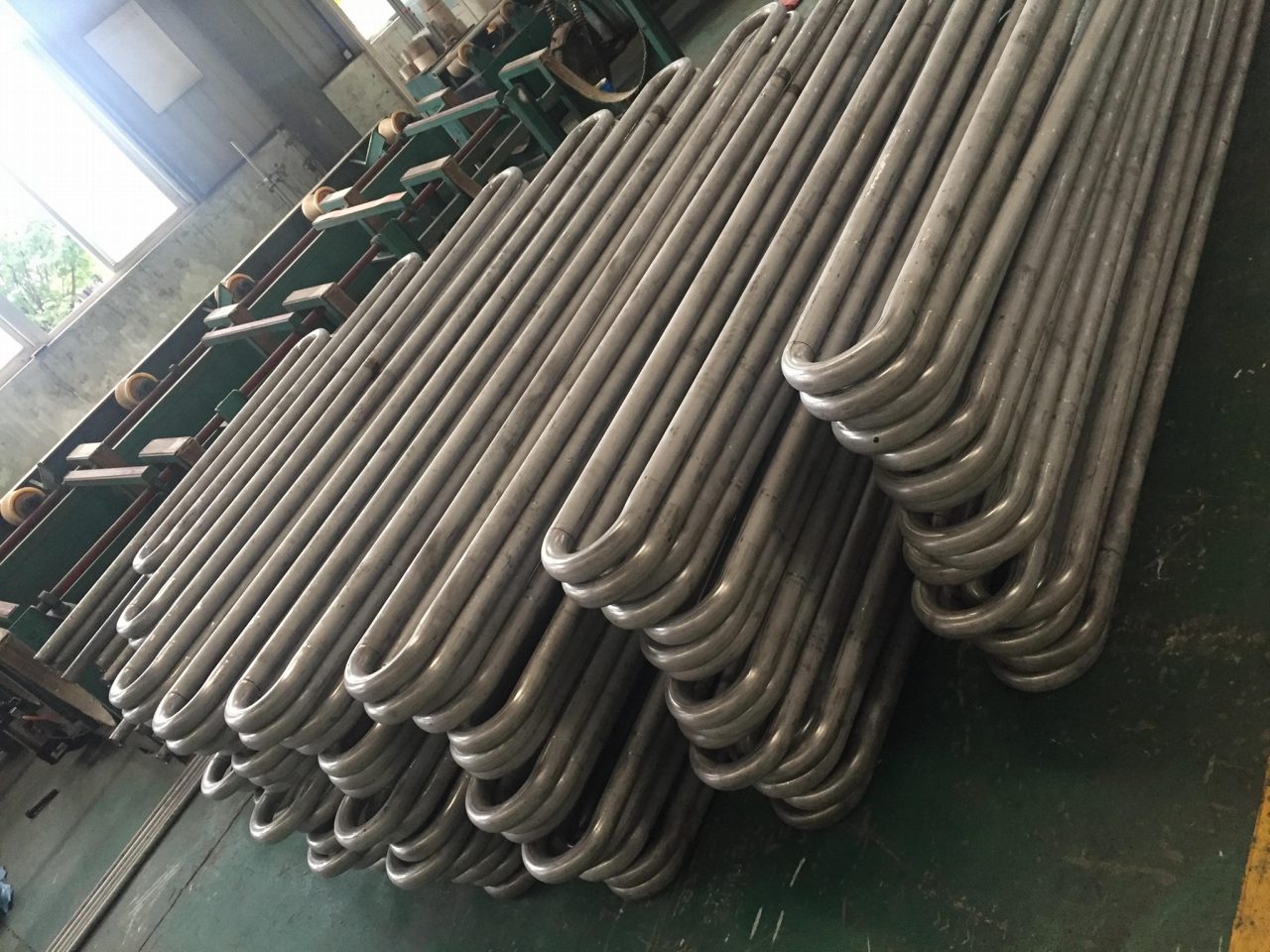

UNS N04400 ASTM B165 U Bend Tube for Heat Exchanger

Our product is not merely a conduit for thermal exchange; it is a high-precision engineered component designed to negate the inherent vulnerabilities of the U-bend geometry, where centrifugal forces and turbulence profiles create unique erosive challenges. When a fluid transitions through the 180-degree turn of our tubes, the secondary flow patterns—often referred to as Dean vortices—generate localized high-velocity zones that would strip the protective oxide film from lesser alloys. However, our Monel 400 tubes utilize a self-healing nickel-copper passive layer that thrives under these kinetic conditions, ensuring that the extrados of the bend, despite the natural thinning that occurs during fabrication, maintains a corrosion allowance that exceeds industry expectations for lifecycle longevity.

