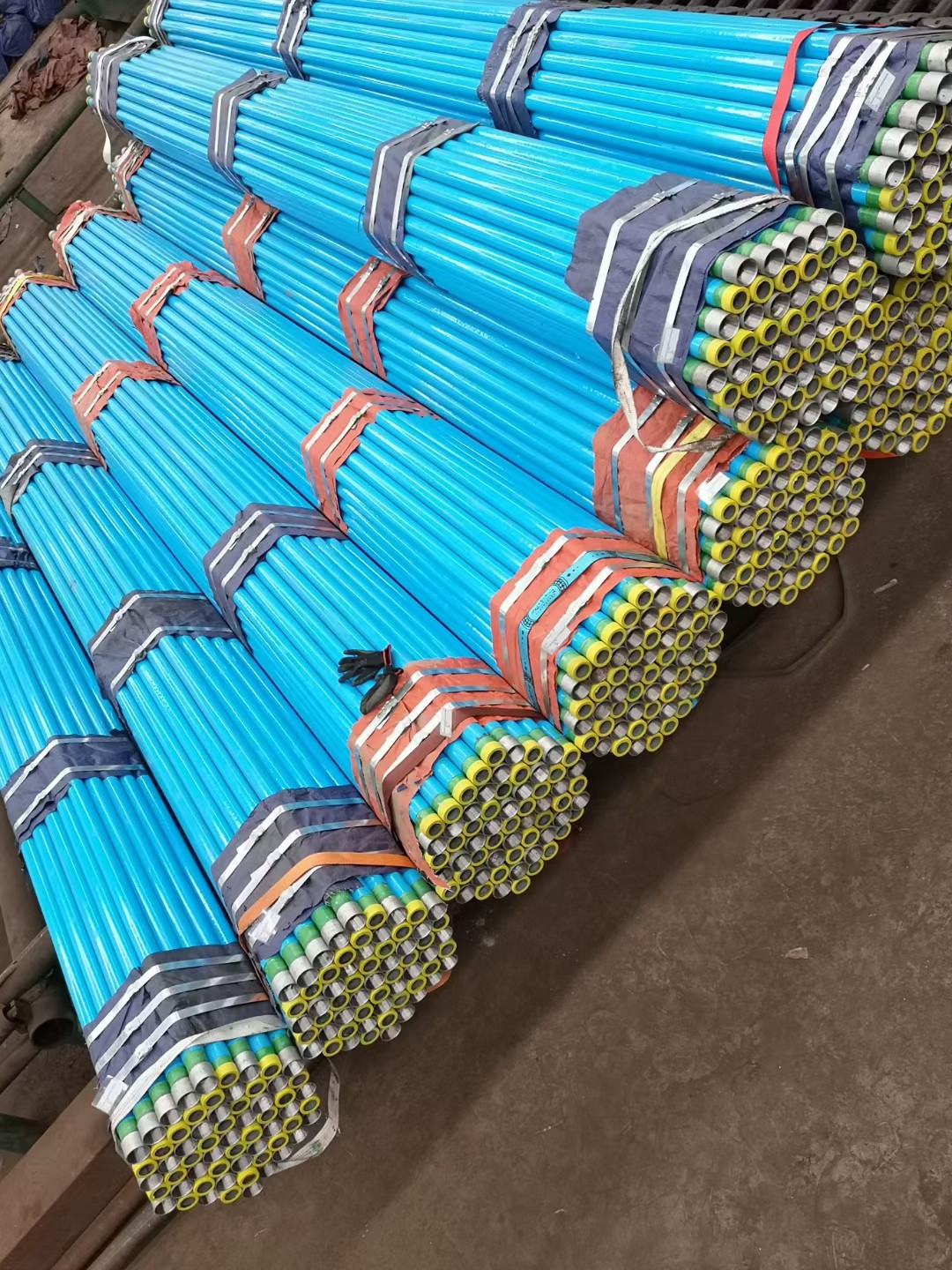

The ASTM A53 ERW Galvanized pipe is a masterpiece of balanced engineering—efficient to produce, high in performance, and incredibly durable. By adhering to the most rigorous interpretations of the ASTM standard and surpassing international benchmarks like JIS and EN, our company delivers a product that is built to endure.

admin

When you choose our galvanized Square Hollow Sections, you aren't just buying steel; you are investing in a structural foundation that is scientifically optimized for strength, chemically protected against the elements, and certified to the world’s most demanding standards.

However, 904L remains the indispensable choice for complex chemical environments where seawater is mixed with reducing acids, or for stagnant systems where its copper content may aid in resisting specific types of bio-corrosion. Furthermore, if the application requires extensive cold-forming or involves cryogenic conditions, the pure austenitic nature of 904L provides a level of reliability that the duplex structure cannot guarantee.

Ultimately, the 904L pipe is a testament to the power of precise alloying. It is a material that accepts the challenge of the most aggressive chemical environments, providing a service life that far exceeds standard stainless steels. By mastering the delicate balance of nickel, chromium, molybdenum, and copper, we provide a conduit that is as reliable as the physics upon which it is built.

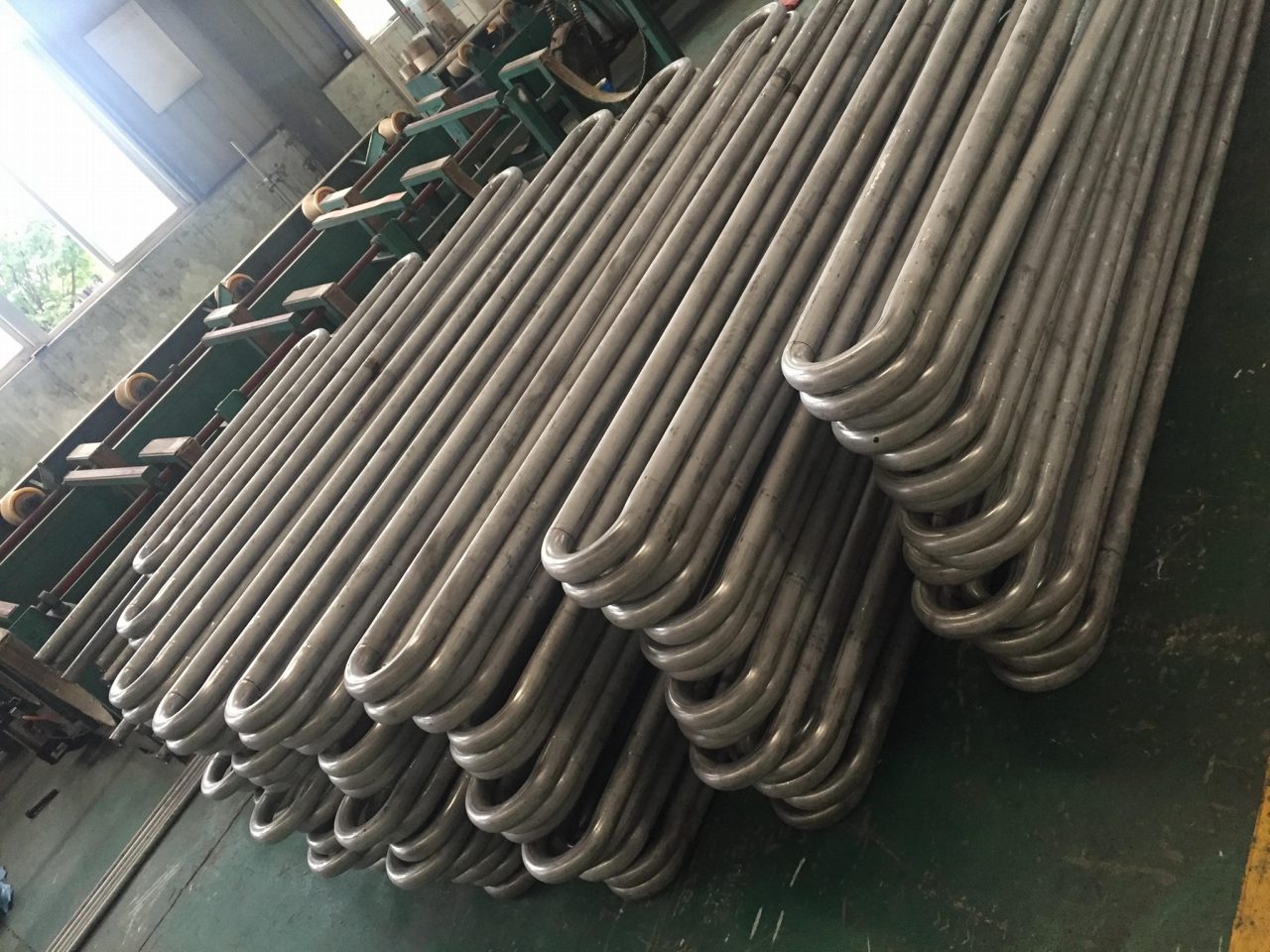

In advancing the technical narrative of our UNS N04400 ASTM B165 U-Bend tubes, we must pivot from the foundational metallurgy toward the sophisticated intersection of fluid dynamics and long-term structural reliability within the heat exchanger bundle.

