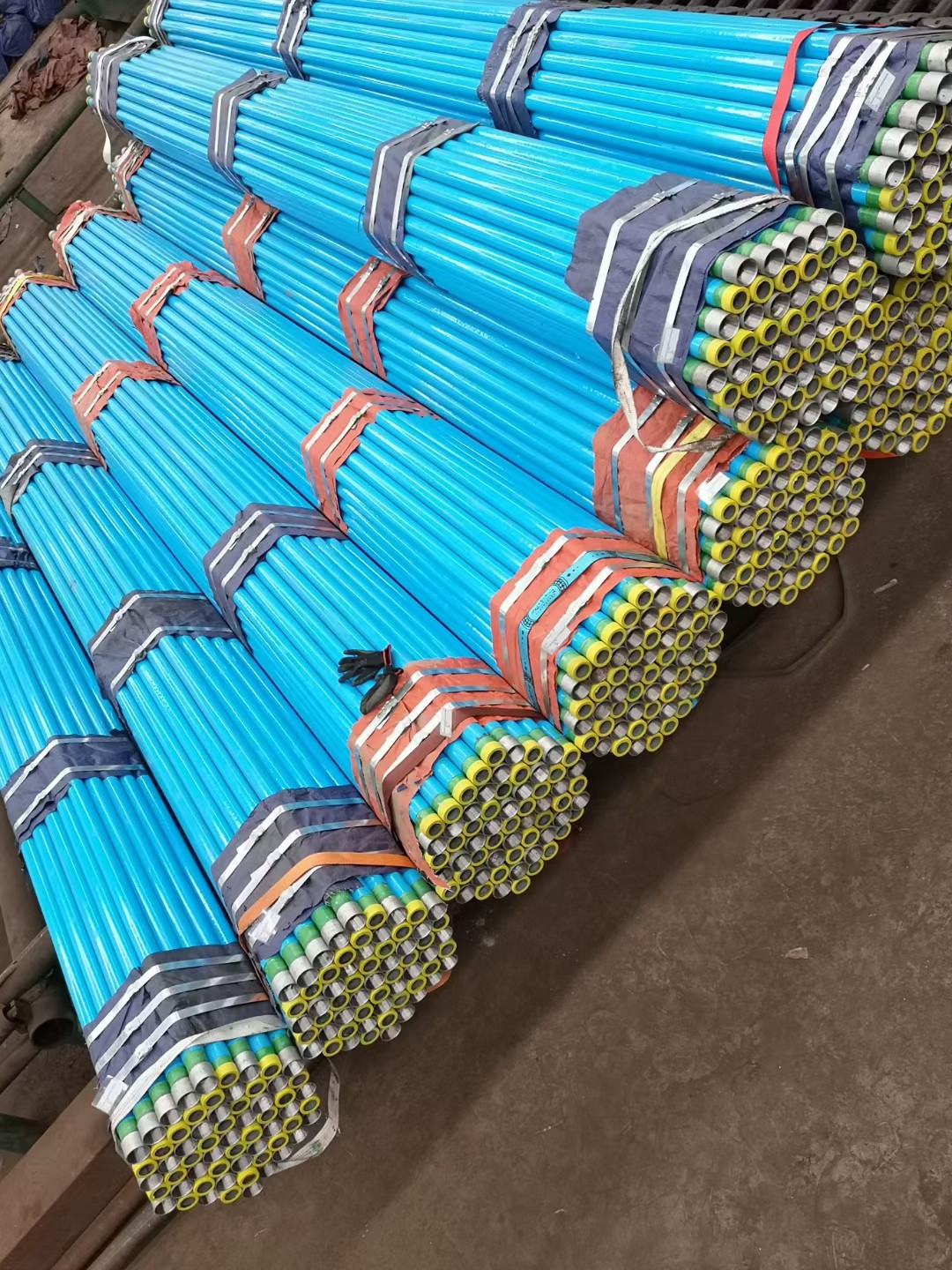

Paip Tergalvani ASTM A53 ERW ialah karya agung kejuruteraan seimbang—cekap untuk dihasilkan, tinggi dalam prestasi, dan sangat tahan lama. Dengan mematuhi tafsiran standard ASTM yang paling ketat dan mengatasi penanda aras antarabangsa seperti JIS dan EN, syarikat kami menyampaikan produk yang dibina untuk bertahan.

admin

Apabila anda memilih Bahagian Hollow Square Tergalvani kami, you aren't just buying steel; anda melabur dalam asas struktur yang dioptimumkan secara saintifik untuk kekuatan, dilindungi secara kimia daripada unsur-unsur, dan diperakui mengikut piawaian yang paling menuntut di dunia.

Namun begitu, 904L kekal sebagai pilihan yang sangat diperlukan untuk persekitaran kimia yang kompleks di mana air laut bercampur dengan asid penurun, atau untuk sistem bertakung di mana kandungan kuprumnya boleh membantu dalam menentang jenis bio-karat tertentu. Tambahan pula, jika aplikasi memerlukan pembentukan sejuk yang meluas atau melibatkan keadaan kriogenik, sifat austenit tulen 904L memberikan tahap kebolehpercayaan yang tidak dapat dijamin oleh struktur dupleks.

Akhirnya, the 904L pipe is a testament to the power of precise alloying. It is a material that accepts the challenge of the most aggressive chemical environments, providing a service life that far exceeds standard stainless steels. By mastering the delicate balance of nickel, kromium, molibdenum, dan tembaga, we provide a conduit that is as reliable as the physics upon which it is built.

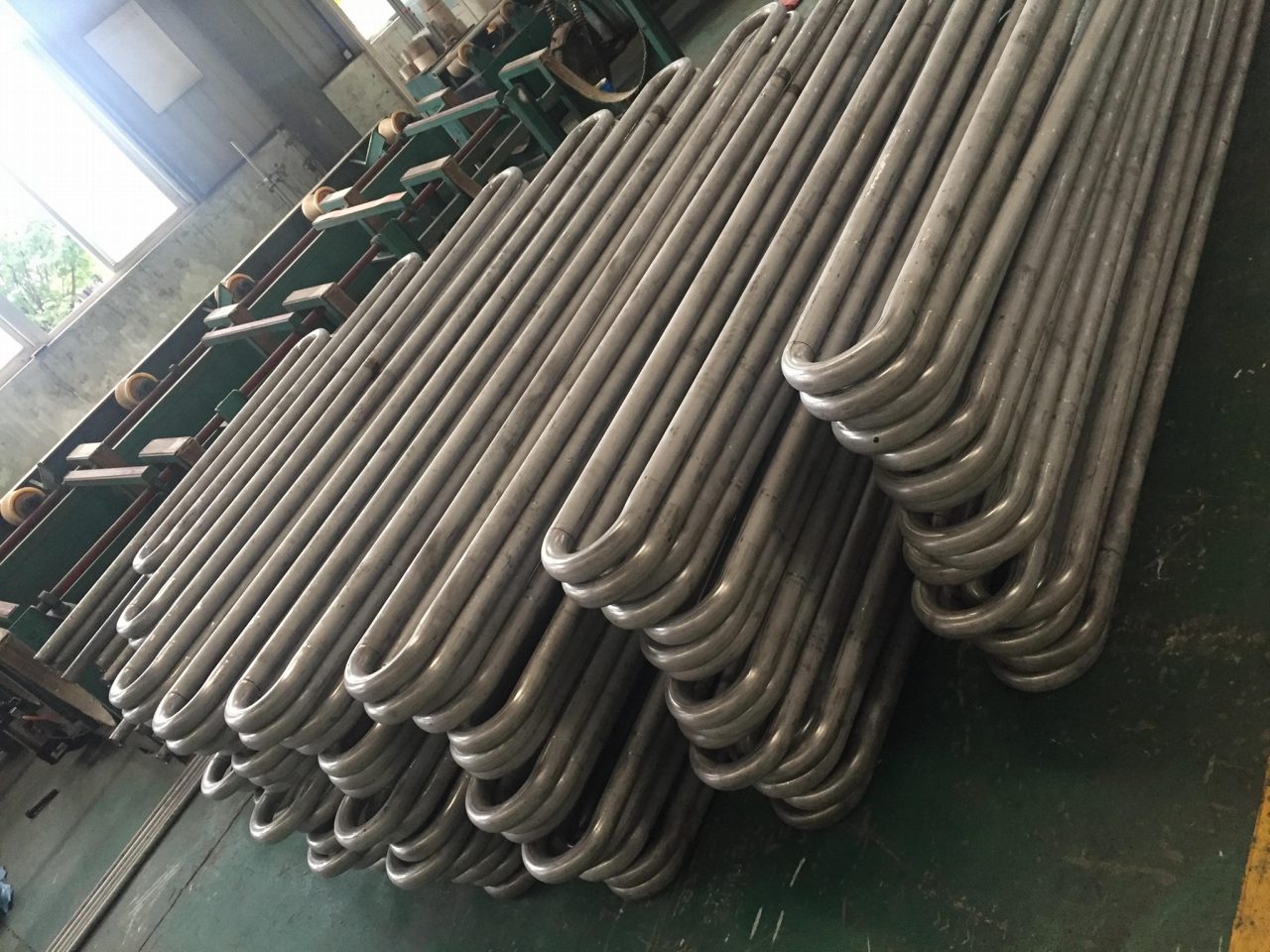

Dalam memajukan naratif teknikal tiub UNS N04400 ASTM B165 U-Bend kami, kita mesti beralih daripada metalurgi asas ke arah persimpangan dinamik bendalir yang canggih dan kebolehpercayaan struktur jangka panjang dalam berkas penukar haba.

Ringkasnya, kejayaan teknikal en 10219 Paip bergantung pada hubungan yang sangat bersepadu antara kimia (dikawal oleh $text{Berkhidmat}$ untuk kebolehkimpalan dan $text{P}/\teks{S}$ untuk ketangguhan), proses pembuatan (pembentukan sejuk untuk kecekapan dan pengerasan kerja), dan jaminan mekanikal terakhir (kekuatan hasil dan tenaga kesan suhu rendah). Kemajuan dari S235 hingga S355J2H adalah laluan yang didorong oleh kejuruteraan, Menyediakan spektrum prestasi yang dinilai yang membolehkan pereka memilih bahan yang paling berkesan dan selamat untuk tugas struktur yang diberikan. Kecekapan struktur yang wujud dalam bentuk seksyen berongga, digabungkan dengan kebolehkimpalan yang sangat baik dan ketangguhan yang dijamin $text ini{DALAM}$ gred, ensures their continued preeminence as the material of choice for the world's most vital structural works.

