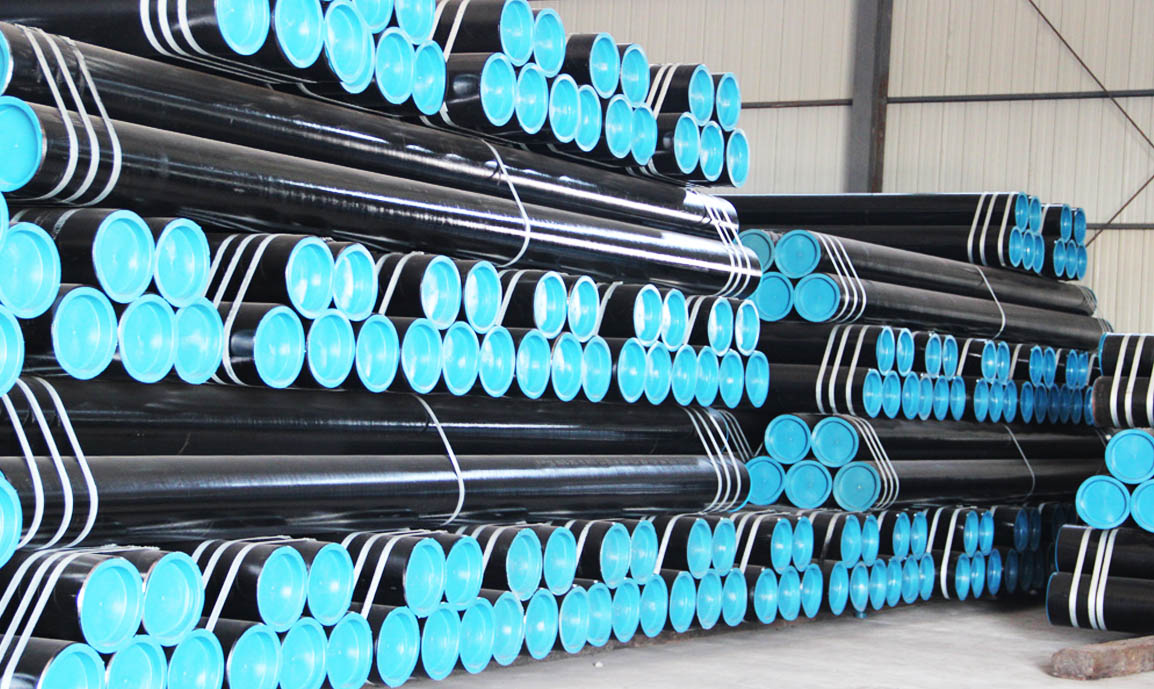

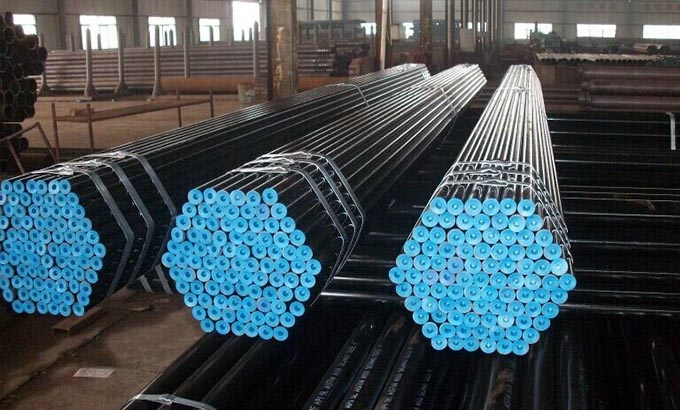

Boiler Steel Pipes

Boiler Steel Pipes: Specifications, Standards, Applications, and Comparisons

Boiler steel pipes are critical components in industries such as power generation, petrochemicals, and manufacturing, where they are used to transport high-temperature, high-pressure fluids like steam and water. These pipes must withstand extreme conditions, including high temperatures, pressures, and corrosive environments. This document provides an in-depth analysis of boiler pipe materials, standards, sizes, differences between medium and high-pressure pipes, and detailed specifications for ASTM A179, A192, A209, A210, A213, A335, DIN 17175, JIS G3461, and JIS G3462 standards. It includes tables for parameter comparisons, chemical composition, mechanical properties, manufacturing processes, and quality control, ensuring a comprehensive understanding of these critical components.

