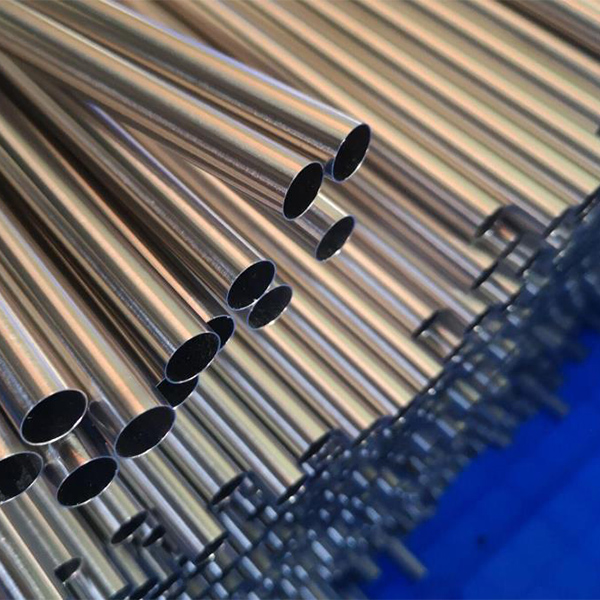

ASTM A270 304L Stainless Steel Sanitary Pipes for Biopharmaceutical and Sanitary Applications

Technical Product Overview: ASTM A270 304L Stainless Steel Sanitary Pipes for Biopharmaceutical and Sanitary Applications

Introduction

In the biopharmaceutical and food processing industries, the choice of piping material is critical to ensuring product purity, operational efficiency, and compliance with stringent hygiene standards. ASTM A270 304L stainless steel sanitary pipes are widely recognized for their suitability in fluid equipment used for biopharmaceutical and sanitary applications, such as in pharmaceutical manufacturing, food and beverage processing, and dairy production. These pipes, made from low-carbon 304L stainless steel, offer excellent corrosion resistance, hygienic properties, and weldability, making them ideal for handling sensitive fluids like purified water, biologics, and food-grade liquids. This article provides a comprehensive technical overview of ASTM A270 304L stainless steel sanitary pipes, detailing their material composition, mechanical and physical properties, dimensional specifications, manufacturing processes, and a comparative analysis with other materials. Our company specializes in producing high-quality ASTM A270 304L sanitary pipes, designed to meet the rigorous demands of biopharmaceutical and sanitary environments, including resistance to acidic and chloride-containing fluids, compatibility with cleaning-in-place (CIP) systems, and compliance with global standards such as FDA, 3-A, and EHEDG. The low carbon content of 304L minimizes the risk of intergranular corrosion during welding, ensuring long-term reliability in complex piping systems. By exploring these aspects in detail, supported by technical tables, this article aims to demonstrate why ASTM A270 304L stainless steel sanitary pipes are the preferred choice for fluid equipment in biopharmaceutical and sanitary applications, offering a balance of performance, cost-effectiveness, and regulatory compliance.[]

1. Material Composition and Properties of 304L Stainless Steel

1.1 Chemical Composition

ASTM A270 304L stainless steel is an austenitic alloy, characterized by its low carbon content (≤ 0.03%), which enhances its weldability and reduces the risk of intergranular corrosion in biopharmaceutical and sanitary applications. The alloy’s composition includes 18–20% chromium and 8–12% nickel, providing excellent corrosion resistance to oxidizing environments, such as those encountered in food processing or pharmaceutical fluid systems. Unlike 316L, 304L lacks molybdenum, making it slightly less resistant to chloride-induced pitting but more cost-effective for applications with moderate corrosion demands. The chemical composition, as specified in ASTM A270, is tightly controlled to ensure consistency and compliance with sanitary standards. Chromium forms a passive oxide layer that protects the pipe from environmental degradation, while nickel enhances ductility and toughness, ensuring the pipes can withstand mechanical stresses during installation and operation. Manganese, silicon, phosphorus, and sulfur are included in trace amounts to optimize mechanical properties and manufacturability. Table 1 details the chemical composition of 304L stainless steel, highlighting its suitability for hygienic applications. The low carbon content is particularly critical in biopharmaceutical systems, where welded joints are common, as it prevents carbide precipitation during welding, maintaining corrosion resistance. This makes ASTM A270 304L pipes ideal for fluid equipment handling purified water, biologics, or food-grade liquids, where product purity is paramount. The alloy’s compliance with ASTM A270 ensures it meets the stringent requirements of the food, dairy, and pharmaceutical industries, as well as standards like 3-A and FDA, guaranteeing safety for direct contact with consumable products.