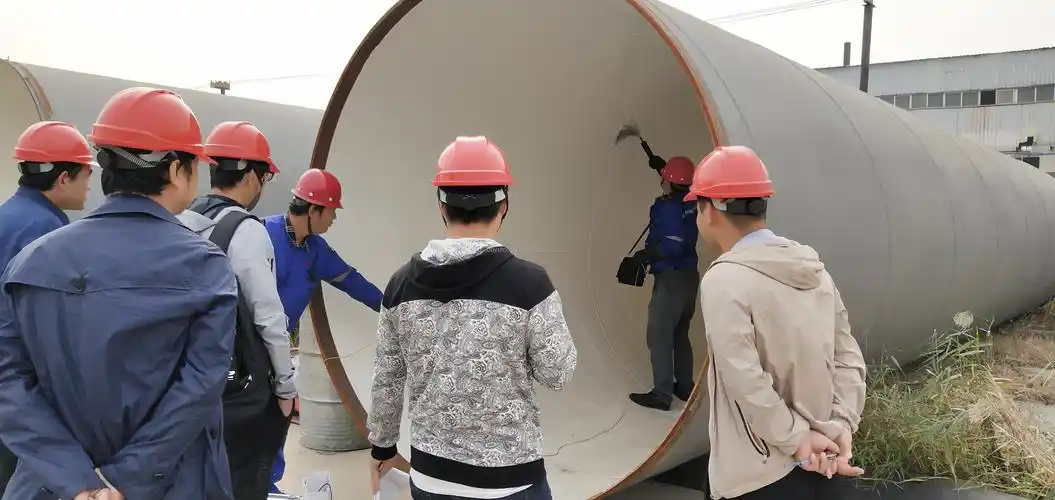

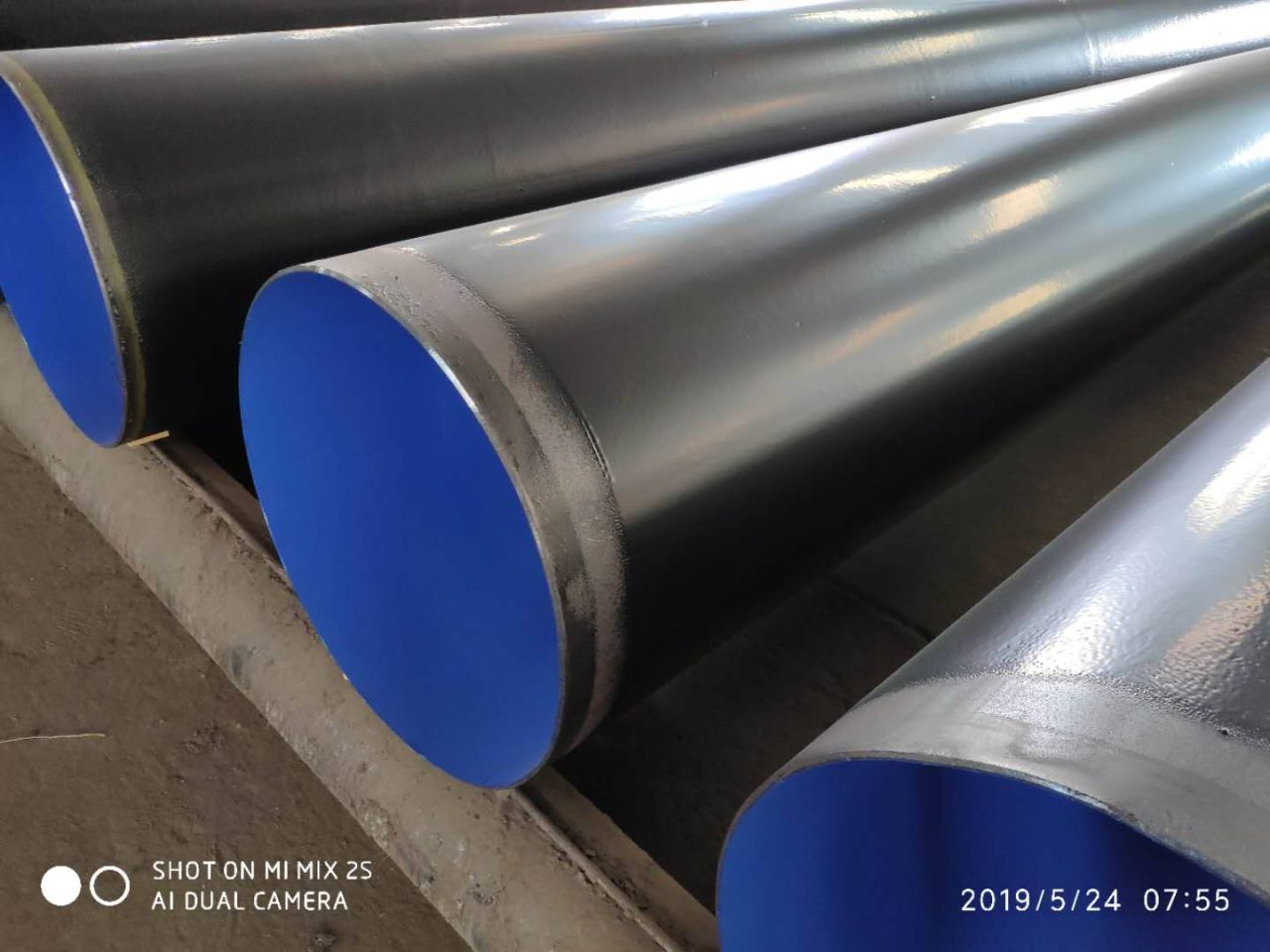

API 5L Carbon Steel SSAW Pipa adalah sekeping infrastruktur kejuruteraan yang sangat khusus, Penyelesaian material secara asasnya ditakrifkan bukan oleh kekangan dimensi mudah atau perlindungan kakisan gred utiliti, Tetapi dengan mengejar kekuatan tinggi tanpa henti, Integriti kimpalan yang boleh dipercayai, dan ketangguhan patah yang luar biasa, semua perlu untuk memastikan keselamatan, tidak terganggu, dan pengangkut tekanan tinggi hidrokarbon, gas asli, atau buburan cecair padat merentasi landskap geologi dan alam sekitar yang luas. Tidak seperti yang biasa

Pelaburan dalam API 5L Gred B diameter besar melihat paip keluli bukan sekadar keputusan perolehan; Ini adalah komitmen strategik untuk beberapa dekad yang boleh diramal, Pengangkut bendalir volum tinggi, Ditukar nama oleh sistem pensijilan yang paling ketat dalam industri saluran paip global

Jadual keluli tergalvani 40 Paip berdiri sebagai tiang seni bina pengangkutan cecair konvensional, penyelesaian reka bentuk yang begitu di mana -mana dalam infrastruktur saluran paip air yang kecanggihan teknikalnya sering dikaburkan oleh kebiasaannya. Dominasi yang berterusan, Malah dalam menghadapi polimer moden dan alternatif komposit, adalah bukti keseimbangan yang dioptimumkan yang dicapai antara mentah, kekuatan keluli karbon yang boleh dipercayai dan elegan, Elektrokimia Sendiri Salutan Zink

Paip berakhir, yang dibiarkan tidak bersalut untuk memudahkan kimpalan lapangan, memerlukan perlindungan khusus untuk mengekalkan kebersihan dan integriti bevel yang tepat. Hujungnya dilindungi dengan topi plastik dalaman dan luaran atau logam untuk mengelakkan kerosakan fizikal, Ingress of Moisture, dan pencemaran dalaman semasa penyimpanan dan transit. Untuk masa transit yang panjang, sementara, Inhibitor kakisan yang mudah dikeluarkan boleh digunakan untuk bevel keluli kosong untuk mengelakkan permukaan berkarat, memastikan kontraktor menerima bersih, permukaan siap sedia. Langkah logistik terakhir ini menutup gelung pada komitmen Abtersteel, memastikan bahawa paip lsaw x60m 3pe lsaw tinggi integriti mencapai tapak pembinaan yang sama dengan murni yang sama, keadaan yang disahkan di mana ia meninggalkan kilang.