Boiler Steel Pipesare classified based on the operating pressure:

Medium-Pressure Boiler Steel Pipes

- Operating Temperature: Less than 450°C

- Manufacturing Process: Typically hot-rolled or cold-drawn

- Applications: Lower pressure environments, often found in heating systems and industrial boilers.

High-Pressure Boiler Steel Pipes

- Operating Conditions: Extreme temperatures and pressures

- Requirements: High tensile strength, resistance to oxidation and corrosion, superior structural stability

- Applications: Power plants, petrochemical industries, and other high-stress environments

1. Boiler Pipe Material Specifications and Applications

Boiler pipes are typically made from carbon steel, alloy steel, or stainless steel, selected based on the operating conditions of the boiler system. The choice of material depends on factors such as temperature, pressure, corrosion resistance, and mechanical strength requirements.

1.1 Material Types

- Carbon Steel: Used for low to medium-pressure boilers due to its cost-effectiveness and adequate strength at moderate temperatures. Common grades include ASTM A179 and ASTM A192.

- Alloy Steel: Preferred for high-pressure and high-temperature applications due to enhanced strength and resistance to thermal stress. Grades like ASTM A213 and A335 include chromium and molybdenum for improved performance.

- Stainless Steel: Used in corrosive environments or where high corrosion resistance is required, such as in chemical processing plants. ASTM A213 includes austenitic stainless steel grades.

1.2 Applications

Boiler pipes are used in:

- Power Generation: In steam boilers for fossil fuel and nuclear power plants.

- Industrial Processing: In chemical plants, refineries, and petrochemical industries for heat exchangers and superheaters.

- Heat Exchangers: For transferring heat in condensers and tubular heat exchangers.

- Petroleum and Gas: In pipelines for transporting high-temperature fluids.

- Other Industries: Including sugar mills, distilleries, and cement plants for various high-pressure fluid transport needs.

1.3 Standards

Boiler pipes are manufactured according to international standards to ensure quality, safety, and performance. Key standards include:

- ASTM/ASME: A179, A192, A209, A210, A213, A335.

- DIN: 17175 for seamless steel tubes.

- JIS: G3461 for carbon steel boiler pipes, G3462 for alloy steel boiler pipes.

- EN: 10216-2 for seamless steel tubes in high-temperature applications.

- GB: 3087 and 5310 for seamless boiler tubes in China.

2. Boiler Pipe Sizes

Boiler pipe sizes vary depending on the standard and application. The size range typically includes:

- Outside Diameter (OD): 6 mm to 1,240 mm.

- Wall Thickness (WT): 1 mm to 50 mm.

- Length: Common lengths are 5.8 m, 6 m, 11.8 m, or 12 m, with custom lengths available.

2.1 Size Ranges by Standard

| Standard | OD Range (mm) | WT Range (mm) | Length (m) |

|---|---|---|---|

| ASTM A179 | 12.7–76.2 | 1–8 | 5.8–12 |

| ASTM A192 | 12.7–177.8 | 2.2–25.4 | 5.8–12 |

| ASTM A209 | 12.7–127 | 2–12 | 5.8–12 |

| ASTM A210 | 12.7–114.3 | 0.8–15 | 5.8–12 |

| ASTM A213 | 6–1240 | 1–50 | 5.8–12 |

| ASTM A335 | 6–1240 | 1–50 | 5.8–12 |

| DIN 17175 | 10–762 | 1–80 | 5–12 |

| JIS G3461 | 15.9–139.8 | 1.2–12.5 | 5–12 |

| JIS G3462 | 15.9–139.8 | 1.2–12.5 | 5–12 |

Note: Custom sizes can be manufactured, provided they meet the standard’s requirements.