| Element | 304L (% Weight) |

|---|---|

| Carbon (C) | ≤ 0.03 |

| Chromium (Cr) | 18.0–20.0 |

| Nickel (Ni) | 8.0–12.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

Source: ASTM A270/A270M

1.2 Mechanical Properties

The mechanical properties of ASTM A270 304L stainless steel sanitary pipes ensure their suitability for fluid equipment in biopharmaceutical and sanitary applications, where pipelines must withstand mechanical stresses, pressure variations, and thermal cycles. According to ASTM A270, 304L stainless steel exhibits a tensile strength of 485–620 MPa and a minimum yield strength of 170 MPa, providing sufficient strength for high-pressure fluid transfer systems. Its elongation (≥ 40%) allows the material to deform without fracturing, which is essential for applications involving thermal expansion, vibration, or installation stresses. The low carbon content enhances weldability, reducing the risk of sensitization and ensuring the pipes maintain their structural integrity in welded configurations, which are common in biopharmaceutical piping systems. Table 2 outlines these properties, highlighting their compliance with ASTM A270 standards. The material’s hardness (≤ 217 HB) ensures resistance to surface wear while maintaining a smooth, hygienic finish critical for preventing bacterial adhesion. These properties make 304L stainless steel pipes ideal for applications such as purified water systems, bioprocessing equipment, and food processing lines, where reliability and hygiene are paramount. The pipes’ ability to perform across a wide temperature range (-196°C to 815°C) supports their use in both cryogenic storage and high-temperature sterilization processes, such as steam-in-place (SIP) systems. Rigorous mechanical testing, including reverse flattening, hydrostatic, and nondestructive electric tests, ensures that ASTM A270 304L pipes meet the stringent requirements of biopharmaceutical and sanitary applications, providing manufacturers with confidence in their performance and durability.

| Property | 304L (Typical) |

|---|---|

| Tensile Strength (MPa) | 485–620 |

| Yield Strength (MPa) | ≥ 170 |

| Elongation (%) | ≥ 40 |

| Hardness (Brinell, HB) | ≤ 217 |

| Density (g/cm³) | 8.0 |

| Modulus of Elasticity (GPa) | 193 |

Source: ASTM A270/A270M

1.3 Physical Properties

The physical properties of ASTM A270 304L stainless steel sanitary pipes are tailored to meet the demands of fluid equipment in biopharmaceutical and sanitary applications, where thermal stability, hygiene, and compatibility with sensitive processes are critical. With a thermal conductivity of 16.3 W/m·K at 100°C, 304L pipes facilitate efficient heat transfer during processes like pasteurization or sterilization, ensuring consistent performance in fluid handling systems. The specific heat capacity (500 J/kg·K) and low coefficient of thermal expansion (17.3 µm/m·°C) minimize dimensional changes during temperature fluctuations, maintaining tight seals in biopharmaceutical piping systems. The high melting point (1400–1450°C) ensures the pipes can withstand high-temperature cleaning processes, such as SIP, without structural degradation. The non-magnetic austenitic structure of 304L stainless steel eliminates the risk of magnetic interference in sensitive bioprocessing equipment, such as bioreactors or chromatography systems. Its electrical resistivity (720 nΩ·m) supports its use in environments requiring electrical insulation. Table 3 summarizes these properties, highlighting their relevance to sanitary applications. These characteristics ensure that 304L pipes can handle the thermal and mechanical stresses of biopharmaceutical and food processing, including exposure to acidic fluids and aggressive cleaning agents. The smooth, polished surfaces required by ASTM A270, typically with a maximum roughness of 0.8 µm Ra, enhance cleanability and prevent bacterial adhesion, making these pipes ideal for applications requiring high hygiene standards, such as pharmaceutical fluid transfer or dairy processing. By combining these physical properties with rigorous manufacturing standards, ASTM A270 304L pipes provide a reliable, hygienic solution for fluid equipment in sensitive industries.[](