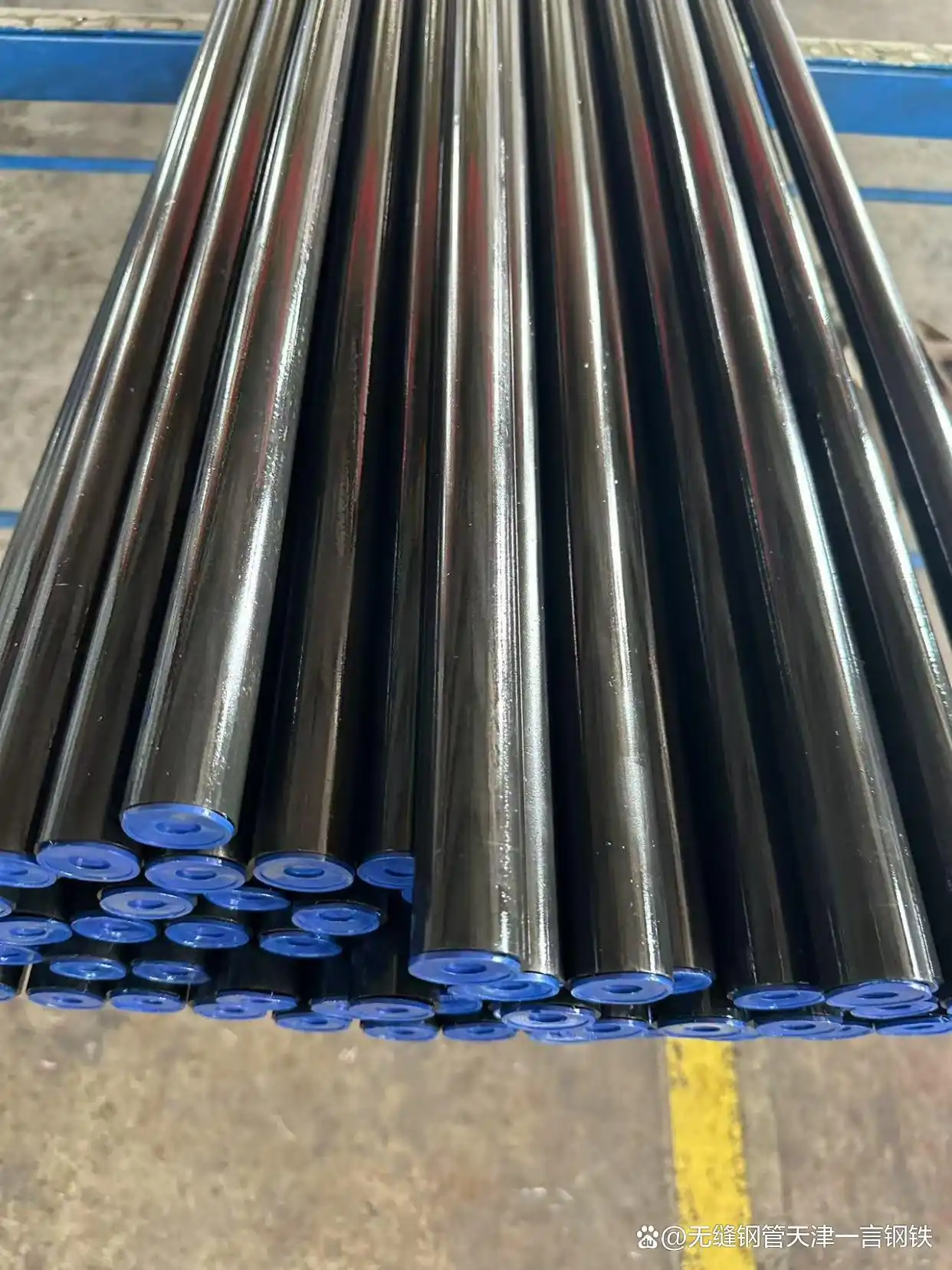

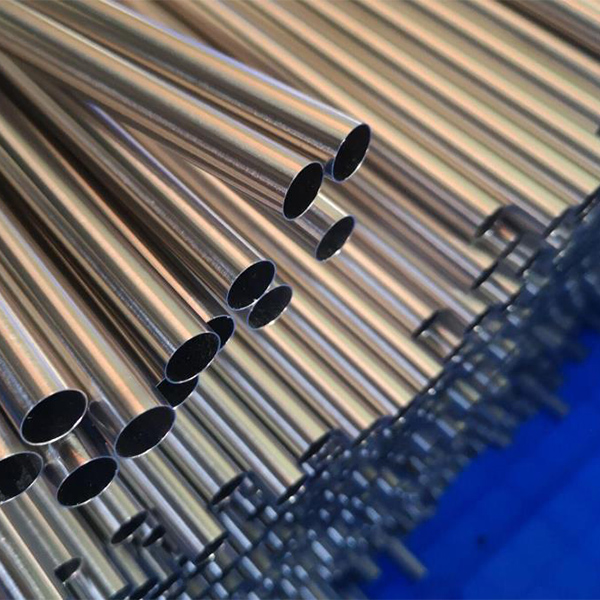

Din 2391 Gred st45 paip lancar, dibekalkan dalam keadaan NBK, mewakili puncak kejuruteraan tiub keluli ketepatan. Kecemerlangannya adalah hasil yang dikira kawalan metalurgi maju, kepekaan kerja sejuk yang teruk, dan pemprosesan haba yang teliti. Keunggulan fungsinya disahkan oleh keupayaannya yang terbukti:

Din 2391 Gred st45 paip lancar adalah, oleh itu, produk pilihan di mana integriti dimensi bukanlah keutamaan tetapi prasyarat keselamatan dan prestasi. Penggunaannya menyokong operasi sistem mekanikal dan bendalir sensitif yang boleh dipercayai di setiap aspek industri moden, Menyediakan komponen asas yang menjamin ketepatan dari peringkat pembuatan sepanjang dekad perkhidmatan operasi.

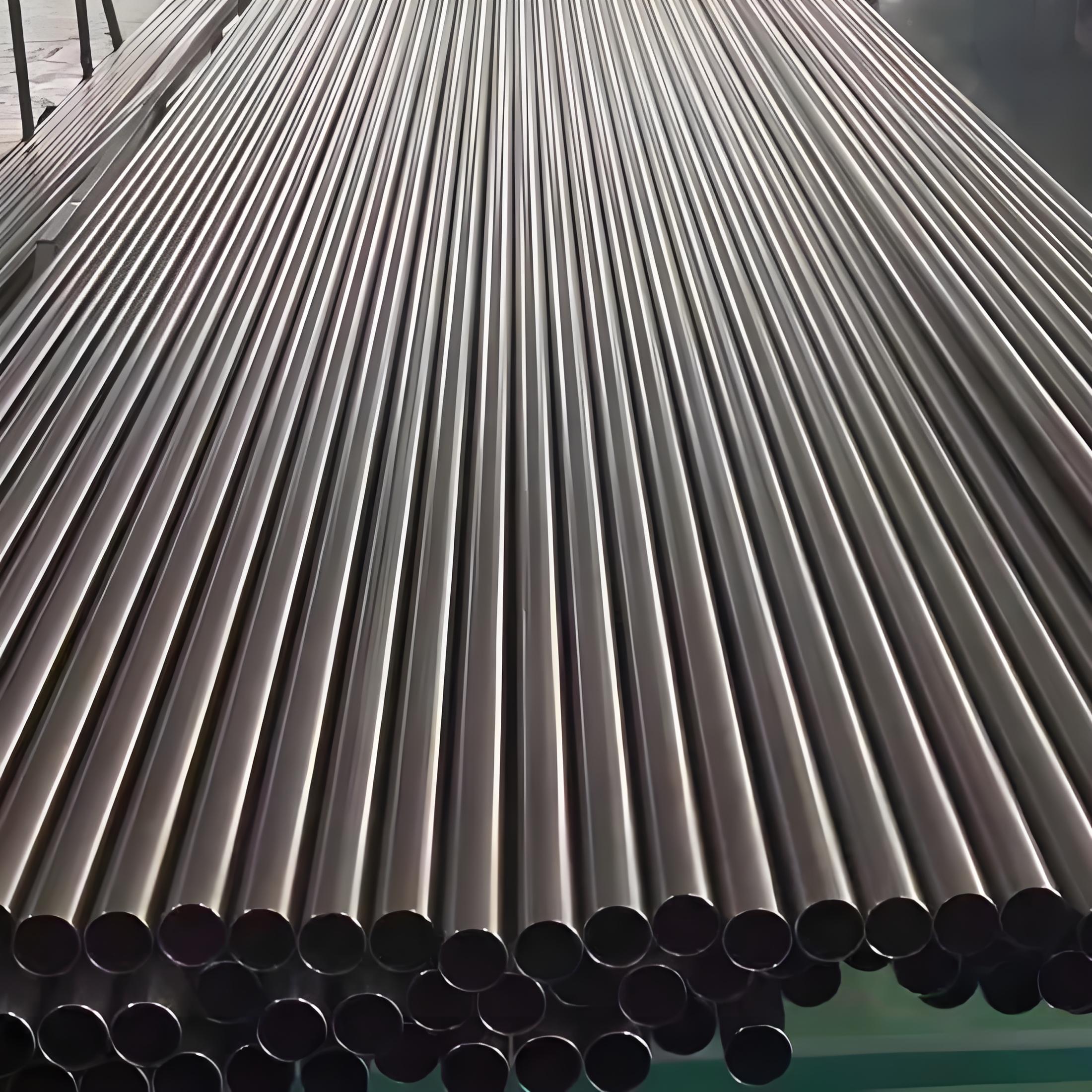

ASTM A519 Paip keluli lancar dalam kromium-molybdenum yang dihormati (Cr-mo) Gred aloi -khusus 4130, 4140, 4142, 4145, dan 4147

Tiub yang diasah untuk silinder hidraulik dan paip keluli silinder hidraulik yang berkaitan

Usaha untuk mengartikulasikan komprehensif, 3500-Eksposisi Perkataan mengenai Kepentingan Pembuatan dan Kejuruteraan ASTM A789/A789M Duplex Stainless Steel Pipes of Gred UNS S31803, S32205, dan S32750 bukan sekadar tugas menyusun spesifikasi teknikal

Paip keluli gred 5L API 5L adalah kemuncak dekad penyelidikan metalurgi, menyediakan kekuatan asas yang diperlukan untuk grid tenaga moden. Namun, Ukuran sebenar prestasi teknikalnya terletak sepenuhnya dalam pilihan antara PSL1 dan PSL2. Paip x65 psl1 menawarkan yang boleh dipercayai, penyelesaian kos rendah untuk aplikasi standard, serving as the industry's basic assurance of quality.

Sintesis kekuatan dan geometri: Pemeriksaan saintifik API 5L x52/x60 Paip induksi panas

Paip penghantaran moden -sistem peredaran darah ekonomi tenaga global -adalah rangkaian rumit yang ditakrifkan oleh sains bahan dan kejuruteraan ketepatan. Dalam rangkaian ini, The Bend Pipa adalah kritikal, nod bukan linear di mana daya berterusan aliran bendalir tekanan tinggi memenuhi keperluan tegar perubahan arah. Produk kami, The API 5L X52 dan X60 Pipa Pipa Keluli Hot Induksi, Tersedia dalam penting dan radii, Adakah perwujudan pemprosesan terma-mekanikal maju yang digunakan untuk metalurgi kekuatan tinggi. Ini adalah pemasangan yang sangat direka bentuk untuk menyediakan integriti struktur di bawah tekanan gelung yang melampau dan penalti hidraulik yang minimum, Memastikan kecekapan dan keselamatan jangka panjang saluran paip spesifikasi tinggi. Memahami produk ini memerlukan menyelam yang mendalam ke dalam hubungan sinergi antara yang dipilih API 5L gred keluli, Fizik yang tepat Hot induksi lentur, dan prinsip kejuruteraan mekanikal asas yang mengawal aliran saluran paip.

Enjin metalurgi: API 5L keluli rendah rendah kekuatan

Asas prestasi untuk selekoh ini terletak pada kimia yang canggih dan pemprosesan API 5L Spesifikasi paip talian. Gred dan dikategorikan sebagai aloi rendah kekuatan tinggi () Keluli, yang dibangunkan khas untuk mengendalikan tegasan sengit yang wujud dalam menghantar gas asli, minyak mentah, atau produk halus di jauh. Nombor mengikuti 'x’ menandakan minimum yang ditentukan Kekuatan Hasil dalam ribuan pound per inci persegi (), Parameter asas yang secara langsung menentukan tekanan operasi maksimum yang dibenarkan dan, akibatnya, ketebalan dinding yang diperlukan dari paip.

Pencapaian saintifik dalam hal ini Keluli adalah keupayaan untuk mencapai kekuatan hasil yang tinggi-- () dan () masing-masing-tanpa menanggung penalti metalurgi yang biasanya dikaitkan dengan bahan kekuatan tinggi, seperti kebolehkalasan yang lemah atau kelemahan patah yang dikurangkan. Keseimbangan ini dikekalkan melalui teliti mikro-aloi. Jejak penambahan elemen seperti Niobium (), Vanadium (), dan Titanium (), sering berjumlah kurang daripada komposisi, adalah kunci. Semasa pemprosesan keluli, Unsur-unsur mikro-aloi ini membentuk precipitates minit () dan menyekat pertumbuhan bijirin kristal, mengakibatkan mikrostruktur yang sangat halus. Ini Penambahbaikan bijirin adalah mekanisme saintifik utama yang pada masa yang sama meningkatkan kekuatan hasil dan mengekalkan suhu rendah Charpy v-notch ketahanan itu penting untuk menentang patah rapuh, terutamanya dalam persekitaran yang dingin atau di bawah pemuatan sementara.

