Pengurang Paip – Konsentrik dan Sipi

Syarikat Abter membawa pelbagai jenis penurunan sepusat dan eksentrik.

Toleransi dimensi mematuhi ASME B16.9. Ketebalan dinding yang sesuai sesuai dengan jadual standard SCH10,SCH20,SCH30,STD,SCH40,SCH60,SCH80,SCH100,SCH120,SCH160 dan ASME B36.19m Pipa Dinding.

Kelengkapan kimpalan pantat ditandai secara kekal oleh etsa elektro-kimia mengikut ASME B16.9. Anggaran berat badan adalah berdasarkan ketumpatan .163 lbs/inci kubik.

Pengurangan paip keluli adalah komponen dalam saluran paip yang mengurangkan saiz paip ke lubang yang lebih kecil. Terdapat dua jenis pengurangan utama: pengurangan sepusat dan eksentrik. Sebilangan pengurangan paip dihasilkan dengan cara membentuk punch dan yang lain dengan membongkok, extruding, menolak, acuan atau pemesinan.

Pengurangan paip keluli digunakan apabila aliran cecair meningkat atau berkurangan dalam kuantiti yang kecil. Untuk mengelakkan peronggaan, Ia juga digunakan untuk menyambung ke lubang salur masuk. Selain, Ia juga berguna untuk menghubungkan sendi dalam instrumen seperti meter aliran dan injap kawalan. Reducer keluli juga mendapati aplikasi dalam kilang gula dan penyulingan, Pam, petrokimia, industri simen dan pembinaan dan loji keluli. Ia boleh disimpan dalam kotak bebas pengasapan atau pemegang kayu.

Bahan Mentah

* A234 - WPB WP5, WP9, WP11, WP22

* A420 – WPL3/ WPL6

* A403 - WP304/L.; WP316/L.

* A860-WPHY 42-46/52-60/65-70

Bahan khas seperti Monel, Inconel, Dengan kami, Dupleks ss dll boleh didapati atas permintaan

Spesifikasi pengurangan paip keluli

| taip | |||

| Reducer lancar | Pengurangan kimpalan | Reducer kimpalan pantat | |

| Diameter Keluar | 1/2″ ~ 24″ | 4″ ~ 24″ | 12″ ~ 78″ |

| Ketebalan Dinding | 3 mm ~ 150 mm | ||

| Jenis Produk | Reducer sepusat, pengurangan eksentrik | ||

Standard yang ada

Syarikat kami menyediakan pengurangan paip keluli dengan standard yang berbeza untuk memenuhi keperluan pelanggan.

GB/T12459-2005 GB/T13401-2005 GB/T10752-2005

SH/T3408-1996 SH/T3409-1996

SY/T0518-2002 SY/T0510-1998

DL/T695-1999 GD2000 GD87-1101

HG/T21635-1987 HG/T21631-1990

ASME B16.9-2007 ASME B16.25-2007

MSS SP 75-2008

CSA Z245.11-05-2005

EN10253-1-1999 EN10253-2-2007 EN10253-3-2008 EN10253-4-2008

DIN2605-1-1992 DIN2605-2-1995

BS1640-1-1962 BS1640-2-1962 BS1640-3-1968 BS1640-4-1968 BS1965-1-1963

AFNOR NF A 49-289-1990 AFNOR NF A 49-170-1-1999 AFNOR NF A 49-170-2-2009 AFNOR NF A 49-170-3-2009 AFNOR NF A 49-170-4-2009