Advanced Stress Management and Geometrical Precision

The true differentiator of our manufacturing process lies in our post-bending thermal stabilization protocols. While ASTM B165 provides the baseline for the seamless straight tube, the act of cold-forming a U-bend introduces a complex tensor of residual stresses that, if left unaddressed, could become a focal point for hydrogen embrittlement or caustic stress corrosion cracking in high-pH environments. We employ a specialized “Stabilization Heat Treatment” on the bend radius and the adjacent tangent legs. This process is not a generic anneal; it is a precisely calibrated thermal cycle designed to facilitate dislocation climbing and sub-grain boundary reorganization without inducing deleterious grain growth. This ensures that the mechanical transition from the straight section to the apex of the bend is metallurgically seamless, providing a uniform electrochemical potential across the entire length of the tube which prevents the formation of galvanic micro-cells.

| Property | ASTM B165 Requirement | Our Enhanced Internal Standard |

| Wall Thinning Control | Not explicitly defined | Max 10% deviation from nominal |

| Ovality (at bend) | Max 10% of OD | Max 5% for optimized flow dynamics |

| Surface Finish (ID) | Standard Mill Finish | Ra ≤ 0.8 μm to minimize fouling |

| Hydrostatic Test | $P = 2St/D$ | 1.5x Design Pressure with 10s dwell |

Thermal Performance and Fouling Resistance

In the rigorous world of refinery alkylation units and marine steam generators, the efficiency of a heat exchanger is often compromised by the “fouling factor.” Our UNS N04400 tubes exhibit a unique bio-static property due to the controlled leaching of copper ions at the molecular level, which inhibits the attachment of marine organisms and the formation of biofilms in brackish water applications. Scientifically, this maintains a higher heat transfer coefficient ($U$-value) over thousands of operational hours compared to titanium or stainless steel alternatives which may suffer from rapid organic scaling. Furthermore, the thermal expansion coefficient of our Monel 400 is closely matched to that of carbon steel tubesheets, significantly reducing the mechanical fatigue at the tube-to-tubesheet joint during the repeated startup and shutdown cycles typical of modern industrial processing.

Environmental Integrity and Lifecycle Analysis

Choosing our ASTM B165 U-bend tubes is an exercise in “Value Engineering” that looks beyond the initial procurement cost and focuses on the Total Cost of Ownership (TCO). In environments containing hydrofluoric acid, where oxygen levels are meticulously managed, our tubes develop a tenacious metal-fluoride film that is virtually insoluble, resulting in corrosion rates of less than 0.1 mm/year. This level of predictability allows plant operators to extend turnaround intervals and reduce the risk of catastrophic tube ruptures. By integrating sophisticated non-destructive testing (NDT)—including eddy current testing and ultrasonic thickness gauging of the bend area—we provide a documented pedigree for every tube that leaves our facility, ensuring that the “weakest link” in your heat exchanger is actually its strongest asset.

| Service Condition | Temperature | Concentration | Corrosion Rate (Typical) |

| Hydrofluoric Acid | $120^{\circ}C$ | 40% (Deaerated) | < 0.025 mm/year |

| Sulfuric Acid | $80^{\circ}C$ | 80% (Reducing) | < 0.15 mm/year |

| Seawater | Ambient | Flowing (>1.5 m/s) | Negligible |

| Caustic Soda | $150^{\circ}C$ | 50% | < 0.01 mm/year |

Our commitment to the UNS N04400 product line is rooted in a culture of metallurgical excellence and an uncompromising approach to quality control. We do not just manufacture tubes; we engineer thermal solutions that withstand the test of time, pressure, and chemistry.