| Property | Value |

|---|---|

| Melting Point (°C) | 1400–1450 |

| Thermal Conductivity (W/m·K) | 16.3 (at 100°C) |

| Specific Heat Capacity (J/kg·K) | 500 |

| Coefficient of Thermal Expansion (µm/m·°C) | 17.3 (0–100°C) |

| Electrical Resistivity (nΩ·m) | 720 |

Source: ASTM Standards and Material Data Sheets

2. Dimensional Specifications

2.1 Standard Sizes and Schedules

ASTM A270 304L stainless steel sanitary pipes are available in a range of sizes and schedules to meet the diverse needs of biopharmaceutical and sanitary fluid equipment. As specified by ASTM A270, these pipes typically range from 1/2” to 8” in outer diameter (OD), with wall thicknesses from 1.24 mm to 3.81 mm, ensuring compatibility with various fluid transfer systems. The standard uses inch-pound units, with a wall thickness tolerance of ±12.5% to ensure precision and consistency. Common schedules include SCH 5S, 10S, and 40S, with SCH 10S being widely used in sanitary applications due to its balance of strength and lightweight design. Table 4 provides common dimensions for ASTM A270 304L pipes, illustrating their suitability for applications like purified water systems or bioprocessing pipelines. Standard pipe lengths are typically 6 meters (20 feet), with custom lengths available for specific project requirements. Seamless pipes are available up to 8” OD, while welded pipes can be produced in larger diameters for electric fusion welded (EFW) applications. The precise dimensional control ensures leak-free connections and compatibility with sanitary fittings, such as clamps or tri-clover fittings, commonly used in biopharmaceutical and food processing systems. These pipes are designed to withstand the mechanical stresses of high-pressure fluid transfer and the thermal cycles of CIP and SIP processes, making them ideal for demanding applications. The adherence to ASTM A270 ensures that these pipes meet the hygienic and performance requirements of industries where cleanliness and reliability are non-negotiable.[]