3. Medium vs. High-Pressure Boiler Pipe Differences

Medium and high-pressure boiler pipes differ in material composition, mechanical properties, and applications due to the varying operating conditions they are designed to withstand.

3.1 Key Differences

| Parameter | Medium-Pressure Boiler Pipes | High-Pressure Boiler Pipes |

|---|---|---|

| Pressure Range | Up to 9.8 MPa | Above 9.8 MPa |

| Temperature Range | Up to 450°C | Above 450°C |

| Material | Carbon steel (e.g., ASTM A179, A192) | Alloy steel (e.g., ASTM A213, A335) |

| Applications | Low/medium-pressure boilers, heat exchangers | High-pressure boilers, superheaters, power plants |

| Wall Thickness | Thinner (e.g., 1–8 mm for A179) | Thicker (e.g., 2–50 mm for A335) |

| Corrosion Resistance | Moderate, suitable for non-corrosive environments | High, with alloying elements like Cr, Mo |

| Cost | Lower due to simpler materials | Higher due to advanced alloys |

3.2 Design Considerations

- Medium-Pressure Pipes: Used in applications like industrial boilers and heat exchangers where pressures and temperatures are moderate. Carbon steel is sufficient due to lower thermal and mechanical stress.

- High-Pressure Pipes: Designed for extreme conditions in power plants and refineries. Alloy steels with chromium and molybdenum enhance creep resistance and strength at high temperatures.

4. ASTM and International Standards for Boiler Pipes

Below is a detailed analysis of the specified ASTM, DIN, and JIS standards for seamless boiler pipes, including their scope, applications, and key requirements.

4.1 ASTM A179 Seamless Boiler Pipes

- Standard: ASTM A179/ASME SA179

- Scope: Seamless cold-drawn low-carbon steel tubes for tubular heat exchangers, condensers, and similar heat transfer equipment.

- Applications: Sugar mills, distilleries, petrochemicals, and low-temperature heat exchangers.

- Size Range: OD: 12.7–76.2 mm; WT: 1–8 mm; Length: 5.8–12 m.

- Manufacturing: Cold-drawn seamless process.

- Heat Treatment: Annealed at 650°C or higher to remove residual stresses.

4.2 ASTM A192 Seamless Boiler Pipes

- Standard: ASTM A192/ASME SA192

- Scope: Seamless carbon steel boiler and superheater tubes for high-pressure service.

- Applications: High-pressure boilers, superheaters, and steam conduits in power plants.

- Size Range: OD: 12.7–177.8 mm; WT: 2.2–25.4 mm; Length: 5.8–12 m.

- Manufacturing: Hot-rolled or cold-drawn seamless process.

- Heat Treatment: Hot-finished tubes require heat treatment at 650°C or higher; cold-drawn tubes are annealed post-drawing.

4.3 ASTM A209 Seamless Boiler Pipes

- Standard: ASTM A209/ASME SA209

- Scope: Seamless carbon-molybdenum alloy steel boiler and superheater tubes.

- Applications: Boilers and superheaters requiring moderate corrosion resistance and high-temperature strength.

- Size Range: OD: 12.7–127 mm; WT: 2–12 mm; Length: 5.8–12 m.

- Manufacturing: Seamless process, typically hot-rolled or cold-drawn.

- Heat Treatment: Normalized or annealed to achieve desired mechanical properties.

4.4 ASTM A210 Seamless Boiler Pipes

- Standard: ASTM A210/ASME SA210

- Scope: Seamless medium-carbon steel boiler and superheater tubes.

- Applications: Medium-pressure boilers and superheaters in industrial plants.

- Size Range: OD: 12.7–114.3 mm; WT: 0.8–15 mm; Length: 5.8–12 m.

- Manufacturing: Seamless, hot-rolled, or cold-drawn.

- Heat Treatment: Hot-finished tubes are heat-treated at 650°C or higher; cold-drawn tubes are annealed.