In summary, the technical success of EN 10219 pipe relies on a deeply integrated relationship between the chemistry (controlled by $\text{CEV}$ for weldability and $\text{P}/\text{S}$ for toughness), the manufacturing process (cold forming for efficiency and work-hardening), and the final mechanical guarantees (yield strength and low-temperature impact energy). The progression from S235 to S355J2H is an engineering-driven pathway, providing a graded spectrum of performance that allows designers to precisely select the most efficient and safe material for any given structural task. The inherent structural efficiency of the hollow section form, combined with the excellent weldability and guaranteed toughness of these $\text{EN}$ grades, ensures their continued preeminence as the material of choice for the world's most vital structural works.

The API 5L Carbon Steel SSAW Pipe is a highly specialized piece of engineered infrastructure, a material solution fundamentally defined not by simple dimensional constraint or utility-grade corrosion protection, but by the relentless pursuit of high strength, reliable weld integrity, and exceptional fracture toughness, all necessary to ensure the safe, uninterrupted, and high-pressure conveyance of hydrocarbons, natural gas, or dense fluid slurries across vast geological and environmental landscapes. Unlike the familiar

The investment in API 5L Grade B Large Diameter SAW Steel Pipe is not merely a procurement decision; it is a strategic commitment to decades of predictable, high-volume fluid conveyance, underwritten by the most stringent certification system in the global pipeline industry

The Galvanized Steel Schedule 40 Pipe stands as an architectural pillar of conventional fluid transport, a design solution so ubiquitous in water pipeline infrastructure that its technical sophistication is often obscured by its sheer familiarity. Its continued dominance, even in the face of modern polymer and composite alternatives, is a testament to the optimized balance achieved between the raw, dependable strength of carbon steel and the elegant, self-sacrificial electrochemistry of the zinc coating

