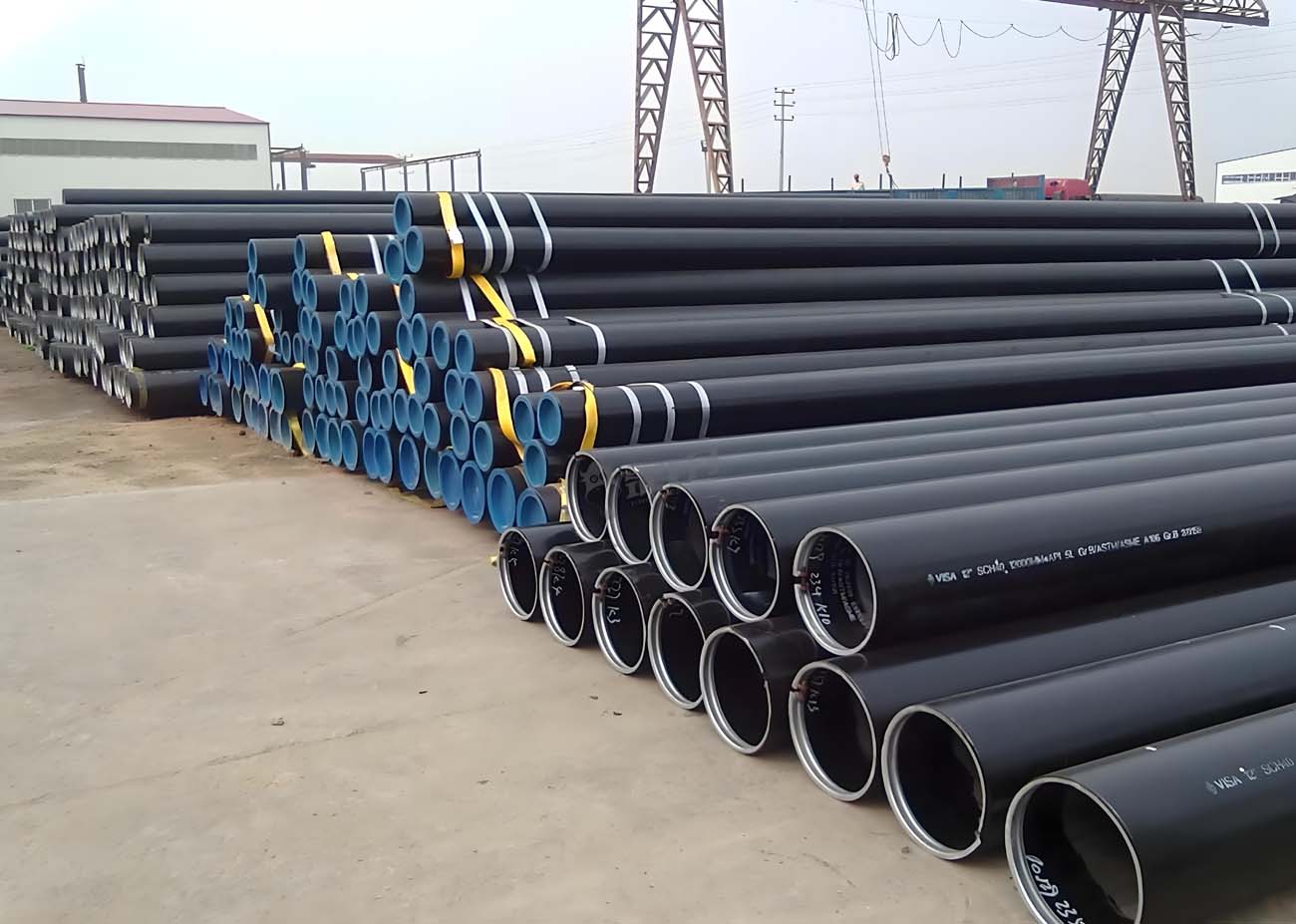

API 5L PSL2 BNS LSAW Steel Pipe

API 5L PSL2 BNS LSAW Steel Pipe 914.4 x 12.7 mm

Introduction to API 5L PSL2 BNS LSAW Steel Pipe

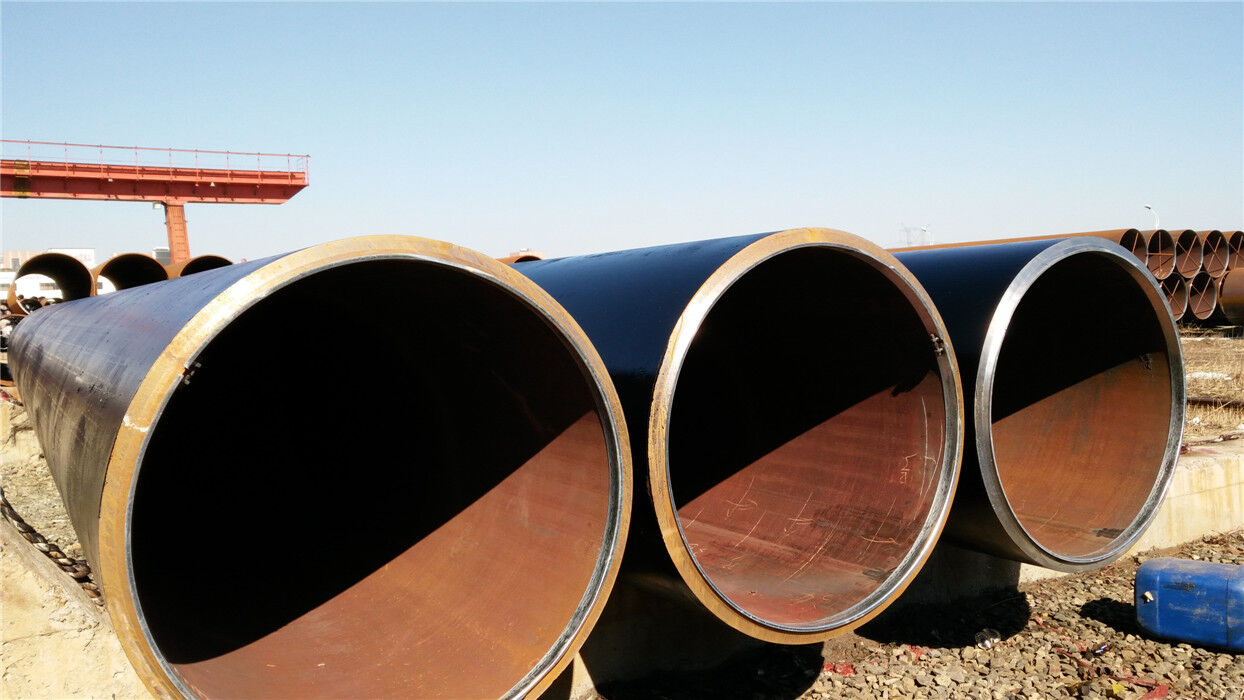

API 5L PSL2 BNS LSAW steel pipe, with an outer diameter of 914.4 mm (36 inches) and a wall thickness of 12.7 mm, is a high-quality longitudinal submerged arc welded (LSAW) carbon steel pipe designed for pipeline transportation systems in the oil and gas industry. Conforming to the American Petroleum Institute (API) 5L specification, Product Specification Level 2 (PSL2), and designated as Grade BNS (Grade B for sour service), this pipe is engineered for enhanced mechanical properties, stringent testing, and resistance to sulfide stress cracking (SSC) in hydrogen sulfide (H2S)-containing environments. The LSAW manufacturing process ensures a robust weld seam, making it suitable for large-diameter, high-pressure applications like main transmission trunk lines and offshore pipelines.

The pipe’s minimum yield strength of 245 MPa (35,500 psi) and compliance with NACE MR0175 for sour service make it ideal for harsh conditions. Its cost-effectiveness, compared to high-performance alloys like Inconel® 718, and versatility in applications such as slag and powder transport pipelines, as seen in projects like the Spanish slag transport pipeline, highlight its practical value. This article explores the pipe’s chemical composition, mechanical properties, corrosion resistance, manufacturing processes, applications, and dimensional tolerances, with detailed tables for engineering reference. Comparisons with Inconel 718, Incoloy 901, ASTM A671 CC60 CL22, and API 5L X70 provide context for its specialized role in critical infrastructure.

Chemical Composition and Material Analysis

The chemical composition of API 5L PSL2 BNS LSAW steel pipe is optimized for strength, weldability, and resistance to sour service environments. Per API 5L PSL2, Grade BNS typically contains carbon (≤0.12%), manganese (≤1.20%), phosphorus (≤0.025%), sulfur (≤0.015%), silicon (≤0.45%), and trace elements like vanadium, niobium, and titanium (V+Nb+Ti ≤0.15%). For sour service (BNS), the carbon equivalent (CEpcm) is calculated as CEpcm = C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B, typically ≤0.25% to enhance weldability and SSC resistance. Low sulfur and phosphorus levels reduce inclusions, improving toughness and corrosion resistance in H2S environments.