4.5 ASTM A213 Seamless Boiler Pipes

- Standard: ASTM A213/ASME SA213

- Scope: Seamless ferritic and austenitic alloy steel boiler, superheater, and heat-exchanger tubes.

- Applications: High-temperature services in power plants, refineries, and chemical plants.

- Size Range: OD: 6–1240 mm; WT: 1–50 mm; Length: 5.8–12 m.

- Manufacturing: Seamless, hot-rolled, or cold-drawn.

- Heat Treatment: Varies by grade (e.g., normalized, tempered, or annealed).

4.6 ASTM A335 Seamless Alloy Steel Boiler Pipes

- Standard: ASTM A335/ASME SA335

- Scope: Seamless ferritic alloy steel pipes for high-temperature service.

- Applications: Power plants, refineries, and petrochemical industries for high-temperature pipelines.

- Size Range: OD: 6–1240 mm; WT: 1–50 mm; Length: 5.8–12 m.

- Manufacturing: Seamless, hot-rolled, or cold-drawn.

- Heat Treatment: Normalized and tempered to enhance creep resistance.

4.7 DIN 17175 Seamless Steel Pipes

- Standard: DIN 17175

- Scope: Seamless steel tubes for elevated temperatures in boiler installations and pressure vessels.

- Applications: Boilers, pipelines, and pressure vessels in power generation and chemical industries.

- Size Range: OD: 10–762 mm; WT: 1–80 mm; Length: 5–12 m.

- Manufacturing: Seamless, hot-rolled, or cold-drawn.

- Heat Treatment: Normalized or annealed based on grade.

4.8 JIS G3461 Boiler Pipes

- Standard: JIS G3461

- Scope: Carbon steel tubes for boilers and heat exchangers.

- Applications: Low to medium-pressure boilers and heat exchangers in industrial settings.

- Size Range: OD: 15.9–139.8 mm; WT: 1.2–12.5 mm; Length: 5–12 m.

- Manufacturing: Seamless or welded.

- Heat Treatment: Annealed or normalized as required.

4.9 JIS G3462 Alloy Boiler Pipes

- Standard: JIS G3462

- Scope: Alloy steel tubes for boilers and heat exchangers.

- Applications: High-temperature and high-pressure boilers in power plants and refineries.

- Size Range: OD: 15.9–139.8 mm; WT: 1.2–12.5 mm; Length: 5–12 m.

- Manufacturing: Seamless or welded.

- Heat Treatment: Normalized, tempered, or annealed based on grade.

5. Chemical Composition Comparison

The chemical composition of boiler pipes determines their suitability for specific applications, particularly in terms of corrosion resistance, strength, and thermal stability. Below is a table comparing the chemical compositions of the specified standards (representative grades).

| Standard/Grade | C (%) | Mn (%) | P (%) | S (%) | Si (%) | Cr (%) | Mo (%) | Other (%) |

|---|---|---|---|---|---|---|---|---|

| ASTM A179 | 0.06–0.18 | 0.27–0.63 | ≤0.035 | ≤0.035 | ≤0.25 | – | – | – |

| ASTM A192 | ≤0.25 | 0.27–0.63 | ≤0.035 | ≤0.035 | ≤0.25 | – | – | – |

| ASTM A209 T1 | 0.10–0.20 | 0.30–0.80 | ≤0.025 | ≤0.025 | 0.10–0.50 | – | 0.44–0.65 | – |

| ASTM A210 A1 | ≤0.27 | ≤0.93 | ≤0.035 | ≤0.035 | ≥0.10 | – | – | – |

| ASTM A213 T11 | 0.05–0.15 | 0.30–0.60 | ≤0.025 | ≤0.025 | 0.50–1.00 | 1.00–1.50 | 0.44–0.65 | – |

| ASTM A335 P11 | 0.05–0.15 | 0.30–0.60 | ≤0.025 | ≤0.025 | 0.50–1.00 | 1.00–1.50 | 0.44–0.65 | – |

| DIN 17175 St35.8 | ≤0.17 | 0.40–0.80 | ≤0.040 | ≤0.040 | 0.10–0.35 | – | – | – |

| JIS G3461 STB340 | ≤0.18 | 0.30–0.60 | ≤0.035 | ≤0.035 | 0.10–0.35 | – | – | – |

| JIS G3462 STBA22 | 0.05–0.15 | 0.30–0.60 | ≤0.035 | ≤0.035 | ≤0.50 | 0.80–1.25 | 0.45–0.65 | – |

Notes:

- ASTM A179 and A192 are low-carbon steels, ideal for low-pressure applications.

