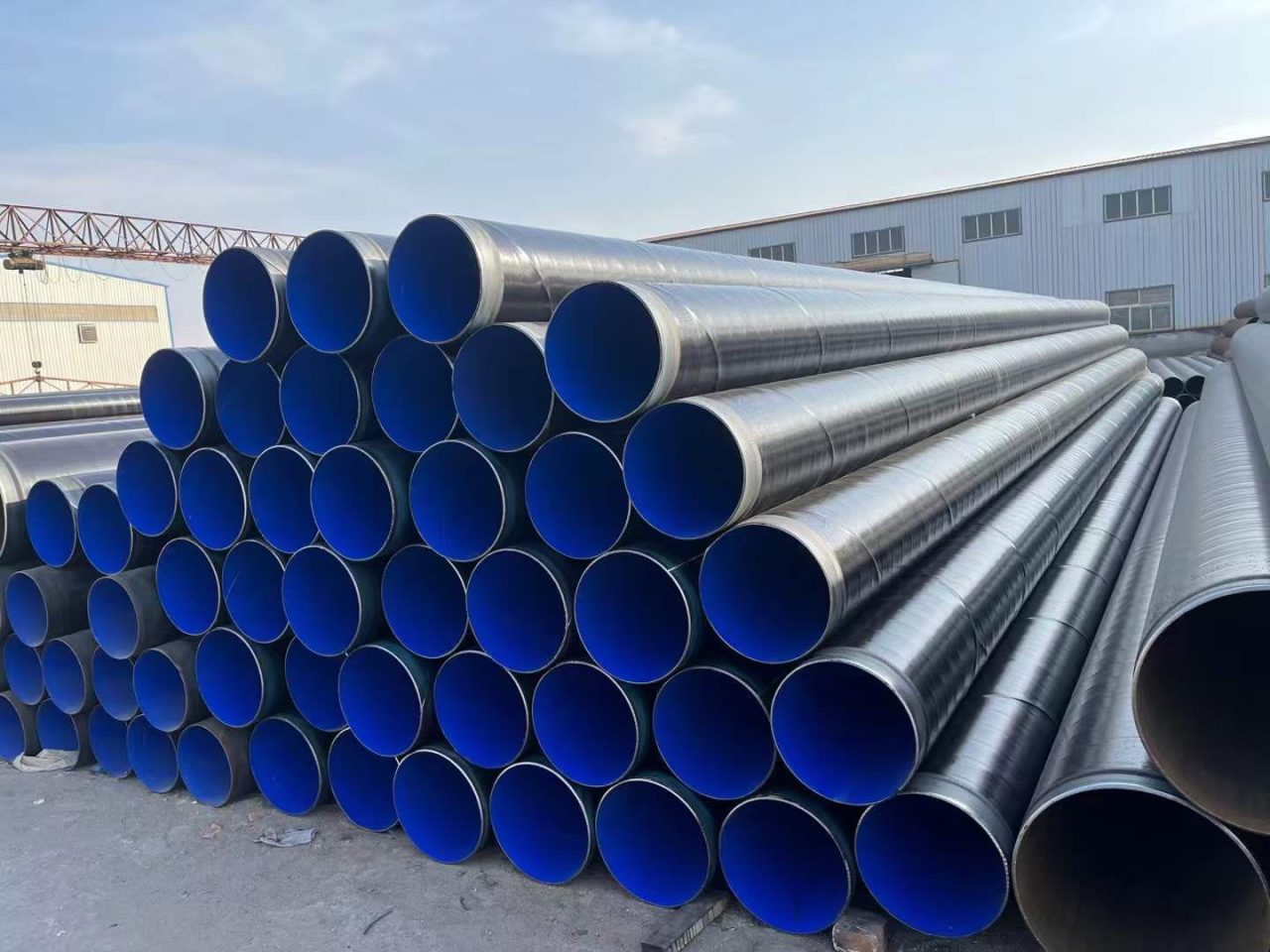

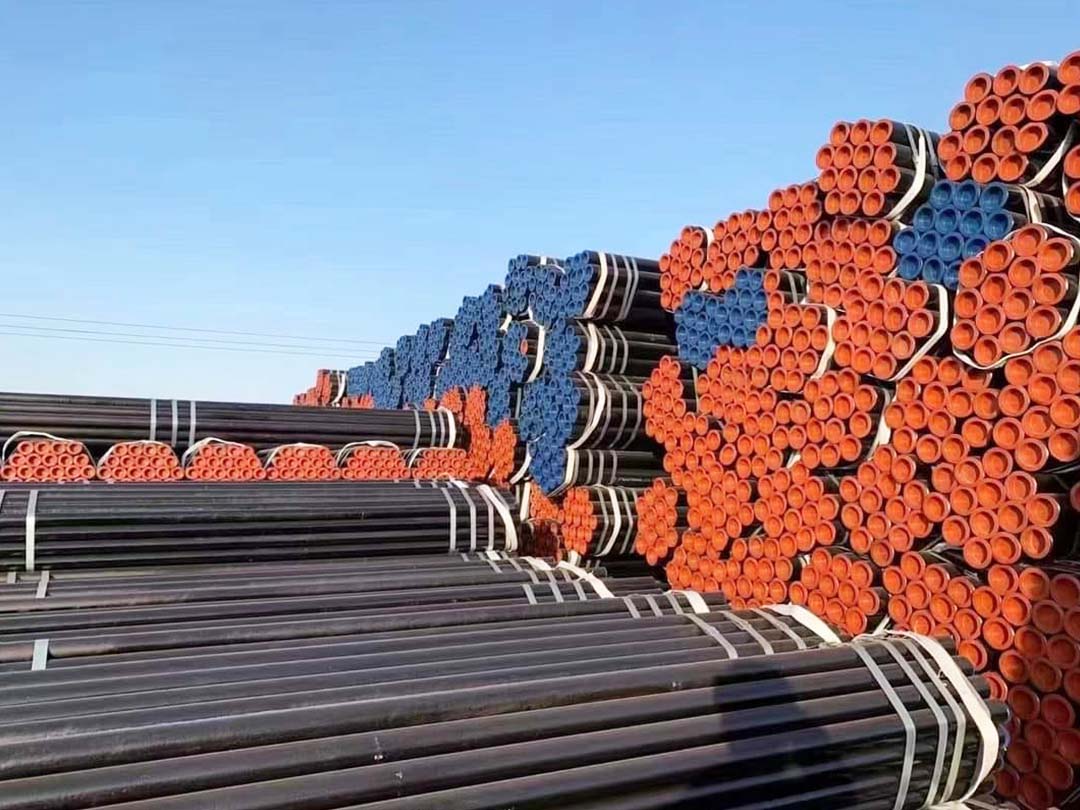

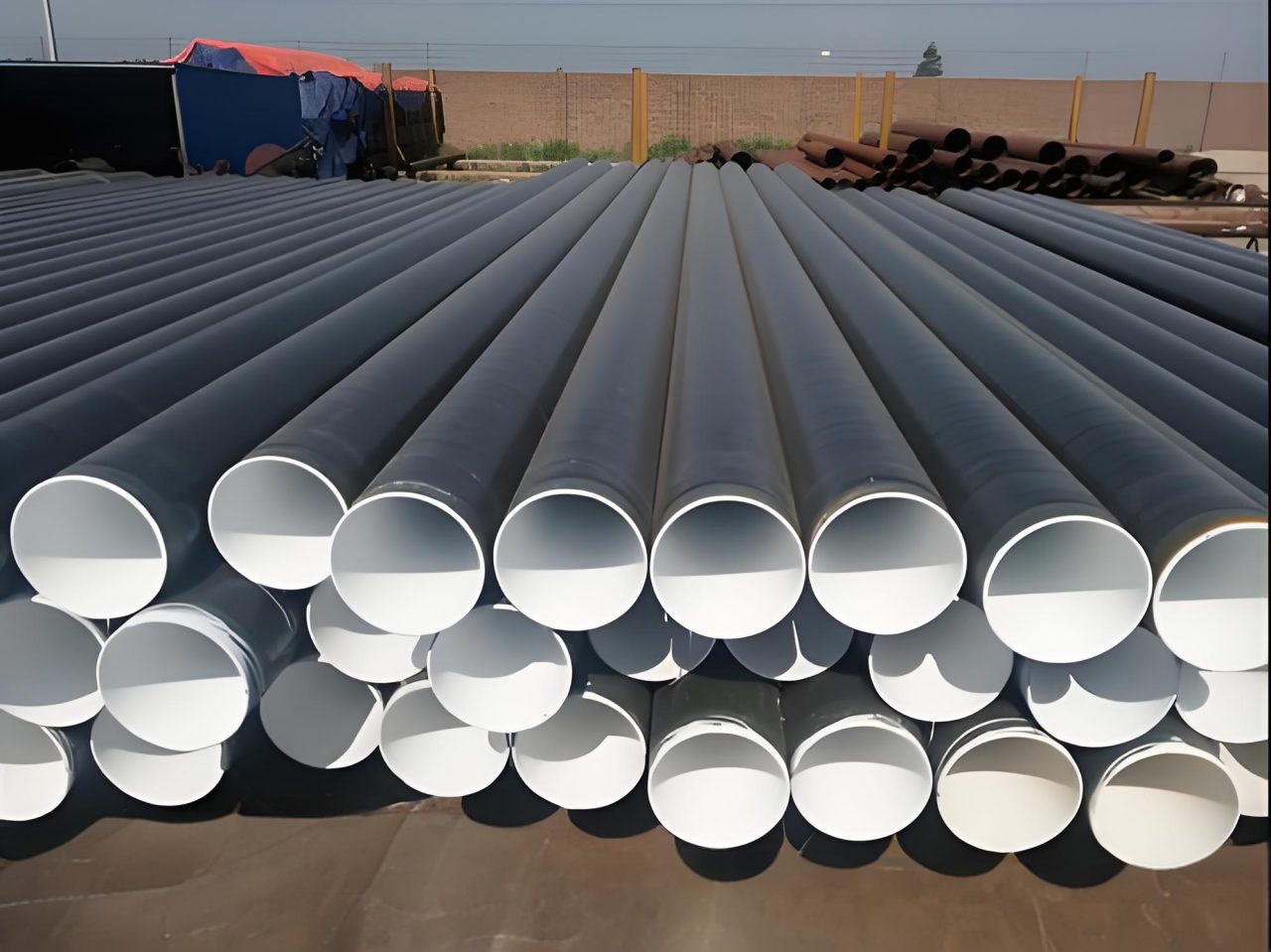

ERW Steel Pipe(Electric Resistance Welded Pipe), A53 ERW Pipe, ERW Carbon Steel Pipe Product Details of ERW steel pipe Pipe End: square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled, Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE) Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

