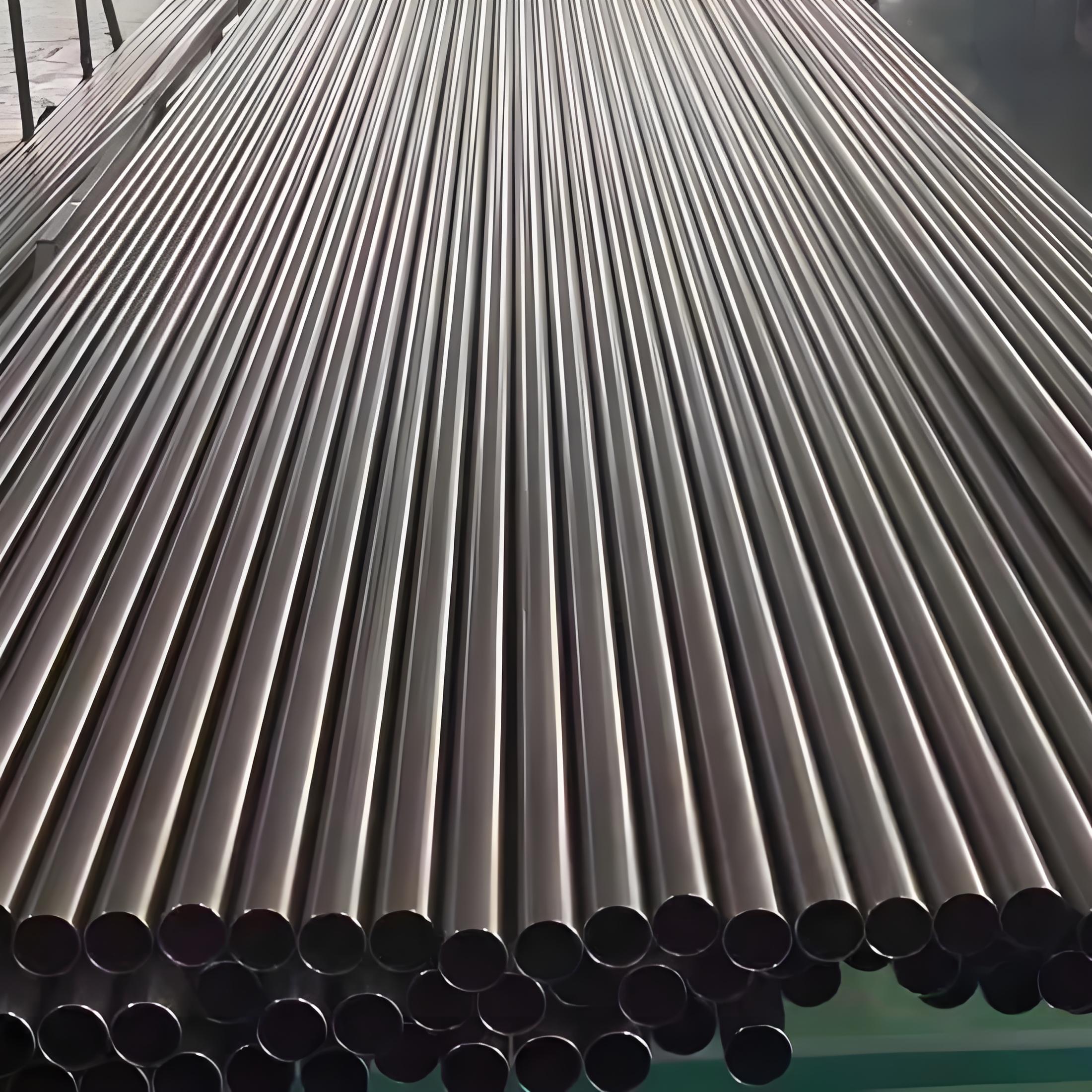

JIS G3454 STPG Carbon Steel Boiler Pipes

The Backbone of Thermal Systems: A Deep Dive into JIS G3454 STPG Carbon Steel Boiler Pipes

The efficiency and safety of modern thermal engineering—encompassing power generation, petrochemical processing, and heavy industrial heating—rely fundamentally on the integrity of their pressure-containing components. Among the most critical of these are the pipes used to convey hot fluids and steam. In the global landscape of material standards, the Japanese Industrial Standard (JIS) G3454 sets a rigorous benchmark for Carbon Steel Pipes for Pressure Service, with the STPG designation being a globally recognized material for boiler and heat exchanger applications. This standard is not merely a set of specifications; it is a meticulously defined framework that ensures the reliability, durability, and safety of piping systems operating under the unforgiving conditions of high temperature and high pressure. To truly appreciate the role of STPG pipes, one must delve into the specifics of its composition, mechanical properties, manufacturing precision, and the demanding applications it serves.