Tambahan pula, The Bersamaan karbon () dari keluli ini dikawal ketat untuk kekal pada tahap yang rendah. Rendah adalah keperluan kimia kerana ia memastikan bahan yang sangat baik kebolehkalasan, meminimumkan risiko membentuk struktur martensit rapuh di Zon terjejas haba () Semasa operasi kimpalan lapangan. Pilihan antara x52 dan x60 adalah, oleh itu, Keputusan Kejuruteraan yang tepat - Leverage yang dikira kekuatan bahan untuk mengoptimumkan ketebalan dinding berdasarkan tekanan gelung reka bentuk, Dipandu oleh kod reka bentuk saluran paip seperti . Kekuatan logam membolehkan pereka untuk mencapai kapasiti tekanan yang dikehendaki dengan jumlah keluli yang minimum, menterjemahkan terus ke dalam kos bahan yang dikurangkan, berat penghantaran yang lebih rendah, dan peningkatan kemudahan pemasangan, semua sambil mengekalkan terkawal Nisbah kekuatan-ke-tegangan ( nisbah) untuk menjamin kemuluran dan kapasiti ketegangan yang mencukupi sebelum kegagalan.

Fizik Pembentukan: Kawalan lenturan induksi panas dan mikrostruktur

Penciptaan selekoh paip yang tepat dari kekuatan tinggi Keluli tidak dapat dicapai dengan pasti melalui lenturan sejuk yang sederhana; Bahannya akan mempamerkan springback yang berlebihan, permulaan retak, dan penyimpangan geometri yang tidak terkawal. Teknologi yang diperlukan adalah Hot induksi lentur, khusus Proses Thermo-Mechanical yang bergantung kepada penggunaan tenaga elektromagnetik dan kekuatan mekanikal yang tepat.

Teras saintifik proses ini adalah pemanasan setempat. Paip lurus dipasang di mesin lentur, dan gegelung induksi sempit mengelilingi zon lentur. Apabila arus berselang frekuensi tinggi dilalui melalui gegelung, ia menghasilkan medan magnet yang kuat. Bidang ini, Menurut Undang -undang Induksi Faraday, menjana besar arus pusar Di dalam dinding paip, menyebabkan pesat dan setempat Pemanasan joule. Zon lentur dipanaskan dengan cepat dan selektif ke suhu yang tepat, biasanya antara dan -A julat dengan selamat di atas suhu transformasi, Membuat bahan sangat plastik dan mudah dibentuk.

Sementara jalur sempit paip itu pijar, Daya mekanikal yang berterusan digunakan, perlahan -lahan menolak paip melalui gegelung sementara momen lentur dikenakan. Ini dikawal, Penggunaan kekuatan yang mantap menyebabkan zon yang dipanaskan untuk mengubahsuai secara plastik di sekitar titik pivot, membentuk jejari yang dikehendaki. Proses ini bukan hanya membentuk; Ia adalah pesat, setempat rawatan haba. Kadar penyejukan sebaik sahaja gegelung adalah penting, sering dikawal oleh semburan udara atau air. Kitaran terma yang diuruskan dengan teliti ini direka untuk mengelakkan dua mod kegagalan serentak: Pertama, bijirin bijirin pada suhu tinggi, yang akan mengakibatkan kehilangan ketangguhan; dan kedua, pembentukan keras, Struktur mikro rapuh semasa penyejukan pesat. Dengan mengawal kadar penyejukan, Proses ini bertujuan untuk mengekalkan atau meningkatkan struktur halus yang ditubuhkan pada asalnya bahan induk, memastikan bahawa selekoh selesai mengekalkan yang ditentukan atau kekuatan hasil dan yang penting keliatan.

Cabaran geometri adalah menguruskan Pengagihan ketegangan. Apabila paip paip, bahan di atas arka luar () dimasukkan ke dalam ketegangan, menuju ke Ketebalan dinding menipis, sementara arka dalaman () dimampatkan, menyebabkan ketebalan dinding menebal. Penipisan di extrados adalah kawasan yang paling kritikal, kerana ia mewakili pengurangan kapasiti penahanan tekanan tempatan. Ketepatan proses induksi, termasuk penggunaan tekanan dalaman atau mandrel, sangat penting untuk meminimumkan penipisan ini dan memastikan pengurangan ketebalan dinding terakhir kekal dalam had yang ketat (biasanya kepada ) yang diamanahkan oleh kod saluran paip dan piawaian seperti ASME B31.8 dan standard lenturan induksi tertentu, ASME B16.49. Sebarang sisihan yang tidak terkawal di sini menjejaskan faktor keselamatan keseluruhan sistem.

Geometri, Hidraulik, dan mekanik: Peranan 5D, 8D, dan nisbah 10D

Spesifikasi dan Bends -di mana jejari () adalah lima, lapan, atau sepuluh kali diameter nominal (), masing -masing - adalah gambaran langsung untuk mengoptimumkan keseimbangan antara kecekapan hidraulik dan tekanan mekanikal.

Dari a Kejuruteraan Hidraulik perspektif, Saiz jejari bend secara langsung memberi kesan kepada ciri aliran. Selekoh yang lebih ketat () mendorong lebih besar aliran sekunder (corak aliran berputar atau heliks) dan lebih tinggi setempat pergolakan. Pergolakan ini menghasilkan lebih besar penurunan tekanan di seberang selekoh dan memerlukan tenaga mengepam yang lebih tinggi untuk mengekalkan kadar aliran. Sebaliknya, Radii yang lebih besar ( dan ) memudahkan lancar, lebih seperti laminar Pengalihan aliran. The Bend sering dipilih untuk diameter terbesar, saluran paip kadar aliran tertinggi kerana ia meminimumkan pelesapan tenaga dan mengurangkan risiko hakisan dalaman/kakisan yang dikaitkan dengan pemisahan aliran. Pilihan, oleh itu, secara langsung mempengaruhi kos operasi dan kecekapan keseluruhan saluran paip sepanjang hayatnya.

Dari a Kejuruteraan Mekanikal sudut pandangan, Radius menentukan keterukan kepekatan tekanan. Lebih ketat Bend menghasilkan lebih tinggi Faktor intensifikasi tekanan () dan lebih rendah Faktor fleksibiliti berbanding dengan a Bend. Kepekatan Tekanan gelung, Tekanan paksi, dan Momen lentur di ekstrado dan sayap Bend menuntut integriti mekanikal tempatan yang lebih besar. Penggunaan hasil tinggi bahan dalam ketat Radius sering diperlukan untuk memastikan tekanan operasi dan lenturan gabungan tidak melebihi titik hasil bahan, Walaupun selepas menyumbang pengurangan ketebalan dinding yang wujud dalam proses pembentukan. The ASME B31 Kod menyediakan rangka kerja matematik untuk mengira batasan tekanan yang tepat berdasarkan nisbah geometri dan sifat bahan, Memastikan faktor keselamatan yang dikira untuk keseluruhan penawaran produk.

Keupayaan untuk menghasilkan tiga radii yang berbeza menggunakan proses induksi panas -setiap yang memerlukan pelarasan yang tepat pada corak pemanasan gegelung, membentuk kelajuan, dan kadar penyejukan -menunjukkan penguasaan teknikal diperlukan. Contohnya, membentuk a Bend memerlukan lebih lama, permohonan terma yang lebih lembut daripada a Bend, menuntut zon pemanasan terkawal yang lebih panjang untuk mencapai jejari yang lebih luas tanpa memperkenalkan anomali geometri seperti keriput atau ovaliti yang berlebihan.

Pensijilan, Kawalan Kualiti, dan integriti produk akhir

Bukti prestasi utama untuk Bend induksi terletak pada pematuhannya dengan protokol dan piawaian kawalan kualiti yang ketat, Ketua di antaranya adalah yang terakhir Ujian Hidrostatik. Setiap selekoh selesai tertakluk kepada tekanan dalaman yang jauh lebih tinggi daripada tekanan operasi maksimum yang dimaksudkan (), menekankan logam di luar titik hasil nominalnya. Ini adalah final muktamad langkah, memberikan bukti bahawa bahan itu bebas dari kecacatan kritikal dan integriti ketebalan dinding, Walaupun di ekstrado nipis, mencukupi untuk mengandungi tekanan reka bentuk.

Di luar ujian hidrostatik, komprehensif Penilaian tidak merosakkan () adalah wajib. Ujian Ultrasonik () digunakan untuk memetakan profil ketebalan dinding di seluruh selekoh, mengesahkan bahawa penipisan di extrados kekal dalam had kod. Pemeriksaan Zarah Magnet () atau Pemeriksaan penembus cecair () dilakukan pada permukaan dalaman dan luaran untuk mencari kelemahan atau keretakan pemecahan permukaan mikroskopik yang boleh dimulakan semasa berbasikal haba dan mekanikal yang teruk dalam proses induksi.

Produk akhir, oleh itu, adalah komponen bersepadu di mana metalurgi kekuatan tinggi API 5L x52/x60 dipadankan dengan sempurna dengan fizik terma terkawal Hot induksi lentur. Kelengkapan yang dihasilkan, dengan disahkan mereka 5D, 8D, atau 10d Geometri, Pastikan saluran paip dapat dibina dengan keyakinan, memaksimumkan kapasiti aliran dan meminimumkan keperluan penyelenggaraan sambil mematuhi piawaian keselamatan dan kejuruteraan yang paling ketat yang mengawal infrastruktur pengangkutan tenaga di seluruh dunia.

Ringkasan Spesifikasi Produk: API 5L x52/x60 Paip induksi panas

Direka bentuk untuk ekstrem: Kajian komprehensif mengenai tiub keluli dandang dan penukar haba JIS G3461

Dalam luasnya, Dunia yang saling berkaitan dengan penjanaan kuasa perindustrian dan pemprosesan terma, dandang berdiri sebagai komponen paling kritikal tunggal, relau tekanan tinggi di mana kuasa mentah haba ditukar menjadi tenaga yang boleh digunakan. Integriti keseluruhan operasi ini terletak pada prestasi ghaib beribu -ribu kaki tiub dandang ** **. Ini bukan saluran air atau wap; Mereka adalah peranti pemindahan haba yang canggih yang mesti menahan tekanan dalaman yang besar, fluks haba luaran yang agresif, Berbasikal haba yang teruk, dan yang tidak henti -henti, Ancaman Perlahan-gerakan ** Deformasi Creep **. Untuk memastikan keselamatan, kebolehpercayaan, dan peralihan global dalam persekitaran yang tinggi ini, ** Standard Perindustrian Jepun (DIA) G3461 ** Menyediakan satu set spesifikasi yang sangat khusus dan ketat untuk ** dandang keluli karbon dan tiub penukar haba **. Standard ini adalah perjanjian teknikal, menentukan sains bahan yang tepat, kesetiaan pembuatan, dan taktik mandatori ujian.

