Polyurethane Insulation Steel Pipes

Polyurethane Insulation Steel Pipe: Sizes, Parameters, and Scientific Analysis

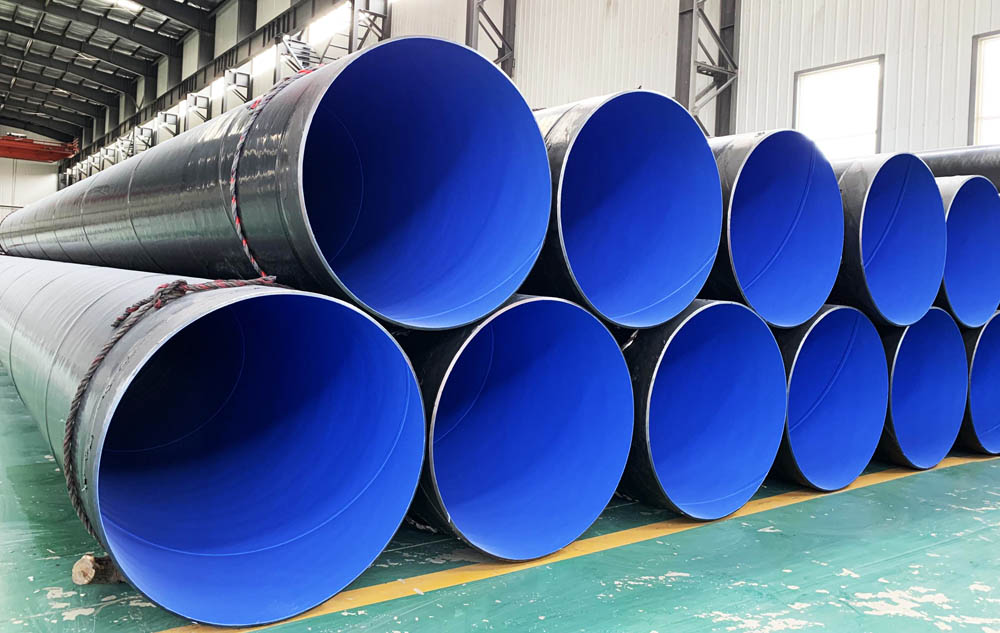

Introduction to Polyurethane Insulation Steel Pipes

Polyurethane insulation steel pipes are engineered solutions designed to transport fluids and gases while maintaining thermal efficiency and structural integrity. These pipes consist of a steel core, a rigid polyurethane foam insulation layer, and an outer protective casing, typically made of high-density polyethylene (HDPE) or fiberglass. Their widespread use in industries like district heating, oil and gas, and refrigeration stems from their superior thermal insulation, corrosion resistance, and durability. This article provides an in-depth exploration of polyurethane insulation steel pipe sizes, technical parameters, and a scientific comparison of their performance metrics, supported by data-driven analysis.

The significance of polyurethane insulation lies in its low thermal conductivity, typically ranging from 0.013 to 0.03 kcal/m·h·°C, which is significantly lower than traditional insulation materials like mineral wool or fiberglass. This property reduces heat loss by up to 4–9 times compared to conventional materials, making it ideal for applications requiring precise temperature control, such as district heating systems or cryogenic pipelines. Additionally, the closed-cell structure of polyurethane foam, with a cell closure rate of approximately 92%, ensures minimal water absorption (around 0.2 kg/m²), enhancing longevity and resistance to environmental degradation.

These pipes are also valued for their versatility in handling extreme temperatures, from -200°C to 250°C, depending on the configuration. The steel core provides mechanical strength, while the outer casing protects against moisture, UV radiation, and mechanical damage. In urban central heating, for instance, polyurethane-insulated pipes reduce heat loss to 2%, far below the international standard of 10%. Their ability to incorporate leakage alarm systems further enhances safety by detecting and locating pipeline failures, ensuring operational reliability.

The construction industry benefits from the lightweight nature of polyurethane insulation, with a density of 35–40 kg/m³, which simplifies installation and reduces project costs by 10–25% compared to traditional piping systems. This combination of energy efficiency, cost-effectiveness, and durability positions polyurethane insulation steel pipes as a cornerstone of modern industrial infrastructure. This article will delve into their sizing standards, technical parameters, and comparative performance, offering insights for engineers, designers, and project managers.