ISO3419-1981 ISO5251-1981

JIS B2311-2009 JIS B2312-2009 JIS B2313-2009

Buttweld-reducer

| Diameter Nominal | Diameter Luar | Berakhir hingga akhir | ||

| D1*D2 | ||||

| DN | NPS | Siri a | Serices b | H |

| 20× 15 | 3/4× 1/2 | 26.9×21.3 | 25×18 | 38 |

| 20×10 | 3/4×3/8 | 26.9×17.3 | 25×14 | 38 |

| 25×20 | 1×3/4 | 33.7×26.9 | 32×25 | 51 |

| 25× 15 | 1× 1/2 | 33.7×21.3 | 32×18 | 51 |

| 32×25 | 1.1/4×1 | 42.4×33.7 | 38×32 | 51 |

| 32×20 | 1.1/4×3/4 | 42.4×26.9 | 38×25 | 51 |

| 32× 15 | 1.1/4× 1/2 | 42.4×21.3 | 38×18 | 51 |

| 40×32 | 1.1/2×1.1/4 | 48.3×42.4 | 45×38 | 64 |

| 40×25 | 1.1/2×1 | 48.3×33.7 | 45×32 | 64 |

| 40×20 | 1.1/2×3/4 | 48.3×26.9 | 45×25 | 64 |

| 40× 15 | 1.1/2× 1/2 | 48.3×21.3 | 45×18 | 64 |

| 50×40 | 2×1.1/2 | 60.3×48.3 | 57×45 | 76 |

| 50×32 | 2×1.1/4 | 60.3×42.4 | 57×38 | 76 |

| 50×25 | 2×1 | 60.3×33.7 | 57×32 | 76 |

| 50×20 | 2×3/4 | 60.3×26.9 | 57×25 | 76 |

| 65×50 | 2.1/2×2 | 73.0×60.3 | 76×57 | 89 |

| 65×40 | 2.1/2×1.1/2 | 73.0×48.3 | 76×45 | 89 |

| 65×32 | 2.1/2×1.1/4 | 73.0×42.4 | 76×38 | 89 |

| 65×25 | 2.1/2×1 | 73.0×33.7 | 76×32 | 89 |

| 80×65 | 3×2.1/2 | 88.9×73.0 | 89×76 | 89 |

| 80×50 | 3×2 | 88.9×60.3 | 89×57 | 89 |

| 80×40 | 3×1.1/2 | 88.9×48.3 | 89×45 | 89 |

| 80×32 | 3×1.1/4 | 88.9×42.4 | 89×38 | 89 |

| 90×80 | 3.1/2×3 | 101.6×88.9 | – | 102 |

| 90×65 | 3.1/2×2.1/2 | 101.6×73.0 | – | 102 |

| 90×50 | 3.1/2×2 | 101.6×60.3 | – | 102 |

| 90×40 | 3.1/2×1.1/2 | 101.6×48.3 | – | 102 |

| 90×32 | 3.1/2×1.1/4 | 101.6×42.4 | – | 102 |

| 100×90 | 4×3.1/2 | 114.3×101.6 | – | 102 |

| 100×80 | 4×3 | 114.3×88.9 | 108×89 | 102 |

| 100×65 | 4×2.1/2 | 114.3×73.0 | 108×76 | 102 |

| 100×50 | 4×2 | 114.3×60.3 | 108×57 | 102 |

| 100×40 | 4×1.1/2 | 114.3×48.3 | 108×45 | 102 |

| 125×100 | 5×4 | 141.3×114.3 | 133×108 | 127 |

| 125×90 | 5×3.1/2 | 141.3×101.6 | – | 127 |

| 125×80 | 5×3 | 141.3×88.9 | 133×89 | 127 |

| 125×65 | 5×2.1/2 | 141.3×73.0 | 133×76 | 127 |

| 125×50 | 5×2 | 141.3×60.3 | 133×57 | 127 |

| 150×125 | 6×5 | 168.3×141.3 | 159×133 | 140 |

| 150×100 | 6×5 | 168.3×114.3 | 159×108 | 140 |

| 150×90 | 6×3.1/2 | 168.3×101.6 | – | 140 |

| 150×80 | 6×3 | 168.3×88.9 | 159×89 | 140 |

| 150×65 | 6×2.1/2 | 168.3×73.0 | 159×76 | 140 |

| 200×150 | 8×6 | 219.1×168.3 | 219×159 | 152 |

| 200×125 | 8×5 | 219.1×141.3 | 219×133 | 152 |

| 200×100 | 8×4 | 219.1×114.3 | 219×108 | 152 |

| 200×90 | 8×3.1/2 | 219.1×101.6 | – | 152 |

| 250×200 | 10×8 | 273.0×219.1 | 273×219 | 178 |

| 250×150 | 10×6 | 273.0×168.3 | 273×159 | 178 |

| 250×125 | 10×5 | 273.0×141.3 | 273×133 | 178 |