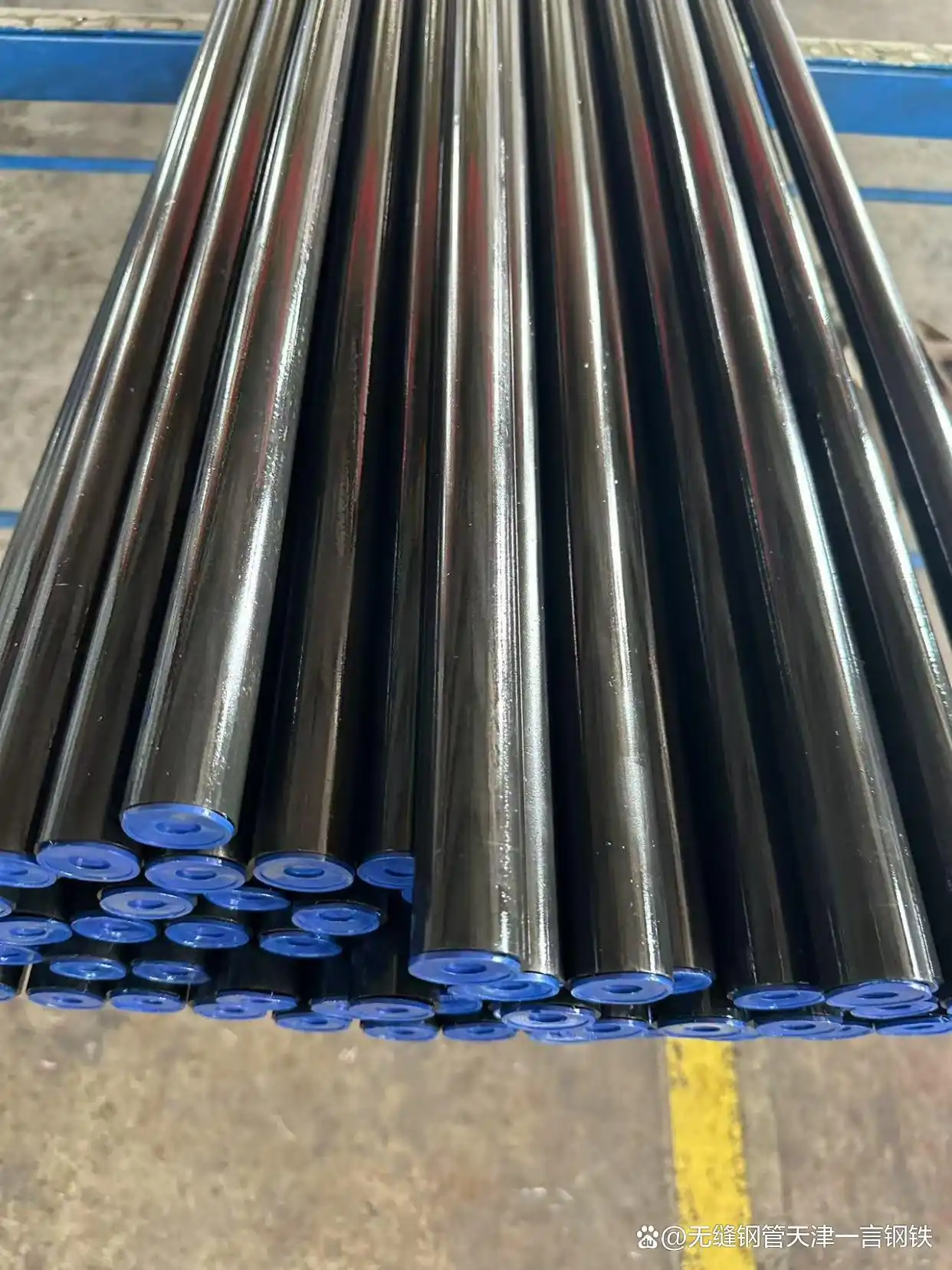

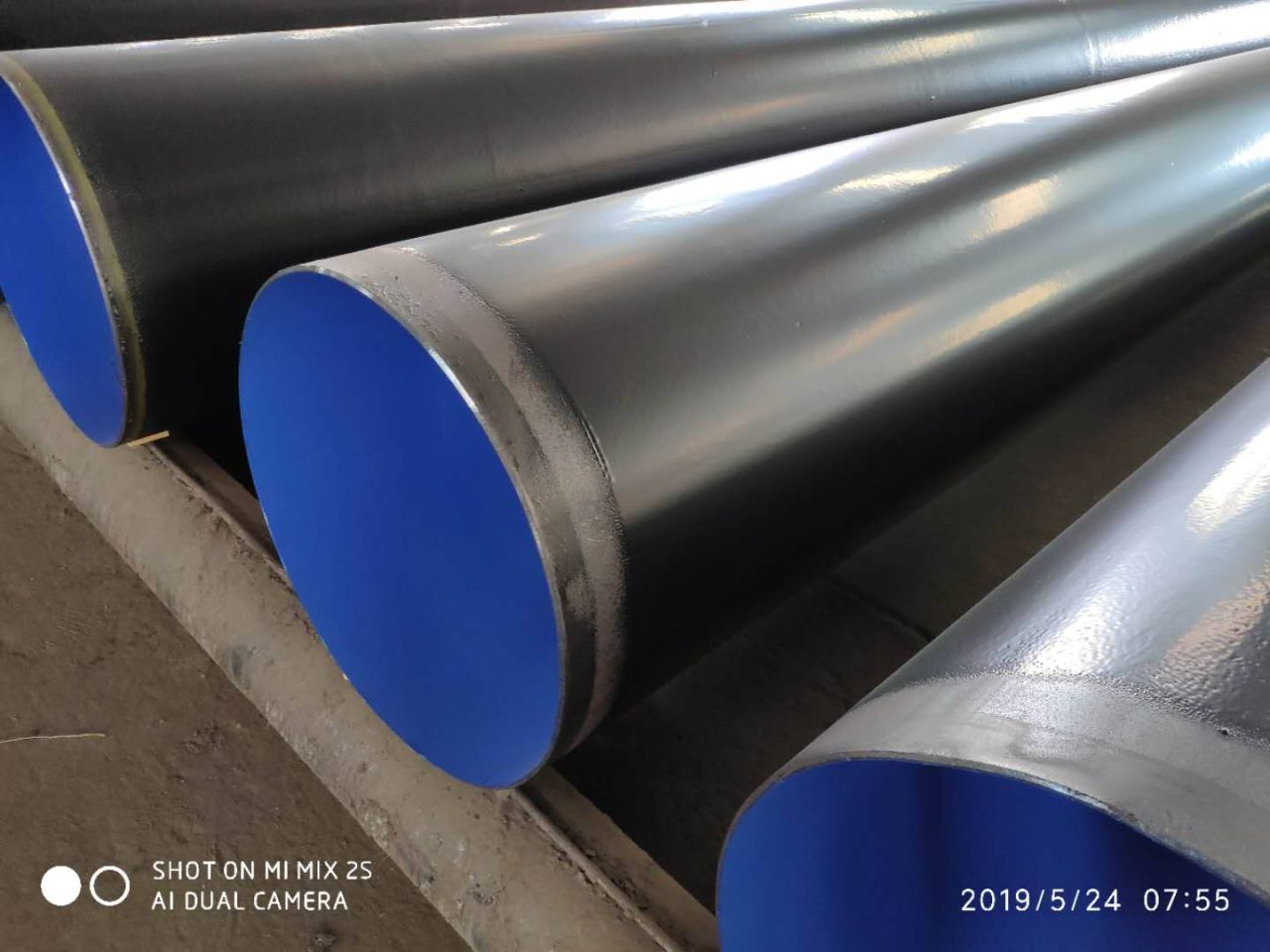

The pipe ends, which are left uncoated to facilitate field welding, require specific protection to maintain the cleanliness and integrity of the precisely machined bevels. The ends are protected with internal and external plastic or metal end caps to prevent physical damage, ingress of moisture, and internal contamination during storage and transit. For particularly long transit times, a temporary, easily removed corrosion inhibitor may be applied to the bare steel bevels to prevent surface rusting, ensuring the contractor receives a clean, ready-to-weld surface. This final logistical step closes the loop on Abtersteel’s commitment, ensuring that the high-integrity X60M PSL2 3PE LSAW pipe reaches the construction site in the same pristine, certified condition in which it left the factory.

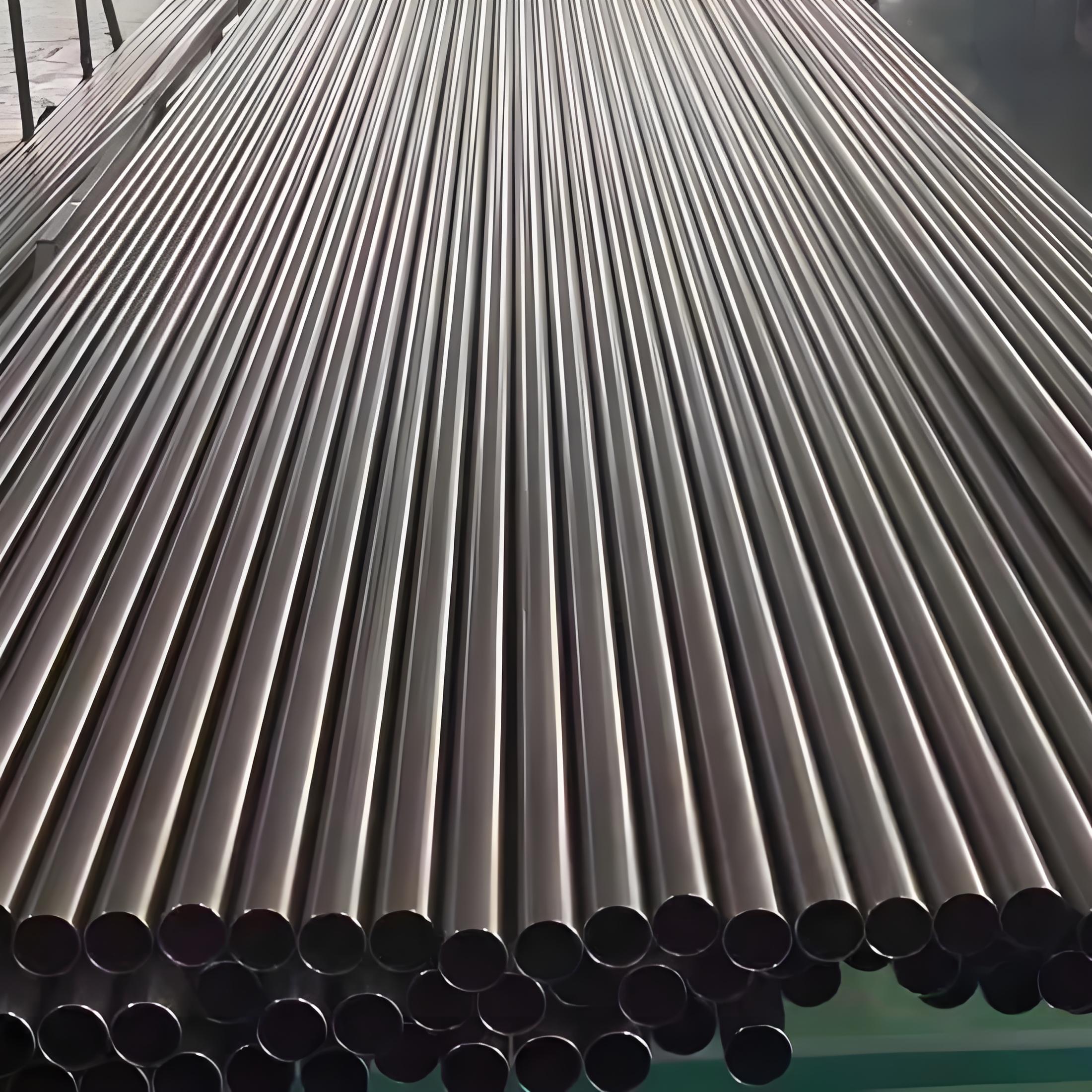

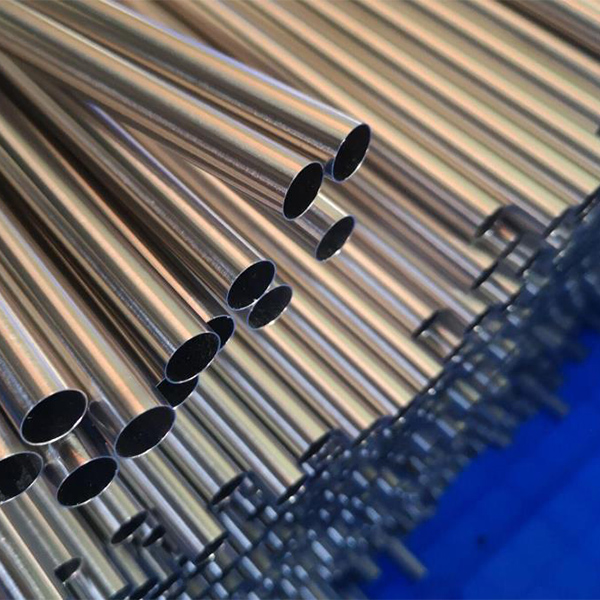

The DIN 2391 Grade St45 Seamless Pipe, supplied in the NBK condition, represents the pinnacle of precision steel tube engineering. Its excellence is a calculated outcome of advanced metallurgical control, severe cold-work plasticity, and meticulous thermal processing. Its functional superiority is validated by its proven ability to:

The DIN 2391 Grade St45 Seamless Pipe is, therefore, the product of choice where dimensional integrity is not a preference but a safety and performance prerequisite. Its use underpins the reliable operation of sensitive mechanical and fluid systems across every facet of modern industry, providing a foundational component that assures precision from the manufacturing stage all the way to decades of operational service.