Pipe Sizes and Specifications

Polyurethane insulation steel pipes come in a range of sizes to accommodate diverse industrial applications. The size of these pipes is determined by the outer diameter (OD) of the steel core, the thickness of the insulation layer, and the outer casing dimensions. Common outer diameters for the steel core range from 6 mm to 1220 mm, with wall thicknesses varying from 1 mm to 120 mm, depending on the application, such as fluid transport, high-pressure boiler systems, or structural purposes. The insulation layer thickness typically ranges from 30 mm to 100 mm, tailored to the thermal requirements of the system.

The following table summarizes standard pipe sizes and specifications for polyurethane insulation steel pipes, based on industry standards like EN/DIN 253 and ASTM specifications:

| Outer Diameter (mm) | Wall Thickness (mm) | Insulation Thickness (mm) | Outer Casing Material | Application |

|---|---|---|---|---|

| 6–21 | 1–5 | 30–50 | HDPE | Precision instruments, small-scale fluid transport |

| 32–57 | 5–10 | 40–60 | HDPE/Fiberglass | Hydraulic piping, district heating |

| 159–1220 | 10–120 | 60–100 | HDPE | Oil and gas pipelines, large-scale heating |

Small-diameter pipes (6–21 mm) are typically used in precision applications, such as medical or laboratory equipment, where minimal heat loss is critical. Medium-diameter pipes (32–57 mm) are common in hydraulic systems and district heating, offering a balance of flow capacity and insulation efficiency. Large-diameter pipes (159–1220 mm) are designed for high-volume transport, such as oil and gas pipelines, where robust insulation is necessary to maintain fluid temperature over long distances. The choice of pipe size depends on factors like flow rate, pressure, and environmental conditions, with larger diameters requiring thicker insulation to minimize heat loss.

Manufacturers can customize pipe sizes to meet specific project requirements, adhering to standards like GB/T 8163-2018 for seamless carbon steel pipes or EN 253 for pre-insulated bonded pipe systems. The outer casing, typically HDPE, adds an additional 2–5 mm to the overall diameter, ensuring protection against mechanical damage and corrosion. The flexibility in sizing makes polyurethane insulation steel pipes suitable for both underground and aboveground installations, with seamless, welded, or spiral-welded steel cores selected based on the conveying medium’s technical demands.

Technical Parameters and Performance Metrics

The performance of polyurethane insulation steel pipes is defined by key technical parameters, including thermal conductivity, density, compressive strength, water absorption, and fire resistance. These parameters determine the pipes’ suitability for specific applications and their long-term reliability. The rigid polyurethane foam used in these pipes has a thermal conductivity of 0.022–0.03 W/(m·K), significantly lower than mineral wool (0.035–0.045 W/(m·K)) or fiberglass (0.033–0.048 W/(m·K)). This low conductivity ensures minimal heat transfer, making polyurethane ideal for both hot and cold applications.

The density of polyurethane foam ranges from 35 to 120 kg/m³, depending on the application. Lower-density foams (35–40 kg/m³) are used in low-pressure systems like hot and cold water transport, while higher-density foams (60–120 kg/m³) are employed in high-temperature or high-pressure environments, such as steam pipelines. The compressive strength of polyurethane foam, typically 0.3–0.5 MPa, allows it to withstand mechanical stress without deformation, ensuring structural integrity in buried or exposed installations.

Water absorption is another critical parameter, with polyurethane foam exhibiting a rate of approximately 0.2 kg/m² due to its high closed-cell ratio (92%). This low absorption rate prevents moisture ingress, which could otherwise degrade insulation performance or corrode the steel core. In contrast, materials like mineral wool have higher water absorption (up to 1 kg/m²), making them less suitable for humid environments. The outer HDPE casing further enhances water resistance, protecting the insulation layer from environmental exposure.

Fire resistance is a key consideration in industrial applications. Polyurethane foam can be formulated to meet international fire safety standards, forming a coking maintenance layer during combustion to prevent flame spread. Unlike expanded polystyrene (EPS) or extruded polystyrene (XPS), polyurethane does not melt or drip, enhancing safety in high-risk environments. Additionally, polyurethane insulation pipes can be equipped with leakage alarm lines, which detect pipeline failures and display their location on specialized instruments, improving maintenance efficiency and system reliability.