| OD (Inches) | OD (mm) | SCH 5S WT (mm) | SCH 10S WT (mm) | SCH 40S WT (mm) |

|---|---|---|---|---|

| 1/2 | 12.7 | 1.24 | 1.65 | 2.77 |

| 3/4 | 19.05 | 1.24 | 1.65 | 2.87 |

| 1 | 25.4 | 1.24 | 1.65 | 3.38 |

| 1-1/2 | 38.1 | 1.24 | 1.65 | 3.68 |

| 2 | 50.8 | 1.24 | 1.65 | 3.91 |

| 3 | 76.2 | 1.65 | 2.11 | 5.49 |

| 4 | 101.6 | 2.11 | 2.11 | 6.02 |

| 6 | 152.4 | 2.77 | 2.77 | 7.11 |

| 8 | 203.2 | 2.77 | 3.05 | 8.18 |

Source: ASTM A270/A270M

2.2 Surface Finish Specifications

The surface finish of ASTM A270 304L stainless steel sanitary pipes is a defining feature for biopharmaceutical and sanitary applications, where hygiene and cleanability are paramount. ASTM A270 specifies surface finishes such as mechanically polished (e.g., 180–320 grit) and electropolished, with maximum internal surface roughness values of 0.8 µm Ra for standard sanitary applications and as low as 0.5 µm Ra for pharmaceutical-grade applications. These finishes minimize bacterial adhesion and facilitate thorough cleaning, critical for preventing contamination in fluid equipment handling biologics, purified water, or food products. Table 5 outlines common surface finishes and their applications. For instance, a 32Ra (0.8 µm) internal finish is standard for food and dairy pipelines, while a 20Ra (0.5 µm) electropolished finish is preferred for biopharmaceutical systems requiring ultra-high purity. The manufacturing process involves mechanical polishing with abrasives or electrochemical polishing to achieve the desired smoothness. Rigorous quality control, including profilometer measurements at 90 degrees to the lay, ensures compliance with ASTM A270 and ASME BPE standards. Electropolished surfaces not only enhance hygiene but also improve corrosion resistance by removing surface imperfections. These finishes are critical for applications like bioprocessing, where even minor contamination can compromise product quality. The ability to achieve precise surface finishes makes ASTM A270 304L pipes ideal for fluid equipment in sensitive industries, ensuring compliance with 3-A, FDA, and EHEDG standards while supporting efficient CIP and SIP processes.[]

| Finish Type | Roughness (Ra, µm) | Typical Applications |

|---|---|---|

| Mill Finish | N/A | Non-sanitary applications |

| No. 180 Grit | ≤ 0.8 | Food and dairy pipelines |

| No. 320 Grit | ≤ 0.6 | Beverage and purified water systems |

| Electropolished | ≤ 0.5 | Biopharmaceutical and high-purity applications |

Source: ASTM A270/A270M, ASME BPE

3. Manufacturing Processes

3.1 Seamless Pipes

Seamless ASTM A270 304L stainless steel sanitary pipes are manufactured through a process that ensures a uniform, weld-free structure, ideal for high-pressure and high-purity fluid equipment in biopharmaceutical and sanitary applications. The process begins with a solid 304L stainless steel billet, heated to 1200–1300°C to achieve malleability. The billet is perforated to form a hollow tube, which is then hot-rolled or cold-drawn to achieve precise dimensions and wall thickness. Cold drawing is preferred for smaller diameters, providing superior dimensional accuracy and surface smoothness. Post-forming, the pipes undergo annealing at a minimum temperature of 1040°C, followed by rapid quenching to relieve stresses and enhance corrosion resistance. Pickling and passivation remove surface oxides, ensuring a clean, hygienic finish. Rigorous testing, including hydrostatic, ultrasonic, and reverse flattening tests, ensures compliance with ASTM A270 standards. Seamless pipes are particularly valued in biopharmaceutical applications, such as purified water systems or bioreactors, where the absence of welds eliminates the risk of contamination or seam failure. Their uniform structure supports high-pressure fluid transfer and withstands aggressive CIP and SIP processes. The manufacturing process, while more costly than welded pipes, delivers superior strength and hygiene, making seamless 304L pipes the preferred choice for critical applications where product purity and system reliability are essential. Our company employs state-of-the-art extrusion and testing technologies to ensure that our seamless ASTM A270 304L pipes meet the stringent requirements of biopharmaceutical and sanitary industries.

3.2 Welded Pipes

Welded ASTM A270 304L stainless steel sanitary pipes provide a cost-effective solution for biopharmaceutical and sanitary fluid equipment, particularly for larger diameters and less demanding pressure applications. The manufacturing process involves rolling a 304L stainless steel strip into a cylindrical shape, followed by automated welding using Tungsten Inert Gas (TIG) or plasma welding techniques. No filler metal is used, as specified by ASTM A270, to maintain material purity and prevent contamination. The weld seam is cold-worked to ensure a smooth, uniform finish, and post-weld annealing at 1040°C restores corrosion resistance in the heat-affected zone. The pipes are then mechanically polished or electropolished to achieve the required surface roughness (e.g., ≤ 0.8 µm Ra). Non-destructive testing, such as X-ray or dye penetrant inspection, verifies weld integrity, ensuring compliance with ASTM A270 and ASME BPE standards. Welded pipes are widely used in food processing, dairy, and biopharmaceutical pipelines, where their cost-effectiveness and hygienic properties make them a practical choice. The low carbon content of 304L minimizes sensitization during welding, ensuring long-term corrosion resistance. These pipes are available in sizes up to 12” OD, making them suitable for large-scale fluid transfer systems. Our company’s advanced welding and polishing technologies ensure that our welded ASTM A270 304L pipes meet the highest standards of hygiene and performance, providing a reliable solution for sanitary applications while balancing cost and quality.[]