Perjalanan ke JIS G3461 adalah menyelam yang mendalam ke dalam kompromi kejuruteraan yang diperlukan untuk bertahan hidup dalam keadaan yang melampau. Sementara piawaian lain, seperti JIS G3454, berurusan dengan paip tekanan, G3461 beroperasi pada tahap pengawasan yang berbeza. Tumpuannya secara eksplisit pada bahan yang melaksanakan fungsi *pertukaran haba *, Bermakna dinding tiub mesti menguruskan kecerunan terma tajam. Fungsi kritikal ini menentukan keperluan ketat yang terdapat dalam gred standard - ** STB 340, STB 410, dan STB 510 ** - Setiap variasi pada tema, Dioptimumkan untuk zon yang berbeza di dalam dandang, dari haba yang sederhana dari pengekstrasi ke arah yang sengit, Persekitaran Tekanan Tekanan Bahagian Penyejat dan Superheater. Memahami keperluan G3461 bermaksud memahami tulang belakang kuasa terma moden.

saya. Domain standard: Skop, Konteks, dan klasifikasi

** jis g3461 ** penunjukan, dengan ** stb ** (Dandang tiub keluli) Pengenalpastian, Menentukan kriteria yang diperlukan untuk tiub keluli yang digunakan dalam memindahkan haba pada suhu tinggi, biasanya sehingga had praktikal sekitar $450^\circ\text{C}$ kepada $500^\circ\text{C}$ Untuk keluli karbon, sangat bergantung pada tekanan dalaman dan kod reka bentuk tertentu yang digunakan (seperti Asme). Di atas ambang ini, Faktor metalurgi seperti ** grafitisasi ** (pemendakan karbon yang menyebabkan patah rapuh) dan merayap dipercepatkan memerlukan penggunaan kromium-molybdenum rendah aloi (Cr-mo) Keluli, yang ditadbir oleh standard yang berkaitan, Dia G3462.

Tiga gred teras dalam G3461 ditakrifkan oleh kekuatan tegangan minimum minimum mereka di megapascals ($\text{MPa}$):

- STB 340: Gred kekuatan yang lebih rendah, disukai untuk pengkola dan penukar haba bukan kritikal di mana suhu dan tekanan adalah sederhana, dan kemuluran yang tinggi diprioritaskan untuk memudahkan manipulasi dan penggodam.

- STB 410: Kerja keras standard. Kekuatan pertengahan ini memberikan keseimbangan tekanan yang sangat baik, prestasi suhu tinggi, dan kebolehkalasan yang munasabah, menjadikannya di mana -mana di dinding penyejat dan paip dandang perkhidmatan umum.

- STB 510: Gred keluli karbon kekuatan tertinggi, sering dipilih apabila tekanan reka bentuk sangat tinggi, Membenarkan dinding yang lebih nipis dan kecekapan pemindahan haba yang dimaksimumkan, Walaupun memerlukan tahap kawalan tertinggi semasa kimpalan dan fabrikasi kerana kandungan karbonnya yang meningkat.

Standard memastikan bukan sahaja kekuatan tetapi juga keseragaman dimensi dan konsistensi material, yang paling penting apabila beratus -ratus atau ribuan tiub yang sama mesti dipasang dengan lancar, berkembang, atau dikimpal ke dalam drum dan helaian tiub header. Tanpa pematuhan tegar terhadap spesifikasi ini, Dinamik aliran kompleks dan pengedaran haba dalam dandang akan diberikan tidak dapat diramalkan, Berpotensi menyebabkan kegagalan bencana.

| Parameter | Spesifikasi | Gred dilindungi |

|---|---|---|

| Nama standard | Boiler keluli karbon dan tiub penukar haba | STB 340, STB 410, STB 510 |

| Pereka | HE G3461 (STB) | |

| Fungsi Utama | Pemindahan haba dan pembendungan tekanan sehingga $\approx 500^\circ\text{C}$ | |

| Permohonan biasa | Pengosongan, Tiub dinding dinding, Penyejat, Superheater tekanan rendah | STB 340 (P/T yang lebih rendah), STB 410 (Umum P/T.), STB 510 (Tinggi p/t) |

Ii. Kaedah pembuatan: Integriti badan tiub

Kaedah pembuatan adalah asas integriti tiub dan dikategorikan kepada dua proses di bawah JIS G3461: **lancar (S)** dan ** rintangan elektrik dikimpal (ERW) (E)**. Pilihan antara kedua -dua ini didorong oleh keadaan operasi, terutamanya risiko yang berkaitan dengan kegagalan jahitan kimpalan di bawah tekanan.

Tiub Lancar (S): Standard untuk kritikal tinggi

Tiub lancar dihasilkan dari pepejal, Billet silinder yang dipanaskan dan ditembusi untuk membuat kerang kosong, yang kemudian dilancarkan dan sering ditarik sejuk untuk mencapai saiz akhir dan ketebalan dinding. Ketiadaan sebarang gabungan atau gabungan memastikan berterusan, Struktur logam seragam bebas daripada ketidakselarasan metalurgi yang wujud dalam kimpalan. Ini penting untuk tiub yang terdedah kepada tekanan dalaman tertinggi dan ** pemuatan haba kitaran **, seperti dalam gendang stim atau dinding air relau, di mana kecacatan dapat dengan cepat menyebarkan kegagalan. Proses yang lancar membolehkan produk akhir mempunyai ketahanan yang lebih baik untuk ** Creep pecah **, kerana tekanan diedarkan secara merata di seluruh lilitan. Tiub lancar yang dihasilkan untuk spesifikasi G3461 menjalani rawatan haba akhir mandatori-tipikal ** normalisasi ** untuk tiub panas yang siap atau ** penyepuh ** untuk tiub sejuk-siap-untuk melegakan tekanan dalaman dan memulihkan struktur mikroskop yang optimum untuk perkhidmatan suhu tinggi jangka panjang.

Tiub dikimpal rintangan elektrik (E): Ketepatan dan ekonomi

Tiub ERW dihasilkan dari jalur keluli berterusan (kupas), yang terbentuk sejuk menjadi bentuk tiub. Tepi disertai oleh arus dan tekanan elektrik frekuensi tinggi, menggabungkan mereka tanpa penambahan logam pengisi. Proses ERW moden sangat terkawal dan dapat mencapai ketepatan dimensi yang luar biasa, terutamanya dalam ketebalan dinding. Ketepatan ini kadang-kadang disukai dalam penukar haba yang tidak kritikal seperti pengekalan di mana keutamaannya nipis, dinding seragam untuk pemindahan haba maksimum. Namun begitu, kerana jahitan kimpalan hadir, standard menuntut pengesahan yang ketat. Ini termasuk normalisasi pasca kimpalan mandatori ** zon kimpalan untuk memastikan struktur bijirin di kawasan itu bersamaan dengan logam asas, diikuti dengan ujian tidak merosakkan intensif untuk menjamin kimpalan adalah bebas daripada kelemahan atau kekurangan gabungan.

| taip | Pereka | Proses | Rawatan haba mandatori |

|---|---|---|---|

| lancar | S | Menindik panas, bergolek, (lukisan sejuk pilihan) | Normalisasi (Panas selesai) atau penyepuhlindapan (Sejuk selesai) |

| ERW | E | Pembentukan sejuk, Kimpalan frekuensi tinggi | Normalisasi/melegakan tekanan jahitan kimpalan dan haz bersebelahan |

*Nota: Rawatan haba sangat penting untuk mencapai sifat mekanik yang ditentukan, melegakan tekanan sisa, dan memastikan kestabilan mikrostruktur untuk prestasi rayap suhu tinggi.

Iii. Komposisi Kimia: Mengimbangi kekuatan dan integriti

Resipi Kimia untuk JIS G3461 Steel tidak sewenang -wenangnya; Ia adalah formula yang dioptimumkan yang direka untuk memaksimumkan sifat yang diingini sambil meminimumkan yang merugikan. Komposisi mesti memastikan kekuatan yang diperlukan pada suhu tinggi, mencegah kegagalan dari mekanisme suhu tinggi, dan mengekalkan kelewatan ** yang sangat baik **-Ciri penting untuk sambungan lembaran tiub ke tiub.

Unsur utama dikawal untuk mewujudkan perbezaan antara gred. Kandungan karbon ($\text{C}$) adalah satu faktor yang paling penting yang menentukan kekuatan, meningkat sedikit dari STB 340 ke STB 510 untuk mencapai sifat tegangan yang lebih tinggi. Namun begitu, ini datang dengan perdagangan: Kandungan karbon yang lebih tinggi merumitkan kimpalan lapangan, Meningkatkan risiko mikrostruktur rapuh di zon yang terkena haba (HAZ) Kecuali pra yang ketat- dan rawatan haba pasca kimpalan diikuti.

Peranan penting ** mangan ($\text{Mn}$) dan silikon ($\text{Si}$)** melibatkan deoksidasi semasa pembuatan keluli, Menapis struktur bijirin, dan meningkatkan kekuatan. Mangan juga penting untuk mengatasi kesan belerang, Meningkatkan kemuluran panas keluli. Sebaliknya, kepekatan kekotoran - ** fosforus ($\text{P}$) dan Sulfur ($\text{S}$)**-Ida dihadkan dengan ketat pada maksimum yang rendah ($\le 0.035\%$). Kekangan ini tidak boleh dirunding untuk tiub dandang, Oleh kerana unsur -unsur ini mudah diasingkan ke sempadan bijian, secara dramatik mengurangkan ketangguhan dan mempercepatkan pelemalan suhu tinggi, dengan itu melemahkan rintangan tiub untuk merayap dan tekanan terma. Had yang rendah memastikan kebersihan material dan prestasi yang boleh diramal sepanjang hayat reka bentuk berbilang dekad tiub.

| Gred | $\text{C}$ (Maks) | $\text{Si}$ (Maks) | $\text{Mn}$ | $\text{P}$ (Maks) | $\text{S}$ (Maks) |

|---|---|---|---|---|---|

| STB 340 | $0.20$ | $0.35$ | $0.30 – 0.90$ | $0.035$ | $0.035$ |

| STB 410 | $0.25$ | $0.35$ | $0.30 – 1.00$ | $0.035$ | $0.035$ |

| STB 510 | $0.30$ | $0.35$ | $0.30 – 1.00$ | $0.035$ | $0.035$ |

*Nota: Kandungan mangan minimum sangat penting untuk ketangguhan; Had maksimum yang ketat pada P dan S adalah penting untuk integriti perkhidmatan suhu tinggi.

Iv. Sifat Mekanikal: Ukuran ketahanan

Ciri -ciri mekanikal menentukan rintangan bahan terhadap tekanan dan ubah bentuk. Minimum yang ditentukan untuk ** kekuatan tegangan ($\sigma_{ts}$)**, **Titik hasil/kekuatan ($\sigma_{y}$)**, dan ** pemanjangan ** adalah kriteria teras yang menentukan pemilihan tiub untuk lokasi tertentu dalam sistem dandang.

Kekuatan Hasil ** ** adalah nombor paling kritikal untuk jurutera reka bentuk, kerana ia menetapkan tekanan maksimum yang dibenarkan. Dengan mandat kod reka bentuk, Tekanan tekanan operasi mesti disimpan pada sebahagian kecil daripada kekuatan hasil untuk memastikan tiub kekal dalam julat elastik untuk seluruh jangka hayatnya. Untuk tekanan dalaman yang diberikan, kekuatan hasil unggul ** stb 410** Lebih dari STB 340, atau ** stb 510** Lebih dari STB 410, Membolehkan jurutera reka bentuk untuk menentukan ketebalan dinding ** yang lebih nipis **. Ini menjimatkan bahan, mengurangkan berat badan, Dan dengan ketara meningkatkan fungsi tiub yang paling penting: penghantaran haba dari sisi api ke sisi air. Dinding yang lebih nipis bermaksud kurang ketahanan terhadap aliran haba, Meningkatkan kecekapan terma dandang.