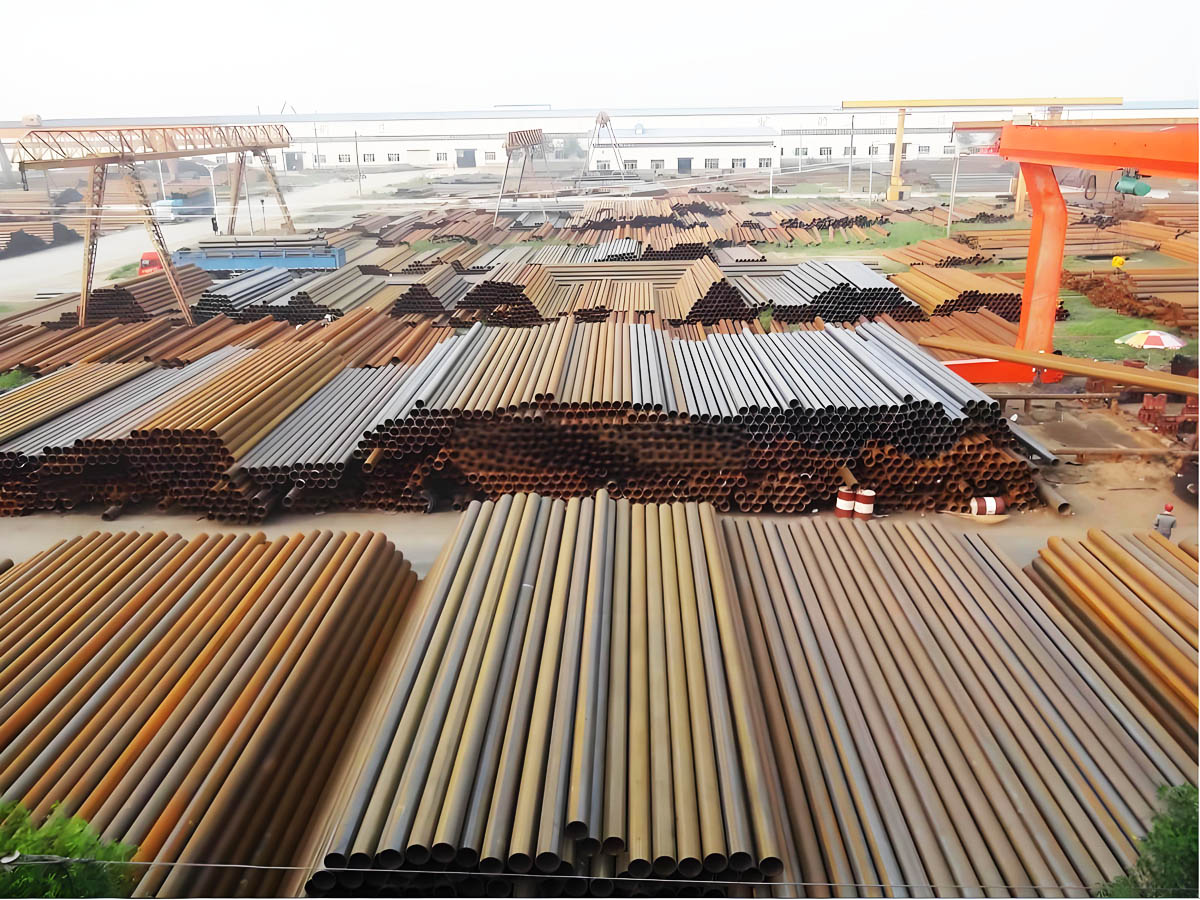

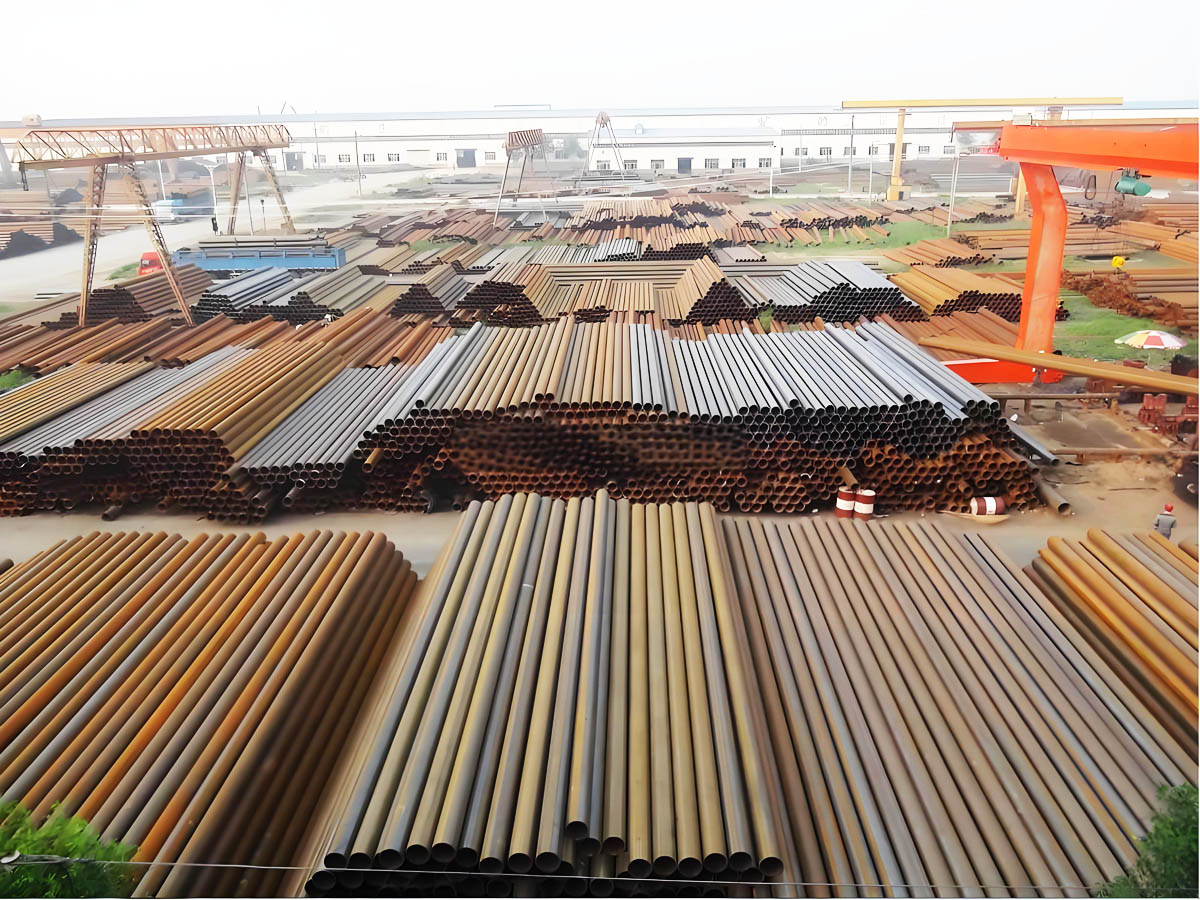

Abter is a China based ERW steel pipe manufacturer and supplier. Our main products include boiler steel tube, 3PE anticorrosion steel pipes, fiberglass insulated pipeline, to name a few. All of our high quality products are offered at competitive prices. The full chain of manufacturing foam insulated pipeline, SSAW steel pipe, etc. can be completed in China, even in one city. Lower manufacturing cost saves your purchasing cost. The detailed information of each product is shown in the corresponding product page.

ERW Steel Pipe(Electric Resistance Welded Pipe), A53 ERW Pipe, ERW Carbon Steel Pipe Product Details of ERW steel pipe Pipe End: square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled, Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE) Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps. Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Hardness Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, NDT TEST ( ET TEST, RT TEST, UT TEST) For ERW Line Pipe For ERW Casing For ERW Structure Tube For High pressure and high temperature