ASTM A519 Seamless Steel Pipe in the venerable Chromium-Molybdenum (Cr-Mo) Alloy Grades—specifically 4130, 4140, 4142, 4145, and 4147

Honed Tubes for Hydraulic Cylinders and the associated Hydraulic Cylinder Steel Pipes

The endeavor to articulate a comprehensive, 3500-word exposition on the manufacture and engineering significance of ASTM A789/A789M Duplex Stainless Steel Pipes of Grades UNS S31803, S32205, and S32750 is not merely a task of compiling technical specifications

The API 5L Grade X65 steel pipe is the culmination of decades of metallurgical research, providing the foundational strength necessary for the modern energy grid. Yet, the true measure of its technical performance lies entirely within the choice between PSL1 and PSL2. The X65 PSL1 pipe offers a reliable, low-cost solution for standard applications, serving as the industry's basic assurance of quality.

The Synthesis of Strength and Geometry: A Scientific Examination of API 5L X52/X60 Hot Induction Pipe Bends

The modern transmission pipeline—the circulatory system of the global energy economy—is an intricate network defined by materials science and precision engineering. Within this network, the pipe bend is a critical, non-linear node where the constant force of high-pressure fluid flow meets the rigid necessity of directional change. Our product, the API 5L X52 and X60 Hot Induction Steel Pipe Bend, available in crucial and radii, is the embodiment of advanced thermal-mechanical processing applied to high-strength metallurgy. It is a highly engineered fitting designed to provide both structural integrity under extreme hoop stress and minimal hydraulic penalty, ensuring the long-term efficiency and safety of high-specification pipelines. Understanding this product requires a deep dive into the synergistic relationship between the chosen API 5L steel grade, the precise physics of hot induction bending, and the fundamental mechanical engineering principles governing pipeline flow.

The Metallurgical Engine: API 5L High-Strength Low-Alloy Steels

The foundation of performance for these bends lies in the sophisticated chemistry and processing of the API 5L line pipe specification. The grades and are categorized as High-Strength Low-Alloy () steels, which are specially developed to handle the intense stresses inherent in transmitting natural gas, crude oil, or refined products over vast distances. The number following the ‘X’ denotes the minimum specified Yield Strength in thousands of pounds per square inch (), a fundamental parameter that directly dictates the maximum allowable operating pressure and, consequently, the required wall thickness of the pipe.

The scientific achievement in these steels is the ability to achieve high yield strength— () and () respectively—without incurring the metallurgical penalties typically associated with high-strength materials, such as poor weldability or reduced fracture toughness. This balance is maintained through meticulous micro-alloying. Trace additions of elements like Niobium (), Vanadium (), and Titanium (), often totaling less than of the composition, are the key. During the steel’s processing, these micro-alloy elements form minute precipitates () and restrict the growth of crystal grains, resulting in an exceptionally fine-grained microstructure. This grain refinement is the primary scientific mechanism that simultaneously elevates the yield strength and preserves the low-temperature Charpy V-notch toughness that is essential for resisting brittle fracture, particularly in frigid environments or under transient loading.

Furthermore, the Carbon Equivalent () of these steels is strictly controlled to remain at low levels. A low is a chemical necessity because it ensures the material’s excellent weldability, minimizing the risk of forming brittle martensitic structures in the Heat Affected Zone () during field welding operations. The choice between X52 and X60 is, therefore, a precise engineering decision—a calculated leverage of the material’s strength to optimize wall thickness based on the design hoop stress, guided by pipeline design codes like . The strength of the metal allows the designer to achieve the desired pressure capacity with the minimal amount of steel, translating directly into reduced material cost, lower shipping weight, and increased ease of installation, all while maintaining a controlled Yield-to-Tensile strength ratio ( ratio) to guarantee sufficient ductility and strain capacity before failure.

The Physics of Formation: Hot Induction Bending and Microstructural Control

The creation of a precise pipe bend from high-strength steel cannot be achieved reliably through simple cold bending; the material would exhibit excessive springback, crack initiation, and uncontrolled geometric distortion. The necessary technology is Hot Induction Bending, a specialized thermo-mechanical process that relies on the precise application of electromagnetic energy and mechanical force.

The scientific core of this process is localized heating. The straight pipe is mounted in a bending machine, and a narrow induction coil encircles the bending zone. When high-frequency alternating current is passed through the coil, it generates a powerful alternating magnetic field. This field, according to Faraday’s law of induction, generates large eddy currents within the pipe wall, causing rapid and localized Joule heating. The bending zone is heated quickly and selectively to a precise temperature, typically between and —a range safely above the transformation temperature, making the material highly plastic and easy to form.

While the narrow band of the pipe is incandescent, a continuous mechanical force is applied, slowly pushing the pipe through the coil while a bending moment is exerted. This controlled, steady application of force causes the heated zone to deform plastically around a pivot point, forming the desired radius. This process is not just shaping; it is a rapid, localized heat treatment. The cooling rate immediately after the coil is crucial, often controlled by air or water sprays. This carefully managed thermal cycle is designed to prevent two simultaneous failure modes: first, grain coarsening at the high temperatures, which would lead to a catastrophic loss of toughness; and second, the formation of hard, brittle microstructures during rapid cooling. By controlling the cooling rate, the process aims to retain or even enhance the fine-grained structure established in the original parent material, ensuring that the finished bend maintains the specified or yield strength and the essential toughness.

The geometric challenge is managing the strain distribution. As the pipe bends, the material on the outer arc () is put into tension, leading to wall thickness thinning, while the inner arc () is compressed, causing wall thickness thickening. The thinning at the extrados is the most critical area, as it represents a local reduction in pressure containment capacity. The precision of the induction process, including the application of internal pressure or mandrels, is crucial for minimizing this thinning and ensuring the final wall thickness reduction remains within the strict limits (typically to ) mandated by pipeline codes and standards like ASME B31.8 and the specific induction bending standard, ASME B16.49. Any uncontrolled deviation here compromises the safety factor of the entire system.

Geometry, Hydraulics, and Mechanics: The Role of 5D, 8D, and 10D Ratios

The specification of and bends—where the radius () is five, eight, or ten times the nominal diameter (), respectively—is a direct reflection of optimizing a balance between hydraulic efficiency and mechanical stress.

From a Hydraulic Engineering perspective, the size of the bend radius directly impacts flow characteristics. Tighter bends () induce greater secondary flow (swirling or helical flow patterns) and higher localized turbulence. This turbulence results in a greater pressure drop across the bend and necessitates higher pumping energy to maintain flow rate. Conversely, larger radii ( and ) facilitate smoother, more laminar-like flow redirection. The bend is often selected for the largest diameter, highest flow rate pipelines because it minimizes energy dissipation and reduces internal erosion/corrosion risks associated with flow separation. The choice, therefore, directly influences the operational cost and efficiency of the entire pipeline over its life.

From a Mechanical Engineering standpoint, the radius dictates the severity of the stress concentration. A tighter bend results in a higher Stress Intensification Factor () and lower flexibility factor compared to a bend. The concentration of hoop stress, axial stress, and the bending moments at the extrados and the flanks of the bend demands greater local mechanical integrity. The use of high-yield material in a tight radius is often necessary to ensure the combined operational and bending stresses do not exceed the material’s yield point, even after accounting for the wall thickness reduction inherent to the forming process. The ASME B31 codes provide the mathematical framework for calculating the exact stress limitations based on these geometric ratios and the material properties, ensuring a quantified factor of safety for the entire range of product offerings.

The ability to produce these three distinct radii using the hot induction process—each requiring precise adjustments to the coil heating pattern, forming speed, and cooling rates—demonstrates the technical mastery required. For example, forming a bend requires a far longer, gentler thermal application than a bend, demanding a more extended zone of controlled heating to achieve the wider radius without introducing geometric anomalies like wrinkling or excessive ovality.

Certification, Quality Control, and Final Product Integrity

The ultimate proof of performance for an induction bend lies in its compliance with rigorous quality control protocols and standards, chief among which is the final Hydrostatic Test. Every finished bend is subjected to internal pressure significantly higher than its maximum intended operating pressure (), stressing the metal beyond its nominal yield point. This is the definitive final step, providing proof that the material is free from critical defects and that the wall thickness integrity, even at the thinnest extrados, is sufficient to contain the design pressure.