Compared to Inconel 718 (50–55% nickel, 4.75–5.50% niobium), API 5L BNS relies on carbon and manganese for strength, lacking the high alloy content that provides Inconel’s superior corrosion resistance. Incoloy 901 (40–45% nickel, 2.35–3.10% titanium) also has a richer composition, enhancing high-temperature performance but not sour service suitability. ASTM A671 CC60 CL22 (0.04–0.27% carbon, 0.85–1.20% manganese) has a similar carbon steel base but is designed for low-temperature service (-46°C), with less stringent sour service requirements. API 5L X70 PSL2 (≤0.26% carbon, ≤1.65% manganese) has a higher carbon equivalent, reducing weldability compared to BNS. The BNS grade’s fine-grain, killed steel microstructure, per PSL2, ensures reliability in sour gas pipelines, meeting NACE MR0175 hardness limits (≤22 HRC).

Mechanical Properties

API 5L PSL2 BNS LSAW steel pipe exhibits robust mechanical properties tailored for oil and gas pipelines. The minimum yield strength is 245 MPa (35,500 psi), with a tensile strength of 415–760 MPa (60,200–110,200 psi) and minimum elongation of 23% for a 914.4 mm OD and 12.7 mm wall thickness, per API 5L PSL2. PSL2 requires Charpy V-notch (CVN) impact testing at 0°C, with a minimum average energy absorption of 41 J (longitudinal) and 27 J (transverse) for grades ≤X60, ensuring toughness in cold environments. For sour service (BNS), additional testing per NACE MR0175 confirms resistance to SSC, with hardness controlled to ≤22 HRC.

Compared to Inconel 718 (yield strength 1035 MPa, tensile strength 1275 MPa), API 5L BNS offers lower strength but is more cost-effective for large-scale pipelines. Incoloy 901 (yield strength ~900 MPa) provides higher strength but lacks sour service optimization. ASTM A671 CC60 CL22 (yield strength 220 MPa, tensile strength 415–550 MPa) is comparable in strength but tested for low-temperature toughness at -46°C, not sour service. API 5L X70 PSL2 (yield strength 485 MPa, tensile strength 570–760 MPa) surpasses BNS in strength but requires stricter processing for sour service. The pipe undergoes hydrostatic, tensile, and bend tests, with PSL2 mandating non-destructive examination (NDE) like ultrasonic testing, ensuring weld integrity for high-pressure applications.

Corrosion Resistance and Sour Service Compliance

API 5L PSL2 BNS LSAW steel pipe is engineered for sour service environments containing H2S, complying with NACE MR0175/ISO 15156. Its low carbon (≤0.12%) and sulfur (≤0.015%) content, combined with a controlled microstructure (hardness ≤22 HRC), minimize susceptibility to sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC). External coatings like fusion-bonded epoxy (FBE), three-layer polyethylene (3LPE), or polypropylene (3LPP) enhance resistance to soil and marine corrosion, while internal coatings or liners protect against fluid-induced corrosion. Galvanizing or anti-corrosion oil may also be applied for additional protection.

Unlike Inconel 718, with its 50–55% nickel and 2.8–3.3% molybdenum for exceptional corrosion resistance in chloride and high-temperature environments, API 5L BNS relies on coatings and material controls for corrosion protection, as its carbon steel base is less inherently resistant. Incoloy 901 offers better corrosion resistance than BNS but is not optimized for sour service. ASTM A671 CC60 CL22, also NACE-compliant, focuses on low-temperature service, with similar coating requirements. API 5L X70 PSL2 requires additional processing for sour service (e.g., X70QS), unlike BNS’s inherent suitability. The pipe’s ability to withstand H2S environments, as demonstrated in projects like the Spanish slag transport pipeline, makes it a cost-effective choice for sour gas pipelines.

Manufacturing and Processing

The manufacturing of API 5L PSL2 BNS LSAW steel pipe involves forming ASTM A516 or equivalent plates into a cylindrical shape using the JCOE process (J-shape, C-shape, O-shape, expansion), followed by longitudinal submerged arc welding (SAW) on internal and external surfaces. The process includes plate feeding, edge milling, crimping, forming, pre-welding, internal/external welding, slag removal, ultrasonic and X-ray inspection, mechanical expansion, hydrostatic testing, and end beveling. The weld seam is reinforced, with a maximum height of 3.2 mm, and undergoes 100% non-destructive examination (NDE) per PSL2, including ultrasonic and radiographic testing, to ensure defect-free welds.