- ASTM A209, A213, A335, and JIS G3462 include molybdenum and chromium for enhanced high-temperature strength and corrosion resistance.

- DIN 17175 St35.8 is similar to ASTM A192 in composition but optimized for European standards.

6. Mechanical Properties Comparison

Mechanical properties such as tensile strength, yield strength, and elongation are critical for ensuring boiler pipes can withstand operational stresses. The table below compares these properties for representative grades.

| Standard/Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HRB/HB) |

|---|---|---|---|---|

| ASTM A179 | ≥325 | ≥180 | ≥35 | ≤72 HRB |

| ASTM A192 | ≥325 | ≥180 | ≥35 | ≤77 HRB |

| ASTM A209 T1 | 380–550 | ≥205 | ≥30 | ≤80 HRB |

| ASTM A210 A1 | ≥415 | ≥255 | ≥30 | ≤79 HRB |

| ASTM A213 T11 | ≥415 | ≥205 | ≥30 | ≤85 HRB |

| ASTM A335 P11 | ≥415 | ≥205 | ≥20 | ≤85 HRB |

| DIN 17175 St35.8 | 360–480 | ≥235 | ≥25 | ≤75 HRB |

| JIS G3461 STB340 | ≥340 | ≥175 | ≥35 | ≤77 HRB |

| JIS G3462 STBA22 | ≥410 | ≥205 | ≥30 | ≤85 HRB |

Notes:

- ASTM A179 and A192 have lower tensile and yield strengths, suitable for low-pressure applications.

- ASTM A213 and A335 grades (e.g., T11, P11) offer higher strength for high-pressure and high-temperature environments.

- DIN 17175 and JIS standards align closely with ASTM for similar applications but may have slight variations in testing requirements.

7. Manufacturing Process

The manufacturing process for seamless boiler pipes involves several stages to ensure high quality and performance. The process varies slightly depending on the standard and material.

7.1 General Manufacturing Steps

- Raw Material Selection: High-quality steel billets (carbon, alloy, or stainless steel) are selected based on the required chemical composition.

- Billet Heating: Billets are heated to a forging temperature (typically 1,200–1,300°C) to make them malleable.

- Piercing: The heated billet is pierced to form a hollow tube using a mandrel or piercing mill.

- Hot Rolling/Cold Drawing:

- Hot89 Rolling: Used for larger diameters and thicker walls, producing seamless pipes with uniform thickness.

- Cold Drawing: Used for smaller diameters and thinner walls, improving surface finish and dimensional accuracy.

- Heat Treatment: Processes like annealing, normalizing, or tempering are applied to relieve stresses and enhance mechanical properties.

- Finishing: Includes cutting to length, straightening, and surface treatment (e.g., pickling or coating).

- Testing and Inspection: Non-destructive tests (e.g., ultrasonic, eddy current) and mechanical tests (e.g., flattening, flaring) ensure quality.