Beyond the hydrostatic test, comprehensive Non-Destructive Evaluation () is mandatory. Ultrasonic Testing () is used to map the wall thickness profile across the entire bend, verifying that the thinning at the extrados remains within the code limits. Magnetic Particle Inspection () or Liquid Penetrant Inspection () is performed on the internal and external surfaces to search for microscopic surface-breaking flaws or cracks that could have initiated during the severe thermal and mechanical cycling of the induction process.

The final product, therefore, is an integrated component where the high-strength metallurgy of API 5L X52/X60 is perfectly matched to the controlled thermal physics of Hot Induction Bending. The resulting fittings, with their verified 5D, 8D, or 10D geometry, ensure that the pipeline can be constructed with confidence, maximizing flow capacity and minimizing maintenance requirements while adhering to the most stringent safety and engineering standards governing energy transportation infrastructure worldwide.

Product Specification Summary: API 5L X52/X60 Hot Induction Pipe Bends

Engineered for Extremes: A Comprehensive Study of JIS G3461 Boiler and Heat Exchanger Steel Tubes

In the vast, interconnected world of industrial power generation and thermal processing, the boiler stands as the single most critical component, a high-pressure furnace where the raw power of heat is converted into usable energy. The integrity of this entire operation rests upon the unseen performance of thousands of feet of **boiler tubes**. These are not mere conduits for water or steam; they are sophisticated heat transfer devices that must simultaneously withstand immense internal pressures, aggressive external heat flux, severe thermal cycling, and the relentless, slow-motion threat of **creep deformation**. To ensure safety, reliability, and global interchangeability in this high-stakes environment, the **Japanese Industrial Standard (JIS) G3461** provides a highly specialized and rigorous set of specifications for **Carbon Steel Boiler and Heat Exchanger Tubes**. This standard is a technical covenant, dictating precise material science, manufacturing fidelity, and a mandatory gauntlet of testing.

The journey into JIS G3461 is a deep dive into the engineering compromises necessary for survival in extreme conditions. While other standards, such as JIS G3454, deal with pressure piping, G3461 operates on a different level of scrutiny. Its focus is explicitly on materials that perform the function of *heat exchange*, meaning the tube wall must manage a sharp thermal gradient. This critical function dictates the stringent requirements found within the standard’s grades—**STB 340, STB 410, and STB 510**—each a variation on a theme, optimized for distinct zones within the boiler, from the moderate heat of the economizer to the intense, pressure-laden environment of the evaporator and superheater sections. Understanding the requirements of G3461 means understanding the very backbone of modern thermal power.

I. The Standard’s Domain: Scope, Context, and Classification

The **JIS G3461** designation, with the **STB** (Steel Tube Boiler) identifier, specifies the necessary criteria for steel tubes used in transferring heat at elevated temperatures, typically up to a practical limit of around $450^\circ\text{C}$ to $500^\circ\text{C}$ for carbon steel, depending heavily on the internal pressure and the specific design code being applied (such as ASME). Above this threshold, metallurgical factors like **graphitization** (the precipitation of carbon that leads to brittle fracture) and accelerated creep necessitate the use of low-alloy chromium-molybdenum (Cr-Mo) steels, which are governed by the related standard, JIS G3462.

The three core grades within G3461 are defined by their minimum guaranteed ultimate tensile strength in megapascals ($\text{MPa}$):

- STB 340: The lower strength grade, favored for economizers and non-critical heat exchangers where temperatures and pressures are moderate, and high ductility is prioritized for ease of manipulation and coiling.

- STB 410: The workhorse of the standard. This mid-range strength provides an excellent balance of pressure capability, high-temperature performance, and reasonable weldability, making it ubiquitous in evaporator walls and general service boiler piping.

- STB 510: The highest strength carbon steel grade, often chosen when design pressures are extremely high, allowing for a thinner wall and maximized heat transfer efficiency, though requiring the highest level of control during welding and fabrication due to its increased carbon content.

The standard ensures not only strength but also dimensional uniformity and material consistency, which is paramount when hundreds or thousands of identical tubes must be seamlessly fitted, expanded, or welded into header drums and tube sheets. Without the rigid adherence to these specifications, the complex flow dynamics and thermal distribution within a boiler would be rendered unpredictable, potentially leading to catastrophic failure.

| Parameter | Specification | Grades Covered |

|---|---|---|

| Standard Name | Carbon Steel Boiler and Heat Exchanger Tubes | STB 340, STB 410, STB 510 |

| Designator | JIS G3461 (STB) | |

| Primary Function | Heat transfer and pressure containment up to $\approx 500^\circ\text{C}$ | |

| Typical Application | Economizers, Water-Wall Tubes, Evaporators, Low-Pressure Superheaters | STB 340 (Lower P/T), STB 410 (General P/T), STB 510 (High P/T) |

II. Method of Manufacture: The Integrity of the Tube Body

The manufacturing method is the foundation of the tube’s integrity and is categorized into two processes under JIS G3461: **Seamless (S)** and **Electric Resistance Welded (ERW) (E)**. The choice between these two is driven by the operating conditions, particularly the risk associated with the failure of a weld seam under stress.

Seamless Tubes (S): The Standard for High-Criticality

Seamless tubes are produced from a solid, cylindrical billet that is heated and pierced to create a hollow shell, which is then rolled and often cold-drawn to achieve the final size and wall thickness. The absence of any fusion or join ensures a continuous, uniform metallic structure free of the metallurgical discontinuities inherent in a weld. This is critical for tubes exposed to the highest internal pressures and **cyclic thermal loading**, such as in steam drums or furnace water walls, where a defect could quickly propagate into a failure. The seamless process allows the final product to have superior resistance to **creep rupture**, as the stress is distributed evenly across the entire circumference. Seamless tubes produced to G3461 specifications undergo mandatory final heat treatments—typically **normalization** for hot-finished tubes or **annealing** for cold-finished tubes—to relieve internal stresses and restore the optimal microstructure for long-term high-temperature service.

Electric Resistance Welded Tubes (E): Precision and Economy

ERW tubes are manufactured from continuous steel strip (skelp), which is cold-formed into a tube shape. The edges are joined by high-frequency electric current and pressure, fusing them without the addition of filler metal. Modern ERW processes are highly controlled and can achieve exceptional dimensional precision, particularly in wall thickness. This precision is sometimes favored in non-critical heat exchangers like economizers where the priority is thin, uniform walls for maximum heat transfer. However, because a weld seam is present, the standard demands rigorous verification. This includes mandatory post-weld **normalization** of the weld zone to ensure the grain structure in that area is equivalent to the base metal, followed by intensive non-destructive testing to guarantee the weld is free from flaws or lack of fusion.

| Type | Designator | Process | Mandatory Heat Treatment |

|---|---|---|---|

| Seamless | S | Hot piercing, rolling, (optional cold drawing) | Normalization (Hot-finished) or Annealing (Cold-finished) |

| ERW | E | Cold forming, High-frequency welding | Normalization/Stress Relief of the weld seam and adjacent HAZ |

*Note: Heat treatment is critical to achieve the specified mechanical properties, relieve residual stress, and ensure microstructural stability for high-temperature creep performance.

III. Chemical Composition: Balancing Strength and Integrity

The chemical recipe for JIS G3461 steel is not arbitrary; it is an optimized formula designed to maximize desirable properties while minimizing detrimental ones. The composition must ensure the necessary strength at elevated temperatures, prevent failure from high-temperature mechanisms, and maintain excellent **weldability**—an essential feature for tube-to-tube sheet connections.

The primary elements are controlled to create the differences between the grades. The carbon content ($\text{C}$) is the single most important factor determining the strength, increasing slightly from STB 340 to STB 510 to achieve the higher tensile properties. However, this comes with a trade-off: higher carbon content complicates field welding, increasing the risk of brittle microstructures in the heat-affected zone (HAZ) unless strict pre- and post-weld heat treatments are followed.