3.3 Quality Control and Testing

Quality control is a critical aspect of manufacturing ASTM A270 304L stainless steel sanitary pipes, ensuring they meet the stringent requirements of biopharmaceutical and sanitary applications. ASTM A270 mandates extensive testing, including chemical analysis to verify composition, mechanical tests (e.g., reverse flattening, hydrostatic, or nondestructive electric tests), and intergranular corrosion tests per ASTM A262 Practice E. These tests confirm the pipes’ suitability for handling sensitive fluids without contamination or failure. Surface roughness is measured using profilometers to ensure compliance with specified Ra values (e.g., ≤ 0.8 µm for standard sanitary applications, ≤ 0.5 µm for pharmaceutical-grade). Eddy current testing is performed on 100% of the pipes to detect surface or subsurface defects, while weld integrity is verified through radiographic or dye penetrant inspection for welded pipes. Annealing and quenching processes are carefully controlled to maintain the austenitic structure and corrosion resistance. Material test reports (MTRs) and certifications per EN 10204 3.1 are provided to verify compliance with ASTM A270, 3-A, and FDA standards. For biopharmaceutical applications, additional testing may be required to meet ASME BPE requirements, such as enhanced chemical composition controls and tighter dimensional tolerances. Our company employs advanced testing equipment and quality management systems to ensure that every ASTM A270 304L pipe meets or exceeds industry standards, providing manufacturers with confidence in their performance for fluid equipment in sensitive applications like bioprocessing, purified water systems, and food production.

4. Comparative Analysis with Other Materials

To highlight the advantages of ASTM A270 304L stainless steel sanitary pipes, a comparison with other materials used in biopharmaceutical and sanitary fluid equipment, such as 316L stainless steel, carbon steel, and plastic (e.g., PVC), is essential. Table 6 provides a detailed comparison across key properties. Compared to 316L stainless steel, 304L offers similar hygienic properties but is less resistant to chloride-induced pitting due to the absence of molybdenum, making it more suitable for applications with moderate corrosion demands, such as purified water or non-acidic food processing. However, 304L is more cost-effective, making it a popular choice for budget-conscious projects. Carbon steel is prone to rust and corrosion, especially in moist or acidic environments, and its rough surface can harbor bacteria, rendering it unsuitable for sanitary applications. Plastic pipes, like PVC, are lightweight and inexpensive but risk chemical leaching and have a limited lifespan (10–20 years) compared to 304L’s 20–50 years. ASTM A270 304L pipes excel in hygienic properties, with polished surfaces that prevent bacterial adhesion, and comply with FDA, 3-A, and EHEDG standards. Their ability to withstand temperatures from -196°C to 815°C and moderate pressure ratings makes them versatile for various fluid transfer systems. This comparative analysis underscores why ASTM A270 304L pipes are a reliable, cost-effective choice for biopharmaceutical and sanitary applications where hygiene and durability are critical, but extreme corrosion resistance is not required

| Property/Material | 304L Stainless Steel | 316L Stainless Steel | Carbon Steel | PVC (Plastic) |

|---|---|---|---|---|

| Corrosion Resistance | Good (oxidizing environments) | Excellent (chloride/acid resistance) | Poor (prone to rust) | Good (but leaches chemicals) |

| Hygienic Properties | Excellent (non-porous, easy to clean) | Excellent (non-porous, easy to clean) | Poor (rusts, harbors bacteria) | Moderate (risk of chemical leaching) |

| Durability (Years) | 20–50 | 25–75 | 5–15 | 10–20 |

| Temperature Range (°C) | -196 to 815 | -196 to 870 | -29 to 425 | 0 to 60 |

| Pressure Rating | Moderate (SCH 10S/40S) | High (SCH 40S/80S) | Moderate | Low |