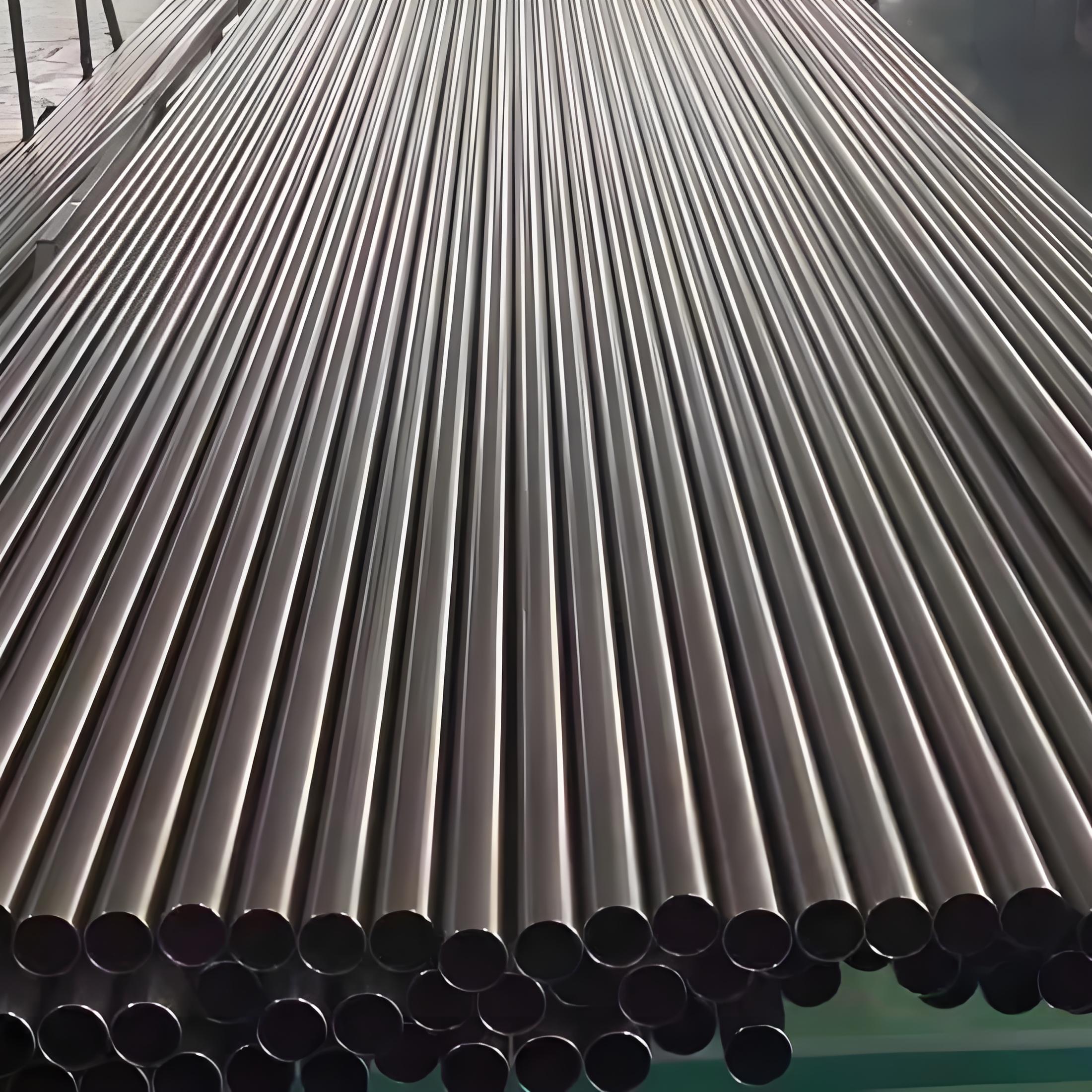

To craft a truly exhaustive technical analysis of UNS N04400 (Monel 400) ASTM B165 U-bend heat exchanger tubes, one must first look beyond the mere numbers of the specification and delve into the metallurgical soul of the alloy itself, understanding that this nickel-copper solid-solution strengthened material is not just a commodity but a sophisticated response to some of the most aggressive corrosive environments known to modern process engineering. The genesis of N04400 lies in its unique binary phase diagram where nickel and copper exhibit complete mutual solubility in all proportions, creating a face-centered cubic (FCC) lattice structure that remains remarkably stable from cryogenic temperatures up to the thresholds of oxidative stress, providing a level of ductility and toughness that few other alloys can replicate when subjected to the mechanical rigors of U-bending and subsequent thermal cycling within a shell-and-tube heat exchanger. When we talk about ASTM B165, we are discussing the rigorous standard for seamless pipe and tube, a manufacturing route that ensures the absence of weld-related discontinuities which is paramount when a tube is destined to be bent into a tight radius, as the extrados of the U-bend will undergo significant thinning and cold work, necessitating a raw material of impeccable purity and uniform grain structure to avoid stress-induced micro-cracking during the fabrication process.

The Chemical and Structural Philosophy of UNS N04400

The mastery of N04400 begins with the precise control of its chemistry, where the nickel content—typically ranging from 63% minimum—acts as the primary defense against chloride-induced stress corrosion cracking, a vulnerability that plagues many austenitic stainless steels in seawater or brackish water applications. The copper component, making up the balance (roughly 28-34%), provides the crucial resistance to non-oxidizing acids and specifically to hydrofluoric acid and sulfuric acid under reducing conditions, a chemical synergy that makes Monel 400 the gold standard for marine engineering and chemical processing. We must also acknowledge the role of minor elements like iron, manganese, silicon, and carbon; while they are often viewed as residual or alloying additions for deoxidation, their levels must be meticulously managed because an excess of iron can diminish the alloy’s resistance to certain acidic media, while carbon levels must be kept low enough to prevent the precipitation of carbides at grain boundaries which could otherwise lead to intergranular corrosion in the heat-affected zones or during high-temperature service.