The essential roles of **Manganese ($\text{Mn}$) and Silicon ($\text{Si}$)** involve deoxidation during steelmaking, refining the grain structure, and boosting strength. Manganese is also crucial for counteracting the effects of sulfur, improving the steel’s hot ductility. Conversely, the concentration of impurities—**Phosphorus ($\text{P}$) and Sulfur ($\text{S}$)**—is strictly capped at a low maximum ($\le 0.035\%$). This constraint is non-negotiable for boiler tubes, as these elements readily segregate to grain boundaries, dramatically reducing toughness and accelerating high-temperature embrittlement, thereby undermining the tube’s resistance to creep and thermal stress. The low limits ensure material cleanliness and predictable performance over the tube’s multi-decade design life.

| Grade | $\text{C}$ (Max) | $\text{Si}$ (Max) | $\text{Mn}$ | $\text{P}$ (Max) | $\text{S}$ (Max) |

|---|---|---|---|---|---|

| STB 340 | $0.20$ | $0.35$ | $0.30 – 0.90$ | $0.035$ | $0.035$ |

| STB 410 | $0.25$ | $0.35$ | $0.30 – 1.00$ | $0.035$ | $0.035$ |

| STB 510 | $0.30$ | $0.35$ | $0.30 – 1.00$ | $0.035$ | $0.035$ |

*Note: The minimum manganese content is crucial for toughness; the stringent maximum limits on P and S are essential for high-temperature service integrity.

IV. Mechanical Properties: The Measure of Endurance

The mechanical properties define the material’s resistance to pressure and deformation. The specified minimums for **Tensile Strength ($\sigma_{ts}$)**, **Yield Point/Strength ($\sigma_{y}$)**, and **Elongation** are the core criteria that determine a tube’s selection for a specific location within the boiler system.

The **Yield Strength** is the most critical number for design engineers, as it sets the maximum permissible stress. By design code mandates, the operating pressure stress must be kept at a fraction of the yield strength to ensure the tube remains in the elastic range for its entire lifespan. For a given internal pressure, the superior yield strength of **STB 410** over STB 340, or **STB 510** over STB 410, allows the design engineer to specify a **thinner wall thickness**. This saves material, reduces weight, and significantly improves the tube’s most important function: the transmission of heat from the fire side to the water side. A thinner wall means less resistance to heat flow, increasing the boiler’s thermal efficiency.

**Elongation**, a measure of the material’s **ductility**, is equally vital. It provides the assurance that the tube will not fail in a brittle manner under impact or during the intense forming processes required during boiler fabrication, such as flaring or expanding the tube ends to create a leak-proof mechanical joint with the tube sheet. As expected, the higher strength grades (STB 410 and STB 510) exhibit slightly lower minimum ductility than the STB 340, reflecting the inherent trade-off between strength and flexibility in carbon steel metallurgy.

| Grade | Tensile Strength (Min.) $\text{N/mm}^2 (\text{MPa})$ | Yield Point/Strength (Min.) $\text{N/mm}^2 (\text{MPa})$ | Elongation (Min.) (Varies by Test Piece) |

|---|---|---|---|

| STB 340 | 340 | 175 | $25\%$ |

| STB 410 | 410 | 215 | $22\%$ |

| STB 510 | 510 | 285 | $18\%$ |

*Note: The elongation value is highly dependent on the thickness and the specific test specimen (No. 4, No. 5, No. 11, No. 12) used in accordance with the standard.

V. Dimensional Tolerances: The Non-Negotiable Geometry of Heat Transfer

The adherence to precise dimensional tolerances in JIS G3461 is not simply a matter of aesthetics or ease of assembly; it is intrinsically linked to **creep life** and **thermal efficiency**. The standard mandates extremely tight controls on both the outside diameter (OD) and the wall thickness (WT).

The Criticality of Wall Thickness Tolerance

For a boiler tube, the **Wall Thickness** tolerance is the most crucial geometric parameter. Because stress is inversely proportional to thickness, any section of the tube that is thinner than specified will experience higher localized stress, accelerating the slow process of creep deformation. If the negative tolerance is too large (i.e., the tube is too thin), the design life can be severely compromised, leading to premature failure and dangerous hot spots. Therefore, G3461 specifies tight limits, often restricting the negative tolerance to be much smaller than the positive tolerance—sometimes as little as $\pm 10\%$ of the nominal WT, or even a strictly positive tolerance (e.g., $+15\%$ to $-0\%$) for high-risk, high-pressure tubes, guaranteeing the minimum thickness is always present.

Outside Diameter and Straightness

The **Outside Diameter (OD)** tolerance is critical for fit-up. Tubes must be precisely sized to fit into the drilled holes of the header drums and tube sheets. A tolerance that is too loose prevents the formation of a secure, leak-tight **expanded joint**. The OD tolerance is often specified as a fixed absolute value for smaller diameters, ensuring high precision. **Straightness** and **ovality** (out-of-roundness) are also strictly controlled to ensure the tubes can be properly coiled, bent, and inserted into complex heat exchanger bundles using automated machinery without binding.

| Dimension/Process | Outside Diameter (OD) Tolerance | Wall Thickness (WT) Tolerance (Typical) |

|---|---|---|

| Seamless (Hot-finished) | $\pm 1\%$ of OD, or $\pm 0.5 \text{ mm}$ (Smaller Sizes) | $+15\%$ / $-12.5\%$ |

| Seamless (Cold-finished) / ERW | $\pm 0.3 \text{ mm}$ to $\pm 0.5 \text{ mm}$ (Tighter Control) | $\pm 10\%$ |

| Straightness | Maximum deviation | $1 \text{ mm}$ per $1000 \text{ mm}$ length |

*Note: The negative wall thickness tolerance is the single most scrutinised dimensional check under this standard to guarantee design life and pressure capacity.

VI. Testing and Inspection: The Non-Negotiable Safety Checklist

The extreme service conditions faced by JIS G3461 tubes dictate a comprehensive and mandatory inspection and testing protocol. These tests are the final, non-negotiable proof that the tube meets all specifications and is fit for service. The protocol is divided into mechanical tests (verifying material properties) and non-destructive tests (verifying structural integrity).

A. Mandatory Mechanical and Ductility Tests

The core of the mechanical verification process involves subjecting samples to severe deformation:

- Tensile Test: Confirms the material meets the minimum strength properties listed in Table 4.

- Flattening Test: A section of the tube is crushed between parallel plates. The material must withstand this severe compression without evidence of cracking or flaws, demonstrating high ductility, especially at the weld line of ERW tubes.

- Flaring Test: The end of the tube is expanded outward to a specified percentage of its original diameter using a conical tool. This test is vital for confirming the material’s ability to undergo the plastic deformation necessary to be securely expanded into the tube sheet holes, a critical step in boiler assembly.

- Reverse Flattening Test (ERW Only): This test specifically targets the weld seam. The sample is flattened with the weld placed at the point of maximum bending stress to prove that the weld zone is as strong and ductile as the base metal, eliminating the risk of weld failure.

B. Non-Destructive Examination (NDE) and Integrity Check

These tests are designed to catch flaws invisible to the eye that could lead to catastrophic failure:

- Hydrostatic Test: Every single length of finished tube must be pressure-tested to a specified minimum pressure. This physical test verifies the tube’s pressure-tightness and structural integrity throughout its entire length.

- Ultrasonic (UT) or Eddy Current (ET) Testing: NDE is mandated to search for internal flaws like laminations, inclusions, or micro-cracks that could compromise the tube’s structure. For ERW tubes, this testing is highly concentrated on the weld seam, ensuring the highest level of integrity in that critical join.

| Test Type | JIS G3461 Requirement | Primary Function |

|---|---|---|

| Chemical Analysis | Ladle and Product Analysis | Confirm C, Mn, P, S content for creep and weldability. |

| Hydrostatic Test | Every tube length | Verify pressure containment and leak-tightness. |

| Flaring Test | Sample testing | Confirm ductility for tube-to-tube sheet expansion. |

| Flattening Test | Sample testing | Verify ductility and structural soundness, especially at welds. |

| NDE (UT or ET) | Every tube length (Weld Zone for ERW) | Detect internal/surface flaws invisible to the eye. |

The **JIS G3461** standard for Boiler and Heat Exchanger Steel Tubes is a fundamental element of global thermal engineering. It is a highly specialized specification that governs the material intended to operate at the edge of its physical limits. From the calculated chemical composition designed to optimize creep resistance, to the precise dimensional tolerances required for maximum heat transfer efficiency, every single requirement within the standard is a direct response to the non-negotiable demands of safety and performance. The selection of **STB 340, STB 410, or STB 510** is not merely a choice of strength, but a choice of the specific life-cycle characteristics required by the boiler’s operating zone. Ultimately, adherence to this rigorous standard ensures that the complex machinery of power generation remains predictable, reliable, and safe for its multi-decade service life.