| Cost (Relative) | Moderate | High | Low | Very Low |

| FDA/3-A Compliance | Yes | Yes | No | Limited |

5. Applications in Biopharmaceutical and Sanitary Fluid Equipment

ASTM A270 304L stainless steel sanitary pipes are integral to fluid equipment in biopharmaceutical and sanitary applications, ensuring hygiene, reliability, and compliance with regulatory standards. In biopharmaceutical manufacturing, these pipes are used in purified water systems, clean-in-place (CIP) and steam-in-place (SIP) systems, and bioprocessing equipment, such as bioreactors and chromatography columns, where their smooth, polished surfaces prevent contamination. In food and beverage processing, they handle liquids like juices, dairy products, and purified water, maintaining product purity during transfer and processing. Their corrosion resistance to oxidizing environments makes them suitable for non-acidic food applications, while their weldability supports complex piping configurations in large-scale facilities. In dairy production, 304L pipes are used for milk processing and cheese production, where hygiene is critical to prevent bacterial growth. The pipes’ ability to withstand CIP and SIP processes ensures they can be thoroughly sanitized without degradation, supporting compliance with 3-A and FDA standards. In pharmaceutical applications, they are used for fluid transfer in drug manufacturing, where product purity is paramount. The versatility of ASTM A270 304L pipes, available in seamless and welded forms with various surface finishes, allows for customization to meet specific process requirements, from small-scale laboratories to large-scale production plants. Their cost-effectiveness compared to 316L makes them a popular choice for applications with moderate corrosion demands, providing a balance of performance and affordability for biopharmaceutical and sanitary fluid equipment.[](

6. Compliance with Industry Standards

ASTM A270 304L stainless steel sanitary pipes are designed to meet the stringent requirements of biopharmaceutical and sanitary applications, complying with multiple international standards to ensure safety and quality. ASTM A270 specifies seamless and welded austenitic stainless steel tubing for sanitary applications, emphasizing surface finish, cleanliness, and mechanical properties. The standard requires rigorous testing, including chemical analysis, mechanical tests, and intergranular corrosion tests (ASTM A262 Practice E), to ensure the pipes are suitable for food, dairy, and pharmaceutical use. The 3-A Sanitary Standards mandate hygienic design and cleanability, which 304L pipes achieve through their polished, non-porous surfaces. FDA regulations confirm that 304L stainless steel is safe for direct food contact, as it does not leach harmful substances. EHEDG guidelines promote hygienic engineering, with 304L pipes meeting requirements for cleanability and durability. For biopharmaceutical applications, compliance with ASME BPE standards may be required, specifying tighter tolerances and enhanced surface finishes for high-purity systems. Our company ensures that all ASTM A270 304L pipes are manufactured and tested to meet these standards, with certifications provided per EN 10204 3.1. This compliance guarantees that the pipes can withstand the harsh conditions of biopharmaceutical and sanitary fluid equipment, including exposure to cleaning agents and thermal sterilization, without compromising product safety. By adhering to these standards, ASTM A270 304L pipes provide manufacturers with a reliable, regulatory-compliant solution for fluid handling systems, ensuring consumer safety and product quality across diverse applications.[]