Compared to Inconel 718, which requires vacuum induction melting and complex heat treatments, API 5L BNS is simpler to produce, using basic oxygen or electric furnace steelmaking with ladle refining for fine-grain, killed steel. Incoloy 901 and ASTM A671 CC60 CL22 involve similar carbon steel processing but lack PSL2’s stringent NDE requirements. API 5L X70 PSL2 follows a similar LSAW process but may require thermomechanical rolling for higher strength. The pipe’s dimensions (914.4 mm OD, 12.7 mm WT) are achieved with precise forming, meeting API 5L tolerances. Sour service compliance involves controlled heat treatment to maintain hardness ≤22 HRC, ensuring reliability in H2S environments.

Applications

API 5L PSL2 BNS LSAW steel pipe is widely used in oil and gas pipeline transportation systems, particularly in sour service environments. Its applications include main transmission trunk lines, offshore pipelines, and specialized projects like the Spanish slag and powder transport pipeline (914.4 x 12.7 mm, 11 pipes, 12 m length). The pipe’s large diameter and sour service compliance make it suitable for high-pressure gas and oil transport, wastewater treatment pipelines, and bridge construction projects, as seen in Chile’s 3rd Street Bridge (API 5L B PSL1, 1016 x 25.4 mm). Its versatility supports both onshore and offshore infrastructure.

Unlike Inconel 718, used in high-temperature aerospace and sour gas well components, API 5L BNS is optimized for cost-effective, large-scale pipelines. Incoloy 901 is reserved for aerospace applications, lacking sour service focus. ASTM A671 CC60 CL22 (1066.8 x 12.7 mm) is used in low-temperature applications like boiler piping, while API 5L X70 PSL2 supports higher-pressure pipelines but requires customization for sour service. The pipe’s end finishes (beveled, plain) and coatings (FBE, 3LPE) enhance adaptability for fluid transport, making it a preferred choice for critical infrastructure in harsh environments.

Dimensional Tolerances

Dimensional tolerances for API 5L PSL2 BNS LSAW steel pipe are specified by API 5L, ensuring precision for large-diameter pipelines. For a 914.4 mm (36-inch) OD, the tolerance is ±0.75% (±6.86 mm). The wall thickness tolerance for 12.7 mm is ±10% (±1.27 mm), ensuring consistent strength. Straightness deviation is ≤0.2% of the pipe length (≤24 mm for 12 m), critical for alignment. The weld seam height is ≤3.2 mm, and end bevels (30–35°, root face 0.8–2.4 mm) comply with ASME B16.25 for welding. Weight tolerance is ±10%, ensuring uniformity.

Compared to Inconel 718 forgings (ASTM B637: ±0.25 mm for small diameters), API 5L BNS has looser tolerances due to its large size. Incoloy 901 follows similar precision standards, while ASTM A671 CC60 CL22 (1066.8 mm OD: ±0.5%, ±5.33 mm) has tighter OD tolerances. API 5L X70 PSL2 shares similar tolerances with BNS but may require stricter controls for higher grades. The pipe’s dimensions are verified through ultrasonic and hydrostatic testing, ensuring reliability for applications like gas transmission pipelines.

Technical Specifications and Parameter Table

The following table summarizes the key parameters of API 5L PSL2 BNS LSAW steel pipe (914.4 x 12.7 mm), providing a reference for engineers.

Product Specification LevelPSL2

| Parameter | Specification |

|---|---|

| Standard | API 5L / ISO 3183 |

| Grade | BNS (Grade B, Sour Service) |

| Outer Diameter | 914.4 mm (36 inches) |

| Wall Thickness | 12.7 mm |

| Chemical Composition | C: ≤0.12%, Mn: ≤1.20%, P: ≤0.025%, S: ≤0.015%, Si: ≤0.45%, V+Nb+Ti: ≤0.15%, CEpcm: ≤0.25% |

| Yield Strength (Min) | 245 MPa (35,500 psi) |

| Tensile Strength | 415–760 MPa (60,200–110,200 psi) |

| Elongation (Min) | 23% |

| Impact Test (PSL2) | 0°C, 41 J (longitudinal), 27 J (transverse) |

| NACE MR0175 | Hardness ≤22 HRC, SSC/HIC resistance |

| Welding Method | LSAW (JCOE, Submerged Arc Welding) |

| Testing | 100% NDE (ultrasonic, radiographic), hydrostatic, tensile, bend, CVN |

| Coatings | FBE, 3LPE, 3LPP, anti-corrosion oil, galvanizing |

| End Finishes | Beveled (30–35°, root face 0.8–2.4 mm), plain |

| Applications | Oil/gas pipelines, slag transport, wastewater treatment, bridge construction |

This table provides a concise overview of the pipe’s specifications, aiding in design and procurement decisions.