The Backbone of Thermal Systems: A Deep Dive into JIS G3454 STPG Carbon Steel Boiler Pipes

The efficiency and safety of modern thermal engineering—encompassing power generation, petrochemical processing, and heavy industrial heating—rely fundamentally on the integrity of their pressure-containing components. Among the most critical of these are the pipes used to convey hot fluids and steam. In the global landscape of material standards, the Japanese Industrial Standard (JIS) G3454 sets a rigorous benchmark for Carbon Steel Pipes for Pressure Service, with the STPG designation being a globally recognized material for boiler and heat exchanger applications. This standard is not merely a set of specifications; it is a meticulously defined framework that ensures the reliability, durability, and safety of piping systems operating under the unforgiving conditions of high temperature and high pressure. To truly appreciate the role of STPG pipes, one must delve into the specifics of its composition, mechanical properties, manufacturing precision, and the demanding applications it serves.

Understanding the JIS G3454 Framework: Context and Scope

The designation JIS G3454 falls under the broader category of Japanese Industrial Standards (JIS) related to ferrous materials. Specifically, G3454 is the standard dedicated to Carbon Steel Pipes for Pressure Service. The “STPG” nomenclature within this standard is an acronym derived from the Japanese terms for Steel (S), Tube (T), Pressure (P), and General (G), indicating a general-purpose steel pipe intended for pressure applications. This is distinct from other JIS standards like G3455 (High Pressure Service) or G3461 (Boiler and Heat Exchanger Tubes), though there are often overlaps in application.

The primary function of pipes manufactured to JIS G3454 STPG specifications is the safe and efficient conveyance of pressurized fluids, gases, and steam at elevated temperatures. Their application typically involves components such as steam lines, headers, economizers, and various piping within boiler plants where the operating temperature does not typically exceed $350^\circ\text{C}$ to $400^\circ\text{C}$. Beyond these temperatures, creep phenomena become significant, often necessitating the use of low-alloy steels (like Cr-Mo steels defined by JIS G3458 or international equivalents). Therefore, the STPG grades are the workhorses of the conventional pressure piping systems that form the heart of countless industrial operations. The two primary grades within this standard, STPG 370 and STPG 410, are differentiated by their specified minimum tensile strength, which is the cornerstone of their selection criteria.

The strict adherence to this standard by Japanese and international manufacturers alike provides a crucial assurance of quality. It establishes uniform criteria for material composition, dimensions, tolerances, testing procedures, and documentation. This global interchangeability and predictability are vital in large-scale engineering projects where materials from various suppliers must integrate seamlessly into a single, cohesive, high-integrity system.

Chemical Composition: The Recipe for Strength and Weldability

The foundational performance of any steel material is dictated by its precise chemical composition. For STPG pipes, the composition is carefully controlled to balance two critical, often conflicting, requirements: high tensile strength to withstand internal pressure and excellent weldability for ease of fabrication and installation in complex piping networks. As carbon steel, the primary alloying elements are carbon, silicon, manganese, phosphorus, and sulfur.

The grades STPG 370 and STPG 410 are fundamentally low-carbon steels, with carbon content being the key determinant of their strength differential. A lower carbon content in STPG 370 enhances its ductility and weldability, making it suitable for applications where extensive forming or complex welding is necessary. Conversely, the slightly higher carbon and manganese content in STPG 410 contribute to its increased tensile and yield strength, allowing it to handle higher operating pressures, albeit with a marginal reduction in ease of welding. The limits on residual elements like phosphorus ($\text{P}$) and sulfur ($\text{S}$) are extremely stringent, as these impurities can lead to issues such as hot shortness during rolling and reduced toughness, which are unacceptable risks in pressure service piping.

The following table details the maximum permissible chemical composition for the two primary grades, reflecting the stringent control necessary for pressure piping integrity (all values are in mass percent, maximum unless otherwise noted):

| Element | STPG 370 | STPG 410 | Purpose/Impact |

|---|---|---|---|

| Carbon (C) | $\le 0.25$ | $\le 0.30$ | Primary strength-imparting element; higher C reduces weldability. |

| Silicon (Si) | $\le 0.35$ | $\le 0.35$ | Deoxidizer; increases strength and hardness slightly. |

| Manganese (Mn) | $0.30 – 0.90$ | $0.30 – 1.00$ | Increases strength, hardness, and wear resistance; counteracts P and S effects. |

| Phosphorus (P) | $\le 0.040$ | $\le 0.040$ | Highly restricted impurity; reduces ductility and toughness (cold shortness). |

| Sulfur (S) | $\le 0.040$ | $\le 0.040$ | Highly restricted impurity; promotes hot shortness and lowers impact strength. |

*Note: The actual specifications may include specific carbon equivalent (CE) limits or more detailed alloying restrictions, which are crucial for welding procedure specification (WPS). The maximum P and S content is often tighter in practice, but the standard specifies $\le 0.040\%$.

Mechanical Properties: Defining Performance Under Stress

The selection of a pipe for pressure service is ultimately governed by its ability to resist the stress exerted by the internal pressure and external loads. The mechanical properties—specifically **tensile strength**, **yield strength**, and **elongation**—are the quantitative measures of this resistance. The numerical designation in the STPG name is directly tied to the minimum specified tensile strength in megapascals ($\text{MPa}$).

STPG 370 denotes a pipe material with a minimum tensile strength of $370 \text{ MPa}$, while STPG 410 specifies a minimum tensile strength of $410 \text{ MPa}$. The yield strength, which is the point at which the material begins to deform permanently, is equally critical for design calculations to ensure the pipe operates safely within its elastic limit. Elongation, a measure of the material’s ductility, ensures the pipe can withstand a degree of deformation without brittle fracture—a non-negotiable requirement for pressurized components.

The following table outlines the minimum mechanical requirements specified by JIS G3454:

| Property | Unit | STPG 370 (Min.) | STPG 410 (Min.) |

|---|---|---|---|

| Tensile Strength ($\sigma_{ts}$) | $\text{N/mm}^2$ ($\text{MPa}$) | 370 (or 373) | 410 (or 412) |

| Yield Strength ($\sigma_{y}$) | $\text{N/mm}^2$ ($\text{MPa}$) | 215 (or 216) | 245 |

| Elongation (Longitudinal, No. 4/5 Test Piece) | $\%$ | $28 \text{ min.}$ | $24 \text{ min.}$ |

*Note: The minimum elongation requirement varies significantly based on the sample type (No. 4, No. 5, No. 11, No. 12) and whether the test is conducted longitudinally or transversely to the pipe axis. The values above represent common minimums for design reference. N/mm$^2$ and MPa are interchangeable units for stress.

The design engineer relies heavily on the guaranteed minimum yield strength, as it forms the basis for wall thickness calculations according to codes like ASME B31.1 or B31.3. A higher yield strength, as offered by **STPG 410**, allows for a potentially thinner wall for the same design pressure, leading to material savings, reduced weight, and improved heat transfer efficiency—a significant factor in heat exchanger and boiler design.

Manufacturing Processes and Pipe Types: Seamed vs. Seamless

The microstructure and resulting mechanical performance of an STPG pipe are intrinsically linked to its manufacturing method. JIS G3454 covers both **Seamless** and **Electric Resistance Welded (ERW)** pipe processes, although for critical high-pressure and high-temperature boiler applications, **seamless** pipe is overwhelmingly preferred due to its superior integrity and uniformity.

Seamless Pipe (S)

Seamless STPG pipes are produced by piercing a hot, solid billet of steel, which is then rolled and drawn to the final specified dimensions. The absence of a weld seam means there are no inherent metallurgical or structural discontinuities in the pipe body. This makes seamless pipe the ideal choice for applications where the pipe will be subjected to the highest internal pressures, thermal cycling, and complex bending or coiling during fabrication. The uniform grain structure and absence of a potential weld defect path provide the highest level of assurance against catastrophic failure, which is paramount in a boiler environment.