7.2 Manufacturing by Standard

| Standard | Process | Heat Treatment | Key Features |

|---|---|---|---|

| ASTM A179 | Cold-drawn | Annealed at ≥650°C | High precision, smooth surface |

| ASTM A192 | Hot-rolled/Cold-drawn | Hot-finished: ≥650°C; Cold-drawn: Annealed | Suitable for high-pressure service |

| ASTM A209 | Hot-rolled/Cold-drawn | Normalized/Annealed | Carbon-molybdenum alloy for strength |

| ASTM A210 | Hot-rolled/Cold-drawn | Hot-finished: ≥650°C; Cold-drawn: Annealed | Medium-carbon steel for boilers |

| ASTM A213 | Hot-rolled/Cold-drawn | Normalized/Tempered/Annealed | Ferritic/austenitic alloys for high temperatures |

| ASTM A335 | Hot-rolled/Cold-drawn | Normalized/Tempered | High-temperature alloy steel |

| DIN 17175 | Hot-rolled/Cold-drawn | Normalized/Annealed | Optimized for European boiler standards |

| JIS G3461 | Seamless/Welded | Annealed/Normalized | Carbon steel for low/medium pressure |

| JIS G3462 | Seamless/Welded | Normalized/Tempered | Alloy steel for high temperatures |

Notes:

- Cold-drawn processes are common for ASTM A179 and A192 to achieve tight tolerances.

- ASTM A213 and A335 often require complex heat treatments to optimize alloy properties.

- JIS G3461 and G3462 allow welded options, though seamless is preferred for high-pressure applications.

8. Quality Control

Quality control is critical to ensure boiler pipes meet stringent safety and performance requirements. Common quality control measures include:

8.1 Testing Requirements

| Test Type | Description | Standards Applied |

|---|---|---|

| Chemical Analysis | Verifies composition (C, Mn, P, S, etc.) | ASTM A179, A192, A209, A210, A213, A335, DIN 17175, JIS G3461, G3462 |

| Tensile Test | Measures tensile strength, yield strength, and elongation | All standards |

| Hardness Test | Ensures hardness within specified limits (e.g., ≤85 HRB for A213 T11) | ASTM A192, A213, A335, DIN 17175 |

| Flattening Test | Checks ductility by flattening the tube | ASTM A179, A192, A210, A213 |

| Flaring Test | Tests tube ends for formability | ASTM A179, A192, A210 |

| Hydrostatic Test | Verifies leak resistance under pressure | All standards |

| Non-Destructive Testing (NDT) | Includes ultrasonic, eddy current, or X-ray testing for defects | ASTM A213, A335, DIN 17175 |

| Dimensional Inspection | Ensures OD, WT, and length meet tolerances | All standards |

| Surface Inspection | Checks for scale, cracks, or imperfections | ASTM A192, A213, JIS G3462 |

8.2 Quality Control by Standard

- ASTM A179: Requires chemical analysis, tensile test, flattening test, flaring test, and hydrostatic test. Tubes must be free of scale and defects.

- ASTM A192: Includes hardness test (≤77 HRB), flattening test, flaring test, and hydrostatic test. Surface must be free of scale.

- ASTM A209: Similar to A192 but includes additional tests for alloy properties (e.g., molybdenum content).

- ASTM A210: Requires tensile test, flattening test, and hydrostatic test. Hardness limited to ≤79 HRB for A1 grade.

- ASTM A213: Extensive NDT (ultrasonic, eddy current) and mechanical tests due to high-temperature applications.

- ASTM A335: Includes transverse/longitudinal tension tests and hardness tests (e.g., ≤265 HV for P91).

- DIN 17175: Emphasizes NDT and dimensional accuracy for European standards.

- JIS G3461/G3462: Similar to ASTM but may include additional visual inspections for surface quality.

9. Parameter Comparison Table

The following table summarizes key parameters across the specified standards for quick reference.

| Standard | Material Type | Pressure Range | Temp. Range (°C) | OD (mm) | WT (mm) | Applications |

|---|---|---|---|---|---|---|

| ASTM A179 | Low-carbon steel | Low | Up to 350 | 12.7–76.2 | 1–8 | Heat exchangers, condensers |

| ASTM A192 | Carbon steel | High | Up to 450 | 12.7–177.8 | 2.2–25.4 | High-pressure boilers, superheaters |

| ASTM A209 | Carbon-Mo alloy | Medium-High | Up to 500 | 12.7–127 | 2–12 | Boilers, superheaters |

| ASTM A210 | Medium-carbon | Medium | Up to 450 | 12.7–114.3 | 0.8–15 | Boilers, superheaters |