| Element | Content (%) |

| Nickel (Ni) + Cobalt (Co) | 63.0 min |

| Copper (Cu) | 28.0 – 34.0 |

| Iron (Fe) | 2.5 max |

| Manganese (Mn) | 2.0 max |

| Silicon (Si) | 0.5 max |

| Carbon (C) | 0.3 max |

| Sulfur (S) | 0.024 max |

Mechanical Resilience and the Physics of U-Bending

The mechanical integrity of ASTM B165 tubes is defined not only by their initial annealed state but by how they respond to the deformation energy during the U-bending process. When a seamless tube is bent, the material on the outer radius (the extrados) is subjected to tensile stress and thinning, while the inner radius (the intrados) experiences compression and thickening, a duality of forces that can induce significant residual stresses if not managed through precise tooling and lubrication. The ASTM B165 specification mandates specific tensile properties to ensure the tube can withstand both the internal pressure of the process fluid and the external stresses of the heat exchanger assembly, but for U-bend applications, we must go further to consider the “Springback” effect and the potential for work hardening, which is why a controlled annealing process prior to bending—and often a stress-relief anneal on the U-bend portion specifically—is vital to restore the material’s corrosion resistance and prevent premature failure due to stress corrosion.

| Property | Value (Min/Max) |

| Tensile Strength (min) | 70 ksi (480 MPa) |

| Yield Strength (0.2% Offset, min) | 28 ksi (195 MPa) |

| Elongation in 2 in. (50mm) (min) | 35% |

| Hardness (Rockwell B) | 75 HRB (Approx.) |

Thermal Evolution and Stress Management

The heat treatment requirements for UNS N04400 are deeply intertwined with its metallurgical stability, as the alloy does not undergo phase transformations like steel, meaning its properties are primarily manipulated through cold work and subsequent annealing. ASTM B165 requires the tubes to be supplied in the annealed condition to ensure maximum ductility and corrosion resistance, typically involving heating the material to a range between $760^{\circ}C$ and $980^{\circ}C$ ($1400^{\circ}F$ to $1800^{\circ}F$), followed by a rapid quench or cooling in a controlled atmosphere to prevent oxidation. For U-bend tubes, the bending region itself becomes a zone of localized cold work where the dislocation density increases significantly, leading to higher hardness and potentially making that specific area more susceptible to certain types of environmental cracking; therefore, it is common industry practice to perform a localized stress-relief anneal on the bent portion—specifically the U-bend plus a short distance of the straight legs—at temperatures around $550^{\circ}C$ to $650^{\circ}C$ to redistribute these internal stresses without causing excessive grain growth or loss of overall strength.

| Heat Treatment State | Temperature Range | Cooling Method |

| Solution Annealing | $760^{\circ}C – 980^{\circ}C$ | Rapid Air Cool or Water Quench |

| Stress Relieving (Post-Bend) | $540^{\circ}C – 600^{\circ}C$ | Controlled Cooling |

Performance in Extreme Working Conditions

In the practical theater of a heat exchanger, the UNS N04400 U-bend tube is often the primary barrier between a high-pressure, corrosive process medium and a cooling fluid, necessitating a deep understanding of its galvanic behavior and its resistance to pitting and crevice corrosion. In marine environments, Monel 400 is legendary for its resistance to flowing seawater, where it develops a thin, tenacious protective film of nickel-copper oxides; however, in stagnant conditions, it may be susceptible to localized pitting from biofouling, which underscores the importance of maintaining adequate flow velocities within the tubes. Furthermore, its performance in hydrofluoric acid alkylation units is unparalleled, as it resists the acid across all concentrations up to the boiling point, provided that oxygen and other oxidants are strictly excluded, as the presence of oxygen can break down the protective fluoride film and lead to accelerated corrosion rates. The U-bend geometry adds another layer of complexity to the fluid dynamics, as the change in direction can cause localized turbulence and erosion-corrosion at the intrados if the flow rates are excessively high, requiring a nuanced balance between heat transfer efficiency and the long-term mechanical erosion of the tube wall.

The scientific depth of this material also extends to its cryogenic properties, where unlike many ferritic materials that undergo a ductile-to-brittle transition, UNS N04400 maintains its toughness and ductility even at temperatures approaching absolute zero, making it an excellent candidate for liquefied gas heat exchangers. Conversely, at elevated temperatures, one must be cautious of sulfur-bearing atmospheres, as nickel-rich alloys are prone to “sulfidation” or “liquid metal embrittlement” if exposed to sulfur compounds above $315^{\circ}C$ ($600^{\circ}F$), leading to the formation of low-melting-point nickel sulfides at the grain boundaries which can cause catastrophic intergranular failure. This multifaceted nature of Monel 400—being a titan of corrosion resistance in some media while requiring careful handling in others—is what makes the ASTM B165 U-bend tube a masterpiece of metallurgical engineering, demanding a holistic approach to design, fabrication, and operation that honors the sophisticated chemistry of this timeless nickel-copper alloy.