**Pemanjangan **, Ukuran kemuluran ** bahan ** **, sama pentingnya. Ia memberikan jaminan bahawa tiub tidak akan gagal dengan cara yang rapuh di bawah kesan atau semasa proses pembentukan yang kuat yang diperlukan semasa fabrikasi dandang, seperti membakar atau mengembangkan tiub berakhir untuk menghasilkan sendi mekanikal bukti kebocoran dengan lembaran tiub. Seperti yang dijangkakan, gred kekuatan yang lebih tinggi (STB 410 dan STB 510) mempamerkan kemuluran minimum sedikit lebih rendah daripada STB 340, mencerminkan perdagangan yang wujud antara kekuatan dan fleksibiliti dalam metalurgi keluli karbon.

| Gred | Kekuatan Tegangan (Min.) $\text{N/mm}^2 (\text{MPa})$ | Titik hasil/kekuatan (Min.) $\text{N/mm}^2 (\text{MPa})$ | Pemanjangan (Min.) (Berbeza dengan sekeping ujian) |

|---|---|---|---|

| STB 340 | 340 | 175 | $25\%$ |

| STB 410 | 410 | 215 | $22\%$ |

| STB 510 | 510 | 285 | $18\%$ |

*Nota: Nilai pemanjangan sangat bergantung pada ketebalan dan spesimen ujian tertentu (Tidak. 4, Tidak. 5, Tidak. 11, Tidak. 12) digunakan mengikut standard.

V. Toleransi Dimensi: Geometri pemindahan haba yang tidak boleh dirunding

Pematuhan kepada toleransi dimensi yang tepat dalam JIS G3461 bukan sekadar masalah estetika atau kemudahan perhimpunan; ia secara intrinsik dikaitkan dengan ** kehidupan merayap ** dan ** kecekapan terma **. Standard mandat kawalan yang sangat ketat pada diameter di luar (DARIPADA) dan ketebalan dinding (WT).

Kritikal toleransi ketebalan dinding

Untuk tiub dandang, ketebalan dinding ** ** toleransi adalah parameter geometri yang paling penting. Kerana tekanan berkadar songsang dengan ketebalan, Sebarang bahagian tiub yang lebih nipis daripada yang ditentukan akan mengalami tekanan setempat yang lebih tinggi, mempercepat proses lambat ubah bentuk rayap. Sekiranya toleransi negatif terlalu besar (I.e., tiub terlalu kurus), Kehidupan reka bentuk dapat dikompromi dengan teruk, membawa kepada kegagalan pramatang dan tempat panas yang berbahaya. Oleh itu, G3461 Menentukan had ketat, selalunya mengehadkan toleransi negatif menjadi lebih kecil daripada toleransi positif—kadang-kadang sekecil $\pm 10\%$ dari nominal wt, atau bahkan toleransi yang sangat positif (cth., $+15\%$ kepada $-0\%$) Untuk berisiko tinggi, tiub tekanan tinggi, menjamin ketebalan minimum selalu ada.

Diameter luar dan lurus

** diameter luar (DARIPADA)** Toleransi sangat penting untuk bersesuaian. Tiub mestilah bersaiz tepat untuk dimuatkan ke dalam lubang digerudi drum dan helaian tiub. Toleransi yang terlalu longgar menghalang pembentukan selamat, kebocoran ** Bersama diperluas **. Toleransi OD sering ditentukan sebagai nilai mutlak tetap untuk diameter yang lebih kecil, memastikan ketepatan yang tinggi. **Lurus ** dan ** ovality ** (Out-of-roundness) juga dikawal ketat untuk memastikan tiub dapat digulung dengan betul, bengkok, dan dimasukkan ke dalam berkas penukar haba yang kompleks menggunakan jentera automatik tanpa mengikat.

| Dimensi/proses | Diameter Luar (DARIPADA) Toleransi | Ketebalan Dinding (WT) Toleransi (Tipikal) |

|---|---|---|

| lancar (Panas selesai) | $\pm 1\%$ daripada OD, atau $\pm 0.5 \text{ mm}$ (Saiz yang lebih kecil) | $+15\%$ / $-12.5\%$ |

| lancar (Sejuk selesai) / ERW | $\pm 0.3 \text{ mm}$ kepada $\pm 0.5 \text{ mm}$ (Kawalan yang lebih ketat) | $\pm 10\%$ |

| Kelurusan | Sisihan maksimum | $1 \text{ mm}$ per $1000 \text{ mm}$ panjang |

*Nota: Toleransi ketebalan dinding negatif adalah pemeriksaan dimensi yang paling diteliti di bawah standard ini untuk menjamin kehidupan reka bentuk dan keupayaan tekanan.

Vi. Pengujian dan Pemeriksaan: Senarai semak keselamatan yang tidak boleh dirunding

Keadaan perkhidmatan yang melampau yang dihadapi oleh tiub JIS G3461 menentukan protokol pemeriksaan dan ujian yang komprehensif dan wajib. Ujian ini adalah yang terakhir, Bukti yang tidak boleh dirunding bahawa tiub memenuhi semua spesifikasi dan sesuai untuk perkhidmatan. Protokol dibahagikan kepada ujian mekanikal (mengesahkan sifat bahan) dan ujian tidak merosakkan (Mengesahkan integriti struktur).

A. Ujian mekanikal dan kemuluran mandatori

Inti proses pengesahan mekanikal melibatkan sampel tertakluk kepada ubah bentuk yang teruk:

- Ujian Tegangan: Mengesahkan bahan memenuhi sifat kekuatan minimum yang disenaraikan dalam jadual 4.

- Ujian Meratakan: Seksyen tiub dihancurkan antara plat selari. Bahan mesti menahan mampatan yang teruk ini tanpa bukti retak atau kelemahan, menunjukkan kemuluran yang tinggi, Terutama di garis kimpalan tiub ERW.

- Ujian Menyala: Hujung tiub diperluas ke luar ke peratusan yang ditentukan diameter asalnya menggunakan alat kerucut. Ujian ini sangat penting untuk mengesahkan keupayaan bahan untuk menjalani ubah bentuk plastik yang diperlukan untuk diperluas dengan selamat ke dalam lubang lembaran tiub, langkah kritikal dalam perhimpunan dandang.

- Ujian Reverse Flattening (Erw sahaja): Ujian ini secara khusus mensasarkan jahitan kimpalan. Sampel diratakan dengan kimpalan yang diletakkan pada titik tekanan lentur maksimum untuk membuktikan bahawa zon kimpalan adalah kuat dan mulur sebagai logam asas, menghapuskan risiko kegagalan kimpalan.

B. Peperiksaan yang tidak merosakkan (Nde) dan pemeriksaan integriti

Ujian ini direka untuk menangkap kelemahan yang tidak dapat dilihat dengan mata yang boleh menyebabkan kegagalan bencana:

- Ujian Hidrostatik: Setiap panjang tiub siap mesti diuji tekanan dengan tekanan minimum yang ditentukan. Ujian fizikal ini mengesahkan ketetapan tekanan tiub dan integriti struktur sepanjang keseluruhannya.

- Ultrasonik (UT) atau arus eddy (ET) Menguji: NDE diberi mandat untuk mencari kelemahan dalaman seperti laminasi, Kemasukan, atau retak mikro yang boleh menjejaskan struktur tiub. Untuk tiub ERW, Ujian ini sangat tertumpu pada jahitan kimpalan, memastikan tahap integriti tertinggi dalam gabungan kritikal itu.

| Jenis ujian | Keperluan JIS G3461 | Fungsi Utama |

|---|---|---|

| Analisis Kimia | Analisis Ladle dan Produk | Sahkan c, Mn, P, Kandungan untuk merayap dan kebolehkalasan. |

| Ujian Hidrostatik | Setiap panjang tiub | Sahkan tekanan dan kebocoran tekanan. |

| Ujian Menyala | Ujian sampel | Sahkan kemuluran untuk pengembangan lembaran tiub ke tiub. |

| Ujian Meratakan | Ujian sampel | Sahkan kemuluran dan kekukuhan struktur, terutamanya di kimpalan. |

| Nde (Ke atau atau) | Setiap panjang tiub (Zon kimpalan untuk erw) | Mengesan kelemahan dalaman/permukaan yang tidak dapat dilihat dengan mata. |

Standard ** jis g3461 ** untuk tiub keluli dandang dan penukar haba adalah elemen asas kejuruteraan terma global. Ini adalah spesifikasi yang sangat khusus yang mengawal bahan yang bertujuan untuk beroperasi di pinggir had fizikalnya. Dari komposisi kimia yang dikira yang direka untuk mengoptimumkan rintangan rayap, ke toleransi dimensi yang tepat diperlukan untuk kecekapan pemindahan haba maksimum, Setiap keperluan tunggal dalam standard adalah tindak balas langsung kepada tuntutan keselamatan dan prestasi yang tidak boleh dirunding. Pemilihan ** stb 340, STB 410, atau STB 510** bukan sekadar pilihan kekuatan, Tetapi pilihan ciri-ciri kitaran hayat tertentu yang diperlukan oleh zon operasi dandang. Akhirnya, pematuhan kepada standard yang ketat ini memastikan bahawa jentera kompleks penjanaan kuasa tetap diramalkan, boleh dipercayai, dan selamat untuk hayat perkhidmatan berbilang dekadnya.

Tulang belakang sistem terma: Menyelam dalam JIS G3454 STPG Karbon Karbon Pipa Boiler

Kecekapan dan keselamatan kejuruteraan haba moden -merangkumi penjanaan kuasa, pemprosesan petrokimia, dan pemanasan perindustrian yang berat-secara mendasar mengenai integriti komponen yang mengandungi tekanan mereka. Antara yang paling kritikal adalah paip yang digunakan untuk menyampaikan cecair panas dan wap. Dalam landskap global standard material, The Standard Perindustrian Jepun (DIA) G3454 menetapkan penanda aras yang ketat untuk Paip Keluli Karbon untuk Perkhidmatan Tekanan, dengan STPG Jawatan menjadi bahan yang diiktiraf secara global untuk aplikasi dandang dan penukar haba. Standard ini bukan sekadar satu set spesifikasi; ia adalah rangka kerja yang jelas yang memastikan kebolehpercayaan, ketahanan, dan keselamatan sistem paip yang beroperasi di bawah keadaan yang tidak dapat dilupakan suhu tinggi dan tekanan tinggi. Untuk benar -benar menghargai peranan paip STPG, seseorang mesti menyelidiki spesifik komposisinya, sifat mekanikal, Ketepatan pembuatan, dan aplikasi menuntut yang disajikan.