| 250×100 | 10×4 | 273.0×114.3 | 273×108 | 178 |

| 300×250 | 12×10 | 323.9×273.1 | 325×273 | 203 |

| 300×200 | 12×8 | 323.9×219.1 | 325×219 | 203 |

| 300×150 | 12×6 | 323.9×168.3 | 325×159 | 203 |

| 300×125 | 12×5 | 323.9×141.3 | 325×133 | 203 |

| 350×300 | 14×12 | 355.6×323.9 | 377×325 | 330 |

| 350×250 | 14×10 | 355.6×273.0 | 377×273 | 330 |

| 350×200 | 14×8 | 355.6×219.1 | 377×219 | 330 |

| 350×150 | 14×6 | 355.6×168.3 | 377×159 | 330 |

| 400×350 | 16×14 | 406.4×355.6 | 426×377 | 356 |

| 400×300 | 16×12 | 406.4×323.9 | 426×325 | 356 |

| 400×250 | 16×10 | 406.4×273.0 | 426×273 | 356 |

| 400×200 | 16×8 | 406.4×219.1 | 426×219 | 356 |

| 450×400 | 18×16 | 457×406.4 | 478×426 | 381 |

| 450×350 | 18×14 | 457×355.6 | 478×377 | 381 |

| 450×300 | 18×12 | 457×323.9 | 478×325 | 381 |

| 450×250 | 18×10 | 457×273.0 | 478×273 | 381 |

| 500×450 | 20×18 | 508×457 | 529×478 | 508 |

| 500×400 | 20×16 | 508×406.4 | 529×426 | 508 |

| 500×350 | 20×14 | 508×355.6 | 529×377 | 508 |

| 500×300 | 20×12 | 508×323.9 | 529×325 | 508 |

| 550×500 | 22×20 | 559×508 | – | 508 |

| 550×450 | 22×18 | 559×457 | – | 508 |

| 550×400 | 22×16 | 559×406.4 | – | 508 |

| 550×350 | 22×14 | 559×355.6 | – | 508 |

| 600×550 | 24×22 | 610×559 | – | 508 |

| 600×500 | 24×20 | 610×508 | 630×529 | 508 |

| 600×450 | 24×18 | 610×457 | 630×478 | 508 |

| 600×400 | 24×22 | 610×406.4 | 630×426 | 508 |

| 650×600 | 26×24 | 660×610 | – | 610 |

| 650×550 | 26×22 | 660×559 | – | 610 |

| 650×500 | 26×20 | 660×508 | – | 610 |

| 650×450 | 26×18 | 660×457 | – | 610 |

| 700×650 | 28×26 | 711×660 | – | 610 |

| 700×600 | 28×24 | 711×610 | 720×630 | 610 |

| 700×550 | 28×22 | 711×559 | – | 610 |

| 700×500 | 28×20 | 711×508 | 720×530 | 610 |

| 750×700 | 30×28 | 762×711 | – | 610 |

| 750×650 | 30×26 | 762×660 | – | 610 |

| 750×600 | 30×24 | 762×610 | – | 610 |

| 750×550 | 30×22 | 762×559 | – | 610 |

| 800×750 | 32×30 | 813×762 | – | 610 |

| 800×700 | 32×28 | 813×711 | 820×720 | 610 |

| 800×650 | 32×26 | 813×660 | – | 610 |

| 800×600 | 32×24 | 813×610 | 820×630 | 610 |

| 850×800 | 34×32 | 864×813 | – | 610 |

| 850×750 | 34×30 | 864×762 | – | 610 |

| 850×700 | 34×28 | 864×711 | – | 610 |

| 850×650 | 34×26 | 864×660 | – | 610 |

| 900×850 | 36×34 | 914×864 | – | 610 |

| 900×800 | 36×32 | 914×813 | 920×820 | 610 |

| 900×750 | 36×30 | 914×762 | – | 610 |

| 900×700 | 36×28 | 914×711 | 920×720 | 610 |

| 950×900 | 38×36 | 965×914 | – | 610 |

| 950×850 | 38×34 | 965×864 | – | 610 |

| 950×800 | 38×32 | 965×813 | – | 610 |