Understanding the JIS G3454 Framework: Context and Scope

The designation JIS G3454 falls under the broader category of Japanese Industrial Standards (JIS) related to ferrous materials. Specifically, G3454 is the standard dedicated to Carbon Steel Pipes for Pressure Service. The “STPG” nomenclature within this standard is an acronym derived from the Japanese terms for Steel (S), Tube (T), Pressure (P), and General (G), indicating a general-purpose steel pipe intended for pressure applications. This is distinct from other JIS standards like G3455 (High Pressure Service) or G3461 (Boiler and Heat Exchanger Tubes), though there are often overlaps in application.

The primary function of pipes manufactured to JIS G3454 STPG specifications is the safe and efficient conveyance of pressurized fluids, gases, and steam at elevated temperatures. Their application typically involves components such as steam lines, headers, economizers, and various piping within boiler plants where the operating temperature does not typically exceed $350^\circ\text{C}$ to $400^\circ\text{C}$. Beyond these temperatures, creep phenomena become significant, often necessitating the use of low-alloy steels (like Cr-Mo steels defined by JIS G3458 or international equivalents). Therefore, the STPG grades are the workhorses of the conventional pressure piping systems that form the heart of countless industrial operations. The two primary grades within this standard, STPG 370 and STPG 410, are differentiated by their specified minimum tensile strength, which is the cornerstone of their selection criteria.

The strict adherence to this standard by Japanese and international manufacturers alike provides a crucial assurance of quality. It establishes uniform criteria for material composition, dimensions, tolerances, testing procedures, and documentation. This global interchangeability and predictability are vital in large-scale engineering projects where materials from various suppliers must integrate seamlessly into a single, cohesive, high-integrity system.

Chemical Composition: The Recipe for Strength and Weldability

The foundational performance of any steel material is dictated by its precise chemical composition. For STPG pipes, the composition is carefully controlled to balance two critical, often conflicting, requirements: high tensile strength to withstand internal pressure and excellent weldability for ease of fabrication and installation in complex piping networks. As carbon steel, the primary alloying elements are carbon, silicon, manganese, phosphorus, and sulfur.

The grades STPG 370 and STPG 410 are fundamentally low-carbon steels, with carbon content being the key determinant of their strength differential. A lower carbon content in STPG 370 enhances its ductility and weldability, making it suitable for applications where extensive forming or complex welding is necessary. Conversely, the slightly higher carbon and manganese content in STPG 410 contribute to its increased tensile and yield strength, allowing it to handle higher operating pressures, albeit with a marginal reduction in ease of welding. The limits on residual elements like phosphorus ($\text{P}$) and sulfur ($\text{S}$) are extremely stringent, as these impurities can lead to issues such as hot shortness during rolling and reduced toughness, which are unacceptable risks in pressure service piping.

The following table details the maximum permissible chemical composition for the two primary grades, reflecting the stringent control necessary for pressure piping integrity (all values are in mass percent, maximum unless otherwise noted):

| Element | STPG 370 | STPG 410 | Purpose/Impact |

|---|---|---|---|

| Carbon (C) | $\le 0.25$ | $\le 0.30$ | Primary strength-imparting element; higher C reduces weldability. |

| Silicon (Si) | $\le 0.35$ | $\le 0.35$ | Deoxidizer; increases strength and hardness slightly. |

| Manganese (Mn) | $0.30 – 0.90$ | $0.30 – 1.00$ | Increases strength, hardness, and wear resistance; counteracts P and S effects. |

| Phosphorus (P) | $\le 0.040$ | $\le 0.040$ | Highly restricted impurity; reduces ductility and toughness (cold shortness). |

| Sulfur (S) | $\le 0.040$ | $\le 0.040$ | Highly restricted impurity; promotes hot shortness and lowers impact strength. |

*Note: The actual specifications may include specific carbon equivalent (CE) limits or more detailed alloying restrictions, which are crucial for welding procedure specification (WPS). The maximum P and S content is often tighter in practice, but the standard specifies $\le 0.040\%$.