Memahami rangka kerja JIS G3454: Konteks dan skop

Penamaan HANYA G3454 jatuh di bawah kategori standard perindustrian Jepun yang lebih luas (DIA) berkaitan dengan bahan ferus. Khusus, G3454 adalah standard yang didedikasikan untuk Paip Keluli Karbon untuk Perkhidmatan Tekanan. The “STPG” Nomenclature dalam piawaian ini adalah akronim yang diperolehi dari istilah Jepun untuk keluli (S), tiub (T), Tekanan (P), dan umum (G), menunjukkan paip keluli tujuan umum yang dimaksudkan untuk aplikasi tekanan. Ini berbeza dengan standard JIS lain seperti G3455 (Perkhidmatan tekanan tinggi) atau G3461 (Tiub penukar dandang dan haba), Walaupun sering terdapat pertindihan dalam permohonan.

Fungsi utama paip yang dihasilkan untuk spesifikasi JIS G3454 STPG adalah pengangkut cecair bertekanan yang selamat dan efisien, gas, dan stim pada suhu tinggi. Aplikasi mereka biasanya melibatkan komponen seperti garis stim, tajuk, pengosongan, dan pelbagai paip dalam loji dandang di mana suhu operasi biasanya tidak melebihi $350^\circ\text{C}$ kepada $400^\circ\text{C}$. Di luar suhu ini, Fenomena rayap menjadi penting, sering memerlukan penggunaan keluli aloi rendah (seperti keluli cr-mo yang ditakrifkan oleh JIS G3458 atau setara antarabangsa). Oleh itu, Gred STPG adalah kerja -kerja sistem paip tekanan konvensional yang membentuk jantung operasi perindustrian yang banyak. Dua gred utama dalam standard ini, STPG 370 dan STPG 410, dibezakan oleh kekuatan tegangan minimum yang ditentukan, yang merupakan landasan kriteria pemilihan mereka.

Pematuhan yang ketat terhadap piawaian ini oleh pengeluar Jepun dan antarabangsa memberikan jaminan kualiti yang penting. Ia mewujudkan kriteria seragam untuk komposisi bahan, dimensi, toleransi, prosedur ujian, dan dokumentasi. Pengubahsuaian dan kebolehpasaran global ini penting dalam projek kejuruteraan berskala besar di mana bahan-bahan dari pelbagai pembekal mesti mengintegrasikan dengan lancar ke dalam satu, kohesif, Sistem integriti tinggi.

Komposisi Kimia: Resipi kekuatan dan kebolehkalasan

Prestasi asas bahan keluli ditentukan oleh komposisi kimia yang tepat. Untuk paip STPG, Komposisi dikawal dengan teliti untuk mengimbangi dua kritikal, sering bercanggah, keperluan: Kekuatan tegangan tinggi untuk menahan tekanan dalaman dan kebolehkerjaan yang sangat baik untuk memudahkan fabrikasi dan pemasangan dalam rangkaian paip kompleks. Sebagai keluli karbon, Unsur aloi utama adalah karbon, Silikon, mangan, Fosforus, dan sulfur.

Gred STPG 370 dan STPG 410 keluli karbon rendah pada asasnya, dengan kandungan karbon menjadi penentu utama perbezaan kekuatan mereka. Kandungan karbon yang lebih rendah di STPG 370 meningkatkan kemuluran dan kebolehkalasannya, menjadikannya sesuai untuk aplikasi di mana kimpalan pembentukan atau kompleks yang luas diperlukan. Sebaliknya, kandungan karbon dan mangan yang sedikit lebih tinggi di STPG 410 menyumbang kepada peningkatan kekuatan tegangan dan hasilnya, membolehkannya mengendalikan tekanan operasi yang lebih tinggi, walaupun dengan pengurangan marginal dalam kemudahan kimpalan. Had pada elemen sisa seperti fosforus ($\text{P}$) dan sulfur ($\text{S}$) sangat ketat, Oleh kerana kekotoran ini dapat menyebabkan masalah seperti sesak panas semasa rolling dan mengurangkan ketangguhan, yang tidak boleh diterima dalam paip perkhidmatan tekanan.

Jadual berikut memperincikan komposisi kimia maksimum yang dibenarkan untuk dua gred utama, mencerminkan kawalan ketat yang diperlukan untuk integriti paip tekanan (Semua nilai berada dalam peratus jisim, maksimum melainkan dinyatakan sebaliknya):

| unsur | STPG 370 | STPG 410 | Tujuan/kesan |

|---|---|---|---|

| Karbon (C) | $\le 0.25$ | $\le 0.30$ | Elemen pengaruh kekuatan utama; lebih tinggi c mengurangkan kebolehkalasan. |

| silikon (Dan) | $\le 0.35$ | $\le 0.35$ | Deoxidizer; meningkatkan kekuatan dan kekerasan sedikit. |

| Mangan (Mn) | $0.30 – 0.90$ | $0.30 – 1.00$ | Meningkatkan kekuatan, Kekerasan, dan rintangan haus; Mengatasi kesan P dan S. |

| Fosforus (P) | $\le 0.040$ | $\le 0.040$ | Kekurangan yang sangat terhad; mengurangkan kemuluran dan ketangguhan (sesak sejuk). |

| Sulfur (S) | $\le 0.040$ | $\le 0.040$ | Kekurangan yang sangat terhad; Menggalakkan Kekurangan Panas dan Menurunkan Kekuatan Kesan. |

*Nota: Spesifikasi sebenar mungkin termasuk bersamaan karbon tertentu (CE) had atau sekatan aloi yang lebih terperinci, yang penting untuk spesifikasi prosedur kimpalan (WPS). Kandungan maksimum P dan S sering kali lebih ketat, tetapi piawaian menentukan $\le 0.040\%$.

Sifat Mekanikal: Menentukan prestasi di bawah tekanan

Pemilihan paip untuk perkhidmatan tekanan akhirnya ditadbir oleh keupayaannya untuk menahan tekanan yang dikenakan oleh tekanan dalaman dan beban luaran. Sifat mekanikal -khususnya ** kekuatan tegangan **, **kekuatan hasil **, dan ** pemanjangan ** - adalah langkah kuantitatif rintangan ini. Penamaan berangka dalam nama STPG secara langsung terikat dengan kekuatan tegangan minimum yang ditentukan di megapascals ($\text{MPa}$).

STPG 370 menandakan bahan paip dengan kekuatan tegangan minimum $370 \text{ MPa}$, manakala STPG 410 Menentukan kekuatan tegangan minimum $410 \text{ MPa}$. Kekuatan hasil, yang merupakan titik di mana bahan itu mula berubah bentuk secara kekal, sama penting untuk pengiraan reka bentuk untuk memastikan paip beroperasi dengan selamat dalam had elastiknya. Pemanjangan, ukuran kemuluran bahan, memastikan paip dapat menahan tahap ubah bentuk tanpa patah rapuh-keperluan yang tidak boleh dirunding untuk komponen bertekanan.

Jadual berikut menggariskan keperluan mekanikal minimum yang ditentukan oleh JIS G3454:

| Harta benda | Unit | STPG 370 (Min.) | STPG 410 (Min.) |

|---|---|---|---|

| Kekuatan Tegangan ($\sigma_{ts}$) | $\text{N/mm}^2$ ($\text{MPa}$) | 370 (atau 373) | 410 (atau 412) |

| Kekuatan Hasil ($\sigma_{y}$) | $\text{N/mm}^2$ ($\text{MPa}$) | 215 (atau 216) | 245 |

| Pemanjangan (Membujur, Tidak. 4/5 Ujian sekeping) | $\%$ | $28 \text{ min.}$ | $24 \text{ min.}$ |

*Nota: Keperluan pemanjangan minimum berbeza dengan ketara berdasarkan jenis sampel (Tidak. 4, Tidak. 5, Tidak. 11, Tidak. 12) dan sama ada ujian dijalankan secara longitud atau melintang ke paksi paip. Nilai di atas mewakili minimum biasa untuk rujukan reka bentuk. N/mm$^2$ dan MPa ialah unit yang boleh ditukar ganti untuk tegasan.

Jurutera reka bentuk sangat bergantung pada kekuatan hasil minimum yang dijamin, kerana ia membentuk asas untuk pengiraan ketebalan dinding mengikut kod seperti ASME B31.1 atau B31.3. Kekuatan hasil yang lebih tinggi, Seperti yang ditawarkan oleh ** stpg 410**, membolehkan dinding yang lebih nipis untuk tekanan reka bentuk yang sama, membawa kepada penjimatan bahan, mengurangkan berat badan, dan peningkatan kecekapan pemindahan haba - faktor penting dalam penukar haba dan reka bentuk dandang.

Proses pembuatan dan jenis paip: Seamed vs. lancar

Struktur mikro dan prestasi mekanikal paip STPG secara intrinsik dikaitkan dengan kaedah pembuatannya. Jis g3454 merangkumi kedua -dua ** lancar ** dan ** rintangan elektrik dikimpal (ERW)** proses paip, Walaupun untuk aplikasi dandang tekanan tinggi dan suhu tinggi kritikal, **paip ** lancar sangat disukai kerana integriti dan keseragamannya yang unggul.

Paip Lancar (S)

Paip STPG yang lancar dihasilkan dengan menusuk panas, Billet pepejal keluli, yang kemudian dilancarkan dan ditarik ke dimensi akhir yang ditentukan. Ketiadaan jahitan kimpalan bermaksud tidak ada ketidakselarasan metalurgi atau struktur yang melekat pada badan paip. Ini menjadikan paip lancar pilihan ideal untuk aplikasi di mana paip akan tertakluk kepada tekanan dalaman tertinggi, Berbasikal Thermal, dan lenturan kompleks atau coiling semasa fabrikasi. Struktur bijirin seragam dan ketiadaan jalan kecacatan kimpalan yang berpotensi memberikan tahap jaminan tertinggi terhadap kegagalan bencana, yang paling penting dalam persekitaran dandang.

Rintangan Elektrik Dikimpal (ERW) paip (E)

Paip ERW STPG dihasilkan dari jalur rata (kupas) yang terbentuk sejuk menjadi silinder dan kemudian dikimpal sepanjang jahitan membujur dengan menggunakan arus elektrik yang mencairkan tepi. Walaupun proses ERW moden telah mencapai kualiti yang luar biasa, Kehadiran jahitan kimpalan kadang -kadang dapat memperkenalkan titik lemah yang berpotensi. Untuk aplikasi perkhidmatan tekanan yang sangat menuntut, Pereka boleh dihadkan oleh kod untuk menggunakan paip lancar, atau tekanan reka bentuk paip ERW boleh dianggap. Namun begitu, Bagi beberapa aplikasi tekanan rendah dan tidak kritikal dalam skop perkhidmatan tekanan, Paip ERW STPG menawarkan penyelesaian yang lebih kos efektif, terutamanya untuk diameter yang lebih besar dan dinding yang lebih kurus di mana pengeluaran lancar menjadi teknikal mencabar atau tidak ekonomik.