7. Benefits of ASTM A270 304L Stainless Steel Sanitary Pipes

ASTM A270 304L stainless steel sanitary pipes offer numerous benefits for biopharmaceutical and sanitary fluid equipment, making them a preferred choice for manufacturers seeking hygiene, reliability, and cost-effectiveness. Their good corrosion resistance, driven by high chromium and nickel content, ensures durability in oxidizing environments, such as purified water or non-acidic food processing systems. The low carbon content enhances weldability, reducing the risk of intergranular corrosion and ensuring long-term performance in welded piping systems. The hygienic properties, achieved through polished surfaces (e.g., ≤ 0.8 µm Ra), minimize bacterial adhesion and facilitate thorough cleaning, critical for preventing contamination in biopharmaceutical and food applications. With a service life of 20–50 years, 304L pipes offer excellent durability, reducing maintenance costs and downtime compared to alternatives like carbon steel or plastic. Their versatility, available in seamless and welded forms with various sizes and finishes, allows for customization to meet specific process requirements. The pipes’ ability to withstand temperatures from -196°C to 815°C supports their use in both cryogenic and high-temperature processes, such as CIP and SIP systems. Additionally, 304L stainless steel is 100% recyclable, aligning with sustainable manufacturing practices. Compared to 316L, 304L provides a cost-effective solution for applications with moderate corrosion demands, making it ideal for budget-conscious projects without compromising hygiene or compliance with FDA, 3-A, and EHEDG standards. These benefits make ASTM A270 304L pipes a reliable, efficient choice for fluid equipment in biopharmaceutical and sanitary industries, ensuring product purity and operational excellence.[](h

8. Recent Innovations and Trends

Advancements in stainless steel manufacturing and piping technology have enhanced the performance of ASTM A270 304L stainless steel sanitary pipes for biopharmaceutical and sanitary applications. Innovations in welding, such as automated TIG and laser welding, have improved the quality of welded pipes, ensuring seamless, contamination-free joints that meet ASTM A270 requirements. Advanced electropolishing techniques achieve ultra-smooth surfaces (e.g., ≤ 0.5 µm Ra), enhancing corrosion resistance and hygiene for high-purity biopharmaceutical systems. Precision manufacturing, enabled by 3D modeling and CNC cutting, allows for custom pipe configurations tailored to complex fluid equipment layouts, minimizing waste and optimizing flow. The integration of IoT sensors for real-time monitoring of pressure, temperature, and corrosion enables predictive maintenance, reducing downtime and ensuring system reliability. Sustainability initiatives have driven the development of eco-friendly manufacturing processes, with 304L’s recyclability aligning with environmental goals. In biopharmaceutical applications, the adoption of ASME BPE-compliant finishes and tighter tolerances has improved compatibility with high-purity fluid systems. Our company leverages these innovations to produce ASTM A270 304L pipes that meet the evolving needs of the biopharmaceutical and sanitary industries, ensuring high performance, hygiene, and compliance. These advancements reflect the industry’s commitment to improving efficiency, safety, and sustainability, making 304L sanitary pipes a future-proof solution for fluid equipment in sensitive applications like drug manufacturing, food processing, and purified water systems.[]

9. Conclusion

ASTM A270 304L stainless steel sanitary pipes are a cornerstone of fluid equipment in biopharmaceutical and sanitary applications, offering a balance of corrosion resistance, hygienic properties, and cost-effectiveness. Their low carbon content ensures excellent weldability, while polished surfaces (e.g., ≤ 0.8 µm Ra) prevent bacterial adhesion, making them ideal for handling purified water, biologics, and food-grade liquids. Compliance with ASTM A270, 3-A, FDA, and EHEDG standards guarantees their suitability for sensitive applications, while their durability (20–50 years) reduces lifecycle costs. Available in seamless and welded forms with various sizes and finishes, these pipes can be customized to meet diverse process requirements, from small-scale laboratories to large-scale production facilities. Recent innovations, such as advanced welding, electropolishing, and IoT integration, further enhance their performance, ensuring reliability and hygiene in demanding environments. Compared to 316L, 304L offers a cost-effective alternative for applications with moderate corrosion demands, making it a versatile choice for biopharmaceutical and sanitary fluid equipment. Our company is committed to delivering high-quality ASTM A270 304L pipes, manufactured with precision and tested to the highest standards, to support the success of manufacturers worldwide. By choosing these pipes, industries can achieve unparalleled hygiene, compliance, and efficiency, ensuring the production of safe, high-quality products. For more information or to request a quote, please contact us at [insert contact details]. With ASTM A270 304L sanitary pipes, the future of fluid handling is both reliable and sustainable.