Mechanical Properties: Defining Performance Under Stress

The selection of a pipe for pressure service is ultimately governed by its ability to resist the stress exerted by the internal pressure and external loads. The mechanical properties—specifically **tensile strength**, **yield strength**, and **elongation**—are the quantitative measures of this resistance. The numerical designation in the STPG name is directly tied to the minimum specified tensile strength in megapascals ($\text{MPa}$).

STPG 370 denotes a pipe material with a minimum tensile strength of $370 \text{ MPa}$, while STPG 410 specifies a minimum tensile strength of $410 \text{ MPa}$. The yield strength, which is the point at which the material begins to deform permanently, is equally critical for design calculations to ensure the pipe operates safely within its elastic limit. Elongation, a measure of the material’s ductility, ensures the pipe can withstand a degree of deformation without brittle fracture—a non-negotiable requirement for pressurized components.

The following table outlines the minimum mechanical requirements specified by JIS G3454:

| Property | Unit | STPG 370 (Min.) | STPG 410 (Min.) |

|---|---|---|---|

| Tensile Strength ($\sigma_{ts}$) | $\text{N/mm}^2$ ($\text{MPa}$) | 370 (or 373) | 410 (or 412) |

| Yield Strength ($\sigma_{y}$) | $\text{N/mm}^2$ ($\text{MPa}$) | 215 (or 216) | 245 |

| Elongation (Longitudinal, No. 4/5 Test Piece) | $\%$ | $28 \text{ min.}$ | $24 \text{ min.}$ |

*Note: The minimum elongation requirement varies significantly based on the sample type (No. 4, No. 5, No. 11, No. 12) and whether the test is conducted longitudinally or transversely to the pipe axis. The values above represent common minimums for design reference. N/mm$^2$ and MPa are interchangeable units for stress.

The design engineer relies heavily on the guaranteed minimum yield strength, as it forms the basis for wall thickness calculations according to codes like ASME B31.1 or B31.3. A higher yield strength, as offered by **STPG 410**, allows for a potentially thinner wall for the same design pressure, leading to material savings, reduced weight, and improved heat transfer efficiency—a significant factor in heat exchanger and boiler design.

Manufacturing Processes and Pipe Types: Seamed vs. Seamless

The microstructure and resulting mechanical performance of an STPG pipe are intrinsically linked to its manufacturing method. JIS G3454 covers both **Seamless** and **Electric Resistance Welded (ERW)** pipe processes, although for critical high-pressure and high-temperature boiler applications, **seamless** pipe is overwhelmingly preferred due to its superior integrity and uniformity.

Seamless Pipe (S)

Seamless STPG pipes are produced by piercing a hot, solid billet of steel, which is then rolled and drawn to the final specified dimensions. The absence of a weld seam means there are no inherent metallurgical or structural discontinuities in the pipe body. This makes seamless pipe the ideal choice for applications where the pipe will be subjected to the highest internal pressures, thermal cycling, and complex bending or coiling during fabrication. The uniform grain structure and absence of a potential weld defect path provide the highest level of assurance against catastrophic failure, which is paramount in a boiler environment.

Electric Resistance Welded (ERW) Pipe (E)

ERW STPG pipes are manufactured from a flat strip (skelp) that is cold-formed into a cylinder and then welded along the longitudinal seam by applying an electric current that melts the edges. While modern ERW processes have achieved remarkable quality, the presence of the weld seam can sometimes introduce potential weak points. For very demanding pressure service applications, the designer may be restricted by code to use seamless pipes, or the design stress of the ERW pipe may be derated. However, for some lower-pressure and non-critical applications within the pressure service scope, ERW STPG pipes offer a more cost-effective solution, especially for larger diameters and thinner walls where seamless production becomes technically challenging or uneconomical.

The standard mandates strict non-destructive testing (NDT) for all welded pipes, typically involving eddy current testing or ultrasonic testing of the weld seam to ensure its soundness and freedom from flaws. Regardless of the process, the finished pipes must undergo a final heat treatment (normalization or stress relief) to achieve the specified mechanical properties and ensure microstructural uniformity.

Dimensional Tolerances and Standardization

Beyond material properties, the adherence to precise dimensional tolerances is critical for fit-up during fabrication and for meeting design requirements for wall thickness, which directly impacts pressure rating. JIS G3454 defines strict tolerances for outside diameter (OD) and wall thickness based on the pipe’s manufacturing process (hot-finished seamless, cold-finished seamless, or ERW).