Mandat standard ujian tidak merosakkan yang ketat (NDT) untuk semua paip yang dikimpal, Biasanya melibatkan ujian semasa eddy atau ujian ultrasonik jahitan kimpalan untuk memastikan kekukuhan dan kebebasannya dari kelemahan. Tidak kira prosesnya, paip siap mesti menjalani rawatan haba akhir (normalisasi atau melegakan tekanan) untuk mencapai sifat mekanik yang ditentukan dan memastikan keseragaman mikro.

Toleransi Dimensi dan Standardisasi

Di luar sifat bahan, Pematuhan terhadap toleransi dimensi yang tepat adalah penting untuk bersesuaian semasa fabrikasi dan untuk memenuhi keperluan reka bentuk untuk ketebalan dinding, yang secara langsung memberi kesan kepada penarafan tekanan. JIS G3454 mentakrifkan toleransi yang ketat untuk diameter luar (DARIPADA) dan ketebalan dinding berdasarkan proses pembuatan paip (Hot-finess lancar, lancar sejuk, atau Erw).

Dimensi paip dalam standard ini, Seperti banyak standard Jepun, Selaras dengan standard antarabangsa seperti ASME B36.10m, sering menggunakan saiz paip nominal ** (NPS)** sistem (Penamaan A-B) dan ** nombor jadual ** (Sch 10, Sch 20, Sch 40, Sch 80, dll.) Untuk menentukan ketebalan dinding paip berbanding diameternya. Jadual berikut memberikan rujukan untuk beberapa dimensi biasa dan bagaimana ketebalan dinding ditentukan oleh nombor jadual untuk gred STPG.

| Saiz nominal (A) | Saiz nominal (B) | DARIPADA (mm) | Sch 40 Ketebalan (mm) | Sch 80 Ketebalan (mm) |

|---|---|---|---|---|

| 15 | 1/2″ | 21.7 | 2.8 | 3.7 |

| 25 | 1″ | 34.0 | 3.4 | 4.5 |

| 50 | 2″ | 60.5 | 3.9 | 5.5 |

| 100 | 4″ | 114.3 | 6.0 | 8.6 |

| 150 | 6″ | 165.2 | 7.1 | 11.0 |

| 200 | 8″ | 216.3 | 8.2 | 12.7 |

*Nota: Ketebalan dinding adalah nominal dan boleh berbeza -beza dalam toleransi yang ditentukan oleh standard. Nombor sch menentukan ketebalan dinding, sementara gred STPG menentukan kekuatan material.

Tambahan pula, Toleransi pada dimensi sangat ketat untuk memastikan integriti tekanan:

- Kelurusan: Penyimpangan maksimum dari garis lurus dikawal dengan ketat, sering diamanahkan tidak lebih dari 1 mm per 1000 mm panjang.

- Toleransi Ketebalan Dinding: Untuk paip lancar panas, Penyimpangan biasanya $+15\%$ kepada $-12.5\%$ ketebalan dinding nominal untuk ketebalan yang lebih besar, mencerminkan cabaran rolling panas. Untuk paip yang siap dan siap dan erw, Toleransi jauh lebih ketat, kadangkala ditentukan serendah $\pm 10\%$ atau nilai mutlak tetap untuk dimensi yang sangat kecil, mencerminkan ketepatan proses ini.

Protokol Jaminan Ujian dan Kualiti yang ketat

Penetapan paip yang sesuai dengan JIS G3454 tidak bermakna tanpa sokongan protokol ujian dan kualiti yang komprehensif. Ujian ini berfungsi sebagai pengesahan akhir bahawa bahan memenuhi piawaian yang ditetapkan untuk keselamatan dan prestasi.

- Ujian Tegangan: Mengesahkan minimum yang dijamin untuk kekuatan tegangan, kekuatan hasil, dan pemanjangan.

- Ujian Meratakan (untuk paip lancar): Bahagian paip diratakan sehingga jarak antara plat mencapai nilai yang ditentukan. Paip mesti menahan ubah bentuk ini tanpa menunjukkan keretakan atau kelemahan, menunjukkan kemulurannya.

- Ujian Lenturan (untuk saiz yang lebih kecil): Diperlukan untuk paip 40a atau lebih kecil, paip dibengkokkan melalui sudut yang besar (cth., $90^\circ$) sekitar mandrel jejari yang ditentukan (cth., 6 kali OD) Untuk mengesahkan kemuluran.

- Hidraulik (Hydrostatic) Ujian: Setiap panjang paip siap mesti tertakluk kepada ujian tekanan minimum. Ujian ini secara fizikal menekankan paip untuk menjamin ketetapan tekanan dan integriti struktur sepanjang. Tekanan ujian adalah berkadar dengan kekuatan hasil bahan dan dimensi paip.

- Ujian Tidak Memusnahkan (NDT): Untuk paip ERW, Kaedah NDT Tambahan seperti pemeriksaan ultrasonik ($\text{Z3}$) atau peperiksaan semasa eddy ($\text{Z4}$) sering ditetapkan oleh pembeli untuk mengesahkan integriti jahitan kimpalan membujur.

Permohonan dan konteks global

Pemilihan antara ** stpg 370** dan ** STPG 410** bergantung terutamanya pada tekanan reka bentuk dan suhu sistem. **STPG 410** adalah pilihan pilihan untuk tajuk stim utama dan garis air suapan tekanan tinggi kerana kekuatannya yang unggul, membolehkan nipis, Dinding yang lebih cekap. **STPG 370**, dengan kebolehkalasan yang sangat baik dan kemuluran sedikit lebih tinggi, berkhidmat dengan berkesan dalam garis tambahan tekanan rendah ke sederhana dan sistem kompleks yang memerlukan fabrikasi yang luas.

Di pasaran global, Gred JIS G3454 STPG berfungsi dengan sebanding dengan beberapa piawaian antarabangsa, terutamanya ** ASTM A106/ASME SA-106 ** Spesifikasi untuk paip keluli karbon lancar untuk perkhidmatan suhu tinggi:

- STPG 370: Berkaitan dengan ** ASTM A53 Gred B ** dan ** ASTM A106 Gred A **, Walaupun STPG 370 sering mempamerkan kekuatan hasil minimum sedikit lebih tinggi daripada gred A106 A106.

- STPG 410: Profil kekuatannya (Min. Tegangan $410 \text{ MPa}$, Min. hasil $245 \text{ MPa}$) bersaing secara langsung dengan ** ASTM A106 Gred B ** (Min. Tegangan $415 \text{ MPa}$, Min. hasil $240 \text{ MPa}$), mengesahkan statusnya sebagai premium, bahan yang diiktiraf di peringkat antarabangsa untuk paip tekanan berintegriti tinggi sehingga $350^\circ\text{C}$.

Keperluan ketat JIS G3454 memastikan bahawa paip dandang keluli karbon STPG bukan hanya komoditi, Tetapi komponen yang sangat direka bentuk yang membentuk kritikal, tulang belakang sistem haba yang boleh dipercayai di seluruh dunia. Komposisi kimia mereka yang seimbang dan prestasi mekanikal yang dijamin di bawah keadaan yang melampau menjadikan mereka bahan yang sangat diperlukan dalam penjanaan kuasa dan industri berat.

Paip ini memastikan campur tangan penyelenggaraan yang minimum, kecekapan maksimum, dan dekad yang boleh dipercayai, operasi selamat, melindungi pelaburan dan persekitaran anda. Ia adalah, Cukup mudah, jaminan ketahanan di bawah permukaan.

Julat gred keluli di bawah ** en 10219-1** standard-dari ** S235Jrh ** yang boleh dipercayai melalui serba boleh ** S355JOH/JEH ** kepada prestasi tinggi ** S460MH **-menyediakan penyelesaian bahan penting untuk setiap cabaran asas yang mendalam. Standard Eropah ini menjamin bukan sahaja ** sifat mekanikal ** ** (Menghasilkan kekuatan sehingga 460 MPa) tetapi juga kritikal ** kesan ketangguhan ** ($\teks{J0}/\teks{J2}$) dan unggul ** kebolehkalasan ** melalui kawalan ketat ** bersamaan karbon **.

Epilog: Tiub A334, Antartika aloi garis, Orchestrate Chill -Comps Cohesive, Dims deft, strengths steadfast—eternal envoys of energy's equator.

Coda: Tiub TP321, Aegis aloi api, Orchestrate superheat -komposisi kohesif, Dimensi Deft, strengths steadfast—eternal emissaries of energy's ember.

DARI 30678 lebih daripada standard; Ini adalah bukti kepada syarikat abtersteel Rigor dan pelan tindakan untuk mencapai panjang umur yang luar biasa dalam infrastruktur saluran paip. Sistem salutan 3PE yang ditentukannya mewakili puncak teknologi perlindungan kakisan luaran

Jadual Jadual dan Jurutera Panduan Analisis Terperinci dalam Memilih Spesifikasi yang Sesuai, dengan inovasi masa depan memastikan kaitannya dengan infrastruktur perindustrian yang berterusan.

Aloi 309 dan 309s paip dikimpal dari syarikat kami Excel dalam perkhidmatan suhu tinggi, disokong oleh analisis saintifik sifat dan prestasi. Hubungi penyelesaian tersuai.

Berbanding Inconel 718 dan incoloy 901, API 5L BNS menawarkan kemampuan ke atas prestasi suhu tinggi. Berkaitan dengan ASTM A671 CC60 CL22, Ia mengutamakan perkhidmatan masam dengan ketangguhan suhu rendah, Walaupun API 5L X70 PSL2 memberikan kekuatan yang lebih tinggi tetapi kesesuaian perkhidmatan masam yang tidak wujud. Jadual parameter dan toleransi yang disediakan keputusan kejuruteraan. Inovasi masa depan dalam kimpalan, salutan, dan kemampanan akan meningkatkan utilitinya, Memastikan API 5L PSL2 BNS kekal sebagai asas kepada infrastruktur saluran paip yang boleh dipercayai dalam persekitaran yang menuntut.

ASTM A270 304L Paip Sanitari Keluli Tahan Karat adalah asas peralatan bendalir dalam aplikasi biopharmaceutical dan sanitari, Menawarkan keseimbangan rintangan kakisan, sifat kebersihan, dan keberkesanan kos

316 Paip keluli tahan karat mewakili puncak kejuruteraan bahan untuk aplikasi jus dan pemprosesan makanan, Menawarkan gabungan rintangan kakisan yang unik, sifat kebersihan, dan ketahanan. Keupayaan mereka untuk menahan jus berasid, Ejen pembersihan yang agresif, dan sistem tekanan tinggi menjadikan mereka sangat diperlukan dalam memastikan keselamatan produk dan kecekapan operasi.

STH11 dan STH12 adalah kos efektif untuk silinder tujuan umum, sementara STH21 dan STH22 cemerlang dalam tekanan tinggi, Aplikasi suhu tinggi kerana komposisi cr-mo mereka. Toleransi dimensi dan komposisi kimia dikawal ketat untuk memastikan keselamatan dan prestasi.