| 950×750 | 38×30 | 965×762 | – | 610 |

| 1000×950 | 40×38 | 1016×965 | – | 610 |

| 1000×900 | 40×36 | 1016×914 | 1020×920 | 610 |

| 1000×850 | 40×34 | 1016×864 | – | 610 |

| 1000×800 | 40×32 | 1016×813 | 1020×820 | 610 |

| 1050×1000 | 42×40 | 1067×1016 | – | 610 |

| 1050×950 | 42×38 | 1067×965 | – | 610 |

| 1050×900 | 42×36 | 1067×914 | – | 610 |

| 1050×850 | 42×34 | 1067×864 | – | 610 |

| 1100×1050 | 44×42 | 1118×1067 | – | 610 |

| 1100×1000 | 44×40 | 1118×1016 | 1120×1020 | 610 |

| 1100×950 | 44×38 | 1118×965 | – | 610 |

| 1100×900 | 44×36 | 1118×914 | 1220×920 | 610 |

| 1150×1100 | 46×44 | 1168×1118 | – | 711 |

| 1150×1050 | 46×42 | 1168×1067 | – | 711 |

| 1150×1000 | 46×40 | 1168×1016 | – | 711 |

| 1150×950 | 46×38 | 1168×965 | – | 711 |

| 1200×1150 | 48× 46 | 1220× 1168 | – | 711 |

| 1200×1100 | 48×44 | 1220×1118 | 1220× 1120 | 711 |

| 1200×1050 | 48×42 | 1220×1067 | – | 711 |

| 1200×1000 | 48×40 | 1220×1016 | 1220×1020 | 711 |

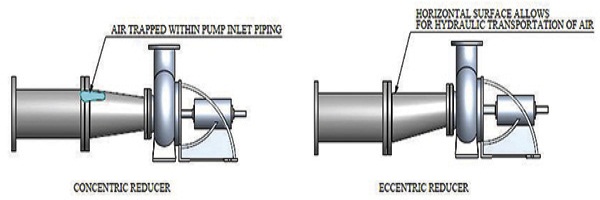

Apa perbezaan antara Reducer sepusat dan Pengurangan eksentrik ?

Reducer sepusat

Hujung terbuka pengurangan sepusat diselaraskan dan berpusat pada yang lain. Secara amnya, Reducer paip jenis ini digunakan untuk mengubah saiz lubang paip dengan dua (maksimum tiga) langkah -langkah, Untuk mengelakkan penurunan tekanan yang berlebihan dalam saluran paip.

Sekiranya pengurangan yang lebih besar diperlukan, maka urutan pengurangan hendaklah digunakan untuk mempunyai penyesuaian saiz saluran paip yang lancar dan beransur -ansur (lwn. perubahan drastik).

Untuk pengurangan saiz kecil, Mengurangkan bebibir mungkin menjadi alternatif kepada pengurangan buttweld.

Pengurangan eksentrikHujung terbuka pengurangan eksentrik berada dalam kedudukan "mengimbangi" satu ke yang lain.

Pengurangan eksentrik digunakan, secara amnya, untuk saluran paip dipasang dalam kedudukan mendatar (manakala pengurangan sepusat digunakan untuk saluran paip dipasang secara menegak atau untuk salur masuk pam sedutan, sebagai pengurangan eksentrik rata atas).

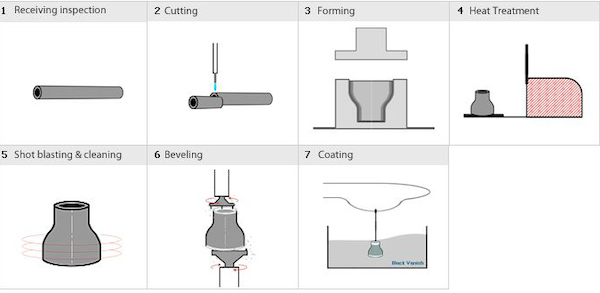

Proses Pembuatan Pengurangan Paip

Pengurangan vs eksentrik yang sepusat

Perbezaan utama antara peninggalan eksentrik vs eksentrik adalah sentraliti salur masuk vs. outlet pemasangan, yang sesuai untuk pengurangan sepusat dan mengimbangi pengurangan eksentrik.

Proses Pembuatan Reducer BW

Pembentukan sejuk adalah proses pembuatan yang paling biasa untuk pengurangan eksentrik/sepusat lancar (pengurangan dikimpal dihasilkan dengan proses kimpalan jahitan tunggal atau berganda):