Scientific Comparison of Polyurethane vs. Other Insulation Materials

To evaluate the performance of polyurethane insulation steel pipes, a scientific comparison with other common insulation materials—mineral wool, fiberglass, and elastomeric foam—is essential. The following table compares key performance metrics based on experimental data and industry standards:

| Material | Thermal Conductivity (W/(m·K)) | Density (kg/m³) | Water Absorption (kg/m²) | Temperature Range (°C) | Fire Resistance |

|---|---|---|---|---|---|

| Polyurethane Foam | 0.022–0.03 | 35–120 | 0.2 | -200 to 250 | Good (coking layer) |

| Mineral Wool | 0.035–0.045 | 80–200 | 1.0 | -50 to 700 | Excellent |

| Fiberglass | 0.033–0.048 | 12–48 | 0.5–1.0 | -20 to 450 | Good |

| Elastomeric Foam | 0.035–0.040 | 40–80 | 0.1–0.3 | -50 to 105 | Moderate |

Polyurethane foam outperforms other materials in thermal conductivity, offering the lowest values and thus the highest insulation efficiency. This makes it particularly effective for applications requiring minimal heat loss, such as district heating or refrigeration. Its low density compared to mineral wool reduces installation costs and simplifies handling, while its low water absorption enhances durability in humid or outdoor environments. However, mineral wool excels in high-temperature applications (up to 700°C) and fire resistance, making it suitable for steam pipelines where temperatures exceed polyurethane’s limit of 250°C.

Fiberglass, while lightweight and cost-effective, has higher thermal conductivity and water absorption than polyurethane, reducing its efficiency in demanding applications. Elastomeric foam, with similar water resistance to polyurethane, is limited by its narrower temperature range and lower fire resistance, making it less versatile for industrial use. Studies, such as those published in the Journal of Thermal Insulation, indicate that polyurethane foam maintains its thermal conductivity (0.022 W/(m·K)) even after accelerated aging, whereas mineral wool and fiberglass show slight degradation over time due to moisture absorption and fiber breakdown.

Applications and Economic Benefits

Polyurethane insulation steel pipes are used across industries, including district heating, oil and gas, refrigeration, and chemical processing. In district heating, they reduce heat loss to 2%, compared to 10% for traditional pipelines, resulting in significant energy savings. In oil and gas, their ability to maintain fluid temperature over long distances ensures operational efficiency, while their corrosion resistance extends service life in harsh environments. Refrigeration systems benefit from polyurethane’s low thermal conductivity, preventing heat gain and condensation on cold pipes.

Economically, these pipes reduce project costs by 10–25%, depending on the protective casing used (fiberglass or HDPE). Life-cycle cost analyses, such as those conducted in HVAC applications, show that polyurethane insulation achieves the shortest payback period compared to materials like expanded polystyrene or rockwool, due to its superior energy savings. The lightweight nature of polyurethane foam (35–40 kg/m³) also reduces labor and transportation costs, while its ease of installation minimizes construction time.

In terms of environmental impact, polyurethane insulation contributes to energy conservation by reducing heat loss, aligning with global sustainability goals. The use of recyclable HDPE casings and advancements in eco-friendly polyurethane formulations further enhance their environmental profile. However, challenges like corrosion under insulation (CUI) must be addressed through proper installation and regular inspections to ensure long-term performance.

Polyurethane insulation steel pipes represent a pinnacle of thermal insulation technology, combining low thermal conductivity, durability, and cost-effectiveness. Their sizing flexibility, ranging from 6 mm to 1220 mm in diameter, accommodates a wide range of applications, from precision instruments to large-scale oil and gas pipelines. Technical parameters like thermal conductivity (0.022–0.03 W/(m·K)), low water absorption (0.2 kg/m²), and high compressive strength make them superior to alternatives like mineral wool and fiberglass in many scenarios. Scientific comparisons confirm polyurethane’s efficiency in maintaining temperature stability, reducing energy loss, and enhancing system longevity.

Future trends in polyurethane insulation include the development of organic-inorganic composite foams, which improve mechanical strength and microbial resistance while maintaining thermal performance. Research into sustainable blowing agents, such as n-pentane, aims to reduce environmental impact without compromising insulation properties. Additionally, advancements in leakage detection systems and smart monitoring technologies will further enhance the reliability of polyurethane-insulated pipelines, making them a cornerstone of next-generation infrastructure.

As industries prioritize energy efficiency and sustainability, polyurethane insulation steel pipes will continue to play a critical role. Their ability to balance performance, cost, and environmental considerations positions them as a preferred choice for engineers and project managers worldwide. By leveraging the data and insights provided in this analysis, stakeholders can make informed decisions to optimize their piping systems for efficiency and durability.