Comparison with Inconel 718, Incoloy 901, ASTM A671 CC60, and API 5L X70

API 5L PSL2 BNS differs significantly from Inconel 718, Incoloy 901, ASTM A671 CC60 CL22, and API 5L X70. Inconel 718 (yield strength 1035 MPa, 50–55% nickel) excels in high-temperature, corrosive environments like aerospace, offering superior corrosion resistance but at a high cost. API 5L BNS (yield strength 245 MPa) is optimized for sour service pipelines, relying on coatings for corrosion protection. Incoloy 901 (yield strength ~900 MPa, 40–45% nickel) is suited for aerospace but lacks sour service optimization. ASTM A671 CC60 CL22 (yield strength 220 MPa) is designed for low-temperature (-46°C) applications, with similar NACE compliance but lower strength. API 5L X70 PSL2 (yield strength 485 MPa) offers higher strength for high-pressure pipelines but requires additional processing for sour service (e.g., X70QS).

API 5L BNS’s low CEpcm and PSL2 testing ensure superior weldability and sour service performance compared to X70, while its cost-effectiveness surpasses Inconel 718 and Incoloy 901. ASTM A671 CC60 is comparable for sour service but prioritizes low-temperature toughness. The choice depends on project needs: BNS for sour service pipelines, Inconel 718 for extreme conditions, Incoloy 901 for aerospace, CC60 for cold climates, and X70 for high-pressure transport.

Challenges and Limitations

API 5L PSL2 BNS LSAW steel pipe faces challenges inherent to carbon steel and sour service applications. Its reliance on coatings for corrosion protection, unlike Inconel 718’s inherent resistance, requires rigorous application and maintenance to prevent external corrosion in soil or marine environments. Sour service compliance demands strict control of hardness (≤22 HRC) and microstructure, necessitating precise heat treatment and NDE, which increases production costs. The LSAW process ensures high-quality welds but requires 100% radiographic and ultrasonic testing, adding complexity compared to seamless pipes.

Compared to API 5L X70 PSL2, BNS has lower strength, limiting its use in ultra-high-pressure pipelines. ASTM A671 CC60 CL22 shares similar coating and NACE requirements but is less suited for high-pressure sour gas transport. Inconel 718 and Incoloy 901 are cost-prohibitive for large-scale pipelines. Field welding must maintain NACE compliance, and large-diameter pipes (914.4 mm) require specialized equipment for installation. These challenges are mitigated through advanced coatings, stringent quality control, and proper design, ensuring reliability in sour gas pipelines and infrastructure projects.

Future Trends and Innovations

The future of API 5L PSL2 BNS LSAW steel pipe is driven by advancements in manufacturing, coatings, and sustainability. Innovations in submerged arc welding and real-time weld monitoring are reducing defects, enhancing seam quality, and lowering costs. Advanced coatings, such as nanotechnology-based FBE and 3LPE, are improving corrosion resistance, extending service life in sour environments. Digital tools, like pipeline monitoring and predictive maintenance, are enhancing operational efficiency and safety in oil and gas applications, aligning with industry demands for reliability.

The growing need for sour gas infrastructure, particularly in offshore and remote regions, is increasing demand for NACE-compliant pipes like API 5L BNS. Sustainable practices, such as recycled steel and low-carbon production, are addressing environmental concerns. Compared to Inconel 718 and Incoloy 901, which focus on additive manufacturing for niche applications, BNS prioritizes scalability for large-diameter pipelines. As energy transitions emphasize efficiency and durability, API 5L BNS will remain a critical component, supporting reliable fluid transport in challenging conditions.

Conclusion

API 5L PSL2 BNS LSAW steel pipe (914.4 x 12.7 mm) is a high-performance, cost-effective solution for sour service oil and gas pipelines. Its chemical composition (≤0.12% carbon, CEpcm ≤0.25%) ensures weldability and SSC resistance, while PSL2’s stringent testing (CVN at 0°C, 100% NDE) guarantees mechanical reliability. With a yield strength of 245 MPa and NACE MR0175 compliance, it excels in H2S environments, as demonstrated in projects like the Spanish slag transport pipeline. The LSAW process and coatings like FBE and 3LPE ensure durability for large-diameter applications.