Electric Resistance Welded (ERW) Pipe (E)

ERW STPG pipes are manufactured from a flat strip (skelp) that is cold-formed into a cylinder and then welded along the longitudinal seam by applying an electric current that melts the edges. While modern ERW processes have achieved remarkable quality, the presence of the weld seam can sometimes introduce potential weak points. For very demanding pressure service applications, the designer may be restricted by code to use seamless pipes, or the design stress of the ERW pipe may be derated. However, for some lower-pressure and non-critical applications within the pressure service scope, ERW STPG pipes offer a more cost-effective solution, especially for larger diameters and thinner walls where seamless production becomes technically challenging or uneconomical.

The standard mandates strict non-destructive testing (NDT) for all welded pipes, typically involving eddy current testing or ultrasonic testing of the weld seam to ensure its soundness and freedom from flaws. Regardless of the process, the finished pipes must undergo a final heat treatment (normalization or stress relief) to achieve the specified mechanical properties and ensure microstructural uniformity.

Dimensional Tolerances and Standardization

Beyond material properties, the adherence to precise dimensional tolerances is critical for fit-up during fabrication and for meeting design requirements for wall thickness, which directly impacts pressure rating. JIS G3454 defines strict tolerances for outside diameter (OD) and wall thickness based on the pipe’s manufacturing process (hot-finished seamless, cold-finished seamless, or ERW).

Pipe dimensions in this standard, as with many Japanese standards, align closely with international standards like ASME B36.10M, often utilizing the **Nominal Pipe Size (NPS)** system (A-B designation) and **Schedule Numbers** (Sch 10, Sch 20, Sch 40, Sch 80, etc.) to define the pipe wall thickness relative to its diameter. The following table provides a reference for some common dimensions and how wall thickness is dictated by the Schedule number for the STPG grades.

| Nominal Size (A) | Nominal Size (B) | OD (mm) | Sch 40 Thickness (mm) | Sch 80 Thickness (mm) |

|---|---|---|---|---|

| 15 | 1/2″ | 21.7 | 2.8 | 3.7 |

| 25 | 1″ | 34.0 | 3.4 | 4.5 |

| 50 | 2″ | 60.5 | 3.9 | 5.5 |

| 100 | 4″ | 114.3 | 6.0 | 8.6 |

| 150 | 6″ | 165.2 | 7.1 | 11.0 |

| 200 | 8″ | 216.3 | 8.2 | 12.7 |

*Note: Wall thicknesses are nominal and can vary within the specified tolerances defined by the standard. Sch numbers define wall thickness, while STPG grades define material strength.

Furthermore, tolerances on dimensions are extremely strict to ensure pressure integrity:

- Straightness: The maximum deviation from a straight line is tightly controlled, often mandated to be no more than 1 mm per 1000 mm of length.

- Wall Thickness Tolerance: For hot-finished seamless pipes, the deviation is typically $+15\%$ to $-12.5\%$ of the nominal wall thickness for larger thicknesses, reflecting the challenges of hot rolling. For cold-finished and ERW pipes, tolerances are much tighter, sometimes specified as low as $\pm 10\%$ or fixed absolute values for very small dimensions, reflecting the precision of these processes.

Rigorous Testing and Quality Assurance Protocols

The designation of a pipe as conforming to JIS G3454 is meaningless without the backing of comprehensive testing and quality assurance protocols. These tests serve as the final verification that the material meets the prescribed standards for safety and performance.

- Tensile Test: Confirms the guaranteed minimums for tensile strength, yield strength, and elongation.

- Flattening Test (for Seamless Pipe): The pipe section is flattened until the distance between the plates reaches a specified value. The pipe must withstand this deformation without showing any cracks or flaws, demonstrating its ductility.

- Bending Test (for smaller sizes): Required for pipes 40A or smaller, the pipe is bent through a large angle (e.g., $90^\circ$) around a mandrel of a specified radius (e.g., 6 times the OD) to confirm ductility.

- Hydraulic (Hydrostatic) Test: Every length of finished pipe must be subjected to a minimum pressure test. This test physically stresses the pipe to guarantee pressure-tightness and structural integrity throughout. The test pressure is proportional to the material’s yield strength and the pipe’s dimensions.

- Non-Destructive Testing (NDT): For ERW pipes, supplementary NDT methods like Ultrasonic Examination ($\text{Z3}$) or Eddy Current Examination ($\text{Z4}$) are often designated by the purchaser to verify the integrity of the longitudinal weld seam.

Application and Global Context

The selection between **STPG 370** and **STPG 410** hinges primarily on the design pressure and temperature of the system. **STPG 410** is the preferred choice for main steam headers and high-pressure feedwater lines due to its superior strength, allowing for thinner, more efficient walls. **STPG 370**, with its excellent weldability and slightly higher ductility, serves effectively in lower-to-medium pressure auxiliary lines and complex systems requiring extensive fabrication.

In the global market, JIS G3454 STPG grades are functionally comparable to several international standards, most notably the **ASTM A106/ASME SA-106** specifications for seamless carbon steel pipe for high-temperature service:

- STPG 370: Closely relates to **ASTM A53 Grade B** and **ASTM A106 Grade A**, though STPG 370 often exhibits slightly higher minimum yield strength than A106 Grade A.

- STPG 410: Its strength profile (Min. Tensile $410 \text{ MPa}$, Min. Yield $245 \text{ MPa}$) is directly competitive with **ASTM A106 Grade B** (Min. Tensile $415 \text{ MPa}$, Min. Yield $240 \text{ MPa}$), confirming its status as a premium, internationally recognized material for high-integrity pressure piping up to $350^\circ\text{C}$.

The rigorous requirements of JIS G3454 ensure that STPG carbon steel boiler pipes are not just commodities, but highly engineered components that form the critical, reliable backbone of thermal systems worldwide. Their balanced chemical composition and guaranteed mechanical performance under extreme conditions make them an indispensable material in power generation and heavy industry.

This pipe ensures minimal maintenance intervention, maximum throughput efficiency, and decades of reliable, safe operation, protecting both your investment and the environment. It is, quite simply, the assurance of endurance beneath the surface.

The range of steel grades under the **EN 10219-1** standard—from the dependable **S235JRH** through the versatile **S355JOH/JEH** to the high-performance **S460MH**—provides the essential material solution for every deep foundation challenge. This European standard guarantees not only high **Mechanical Properties** (Yield Strength up to 460 MPa) but also critical **Impact Toughness** ($\text{J0}/\text{J2}$) and superior **Weldability** through strict control of the **Carbon Equivalent**.

Epilogue: A334 tubes, alloyed antarctics of the line, orchestrate chill—comps cohesive, dims deft, strengths steadfast—eternal envoys of energy's equator.

Coda: TP321 tubes, alloyed aegis of the blaze, orchestrate superheat—compositions cohesive, dimensions deft, strengths steadfast—eternal emissaries of energy's ember.

DIN 30678 is more than a standard; it is a testament to abtersteel company rigor and a blueprint for achieving exceptional longevity in pipeline infrastructure. The 3PE coating system it specifies represents the pinnacle of external corrosion protection technology

The provided table and detailed analysis guide engineers in selecting the appropriate specification, with future innovations ensuring their continued relevance in industrial infrastructure.

Alloy 309 and 309S welded pipes from our company excel in high-temperature service, backed by scientific analysis of properties and performance. Contact for custom solutions.

Compared to Inconel 718 and Incoloy 901, API 5L BNS offers affordability over high-temperature performance. Relative to ASTM A671 CC60 CL22, it prioritizes sour service over low-temperature toughness, while API 5L X70 PSL2 provides higher strength but less inherent sour service suitability. The provided parameter table and tolerances aid engineering decisions. Future innovations in welding, coatings, and sustainability will enhance its utility, ensuring API 5L PSL2 BNS remains a cornerstone of reliable pipeline infrastructure in demanding environments.

ASTM A270 304L stainless steel sanitary pipes are a cornerstone of fluid equipment in biopharmaceutical and sanitary applications, offering a balance of corrosion resistance, hygienic properties, and cost-effectiveness

316 stainless steel pipes represent the pinnacle of material engineering for juice and food processing applications, offering a unique combination of corrosion resistance, hygienic properties, and durability. Their ability to withstand acidic juices, aggressive cleaning agents, and high-pressure systems makes them indispensable in ensuring product safety and operational efficiency.

STH11 and STH12 are cost-effective for general-purpose cylinders, while STH21 and STH22 excel in high-pressure, high-temperature applications due to their Cr-Mo composition. Dimensional tolerances and chemical compositions are tightly controlled to ensure safety and performance.