| ASTM A213 | Ferritic/Austenitic alloy | High | Up to 650 | 6–1240 | 1–50 | Superheaters, heat exchangers |

| ASTM A335 | Ferritic alloy | High | Up to 700 | 6–1240 | 1–50 | Power plants, refineries |

| DIN 17175 | Carbon/Alloy | Medium-High | Up to 600 | 10–762 | 1–80 | Boilers, pressure vessels |

| JIS G3461 | Carbon steel | Low-Medium | Up to 350 | 15.9–139.8 | 1.2–12.5 | Boilers, heat exchangers |

| JIS G3462 | Alloy steel | High | Up to 600 | 15.9–139.8 | 1.2–12.5 | High-pressure boilers |

10. Critical Analysis and Considerations

While the establishment narrative around boiler pipe standards is robust, it’s worth critically examining potential gaps:

- Standard Variations: ASTM, DIN, and JIS standards are not fully interchangeable due to differences in testing protocols and allowable tolerances. For example, DIN 17175 may permit slightly higher sulfur content than ASTM A192, potentially affecting corrosion resistance.

- Material Limitations: Carbon steel pipes like ASTM A179 are cost-effective but unsuitable for high-temperature, high-pressure applications where alloy steels (A213, A335) are required. Over-reliance on cheaper materials can lead to safety risks.

- Manufacturing Consistency: The quality of seamless pipes depends heavily on the manufacturer’s adherence to standards. Variations in heat treatment or NDT can affect performance, suggesting a need for stricter global oversight.

- Environmental Factors: Standards focus on mechanical and chemical properties but may underemphasize long-term corrosion resistance in harsh environments, such as those involving acidic gases or high humidity.

Quality Assurance

ABTER STEEL PIPE maintains stringent quality control throughout the manufacturing process, from steelmaking to the final tube fabrication. Key elements of their quality assurance system include:

- Independence of the Quality Assurance Department: Ensures unbiased quality control.

- Standardization of Tasks: Facilitates unified manufacturing and quality processes.

- Inspector Qualification System: Ensures that all inspectors are qualified and tasks are standardized.

- Nondestructive Tests: Mandatory tests and inspections are conducted, with all items undergoing nondestructive testing during final inspection.

- Periodic Calibration Systems: Regular calibration of gauges and testers to maintain inspection accuracy.

Boiler steel pipes are used in a variety of high-temperature and high-pressure applications, including:

- Boilers: Used in the construction of steam boilers and Boiler Steel Pipes in power plants and industrial facilities.

- Heat Exchangers: For transferring heat between fluids, typically in power plants, chemical industries, and oil refineries.

- Power Plants: Essential for the construction of superheaters, reheaters, and economizers.

- Petrochemical Industry: Used in refinery processes that require high-temperature and high-pressure conditions.

- Mechanical Engineering: Applied in the manufacturing of various pressure vessels and high-pressure equipment.

Key Properties

Boiler steel pipes must possess certain properties to perform effectively in their applications:

- High Strength: To withstand high pressures and mechanical stresses.

- Excellent Heat Resistance: To operate efficiently at high temperatures.

- Corrosion Resistance: Especially important for pipes exposed to steam and other corrosive substances.

- Durability: Ensuring long service life even in harsh conditions.

Conclusion

Boiler steel pipes are vital for safe and efficient operation in high-pressure, high-temperature environments. Standards like ASTM A179, A192, A209, A210, A213, A335, DIN 17175, JIS G3461, and JIS G3462 provide detailed specifications to ensure performance, with variations in material, size, and application tailored to specific needs. Carbon steel pipes are suitable for low to medium-pressure systems, while alloy and stainless steel pipes excel in high-pressure, high-temperature, or corrosive conditions. Comprehensive quality control, including chemical, mechanical, and non-destructive testing, ensures reliability. By understanding the differences in standards, chemical compositions, mechanical properties, and manufacturing processes, engineers and procurement specialists can select the optimal boiler pipes for their applications.