Pipe dimensions in this standard, as with many Japanese standards, align closely with international standards like ASME B36.10M, often utilizing the **Nominal Pipe Size (NPS)** system (A-B designation) and **Schedule Numbers** (Sch 10, Sch 20, Sch 40, Sch 80, etc.) to define the pipe wall thickness relative to its diameter. The following table provides a reference for some common dimensions and how wall thickness is dictated by the Schedule number for the STPG grades.

| Nominal Size (A) | Nominal Size (B) | OD (mm) | Sch 40 Thickness (mm) | Sch 80 Thickness (mm) |

|---|---|---|---|---|

| 15 | 1/2″ | 21.7 | 2.8 | 3.7 |

| 25 | 1″ | 34.0 | 3.4 | 4.5 |

| 50 | 2″ | 60.5 | 3.9 | 5.5 |

| 100 | 4″ | 114.3 | 6.0 | 8.6 |

| 150 | 6″ | 165.2 | 7.1 | 11.0 |

| 200 | 8″ | 216.3 | 8.2 | 12.7 |

*Note: Wall thicknesses are nominal and can vary within the specified tolerances defined by the standard. Sch numbers define wall thickness, while STPG grades define material strength.

Furthermore, tolerances on dimensions are extremely strict to ensure pressure integrity:

- Straightness: The maximum deviation from a straight line is tightly controlled, often mandated to be no more than 1 mm per 1000 mm of length.

- Wall Thickness Tolerance: For hot-finished seamless pipes, the deviation is typically $+15\%$ to $-12.5\%$ of the nominal wall thickness for larger thicknesses, reflecting the challenges of hot rolling. For cold-finished and ERW pipes, tolerances are much tighter, sometimes specified as low as $\pm 10\%$ or fixed absolute values for very small dimensions, reflecting the precision of these processes.

Rigorous Testing and Quality Assurance Protocols

The designation of a pipe as conforming to JIS G3454 is meaningless without the backing of comprehensive testing and quality assurance protocols. These tests serve as the final verification that the material meets the prescribed standards for safety and performance.

- Tensile Test: Confirms the guaranteed minimums for tensile strength, yield strength, and elongation.

- Flattening Test (for Seamless Pipe): The pipe section is flattened until the distance between the plates reaches a specified value. The pipe must withstand this deformation without showing any cracks or flaws, demonstrating its ductility.

- Bending Test (for smaller sizes): Required for pipes 40A or smaller, the pipe is bent through a large angle (e.g., $90^\circ$) around a mandrel of a specified radius (e.g., 6 times the OD) to confirm ductility.

- Hydraulic (Hydrostatic) Test: Every length of finished pipe must be subjected to a minimum pressure test. This test physically stresses the pipe to guarantee pressure-tightness and structural integrity throughout. The test pressure is proportional to the material’s yield strength and the pipe’s dimensions.

- Non-Destructive Testing (NDT): For ERW pipes, supplementary NDT methods like Ultrasonic Examination ($\text{Z3}$) or Eddy Current Examination ($\text{Z4}$) are often designated by the purchaser to verify the integrity of the longitudinal weld seam.

Application and Global Context

The selection between **STPG 370** and **STPG 410** hinges primarily on the design pressure and temperature of the system. **STPG 410** is the preferred choice for main steam headers and high-pressure feedwater lines due to its superior strength, allowing for thinner, more efficient walls. **STPG 370**, with its excellent weldability and slightly higher ductility, serves effectively in lower-to-medium pressure auxiliary lines and complex systems requiring extensive fabrication.

In the global market, JIS G3454 STPG grades are functionally comparable to several international standards, most notably the **ASTM A106/ASME SA-106** specifications for seamless carbon steel pipe for high-temperature service:

- STPG 370: Closely relates to **ASTM A53 Grade B** and **ASTM A106 Grade A**, though STPG 370 often exhibits slightly higher minimum yield strength than A106 Grade A.

- STPG 410: Its strength profile (Min. Tensile $410 \text{ MPa}$, Min. Yield $245 \text{ MPa}$) is directly competitive with **ASTM A106 Grade B** (Min. Tensile $415 \text{ MPa}$, Min. Yield $240 \text{ MPa}$), confirming its status as a premium, internationally recognized material for high-integrity pressure piping up to $350^\circ\text{C}$.

The rigorous requirements of JIS G3454 ensure that STPG carbon steel boiler pipes are not just commodities, but highly engineered components that form the critical, reliable backbone of thermal systems worldwide. Their balanced chemical composition and guaranteed mechanical performance under extreme conditions make them an indispensable material in power generation and heavy industry.